Application and Effects of Ohmic-Vacuum Combination Heating on the Quality Factors of Tomato Paste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Processing

2.2. Conventional Heating

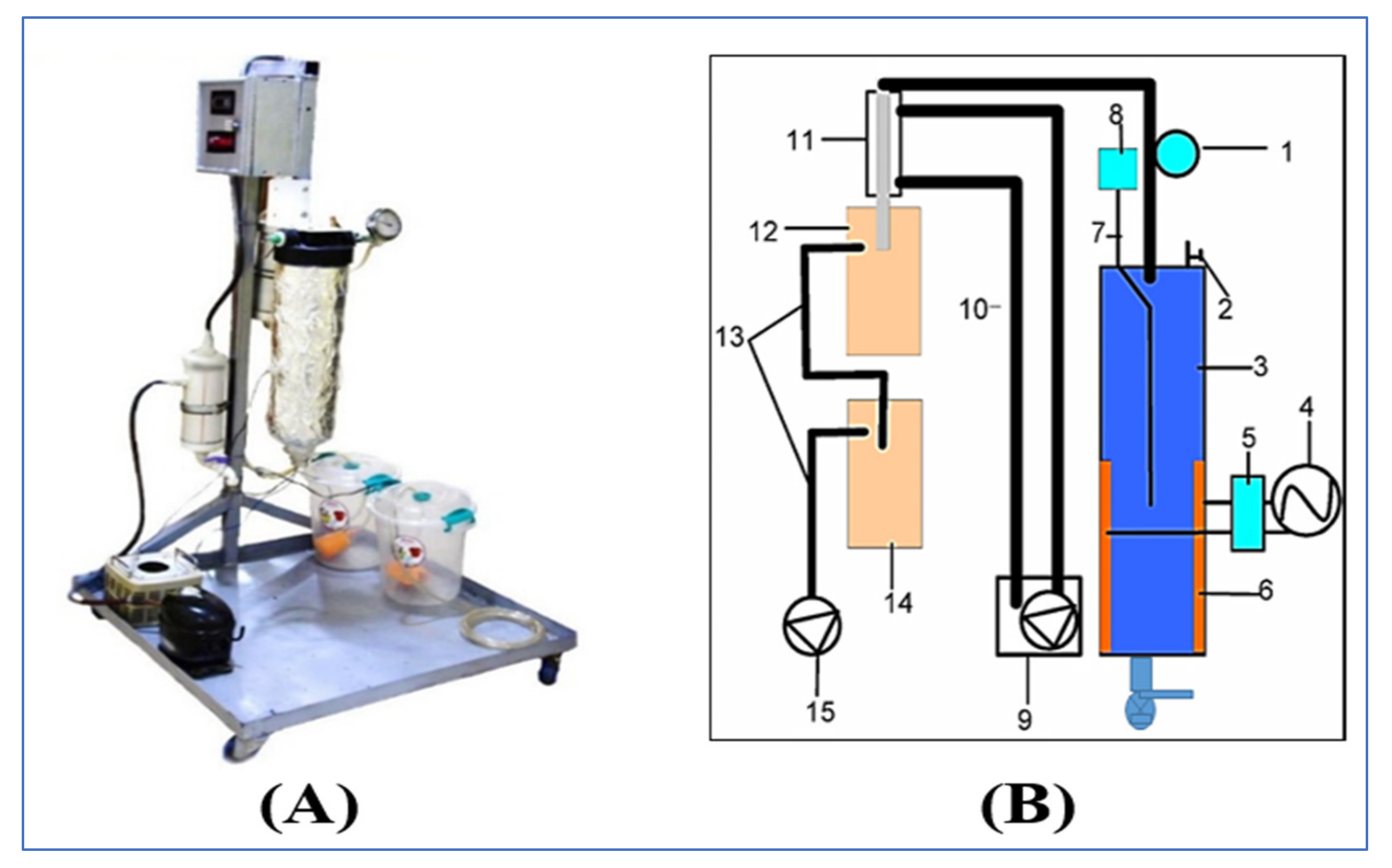

2.3. Ohmic-Vacuum (OH-VC) Combination Heating Device

2.4. Physicochemical Analysis

2.4.1. pH Determination

2.4.2. Titratable Acidity

2.4.3. Total Soluble Solids (TSS)

2.4.4. Density Determination

2.5. Ascorbic Acid (AA) Content

2.6. Lycopene Content

2.7. Hydroxymethyl Furfural (HMF)

2.8. Pectin Methyl Esterase (PME)

2.9. Electrical Conductivity

2.10. Energy Efficiency Energy (%)

2.11. Specific Energy Consumption

2.12. Microbiological Analysis

2.13. Sensory Analysis

2.14. Experiment Design and Statistical Methods

3. Results and Discussion

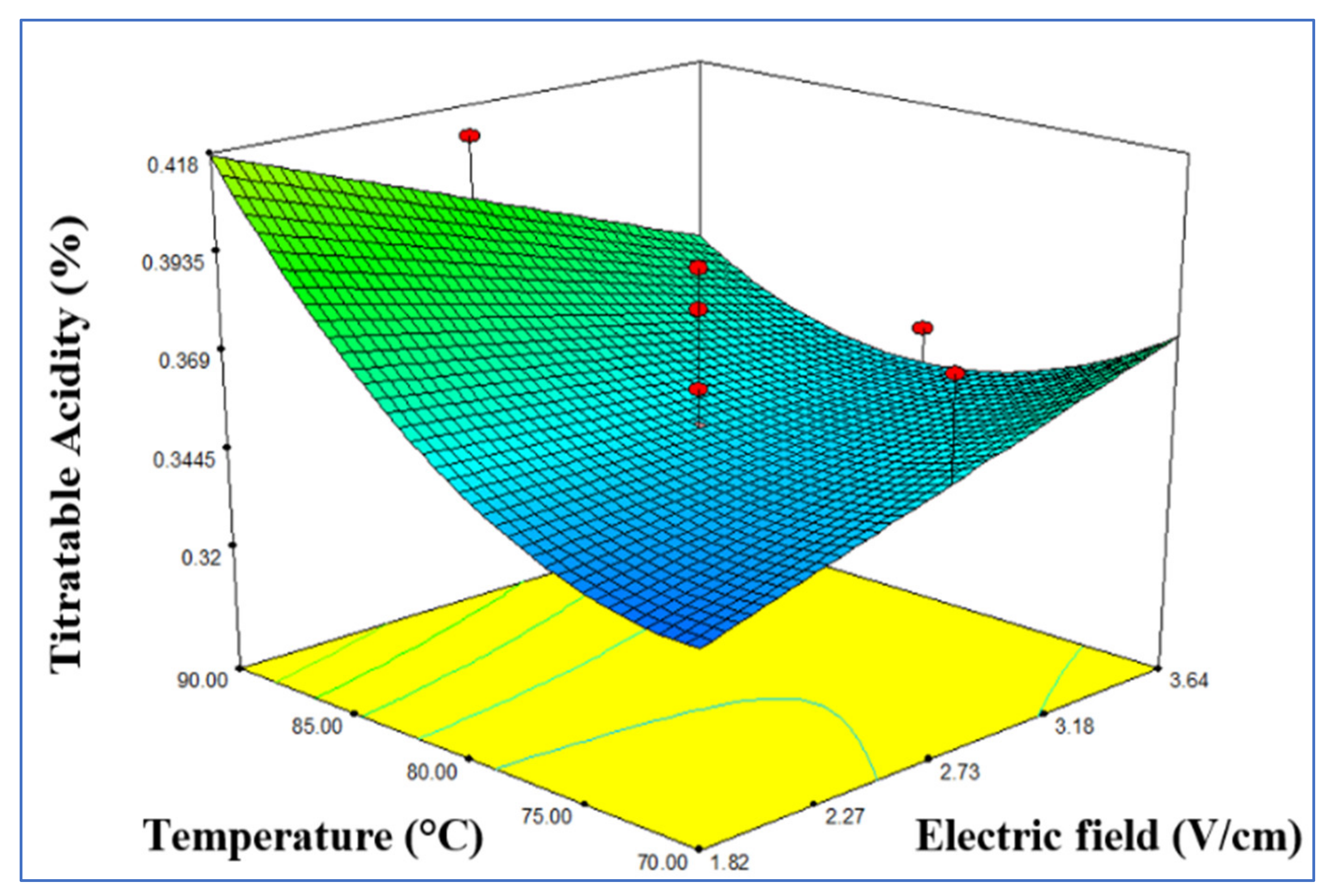

3.1. Influence of OH-VC on pH and Titratable Acidity

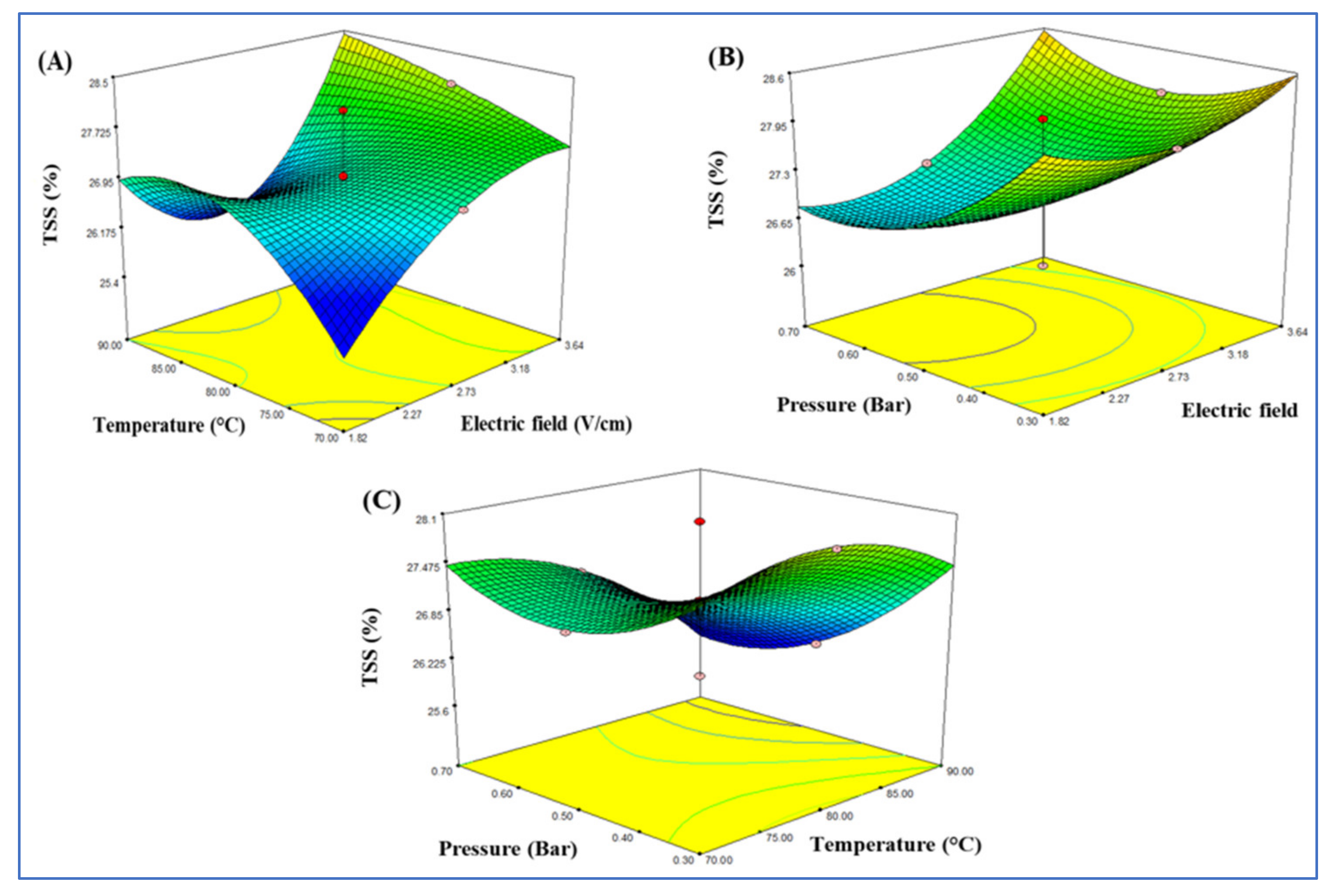

3.2. Effect OH-VC on TSS and Density

3.3. Effect of OH-VC on Ascorbic Acid Content

3.4. Effect of OH-VC on Lycopene Content

3.5. Influence of OH-VC on HMF

3.6. Influence of OH-VC on PME

3.7. Effects of OH-VC on the Microbial Quality

3.8. Effect of OH-VC on the Electrical Conductivity

3.9. Energy Efficiency of OH-VC Combination Heating System

3.10. Specific Energy Consumption

3.11. Productivity

3.12. Sensory Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ochida, C.O.; Itodo, A.U.; Anhwange, B.A.; Abah, C.N.; Nwanganga, P.A. Chemical and microbial quality evaluation of fresh tomato and its processed products using FTIR, SEM and GC-MS. J. Postharvest Technol. 2019, 7, 30–44. [Google Scholar]

- Economic and Social Commission for Western Asia (ESCWA). 2019. Available online: https://www.unescwa.org/ (accessed on 25 September 2021).

- Central Statistical Organization (CSO). Crop and vegetable production. In Directorate of Agricultural Statistics; Republic of Iraq Ministry of Planning: Baghdad, Iraq, 2018. [Google Scholar]

- Munhoz, K.A.S.; Schmidt, F.A.L.I. The tomato paste quality attributes along the industrial processing chain. Afr. J. Food Sci. 2019, 13, 215–224. [Google Scholar]

- Karunanithi, S. Optimization of process parameters of ohmic heating for improving yield and quality of tomato seed oil. Int. J. Pure Appl. Biosci. 2019, 7, 104–114. [Google Scholar] [CrossRef]

- Hassen, Y.; Gebre, H.; Haile, A. Effects of Pre-Heating and concentration temperatures on Physico-Chemical quality of semi concentrated tomato (Solanum lycopersicum) paste. J. Food Process. Technol. 2019, 10, 2. [Google Scholar]

- Ciprovica, I.; Raits, E.; Kirse-Ozolina, A. Designing of thermal treatment parameters for tomato sauces. Eng. Rural Dev. 2019, 18, 1140–1146. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Wang, L.-H.; Zeng, X.-A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Adulvitayakorn, S.; Azhari, S.; Hasan, H. The effects of conventional thermal, microwave heating, and thermosonication treatments on the quality of sugarcane juice. J. Food Process. Preserv. 2019, 44, 1–8. [Google Scholar] [CrossRef]

- Patel, A.; Singh, M. Ohmic Heating for Food Products-A review. Curr. J. Appl. Sci. Technol. 2018, 27, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cappato, L.; Ferreira, M.; Guimaraes, J.; Portela, J.; Costa, A.; Freitas, M.; Cunha, R.; Oliveira, C.; Mercali, G.; Marzack, L.; et al. Ohmic heating in dairy processing: Relevant aspects for safety and quality. Trends Food Sci. Technol. 2017, 62, 104–112. [Google Scholar] [CrossRef]

- Silva, V.L.; Soengas, R.G.; Silva1, A. Ionic liquids and ohmic heating in combination for Pd-catalyzed Cross-coupling reactions: Sustainable synthesis of flavonoids. Molecules 2020, 25, 1564. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, T. A review on ohmic heating technology: Principle, applications and scope. Int. J. Agric. Environ. Biotechnol. 2018, 11. [Google Scholar] [CrossRef]

- Wgiorgis, G.A.; Yildiz, F. Review on high-pressure processing of foods. Cogent Food Agric. 2019, 5, 1568725. [Google Scholar] [CrossRef]

- Stojceska, V.; Atuonwu, J.; Tassou, S.A. Ohmic and conventional drying of citrus products: Energy efficiency, greenhouse gas emissions and nutritional properties. Energy Procedia 2019, 161, 165–173. [Google Scholar] [CrossRef]

- Alkanan, Z.; Altemimi, A.; Al-Hilphy, A.; Watson, D.; Pratap-Singh, A. Ohmic heating in the food industry: Developments in concepts and applications during 2013–2020. Appl. Sci. 2021, 11, 2507. [Google Scholar] [CrossRef]

- Fadavi, A.; Yousefi, S.; Darvishi, H.; Mirsaeedghazi, H. Comparative study of ohmic vacuum, ohmic, and conventional-vacuum heating methods on the quality of tomato concentrate. IFSET 2018, 47, 225–230. [Google Scholar] [CrossRef]

- Alkanan, Z.T.; Al-Hilphy, A.R.; Altemimi, A.B.; Mandal, R.; Pratap-Singh, A. Comparison of quality characteristics of tomato paste produced under ohmic-vacuum combination heating and conventional heating. Appl. Food Res 2012, in press. [Google Scholar] [CrossRef]

- Gavahian, M.; Farahnaky, A. Ohmic-assisted hydrodistillation technology: A review. Trends Food Sci. Technol. 2018, 72, 153–161. [Google Scholar] [CrossRef]

- Ochida, C.O.; Itodo, A.U.; Nwanganga, P.A. A review on postharvest storage, processing and preservation of tomatoes (Lycopersicon esculentum Mill). Asian Food Sci. J. 2018, 6, 1–10. [Google Scholar] [CrossRef]

- Li, H.; Zhang, J.; Wang, Y.; Li, J.; Yang, Y.; Liu, X. The effects of storage conditions on lycopene content and color of tomato hot pot sauce. Int. J. Anal. Chem. 2018, 2018, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Damian, C. Rheological properties of tomato paste from the romanian market. Chem. Res. J. 2018, 3, 36–39. [Google Scholar]

- AOAC (Association of Official Analytical Chemists). Official Methods of Analysis of AOAC International, 17th ed.; Horwitz, W., Ed.; AOAC International: Gaithersburg, MD, USA, 2002; p. 2200. [Google Scholar]

- Bayindirli, L.; Özsan, O. Visne suyunun termofiziksel Özelliklerinin modellenmesi. Gıda Derg. 1992, 17. [Google Scholar]

- AOAC. Food composition; additives; natural contaminants. In Official Methods of Analysis of AOAC, 2 AOAC, Arlington; Medpharm GmbH Scientific Publishers: Hamburg, Germany, 1999. [Google Scholar]

- Tudor-Radu, M.; Vîjan, L.E.; Tudor-Radu, C.M.; Tița, I.; Sima, R.; Mitrea, R. Assessment of Ascorbic Acid, Polyphenols, Flavonoids, Anthocyanins and Carotenoids Content in Tomato Fruits. Not. Bot. Horti Agrobot. Cluj-Napoca 2016, 44, 477–483. [Google Scholar] [CrossRef] [Green Version]

- Ranganna, S. Handbook of Analysis and Quality Control for Fruit and Vegetable Products. Tata McGraw-Hill Education: New York, NY, USA, 1986. [Google Scholar]

- Abdullah, M.A.; Al Dajah, S.; Abu Murad, A.; El-Salem, A.M.; Khafajah, A.M. Extraction, purification, and characterization of lycopene from Jordanian vine tomato cultivar, and study of its potential natural antioxidant effect on Samen Baladi. Curr. Res. Nutr. Food Sci. J. 2019, 7, 532–546. [Google Scholar] [CrossRef] [Green Version]

- Cohen, E.; Birk, Y.; Mannheim, C.; Saguy, I. A Rapid method to monitor quality of apple juice during thermal processing. LWT 1998, 31, 612–616. [Google Scholar] [CrossRef] [Green Version]

- Kimball, D.A. Citrus processing. In A Complete Guide, 2nd ed.; Aspen Publishers Inc.: Gaithersburg, MD, USA, 1999; pp. 257–264. [Google Scholar]

- Icier, F. The Experimental Investigation and Mathematical Modeling of Ohmic Heating of Foods. Ph.D. Thesis, Ege University, Bornova, Turkey, 2003. [Google Scholar]

- Hosainpour, A.; Nargesi, F.; Darvishi, H.; Fadavi, A. Ohmicpre-drying of tomato paste. Food Sci. Technol. Int. 2014, 20, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Keyser, M.; Műller, I.A.; Cilliers, F.P.; Nel, W.; Gouws, P.A. Ultraviolet radiation as a non-thermal treatment for the inactivation of microorganisms in fruit juice. Innov. Food Sci. Emerg. Technol. 2008, 9, 348–354. [Google Scholar] [CrossRef]

- ISO 8589. Sensory Analysis–General Guidance for the Design of Test Rooms; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Batista, A.F.P.; dos Santos, A.R.; da Silva, A.F.; Trevisan, D.A.C.; Ribeiro, L.H.; Campanerut-Sá, P.A.Z.; Mikcha, J.M.G. Inhibition of Salmonella enterica serovar Typhimurium by combined carvacrol and potassium sorbate in vitro and in tomato paste. LWT 2019, 100, 92–98. [Google Scholar] [CrossRef]

- Darvishi, H.; Khostaghaza, M.H.; Najafi, G. Ohmic heating of pomegranate juice: Electrical conductivity and pH change. J. Saudi Soc. Agric. Sci. 2013, 12, 101–108. [Google Scholar] [CrossRef] [Green Version]

- Monti, L.M. The breeding of tomatoes for peeling. Acta Hortic. 1980, 100, 341–349. [Google Scholar] [CrossRef]

- Darvishi, H.; Saba, M.K.; Behroozi-Khazaei, N.; Nourbakhsh, H. Improving quality and quantity attributes of grape juice concentrate (molasses) using ohmic heating. J. Food Sci. Technol. 2020, 57, 1362–1370. [Google Scholar] [CrossRef]

- Sawant, S.R.; Pandey, J.P.; Singh, A.; Prakash, O.M. Effect of ohmic heating and lye-salt concentrations on total soluble solids and titrable acidity of tomato puree. Int. J. Agric. Sci. 2019, 11, 8002–8006. [Google Scholar]

- Astuti, D.S.; Salengke, S.; Laga, A.; Mariyati Bilangd, M.; Mochtar, H.; Warisf, A. Characteristics of pH, total acid, total soluble solid on tomato juice by ohmic heating technology. Int. J. Sci. Basic Appl. Res. 2018, 39, 21–28. [Google Scholar]

- Codex Alimentarius Commission. Codex Committee on Contaminants in Foods (CCCF). 2004. Available online: https://www.fao.org/fao-who-codexalimentarius/committees/committee/en/?committee=CCCF (accessed on 12 December 2019).

- Poojitha, P.; Athmaselvi, K. Influence of sucrose concentration on electric conductivity of banana pulp during ohmic heating. Food Sci. Technol. Int. 2018, 24, 664–672. [Google Scholar] [CrossRef] [PubMed]

- Saberian, H.; Esfahani, Z.H.; Banakar, A. Ohmic heating of Aloe vera Gel: Electrical conductivity and energy efficiency. Iran. J. Chem. Chem. Eng. IJCCE 2018, 37, 157–165. [Google Scholar]

- Takeoka, G.R.; Dao, L.; Flessa, S.; Gillespie, D.M.; Jewell, W.T.; Huebner, B.; Bertow, D.; Ebeler, S.E. Processing effects on lycopene content and antioxidant activity of tomatoes. J. Agric. Food Chem. 2001, 49, 3713–3717. [Google Scholar] [CrossRef] [PubMed]

- Koh, E.; Charoenprasert, S.; Mitchell, A.E. Effects of industrial tomato paste processing on ascorbic acid, flavonoids and carotenoids and their stability over one-year storage. J. Sci. Food Agric. 2012, 92, 23–28. [Google Scholar] [CrossRef]

- Martinez-Hernandez, G.B.; Artes-Hernendez, F.; Colares-Souza, F.; Gomez, P.A.; Garcia-Gomez, P.; Artes-Hernendez, F. Innovative cooking techniques for improving the overall quality of a KailanHybrid broccoli. Food Bioprocess Technol. 2013, 6, 2135–2149. [Google Scholar] [CrossRef]

- Gomathy, K.; Thangavel, K.; Balakrishnan, M.; Kasthuri, R. Effect of ohmic heating on the electrical conductivity, biochemical and rheological properties of papaya pulp. J. Food Process. Eng. 2015, 38, 405–413. [Google Scholar] [CrossRef]

- Assiry, A.M.; Sastry, S.K.; Samaranayake, C.P. Influence of temperature, electrical conductivity, power and pH on ascorbic acid degradation kinetics during ohmic heating using stainless steel electrodes. Bioelectrochemistry 2006, 68, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, B.G.; Roux, S.; Courtois, F.; Bonazzi, C. Kinetic modelling of ascorbic and dehydroascorbic acids concentrations in a model solution at different temperatures and oxygen contents. Food Res. Int. 2018, 106, 901–908. [Google Scholar] [CrossRef]

- Chanforan, C.; Loonis, M.; Mora, N.; Caris-Veyrat, C.; Dufour, C. The impact of industrial processing on health-beneficial tomato microconstituents. Food Chem. 2012, 134, 1786–1795. [Google Scholar] [CrossRef]

- Wu, M.; Kubota, C. Effects of high electrical conductivity of nutrient solution and its application timing on lycopene, chlorophyll and sugar concentrations of hydroponic tomatoes during ripening. Sci. Hortic. 2008, 116, 122–129. [Google Scholar] [CrossRef]

- Achir, N.; Dhuique-Mayer, C.; Hadjal, T.; Madani, K.; Pain, J.-P.; Dornier, M. Pasteurization of citrus juices with ohmic heating to preserve the carotenoid profile. Innov. Food Sci. Emerg. Technol. 2016, 33, 397–404. [Google Scholar] [CrossRef] [Green Version]

- Sabanci, S.; Cevik, M.; Cokgezme, O.F.; Yildiz, H.; Icier, F. Quality characteristics of pomegranate juice concentrates produced by ohmic heating assisted vacuum evaporation. J. Sci. Food Agric. 2019, 99, 2589–2595. [Google Scholar] [CrossRef]

- Pires, R.P.D.S.; Cappato, L.P.; Guimarães, J.T.; Rocha, R.S.; Silva, R.; Balthazar, C.F.; Freitas, M.Q.; Silva, P.H.F.; Neto, R.P.; Tavares, M.I.B.; et al. Ohmic heating for infant formula processing: Evaluating the effect of different voltage gradient. J. Food Eng. 2020, 280, 109989. [Google Scholar] [CrossRef]

- Abedelmaks, T.G.; Mohsen, S.M.; Duedahl-Olesen, L.; Elnikeety, M.M.; Feyissa, A.H. Effect of ohmic heating parameters on inactivation of enzymes and quality of not-from-concentrate mango juice. Asian J. Sci. Res. 2018, 11, 383–392. [Google Scholar] [CrossRef] [Green Version]

- Hernández, A.; Cano, M.P. High-Pressure and temperature effects on enzyme inactivation in tomato puree. J. Agric. Food Chem. 1998, 46, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Hsu, K.-C. Evaluation of processing qualities of tomato juice induced by thermal and pressure processing. LWT-Food Sci. Technol. 2008, 41, 450–459. [Google Scholar] [CrossRef]

- Makroo, H.A.; Rastogi, N.K.; Srivastava, B. Enzyme inactivation of tomato juice by ohmic heating and its effects on physico-chemical characteristics of concentrated tomato paste. J. Food Process. Eng. 2016, 40, e12464. [Google Scholar] [CrossRef]

- Giner, M.J.; Hizarci, O.; Martı´, N.; Saura, D.; Valero, M. Novel approaches to reduce Brown Pigment Formation and Color Changes in Thermal Pasteurized Tomato Juice. Eur. Food Res. Technol. 2013, 236, 507–515. [Google Scholar] [CrossRef]

- Demirdöven, A.; Baysal, T. Optimization of ohmic heating applications for pectin methylesterase inactivation in orange juice. J. Food Sci. Technol. 2012, 51, 1817–1826. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-Y.; Sagong, H.-G.; Ryu, S.; Kang, D.-H. Effect of continuous ohmic heating to inactivate Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice and tomato juice. J. Appl. Microbiol. 2012, 112, 723–731. [Google Scholar] [CrossRef] [PubMed]

- Leizerson, S.; Shimoni, E. Effect of Ultrahigh-Temperature continuous ohmic heating treatment on fresh orange juice. J. Agric. Food Chem. 2005, 53, 3519–3524. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Kim, S.-S.; Kang, D.-H. Effect of pH for inactivation of Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice by ohmic heating. LWT 2015, 62, 83–88. [Google Scholar] [CrossRef]

- Icier, F.; Yildiz, H.; Sabanci, S.; Cevik, M.; Cokgezme, O.F. Ohmic heating assisted vacuum evaporation of pomegranate juice. Electrical conductivity changes. IFSET 2017, 39, 241–246. [Google Scholar] [CrossRef]

- Kemp, M.; Fryer, P. Enhancement of diffusion through foods using alternating electric fields. Innov. Food Sci. Emerg. Technol. 2007, 8, 143–153. [Google Scholar] [CrossRef]

- Icier, F.; Yildiz, H.; Baysal, T. Polyphenoloxidase deactivation kinetics during ohmic heating of grape juice. J. Food Eng. 2008, 85, 410–417. [Google Scholar] [CrossRef]

- Gavahian, M.; Chu, R. Design, development, and performance evaluation of an ohmic extractor to valorize fruit by-products based on Taguchi method: Reduced energy consumption and enhanced total phenolics. J. Food Process. Eng. 2021, 13825, e13825. [Google Scholar] [CrossRef]

- Tumpanuvatr, T.; Jittanit, W. The temperature prediction of some botanical beverages, concentrated juices and purees of orange and pineapple during ohmic heating. J. Food Eng. 2012, 113, 226–233. [Google Scholar] [CrossRef]

| Symbols | Independent Variables | −1 | 0 | 1 |

|---|---|---|---|---|

| X1 | Temperature (°C) | 70 | 80 | 90 |

| X2 | Pressure (bar) | 0.3 | 0.5 | 0.7 |

| X3 | Electrical field (V/cm) | 1.82 | 2.73 | 3.64 |

| Run | Temperature (°C) | Pressure (Bar) | Electrical Conductivity (V/cm) |

|---|---|---|---|

| 1 | 80 | 0.50 | 1.82 |

| 2 | 70 | 0.30 | 3.64 |

| 3 | 70 | 0.50 | 3.64 |

| 4 | 70 | 0.70 | 3.64 |

| 5 | 80 | 0.50 | 2.73 |

| 6 | 80 | 0.50 | 2.73 |

| 7 | 80 | 0.50 | 2.73 |

| 8 | 70 | 0.50 | 3.64 |

| 9 | 80 | 0.70 | 2.73 |

| 10 | 90 | 0.50 | 2.73 |

| 11 | 90 | 0.70 | 1.82 |

| 12 | 80 | 0.30 | 3.64 |

| 13 | 80 | 0.50 | 1.82 |

| 14 | 80 | 0.30 | 2.73 |

| 15 | 80 | 0.50 | 2.73 |

| 16 | 90 | 0.70 | 1.82 |

| 17 | 90 | 0.30 | 2.73 |

| 18 | 70 | 0.30 | 2.73 |

| 19 | 90 | 0.50 | 2.73 |

| 20 | 80 | 0.70 | 1.82 |

| Independent Variables | pH | Titratable Acidity | TSS | Density | AA | Lycopene | HMF | PME | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RUN | Electric Field (V/cm) | Temperature | Pressure (Bar) | ||||||||

| (°C) | |||||||||||

| 1 | 1.82 | 70 | 0.7 | 4.2 | 0.33 | 26 | 1074.07 | 61.6 | 27.53 | 5.854 | 0.0000541 |

| 2 | 3.64 | 90 | 0.3 | 4.4 | 0.34 | 29 | 1075.26 | 48.42 | 27.53 | 1.561 | 0.0000581 |

| 3 | 3.64 | 90 | 0.7 | 4.2 | 0.39 | 29 | 1075.26 | 22 | 24.79 | 4.972 | 0.0000.225 |

| 4 | 3.64 | 70 | 0.3 | 4.1 | 0.34 | 28 | 1079.79 | 44 | 26.26 | 4.195 | 0.0000751 |

| 5 | 2.73 | 70 | 0.5 | 4.1 | 0.38 | 27 | 1074.07 | 66.35 | 24.78 | 5.718 | 0.0000344 |

| 6 | 2.73 | 80 | 0.5 | 4.2 | 0.33 | 27 | 1068.93 | 44.2 | 26.12 | 1.886 | 0.0000585 |

| 7 | 2.73 | 80 | 0.5 | 4.2 | 0.32 | 27 | 1068.93 | 43.98 | 26.25 | 1.861 | 0.0000571 |

| 8 | 3.64 | 70 | 0.7 | 4.3 | 0.39 | 28 | 1079.79 | 27.84 | 25.74 | 3.851 | 0.0000545 |

| 9 | 2.73 | 80 | 0.5 | 4.2 | 0.36 | 27 | 1068.93 | 44.34 | 26.91 | 1.561 | 0.0000408 |

| 10 | 2.73 | 90 | 0.3 | 4.2 | 0.37 | 29 | 1075.26 | 57.61 | 27.97 | 1.587 | 0.0000118 |

| 11 | 1.82 | 80 | 0.5 | 4.2 | 0.35 | 27 | 1068.93 | 26.66 | 25.89 | 3.48 | 0.0000456 |

| 12 | 3.64 | 80 | 0.5 | 4.3 | 0.36 | 28 | 1074.66 | 52.31 | 27.33 | 4.371 | 0.0000445 |

| 13 | 1.82 | 90 | 0.7 | 4.1 | 0.46 | 26 | 1058.08 | 22.03 | 24.21 | 3.731 | 0.000636 |

| 15 | 2.73 | 80 | 0.7 | 4.2 | 0.41 | 26 | 1058.08 | 40.51 | 25.67 | 1.783 | 0.0000362 |

| 16 | 2.73 | 80 | 0.3 | 4.1 | 0.36 | 27 | 1068.93 | 66.17 | 26.15 | 1.82 | 0.0000511 |

| 17 | 1.82 | 70 | 0.3 | 4.2 | 0.33 | 28 | 1074.66 | 67.6 | 26.77 | 1.725 | 0.0000582 |

| 18 | 2.73 | 80 | 0.5 | 4.2 | 0.33 | 26 | 1068.34 | 43.88 | 28.18 | 3.48 | 0.000591 |

| 19 | 2.73 | 80 | 0.5 | 4.2 | 0.39 | 28 | 1074.66 | 44.51 | 26.85 | 1.587 | 0.0000525 |

| 20 | 2.73 | 80 | 0.5 | 4.2 | 0.38 | 27 | 1068.93 | 43.95 | 26.23 | 1.908 | 0.0000543 |

| Regression Coefficient | pH | T.A | Density | A.A | Lycopene | HMF | PME |

|---|---|---|---|---|---|---|---|

| b0 | 4.19106 | 0.978 | 658.3262 | 201.0785 | 269.6063 | 94.7595 | 0.017990129 |

| b1 | 0.050487 | 0.1848 | 46.91637 | −57.1125 | −142.694 | −10.2135 | −0.004534519 |

| b2 | 0.050112 | −0.02523 | 5.641375 | −1.46955 | −4.91786 | −1.96993 | −0.000283933 |

| b1b2 | −0.04996 | 0.11 | 1510.327 | 146.165 | −3.59318 | 12.27199 | −0.018056761 |

| b12 | 0.037312 | −0.00234 | −0.78719 | 0.661925 | 2.633469 | 0.034416 | 5.23476 × 10−5 |

| b22 | 0.012738 | 0.00021 | −118.078 | −0.6875 | 17.30437 | −0.99756 | 0.005480062 |

| b1b22 | −0.06261 | --- | −20.0375 | −2.49 | −0.5 | 0.220313 | 0.0002211 |

| b12 b2 | 0.072873 | - | 3.030672 | 10.85322 | 1.47565 | 0.000114884 | |

| R2 | 0.982955 | 0.666402 | 0.873249 | 0.676866 | 0.945965 | 0.697817 | 0.927586 |

| p-value of the model | 0.0003 | 0.0049 | 0.0056 | 0.0107 | 0.0087 | 0.0792 | 0.0006 |

| p-value of lack of fit | 0.8048 | 0.7833 | 0.0001 | 0.0992 | 0.4158 | 0.0001 |

| Dependent Variable | OH-VC | Conventional Heating |

|---|---|---|

| AA (mg/100 g) | 67.76 ± 1.244 a | 50.16 ± 1.244 b |

| Lycopene (mg/kg) | 33.93 ± 1.435 a | 28.51 ± 1.173 |

| HMF (ppm) | 1.055 a ± 0.052 | 3.493 ± 0.77 b |

| PME (unit/mL) | 0.1135 × 10−3 ± 0.2121 × 106 | 0.15 ×10−3± 0.848528 × 10−6 b |

| pH | 4.2 a | 4.3 a |

| Titratable acidity (%) | 0.42 ± 0.42 a | 0.35 ± 0.0141 b |

| TSS (brix) | 27.5 ± 0.707 a | 28 ± 1.414 a |

| Total plate count | 0 | 0 |

| E. Coli | 0 | 0 |

| Yeast and mold | 0 | 0 |

| Dependent Variable | OH-VC | Conventional Heating |

|---|---|---|

| Electrical Conductivity (V/cm) | 13.08 ± 2.01 a | _ |

| Efficiency (%) | 36.87 ± 2.985 a | 1.3207 ± 0.12 b |

| SEC (kJ/kg) | 6701.750 ± 908.5 a | 31,233.33 ± 805.65 b |

| Productivity kg/h | 0.2763 ± 0.098 a | 0.089647 ± 0.01 b |

| Sample | Color | Texture | Taste | Appearance | Overall Acceptability |

|---|---|---|---|---|---|

| OH-VC | 8.6 ± 0.632 a | 8.33 ± 0.723 a | 8.13 ± 0.743 a | 8.13 ± 0.990 a | 8.13 ± 0.854 a |

| Conventional heating | 6.63 ± 0.972 b | 7.3 ± 1.130 b | 8.03 ± 0.718 a | 7.8 ± 0.797 a | 7.36 ± 0.854 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkanan, Z.T.; Altemimi, A.B.; Al-Hilphy, A.R.S.; Cacciola, F.; Ibrahim, S.A. Application and Effects of Ohmic-Vacuum Combination Heating on the Quality Factors of Tomato Paste. Foods 2021, 10, 2920. https://doi.org/10.3390/foods10122920

Alkanan ZT, Altemimi AB, Al-Hilphy ARS, Cacciola F, Ibrahim SA. Application and Effects of Ohmic-Vacuum Combination Heating on the Quality Factors of Tomato Paste. Foods. 2021; 10(12):2920. https://doi.org/10.3390/foods10122920

Chicago/Turabian StyleAlkanan, Zina T., Ammar B. Altemimi, Asaad R. S. Al-Hilphy, Francesco Cacciola, and Salam A. Ibrahim. 2021. "Application and Effects of Ohmic-Vacuum Combination Heating on the Quality Factors of Tomato Paste" Foods 10, no. 12: 2920. https://doi.org/10.3390/foods10122920

APA StyleAlkanan, Z. T., Altemimi, A. B., Al-Hilphy, A. R. S., Cacciola, F., & Ibrahim, S. A. (2021). Application and Effects of Ohmic-Vacuum Combination Heating on the Quality Factors of Tomato Paste. Foods, 10(12), 2920. https://doi.org/10.3390/foods10122920