The Influence of Hazelnut Skin Addition on Quality Properties and Antioxidant Activity of Functional Yogurt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bacterial Cultures, Raw Cow’s Milk, and Hazelnut Skin

2.2. Manufacture of Yogurt

2.3. Physicochemical Analysis

2.4. Microbiological Analysis

2.5. Rheological and Other Physical Analysis

2.5.1. Hardness, Adhesive Force, Consistency, and Viscosity Index

2.5.2. Apparent Viscosity

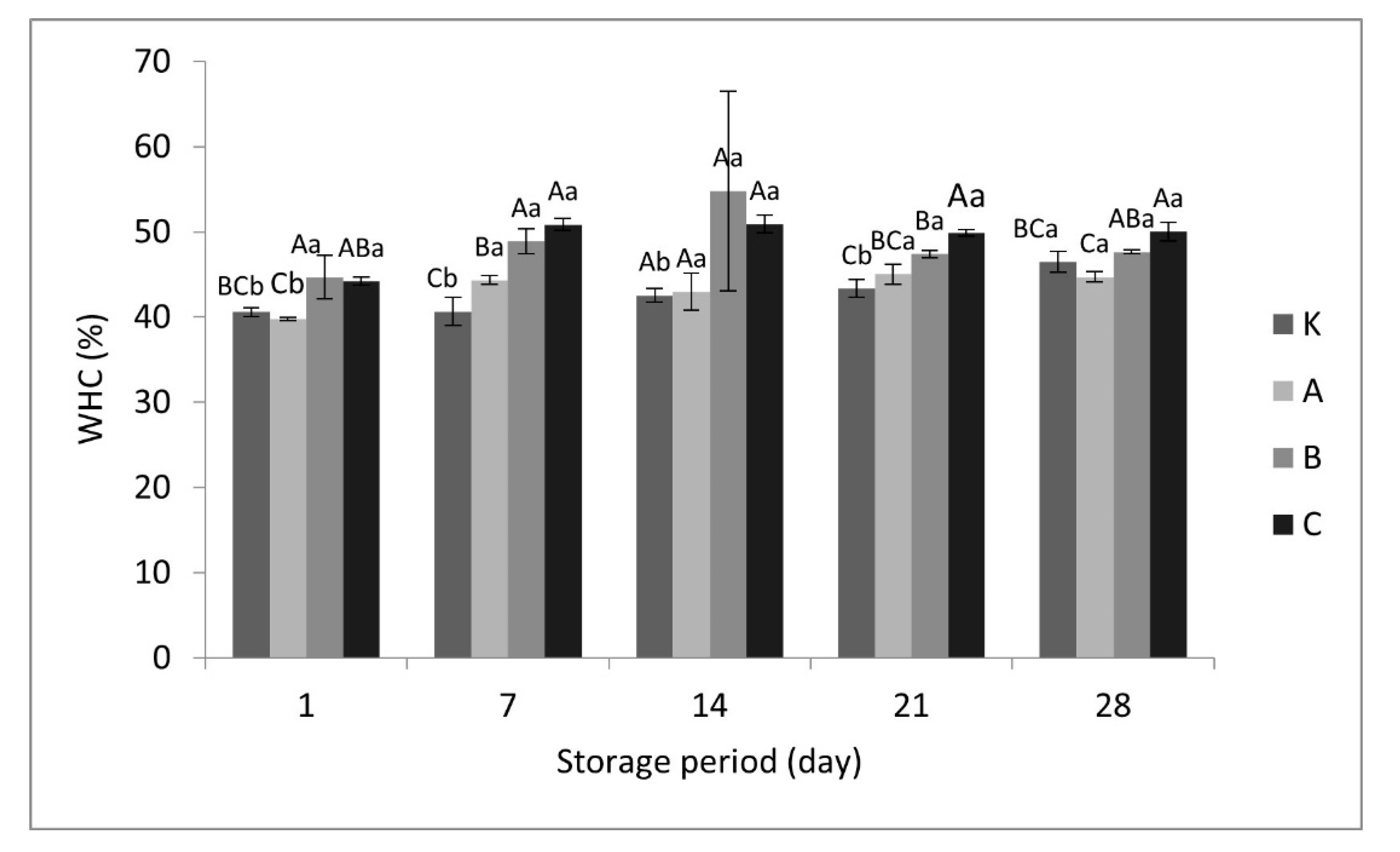

2.5.3. Water Holding Capacity

2.5.4. Colour Analysis

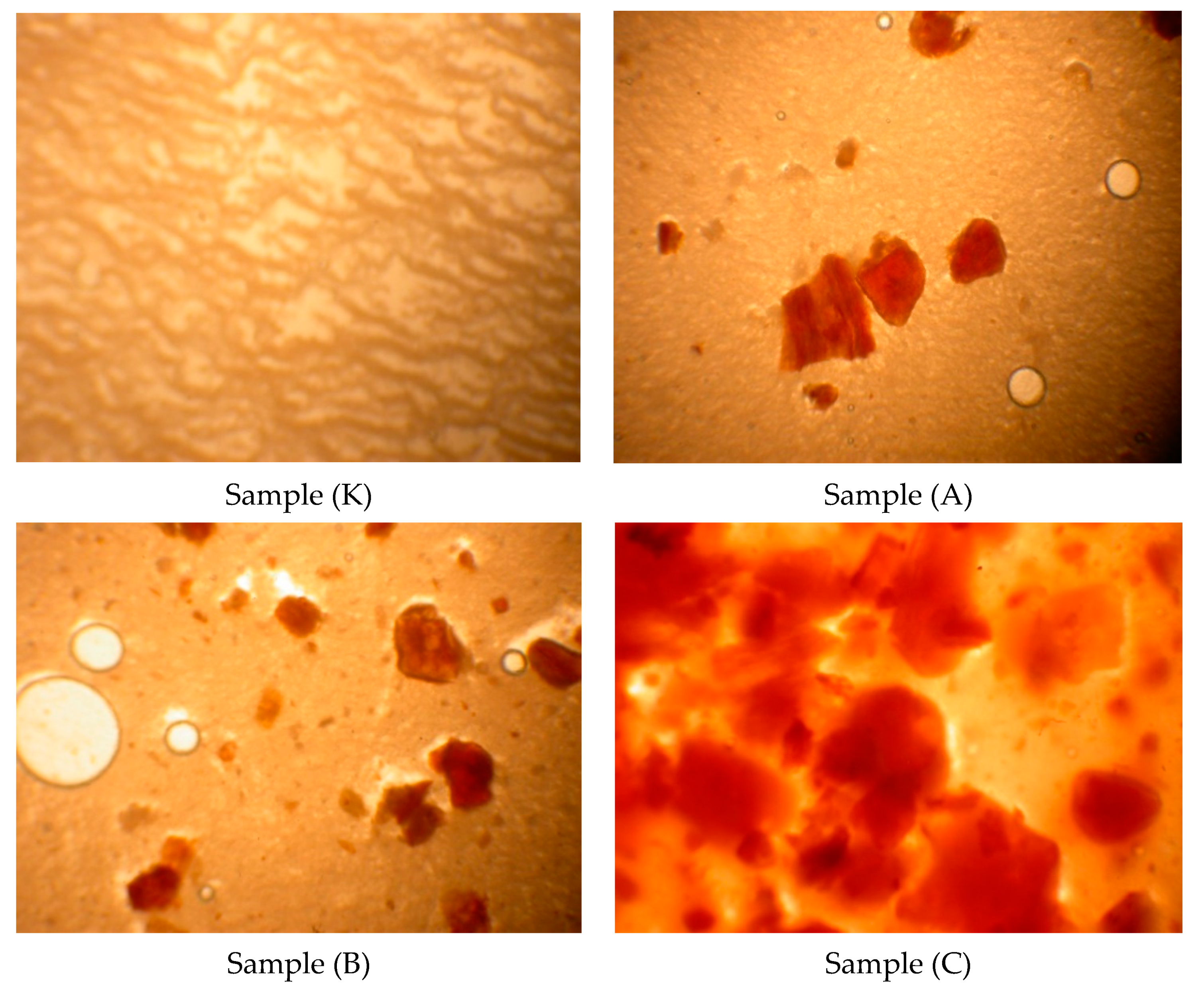

2.5.5. Microstructure

2.6. Biochemical Analysis

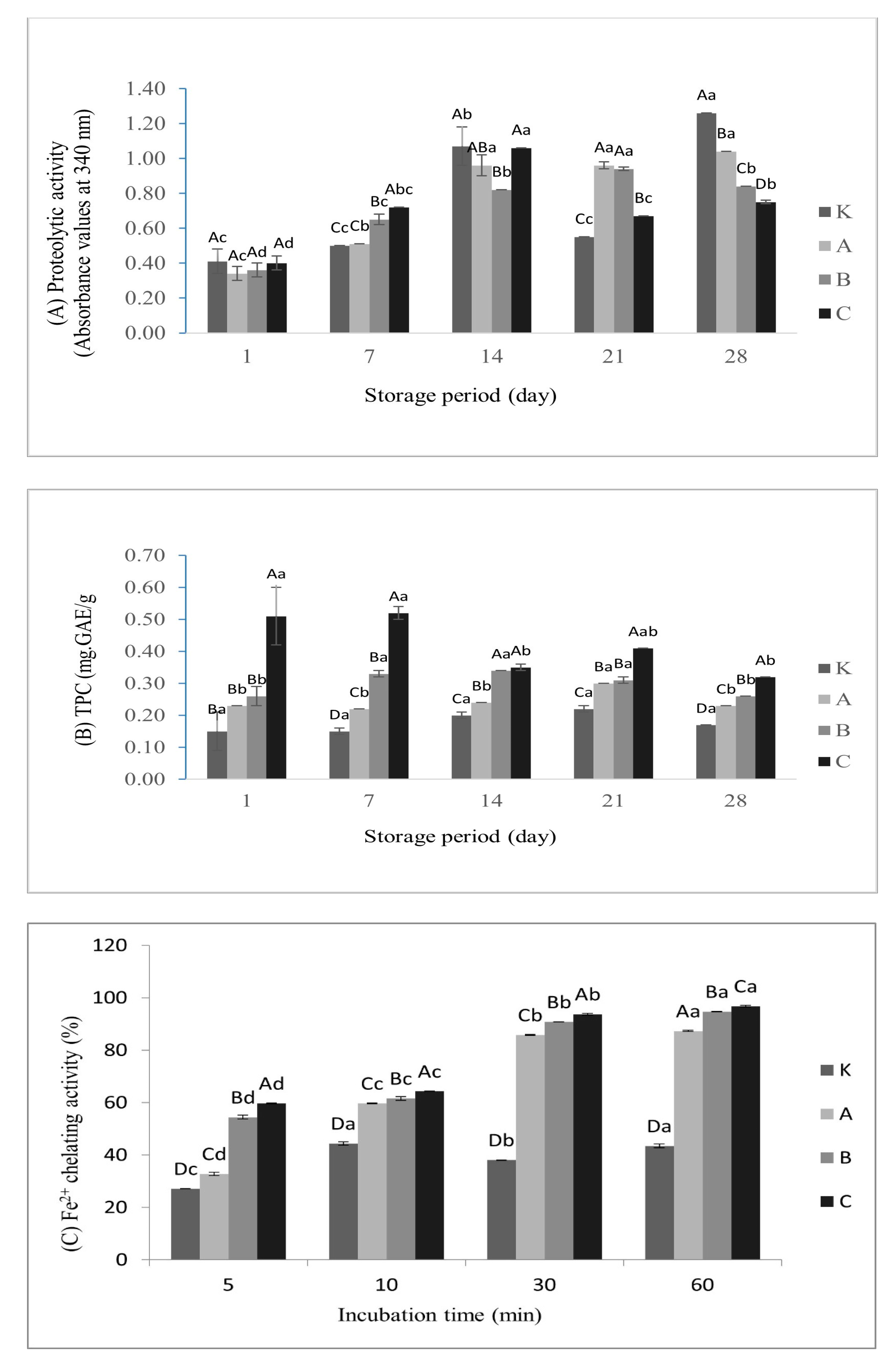

2.6.1. Proteolytic Activity

2.6.2. Antioxidant Activity

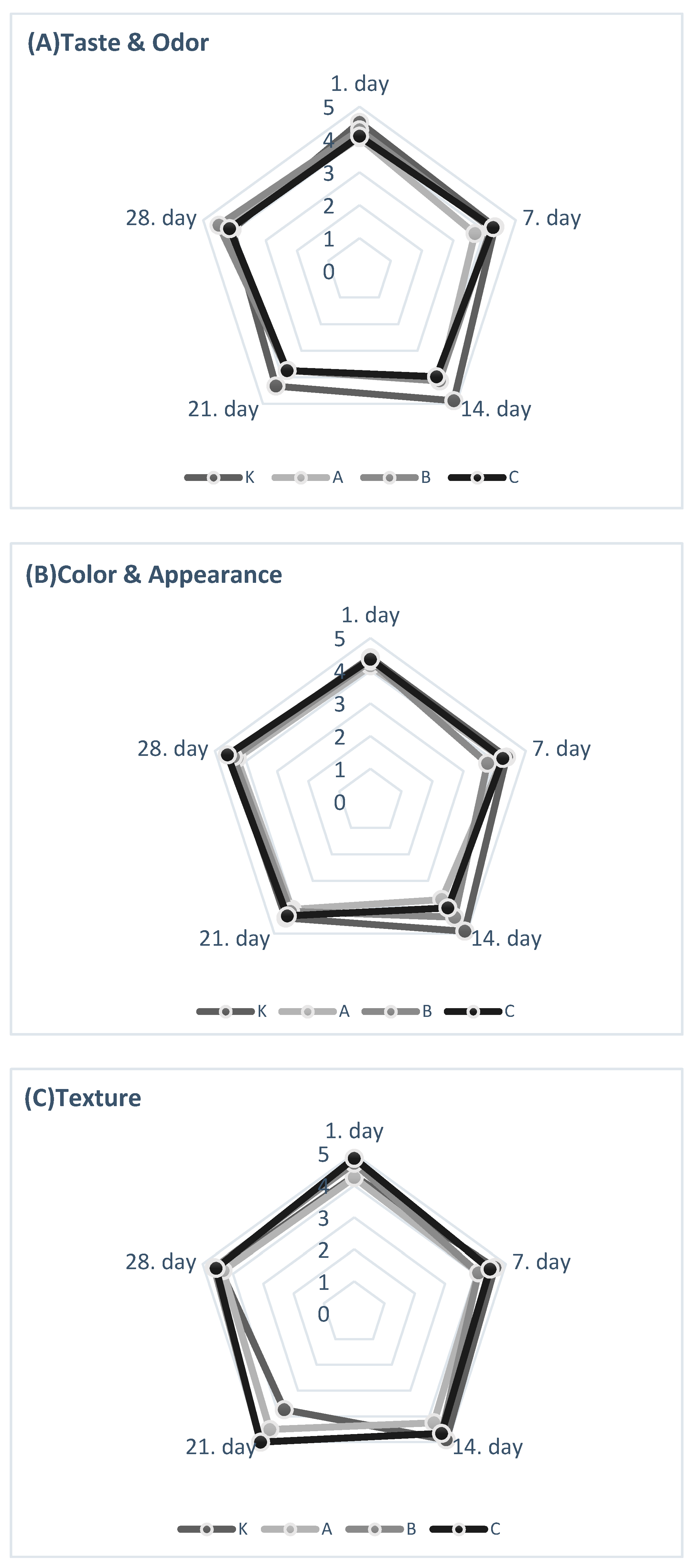

2.7. Sensorial Analysis

2.8. Statistical Analysis

3. Results

3.1. Physicochemical Properties

3.2. Microbiological Properties: Lactic Acid Bacteria Viability

3.3. Rheological Properties

3.4. Water Holding Capacity (WHC)

3.5. Colour

3.6. Microstructure

3.7. Biochemical Properties

3.7.1. Proteolytic Activity

3.7.2. Antioxidant Activity

3.8. Sensorial Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Comunian, T.A.; Silva, M.P.; Souza, C.J.F. The use of food by-products as a novel for functional foods: Their use as ingredients and for the encapsulation process. Trends Food Sci. Technol. 2021, 108, 269–280. [Google Scholar] [CrossRef]

- Bedoic, R.; Cosic, B.; Duic, N. Technical potential and geographic distribution of agricultural residues, co-products and by-products in the European Union. Sci. Total Environ. 2019, 686, 568–579. [Google Scholar] [CrossRef]

- Alasalvar, C.; Karamać, M.; Kosińska, A.; Rybarczyk, A.; Shahidi, F.; Amarowicz, R. Antioxidant activity of hazelnut skin phenolics. J. Agric. Food Chem. 2009, 57, 4645–4650. [Google Scholar] [CrossRef]

- Pelvan, E.; Olgun, E.Ö.; Karadag, A.; Alasalvar, C. Phenolic profiles and antioxidant activity of Turkish Tombul hazelnut samples (natural, roasted, and roasted hazelnut skin). Food Chem. 2018, 244, 102–108. [Google Scholar] [CrossRef] [PubMed]

- Shori, A.B. Proteolytic activity, antioxidant, and α-amylase inhibitory activity of yogurt enriched with coriander and cumin seeds. LWT—Food Sci. Technol. 2020, 133, 109912. [Google Scholar] [CrossRef]

- Bertolino, M.; Belviso, S.; Dal Bello, B.; Ghirardello, D.; Giordano, M.; Rolle, L.; Gerbi, V.; Zeppa, G. Influence of the addition of different hazelnut skins on the physicochemical, antioxidant, polyphenol and sensory properties of yogurt. LWT—Food Sci. Technol. 2015, 63, 1145–1154. [Google Scholar] [CrossRef] [Green Version]

- Zeppa, G.; Belviso, S.; Bertolino, M.; Cavallero, M.C.; Dal Bello, B.; Ghirardello, D.; Giordano, M.; Giorgis, M.; Grosso, A.; Rolle, L.; et al. The effect of hazelnut roasted skin from different cultivars on the quality attributes, polyphenol content and texture of fresh egg pasta. J. Sci. Food Agric. 2015, 95, 1678–1688. [Google Scholar] [CrossRef]

- Faostat. 2020. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 20 October 2021).

- Del Rio, D.; Calani, L.; Dall’Asta, M.; Brighenti, F. Polyphenolic composition of hazelnut skin. J. Agric. Food Chem. 2011, 59, 9935–9941. [Google Scholar] [CrossRef] [PubMed]

- Dinkci, N.; Akdeniz, V.; Akalın, A.S. Survival of probiotics in functional foods during shelf life. In Food Quality and Shelf Life, 1st ed.; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 201–226. ISBN 9780128171912. [Google Scholar]

- Ozturkoglu-Budak, S.; Akal, C.; Yetisemiyen, A. Effect of dried nut fortification on functional, physicochemical, textural, and microbiological properties of yogurt. J. Dairy Sci. 2016, 99, 8511–8523. [Google Scholar] [CrossRef] [Green Version]

- Sah, B.N.P.; Vasiljevic, T.; McKechnie, S.; Donkor, O.N. Physicochemical, Textural and rheological properties of probiotic yogurt fortified with fibre-rich pine-apple peel powder during refrigerated storage. LWT—Food Sci. Technol. 2016, 65, 978–986. [Google Scholar] [CrossRef]

- Karnopp, A.R.; Oliveira, K.G.; de Andrade, E.F.; Postingher, B.M.; Granato, D. Optimization of an organic yogurt based on sensorial, nutritional, and functional perspectives. Food Chem. 2017, 233, 401–411. [Google Scholar] [CrossRef]

- Zhao, M.-Y.; Ju, T.; Ling, X.-X.; Dai, Y.; Zhao, Y.-H. Composition analysis of pine nut seed coat and its application in yogurt. Mod. Food Sci. Technol. 2017, 33, 133–140. [Google Scholar]

- Dabija, A.; Codină, G.G.; Ropciuc, S.; Gâtlan, A.M.; Rusu, L. Assessment of the antioxidant activity and quality attributes of yogurt enhanced with wild herbs extracts. J. Food Qual. 2018, 4, 5329386. [Google Scholar] [CrossRef]

- Buniowska, M.; Znamirowska, A.; Sajnar, K.; Kowalczyk, M.; Kluz, M. Effect of addition of spelt and buckwheat hull on selected properties of yoghurts. J. Microb. Biotechnol. Food Sci. 2020, 10, 296–300. [Google Scholar] [CrossRef]

- EFSA. Scientific opinion on dietary reference values for carbohydrates and dietary fibre. EFSA J. 2010, 8, 1462. [Google Scholar] [CrossRef] [Green Version]

- Staffolo, M.D.; Bertola, N.; Martino, M.; Bevilacqua, A. Influence of dietary fiber addition on sensory and rheological properties of yogurt. Int. Dairy J. 2004, 14, 263–268. [Google Scholar] [CrossRef]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 17th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2000. [Google Scholar]

- Renner, E. Milchpraktikum Skriptum zu den Übüngen; Justus Liebig Universitat: Giesen, Germany, 1993; p. 76. [Google Scholar]

- Lucas, A.; Sodini, I.; Monnet, C.; Jolivet, P.; Corrieu, G. Probiotic cell counts and acidification in fermented milks supplemented with milk protein hydrolysates. Int. Dairy J. 2004, 14, 47–53. [Google Scholar] [CrossRef]

- De Man, J.; Rogosa, M.; Sharpe, E. A medium for the cultivation of lactobacilli. J. Appl. Microbiol. 1960, 23, 130–135. [Google Scholar] [CrossRef]

- Isanga, J.; Guonong, Z. Production and evaluation of some physicochemical parameters of peanut milk yoghurt. LWT—Food Sci. Technol. 2009, 42, 1132–1138. [Google Scholar] [CrossRef]

- Dinkci, N.; Kesenkaş, H.; Seçkin, A.K.; Kınık, Ö.; Gönç, S. Influence of a Vegetable Fat Blend on the Texture, Microstructure and Sensory Properties of Kashar Cheese. Grasas Y Aceites 2011, 62, 275–283. [Google Scholar] [CrossRef]

- Smarzyński, K.; Sarbak, P.; Kowalczewski, P.Ł.; Różańska, M.B.; Rybicka, I.; Polanowska, K.; Fedko, M.; Kmiecik, D.; Masewicz, Ł.; Nowicki, M.; et al. Low-Field NMR Study of Shortcake Biscuits with Cricket Powder, and Their Nutritional and Physical Characteristics. Molecules 2021, 26, 5417. [Google Scholar] [CrossRef] [PubMed]

- Hanafi, F.N.A.; Kamaruding, N.A.; Shaharuddin, S. Influence of coconut residue dietary fiber on physicochemical, probiotic (Lactobacillus plantarum ATCC 8014) survivability and sensory attributes of probiotic ice cream. LWT—Food Sci. Technol. 2022, 154, 112725. [Google Scholar] [CrossRef]

- Donkor, O.N.; Henriksson, A.; Vasiljevic, T.; Shah, N.P. Effect of acidification on the activity of probiotics in yoghurt during cold storage. Int. Dairy J. 2006, 16, 1181–1189. [Google Scholar] [CrossRef]

- Apostolidis, E.; Kwon, Y.L.; Shetty, K. Inhibitory potential of herb, fruit, and fungal-enriched cheese against key enzymes linked to type 2 diabetes and hypertension. Innov. Food Sci. Emerg. Technol. 2007, 8, 46–54. [Google Scholar] [CrossRef]

- Unal, G.; El, S.N.; Akalın, A.S.; Dinkci, N. Antioxidant Activity of Probiotic Yoghurt Fortified With Milk Protein Based Ingredient. Ital. J. Food Sci. 2013, 25, 63–69. [Google Scholar]

- Akalın, A.S.; Unal, G.; Dinkci, N.; Hayaloglu, A.A. Microstructural, textural, and sensory characteristics of probiotic yogurts fortified with sodium calcium caseinate or whey protein concentrate. J. Dairy Sci. 2012, 95, 3617–3628. [Google Scholar] [CrossRef]

- Sendra, E.; Fayos, P.; Lario, Y.; Fernandez-Lopez, J.; Sayas-Barbera, E.; Perez-Alvanez, J. Incorporation of citrus fibers in fermented milk containing probiotic bacteria. Food Microbiol. 2008, 25, 13–21. [Google Scholar] [CrossRef]

- Aportela-Palacios, A.; Sosa-Morales, M.E.; VélezRuiz, J.F. Rheological and physicochemical behavior of fortified yogurt with fiber and calcium. J. Texture Stud. 2005, 36, 333–349. [Google Scholar] [CrossRef]

- Demirci, T.; Aktas, K.; Sözeri, D.; Öztürk, H.I.; Akin, N. Rice bran improve probiotic viability in yoghurt and provide added antioxidative benefits. J. Funct. Foods 2017, 36, 396–403. [Google Scholar] [CrossRef]

- El-Said, M.M.; Haggag, H.F.; Fakhr El-Din, H.M.; Gad, A.S.; Farahat, A.M. Antioxidant activities and physical properties of stirred yoghurt fortified with pomegranate peel extracts. Ann. Agric. Sci. 2014, 59, 207–212. [Google Scholar] [CrossRef] [Green Version]

- Hernández-Carranza, P.; Jattar-Santiago, K.Y.; Avila-Sosa, R.; Pérez-Xochipa, I.; Guerrero-Beltrán, J.A.; Ochoa-Velasco, C.E.; Ruiz-López, I.I. Antioxidant fortification of yogurt with red cactus pear peel and its mucilage. CyTA—J. Food 2019, 17, 824–833. [Google Scholar] [CrossRef] [Green Version]

| Sample | Item | ||

|---|---|---|---|

| TS, % | Fat, % | Protein, % | |

| K | 16.49 ± 0.07 B | 3.45 ± 0.03 D | 5.05 ± 0.07 A |

| A | 16.99 ± 0.05 AB | 4.03 ± 0.03 C | 4.68 ± 0.05 A |

| B | 17.36 ± 0.05 AB | 4.31 ± 0.03 B | 4.68 ± 0.05 A |

| C | 17.68 ± 0.12 A | 4.60 ± 0.03 A | 4.63 ± 0.12 A |

| Item | Sample | Storage Days | ||||

|---|---|---|---|---|---|---|

| 1 | 7 | 14 | 21 | 28 | ||

| pH | K | 4.41 ± 0.01 Ba | 4.21 ± 0.00 Bab | 4.17 ± 0.01 BCb | 4.05 ± 0.02 Cb | 4.21 ± 0.18 Aab |

| A | 4.56 ± 0.06 Aba | 4.21 ± 0.00 Bb | 4.07 ± 0.05 Cc | 4.09 ± 0.01 BCc | 4.08 ± 0.01 Ac | |

| B | 4.57 ± 0.10 Aba | 4.35 ± 0.15 Abab | 4.29 ± 0.12 Abb | 4.13 ± 0.03 Bb | 4.07 ± 0.00 Ab | |

| C | 4.64 ± 0.01 Aa | 4.59 ± 0.08 Aa | 4.39 ± 0.00 Ab | 4.39 ± 0.00 Ab | 4.18 ± 0.02 Ac | |

| Lactic acid (%) | K | 1.39 ± 0.04 Ab | 1.38 ± 0.00 Ab | 1.47 ± 0.02 Aa | 1.54 ± 0.00 Aa | 1.48 ± 0.03 Aa |

| A | 1.22 ± 0.02 Bb | 1.36 ± 0.02 Aa | 1.35 ± 0.02 Aba | 1.24 ± 0.03 Bb | 1.27 ± 0.03 Bb | |

| B | 1.15 ± 0.00 BCb | 1.22 ± 0.06 Bb | 1.46 ± 0.02 Aa | 1.17 ± 0.00 Cb | 1.18 ± 0.00 Cb | |

| C | 1.09 ± 0.03 Cab | 1.04 ± 0.04 Cb | 1.22 ± 0.10 Ba | 0.98 ± 0.01 Db | 0.99 ± 0.02 Db | |

| Lactobacillus delbrueckii subsp. bulgaricus | K | 9.05 ± 0.04 Ba | 8.93 ± 0.02 Aa | 8.64 ± 0.12 Bb | 9.06 ± 0.03 Ca | 8.67 ± 0.04 ABb |

| A | 8.61 ± 0.01 Cd | 8.67 ± 0.04 Bcd | 8.84 ± 0.09 ABb | 9.24 ± 0.00 Ba | 8.77 ± 0.01 Abc | |

| B | 9.09 ± 0.03 ABa | 8.92 ± 0.00 Ab | 8.97 ± 0.00 Ab | 9.10 ± 0.01 Ca | 8.72 ± 0.04 Ac | |

| C | 9.18 ± 0.02 Aa | 8.75 ± 0.02 Bb | 8.87 ± 0.07 ABb | 9.32 ± 0.01 Aa | 8.52 ± 0.10 Bc | |

| Streptococcus thermophilus | K | 8.61 ± 0.04 Bc | 8.76 ± 0.00 Bb | 8.74 ± 0.05 Bb | 8.89 ± 0.00 Ba | 8.52 ± 0.03 Ac |

| A | 8.37 ± 0.08 BCc | 8.68 ± 0.00 Cb | 8.57 ± 0.04 Cb | 8.87 ± 0.00 Ca | 8.62 ± 0.03 Ab | |

| B | 8.30 ± 0.18 Cc | 8.76 ± 0.01 Bab | 8.86 ± 0.00 Aa | 8.79 ± 0.00 Dab | 8.58 ± 0.00 Ab | |

| C | 8.97 ± 0.00 Aa | 8.82 ± 0.02 Ab | 8.79 ± 0.03 Abb | 8.97 ± 0.00 Aa | 8.36 ± 0.02 Bc | |

| Item | Sample | Storage Days | ||||

|---|---|---|---|---|---|---|

| 1 | 7 | 14 | 21 | 28 | ||

| Hardness | K | 299.63 ± 15.02 Ab | 333.88 ± 3.71 Aa | 337.88 ± 19.26 Aa | 341.63 ± 3.00 Aa | 346.00 ± 0.70 Aa |

| A | 264.63 ± 6.89 Aab | 296.00 ± 19.44 Bab | 264.75 ± 20.50 Bb | 283.50 ± 7.42 Ba | 273.13 ± 12.90 Bab | |

| B | 271.63 ± 18.91 Aa | 240.00 ± 24.04 Ba | 262.00 ± 5.30 Ba | 263.50 ± 15.20 BCa | 271.13 ± 0.53 Ba | |

| C | 222.50 ± 16.61 Ba | 243.50 ± 4.94 Ba | 254.75 ± 27.57 Ba | 224.38 ± 24.21 Ca | 220.75 ± 47.37 Ba | |

| Adhesive force | K | 68.37 ± 3.00 Aa | 75.37 ± 7.60 Aa | 71.12 ± 8.30 Aa | 78.37 ± 1.94 Aa | 74.37 ± 2.29 Aa |

| A | 62.62 ± 2.65 ABa | 64.62 ± 2.65 ABa | 65.00 ± 9.54 Aa | 70.00 ± 1.06 ABa | 68.25 ± 1.76 ABa | |

| B | 66.00 ± 6.01 Aa | 55.25 ± 5.65 Ba | 57.75 ± 0.35 Aa | 59.25 ± 3.88 Ba | 62.50 ± 2.12 ABa | |

| C | 51.50 ± 4.94 Ba | 55.12 ± 4.06 Ba | 62.37 ± 7.24 Aa | 47.12 ± 6.89 Ca | 51.25 ± 11.66 Ba | |

| Consistency | K | 32.63 ± 1.46 Aa | 36.26 ± 0.53 Aa | 35.04 ± 5.47 Aa | 38.05 ± 0.30 Aa | 37.66 ± 0.56 Aa |

| A | 27.92 ± 0.72 Bb | 29.17 ± 1.19 Bab | 28.79 ± 2.20 Aab | 31.58 ± 0.51 Ba | 31.17 ± 0.20 ABa | |

| B | 28.92 ± 0.54 Ba | 24.60 ± 4.30 Ba | 28.91 ± 0.38 Aa | 29.45 ± 3.31 BCa | 31.19 ± 0.54 ABa | |

| C | 24.32 ± 1.72 Ca | 26.23 ± 1.03 Ba | 27.88 ± 2.11 Aa | 24.83 ± 1.93 Ca | 24.12 ± 5.86 Ba | |

| Viscosity Index | K | 7.45 ± 0.23 Aa | 7.17 ± 0.91 Aa | 6.67 ± 1.41 Aa | 7.01 ± 0.30 ABa | 6.84 ± 0.07 Aa |

| A | 6.60 ± 0.02 ABa | 7.31 ± 0.28 Aa | 6.98 ± 0.98 Aa | 7.59 ± 0.04 Aa | 7.49 ± 0.03 Aa | |

| B | 7.18 ± 0.53 Aab | 6.14 ± 0.24 Ab | 6.33 ± 0.12 Aab | 6.99 ± 0.64 ABab | 7.24 ± 0.04 Aa | |

| C | 5.42 ± 0.98 Ba | 6.31 ± 0.73 Aa | 6.60 ± 1.04 Aa | 5.57 ± 0.93 Ba | 5.88 ± 1.50 Aa | |

| Apparent viscosity | K | 4,86 ± 0.00 Ac | 5.22 ± 0.13 Abc | 4.46 ± 0.00 Ab | 5.17 ± 0.02 Abc | 5.94 ± 0.34 Aa |

| A | 4,02 ± 0.42 ABa | 4.91 ± 0.26 Aa | 5.25 ± 0.19 Aa | 5.18 ± 0.02 Aa | 5.34 ± 0.11 ABa | |

| B | 4,21 ± 0.34 ABb | 5.16 ± 0.17 Aa | 4.48 ± 0.31 Bb | 4.73 ± 0,18 Aab | 4.75 ± 0.00 Bab | |

| C | 3,47 ± 0.24 Ba | 3.71 ± 0.11 Ba | 3.28 ± 0.11 Ca | 3.20 ± 0.35 Aa | 3.81 ± 0.37 Ca | |

| Item | Sample | Storage Days | ||||

|---|---|---|---|---|---|---|

| 1 | 7 | 14 | 21 | 28 | ||

| L* | K | 87.06 ± 0.76 Aa | 89.81 ± 0.08 Aa | 89.28 ± 0.28 Aa | 88.31 ± 0.78 Aa | 88.97 ± 2.75 Aa |

| A | 68.43 ± 1.95 Ba | 72.94 ± 0.87 Ba | 69.38 ± 1.27 Ba | 68.88 ± 3.73 Ba | 73.04 ± 1.46 Ba | |

| B | 63.44 ± 0.42 Cb | 66.96 ± 0.27 Ca | 58.06 ± 1.11 Cc | 59.75 ± 1.34 Cc | 63.68 ± 1.52 Cb | |

| C | 57.87 ± 1.81 Dbc | 62.64 ± 3.07 Ca | 59.15 ± 0.93 Cabc | 55.01 ± 0.03 Cc | 62.20 ± 1.44 Cab | |

| A* | K | −3.34 ± 0.01 Da | −3.43 ± 0.02 Da | −3.38 ± 0.14 Ca | −3.54 ± 0.06 Da | −3.39 ± 0.16 Da |

| A | 5.72 ± 0.13 Ca | 5.52 ± 0.11 Cab | 5.69 ± 0.06 Ba | 5.57 ± 0.03 Cab | 5.36 ± 0.15 Cb | |

| B | 7.28 ± 0.02 Ba | 7.37 ± 0.01 Ba | 7.35 ± 0.56 Aa | 7.03 ± 0.34 Ba | 7.12 ± 0.04 Ba | |

| C | 8.01 ± 0.08 Aa | 8.08 ± 0.34 Aa | 8.02 ± 0.24 Aa | 7.73 ± 0.04 Aa | 7.77 ± 0.08 Aa | |

| B* | K | 9.23 ± 0.17 Aab | 9.37 ± 0.17 Aa | 9.45 ± 0.20 Aa | 9.29 ± 0.16 Aab | 8.85 ± 0.15 Ab |

| A | 9.69 ± 0.48 Aa | 10.41 ± 0.81 Aa | 10.03 ± 0.70 Aa | 9.63 ± 1.38 Aa | 9.94 ± 0.42 Aa | |

| B | 9.98 ± 0.10 Ab | 10.94 ± 0.25 Aa | 8.09 ± 0.43 Bc | 8.42 ± 0.15 Ac | 8.85 ± 0.53 Ac | |

| C | 9.42 ± 0.75 Aab | 10.56 ± 1.30 Aa | 9.75 ± 0.03 Aa | 7.80 ± 0.16 Ab | 9.75 ± 0.48 Aa | |

| Chroma (C*) | K | 10.60 ± 0.96 Aa | 8.69 ± 0.16 Ba | 9.40 ± 0.65 Ca | 9.94 ± 0.17 Aa | 9.47 ± 0.19 Ca |

| A | 10.26 ± 0.43 Aa | 11.78 ± 0.77 Aa | 11.52 ± 0.64 ABa | 11.13 ± 1.18 Aa | 11.29 ± 0.29 Ba | |

| B | 12.35 ± 0.09 Aa | 13.17 ± 0.22 Aa | 10.92 ± 0.70 BCb | 10.96 ± 0.09 Ab | 11.35 ± 0.39 Bb | |

| C | 12.36 ± 0.63 Aab | 13.29 ± 1.24 Aa | 12.62 ± 0.12 Aab | 10.97 ± 0.08 Ab | 12.47 ± 0.32 Aab | |

| ∆E | K | |||||

| A | 20.72 ± 0.41 Ca | 19.13 ± 0.35 Ca | 21.88 ± 0,37 Ba | 21.46 ± 0.43 Ca | 18.21 ± 0.34 Ca | |

| B | 25.91 ± 0.51 Bc | 25.32 ± 0.46 Bc | 33.04 ± 0,60 Aa | 30.47 ± 0.62 Bab | 27.39 ± 0.56 Bb | |

| C | 31.32 ± 0.59 Ab | 29.53 ± 0.53 Ab | 32.22 ± 0,64 Aab | 35.19 ± 0.69 Aa | 29.02 ± 0.53 Ab | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinkçi, N.; Aktaş, M.; Akdeniz, V.; Sirbu, A. The Influence of Hazelnut Skin Addition on Quality Properties and Antioxidant Activity of Functional Yogurt. Foods 2021, 10, 2855. https://doi.org/10.3390/foods10112855

Dinkçi N, Aktaş M, Akdeniz V, Sirbu A. The Influence of Hazelnut Skin Addition on Quality Properties and Antioxidant Activity of Functional Yogurt. Foods. 2021; 10(11):2855. https://doi.org/10.3390/foods10112855

Chicago/Turabian StyleDinkçi, Nayil, Merve Aktaş, Vildan Akdeniz, and Alexandrina Sirbu. 2021. "The Influence of Hazelnut Skin Addition on Quality Properties and Antioxidant Activity of Functional Yogurt" Foods 10, no. 11: 2855. https://doi.org/10.3390/foods10112855