Production and Physicochemical Characterization of Analog Rice Obtained from Sago Flour, Mung Bean Flour, and Corn Flour Using Hot Extrusion Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hot Moisture Treatment (HMT)

2.3. Analog Rice Production

2.4. Analyses of the Products

2.5. Hedonic Sensory Test

2.6. Statistical Analysis

3. Results and Discussion

3.1. Analysis of the Raw Materials

3.2. Composition of Analog Rice

3.3. Effect of Extrusion Temperature on Analog Rice Nutrients

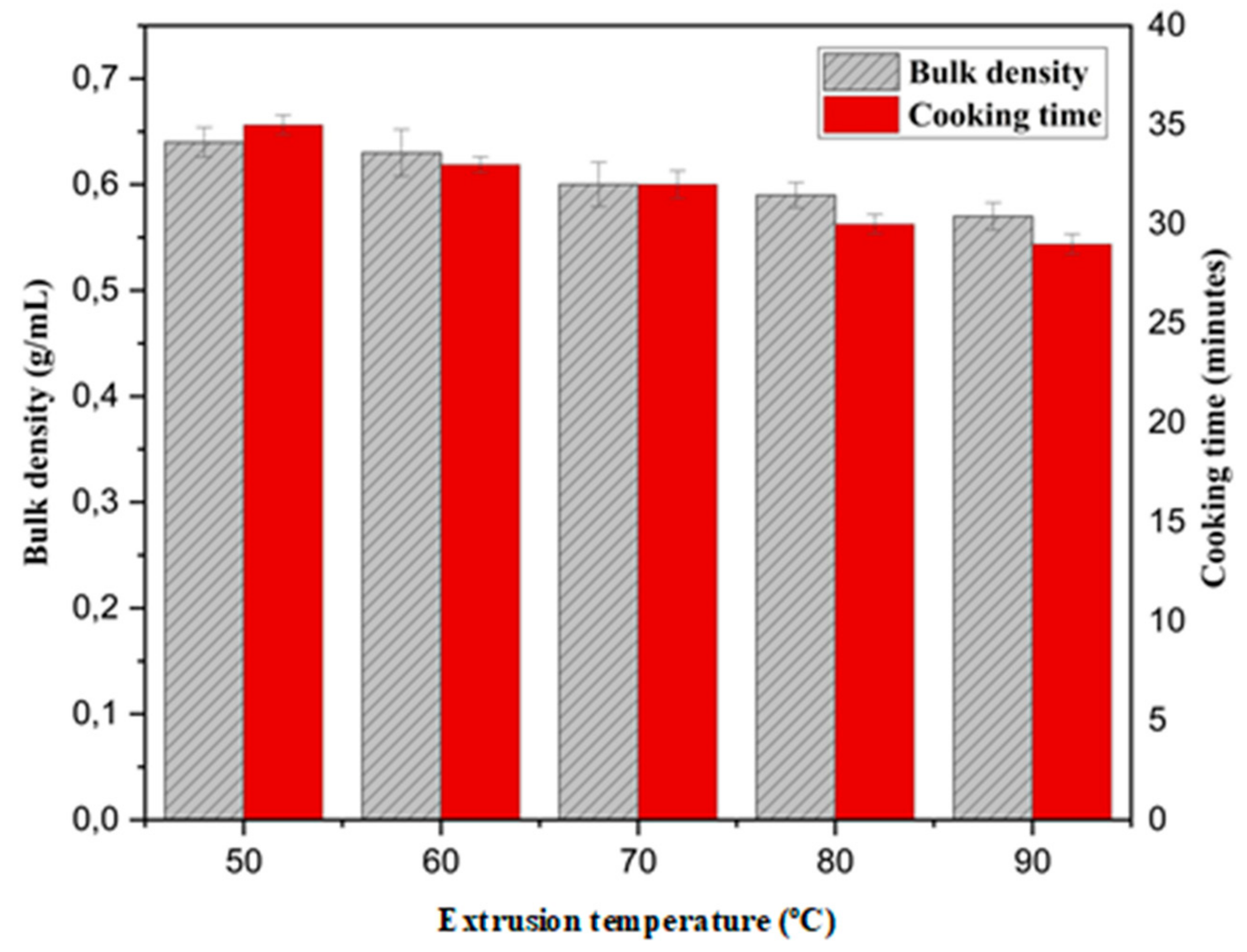

3.4. Physical Analysis of the Analog Rice: Bulk Density and Cooking Time

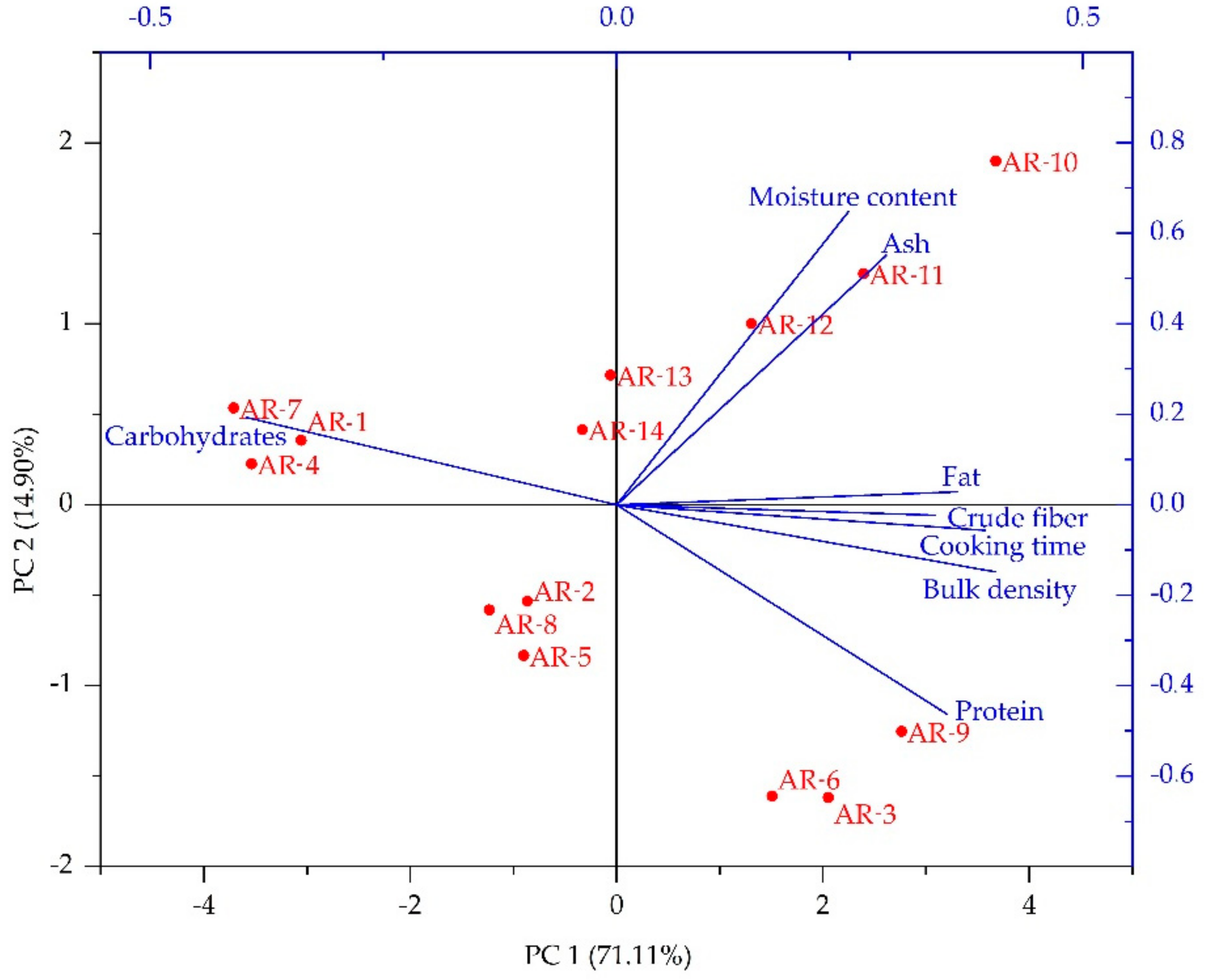

3.5. Principal Component Analysis

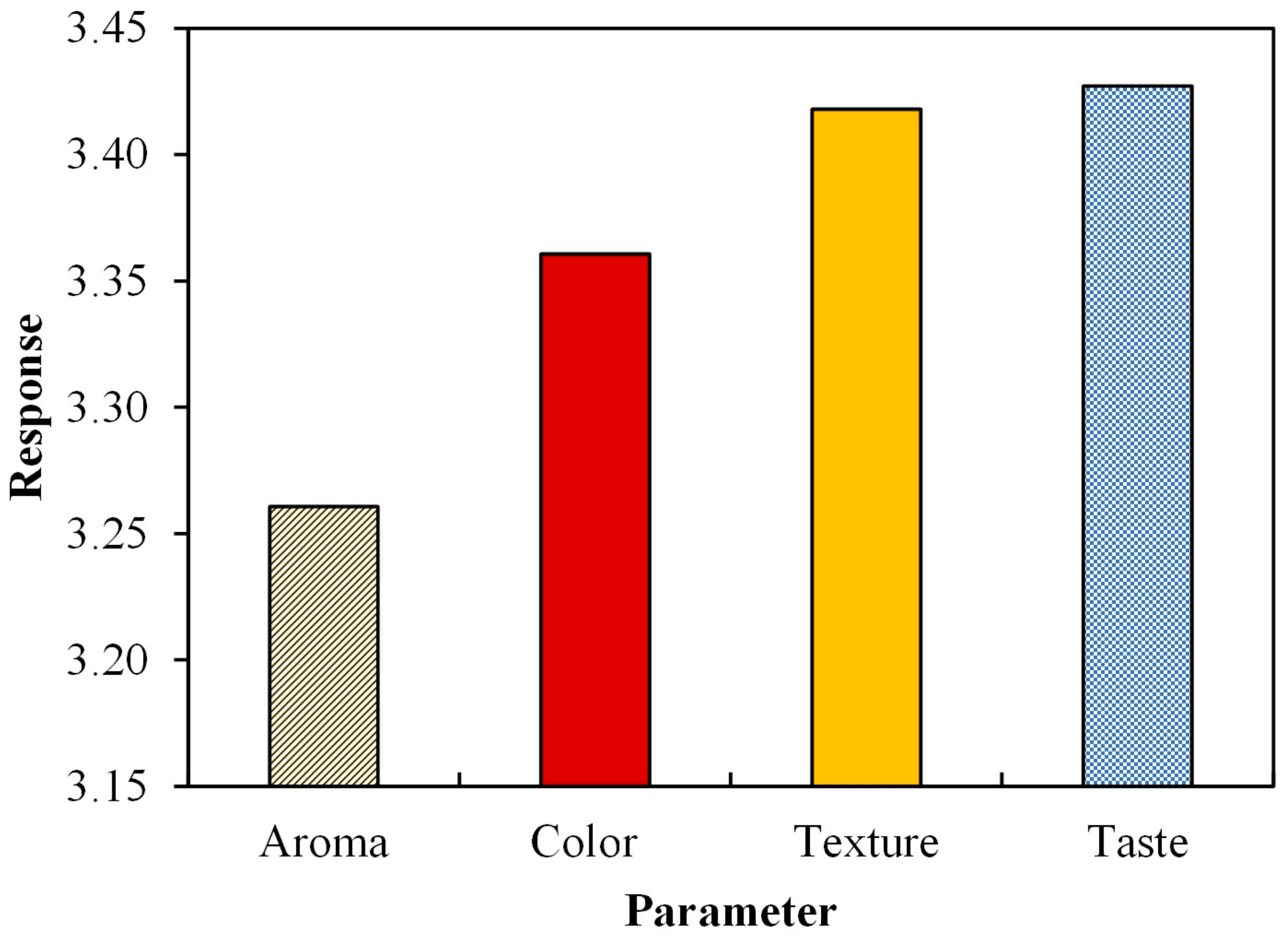

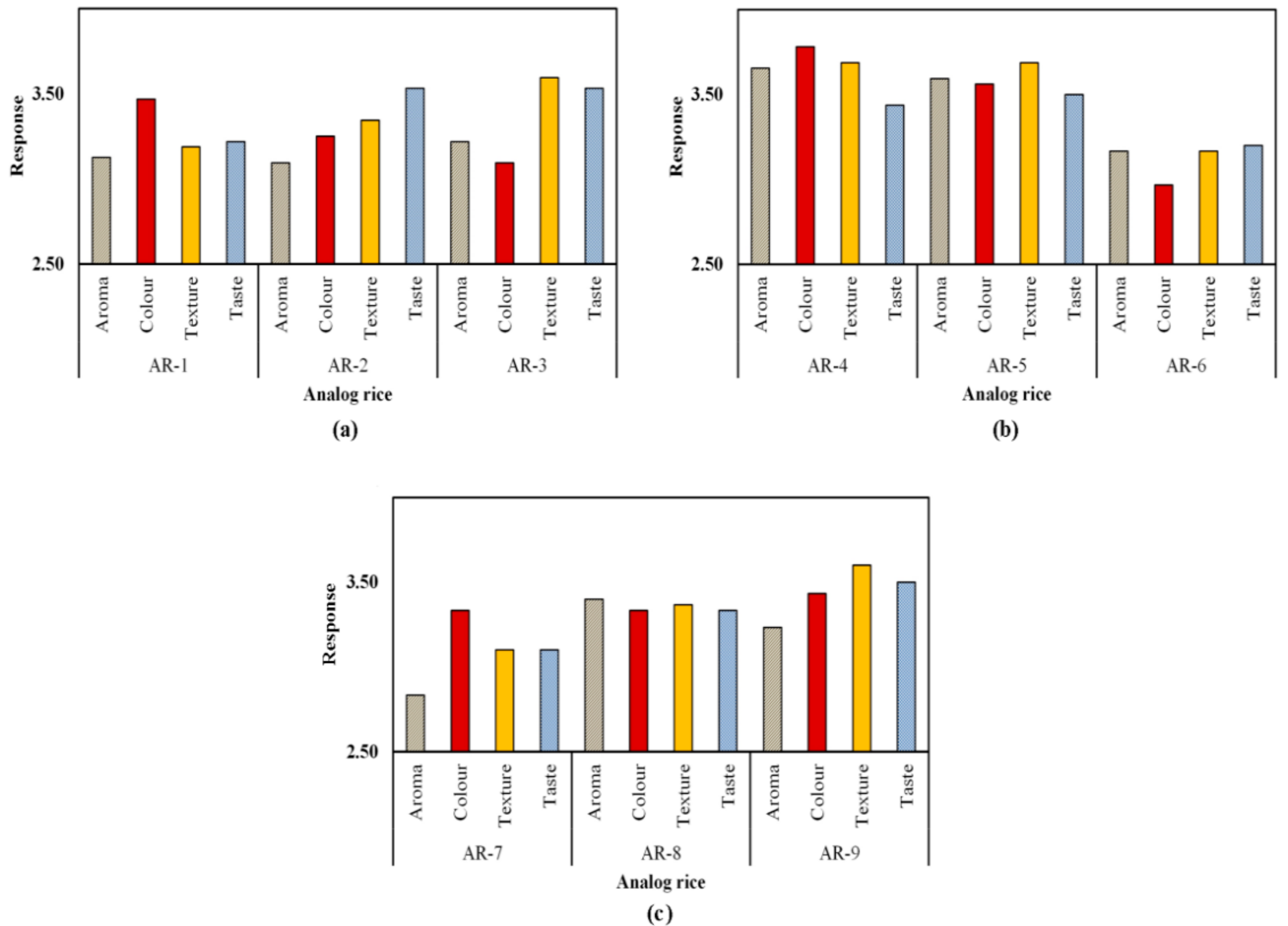

3.6. Hedonic Test of Analog Rice

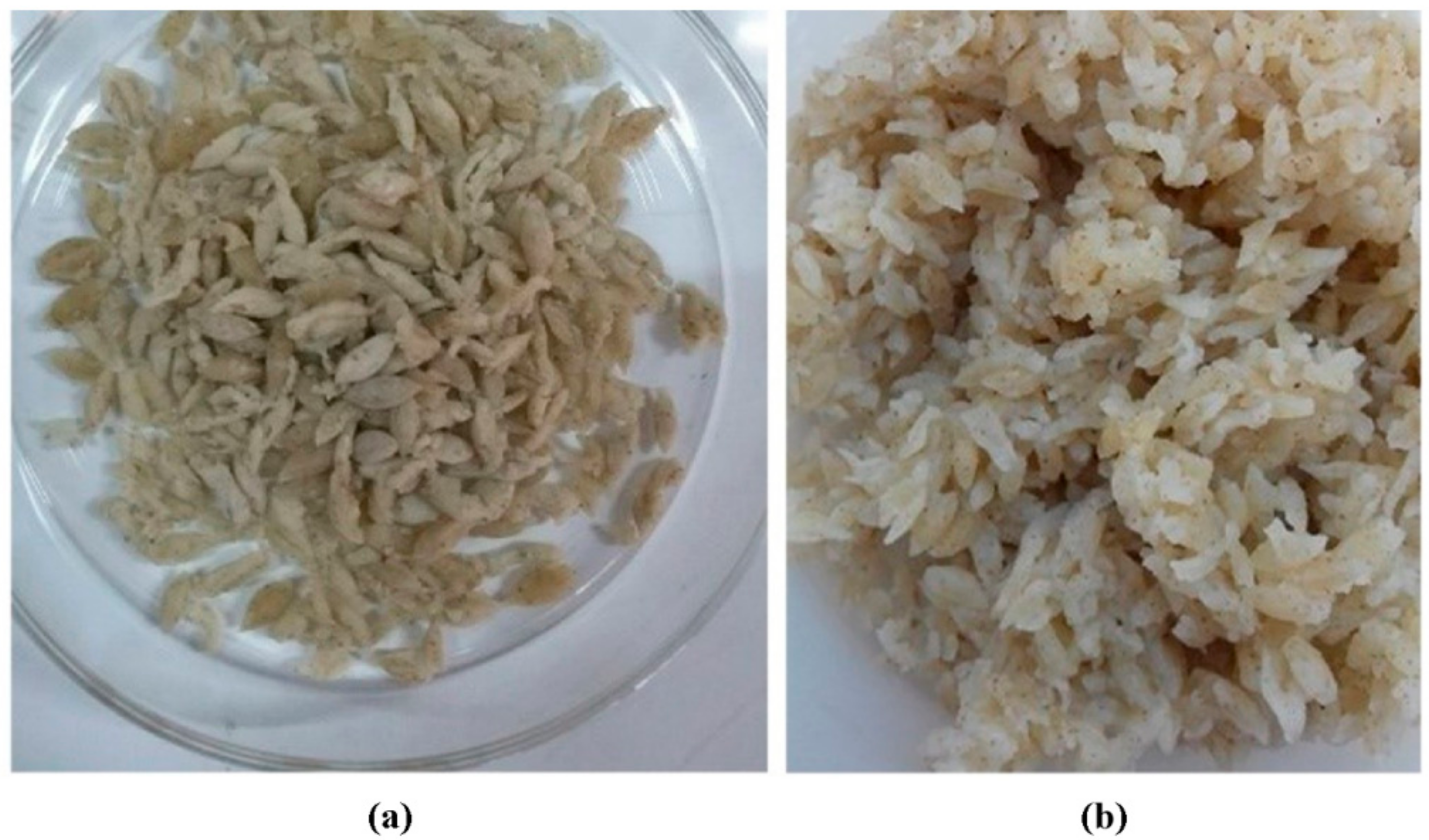

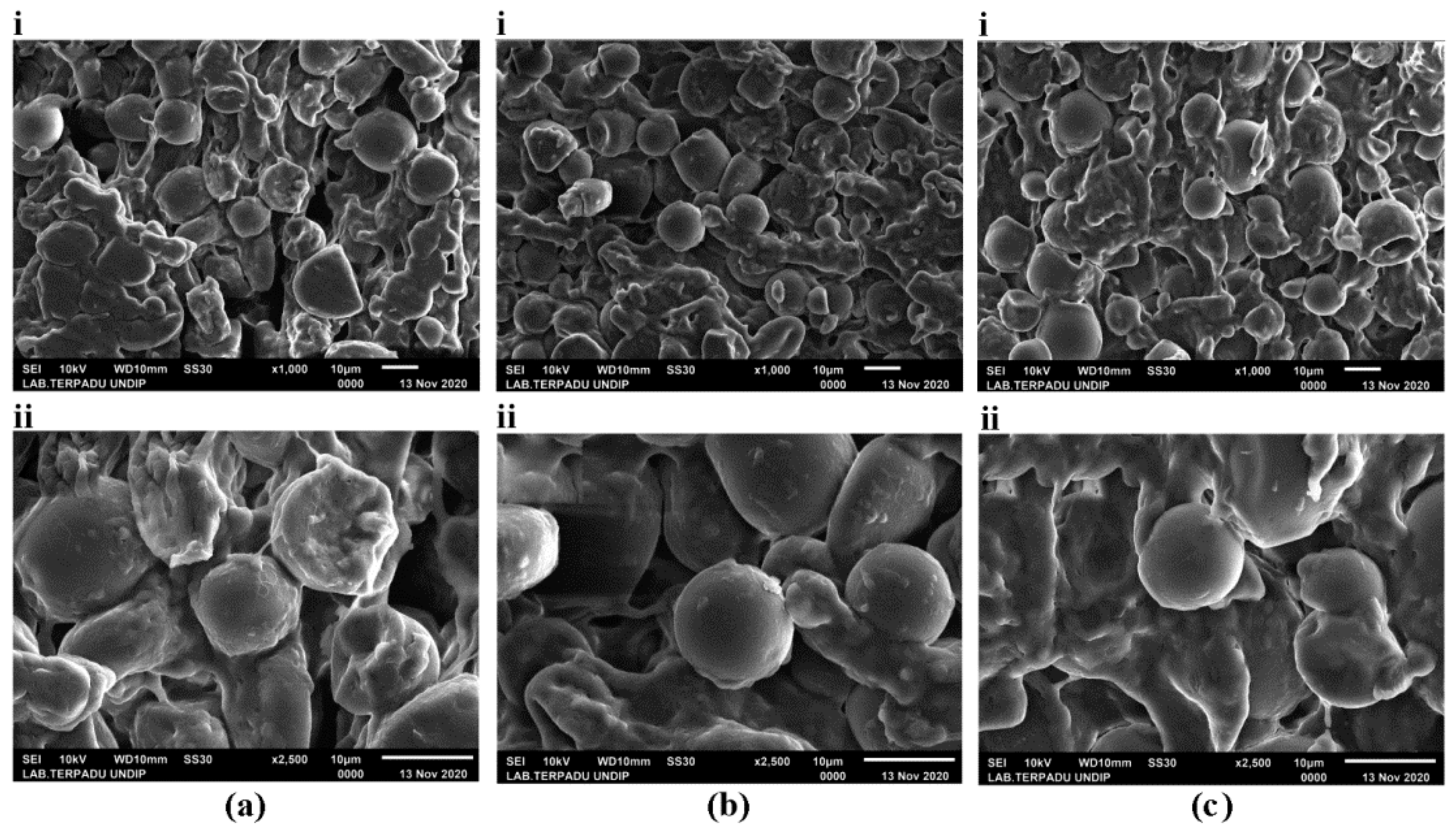

3.7. Morphology of Analog Rice

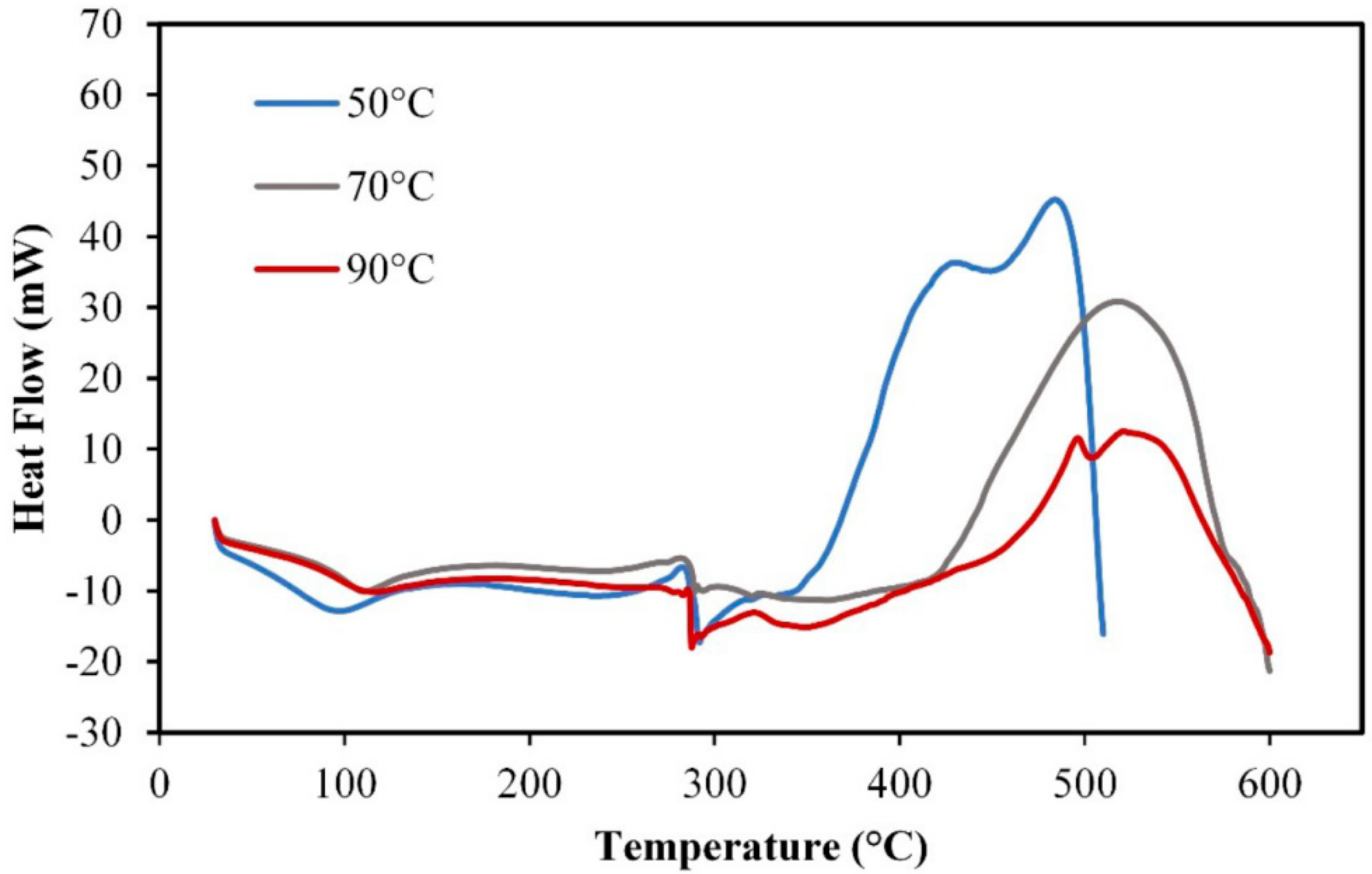

3.8. Differential Scanning Calorimetry (DSC) Analysis of Analog Rice

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Widyanti, A.; Sunaryo, I.; Kumalasari, A.D. Reducing the Dependency on Rice as Staple Food in Indonesia-a Behavior Intervention Approach. J. ISSAAS 2014, 20, 93–103. [Google Scholar]

- Sumardiono, S.; Pudjihastuti, I.; Poerwoprajitno, A.R.; Suswadi, M.S. Physichocemical Properties of Analog Rice from Composite Flour: Cassava, Green Bean and Hanjeli. World Appl. Sci. J. 2014, 32, 1140–1146. [Google Scholar]

- Sumardiono, S.; Budiyono, B.; Kusumayanti, H.; Prakoso, N.I.A.; Paundrianagari, F.P.; Cahyono, H. Influence of Composite Flour Constituents and Extrusion Temperature in the Production of Analog Rice. Food Sci. Nutr. 2021, 9, 4385–4393. [Google Scholar] [CrossRef] [PubMed]

- Sumardiono, S.; Pudjihastuti, I.; Handayani, N.A.; Kusumayanti, H. The Quality of Analog Rice from Composite Flour: Modified Cassava Flour, Zea Mays, Canavalia Ensiformis and Dioscorea Esculenta Using Hot Extrusion. Adv. Sci. Lett. 2018, 24, 9794–9796. [Google Scholar] [CrossRef]

- Pudjihastuti, I.; Sumardiono, S.; Supriyo, E.; Kusumayanti, H. Analog Rice Made from Cassava Flour, Corn and Taro for Food Diversification. E3s Web Conf. 2019, 125, 03010. [Google Scholar] [CrossRef]

- Putri, E.C.J.; Sumardiono, S. Analog Rice Production of Composite Materials Flour (Cassava, Avocado Seeds, and Tofu Waste) for Functional Food. AIP Conf. Proc. 2020, 2197, 070005. [Google Scholar] [CrossRef]

- Budijanto, S.; Andri, Y.I.; Faridah, D.N.; Noviasari, S. Karakterisasi Kimia Dan Efek Hipoglikemik Beras Analog Berbahan Dasar Jagung, Sorgum, Dan Sagu Aren. agriTECH 2017, 37, 402–409. [Google Scholar] [CrossRef]

- Kurachi, H. Process of Making Enriched Artificial Rice. U.S. Patent No. ID 5,403,606, 4 April 1995. [Google Scholar]

- Noviasari, S.; Widara, S.S.; Budijanto, S. Analogue Rice as The Vehicle of Public Nutrition Diversity. KEMAS Jurnal Kesehatan Masyarakat 2017, 13, 18–27. [Google Scholar] [CrossRef] [Green Version]

- Nishimura, Y. Sago Starch: Transformation of Extraction and Consumption Processes in Traditional Indonesian Societies. In Sago Palm: Multiple Contributions to Food Security and Sustainable Livelihoods; Ehara, H., Toyoda, Y., Johnson, D.V., Eds.; Springer: Singapore, 2018; pp. 221–229. ISBN 978-981-10-5269-9. [Google Scholar]

- Ehara, H.; Toyoda, Y.; Johnson, D.V. (Eds.) Sago Palm: Multiple Contributions to Food Security and Sustainable Livelihoods; Springer: Singapore, 2018; ISBN 978-981-10-5268-2. [Google Scholar]

- Karim, A.A.; Tie, A.P.-L.; Manan, D.M.A.; Zaidul, I.S.M. Starch from the Sago (Metroxylon Sagu) Palm Tree—Properties, Prospects, and Challenges as a New Industrial Source for Food and Other Uses. Compr. Rev. Food Sci. Food Saf. 2008, 7, 215–228. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Thangarasu, A.; Dutta, S.; Kashyap, A.V.; Moses, J.A.; Chinnaswamy, A. Iron Deficiency Anemia: A Comprehensive Review on Iron Absorption, Bioavailability and Emerging Food Fortification Approaches. Trends Food Sci. Technol. 2020, 99, 58–75. [Google Scholar] [CrossRef]

- Wardhani, D.H.; Cahyono, H.; Aryanti, N. Performance of Glucomannan-Alginate Combination as A Ph Sensitive Excipient of Vitamin C Encapsulation Using Gelation Method. Int J App. Pharm. 2019, 11, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Sumardiono, S.; Jos, B.; Pudjihastuti, I.; Yafiz, A.M.; Rachmasari, M.; Cahyono, H. Physicochemical Properties of Sago Ozone Oxidation: The Effect of Reaction Time, Acidity, and Concentration of Starch. Foods 2021, 10, 1309. [Google Scholar] [CrossRef]

- Coda, R.; Varis, J.; Verni, M.; Rizzello, C.G.; Katina, K. Improvement of the Protein Quality of Wheat Bread through Faba Bean Sourdough Addition. LWT Food Sci. Technol. 2017, 82, 296–302. [Google Scholar] [CrossRef] [Green Version]

- Mubarak, A.E. Nutritional Composition and Antinutritional Factors of Mung Bean Seeds (Phaseolus Aureus) as Affected by Some Home Traditional Processes. Food Chem. 2005, 89, 489–495. [Google Scholar] [CrossRef]

- Tjokrokusumo, D.; Octaviani, F.C.; Saragih, R. Fortification of Mung Bean (Vigna Radiata) and Ear Mushroom (Auricularia Auricula-Judae) in Dried Sago Noodles. J. Microb. Syst. Biotechnol. 2019, 1, 34–40. [Google Scholar] [CrossRef]

- Pudjihastuti, I.; Sumardiono, S.; Kusumayanti, H. Analog Rice Development as Alternative Food Made of Raw Composite Flour Enriched Protein Canavalia Ensiformis. E3s Web Conf. 2018, 73, 13017. [Google Scholar] [CrossRef]

- Adeloye, J.B.; Osho, H.; Idris, L.O. Defatted Coconut Flour Improved the Bioactive Components, Dietary Fibre, Antioxidant and Sensory Properties of Nixtamalized Maize Flour. J. Agric. Food Res. 2020, 2, 100042. [Google Scholar] [CrossRef]

- Grandison, A.; Brennan, J.G. Food Processing Handbook, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2011; Volume 1. [Google Scholar]

- Viswanathan, V.; Krishnan, D.; Kalra, S.; Chawla, R.; Tiwaskar, M.; Saboo, B.; Baruah, M.; Chowdhury, S.; Makkar, B.M.; Jaggi, S. Insights on Medical Nutrition Therapy for Type 2 Diabetes Mellitus: An Indian Perspective. Adv. Ther. 2019, 36, 520–547. [Google Scholar] [CrossRef] [Green Version]

- Pudjihastuti, I.; Sumardiono, S.; Supriyo, E.; Kusumayanti, H. Quality Analog Rice Composite Flour: Modified Starch, Colocasia Esculenta, Canna Edulis Ker High Protein. AIP Conf. Proc. 2018, 1977, 030017. [Google Scholar] [CrossRef]

- Singh, N.; Kaur, L.; Singh Sodhi, N.; Singh Sekhon, K. Physicochemical, Cooking and Textural Properties of Milled Rice from Different Indian Rice Cultivars. Food Chem. 2005, 89, 253–259. [Google Scholar] [CrossRef]

- He, M.; Qiu, C.; Liao, Z.; Sui, Z.; Corke, H. Impact of Cooking Conditions on the Properties of Rice: Combined Temperature and Cooking Time. Int. J. Biol. Macromol. 2018, 117, 87–94. [Google Scholar] [CrossRef]

- Horwitz, W.; Latimer, G.W., Jr. (Eds.) Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Rockville, MD, USA, 2005; ISBN 0-935584-77-3. [Google Scholar]

- Sumardiono, S.; Pudjihastuti, I.; Jos, B.; Taufani, M.; Yahya, F. Modification of Cassava Starch Using Combination Process Lactic Acid Hydrolysis and Micro Wave Heating to Increase Coated Peanut Expansion Quality. AIP Conf. Proc. 2017, 1840, 060005. [Google Scholar] [CrossRef]

- Du, C.; Jiang, F.; Jiang, W.; Ge, W.; Du, S. Physicochemical and Structural Properties of Sago Starch. Int. J. Biol. Macromol. 2020, 164, 1785–1793. [Google Scholar] [CrossRef]

- Kanetro, B.; Swasono, D.H. Paiman Improvement of Starch Gelatinization and Amino Acids Profile of Growol with Addition of Germinated Mungbean (Vigna Radiata). Syst. Rev. Pharm. 2019, 10, 48–52. [Google Scholar] [CrossRef]

- Van Hung, P.; Hoang Yen, N.T.; Lan Phi, N.T.; Ha Tien, N.P.; Thu Trung, N.T. Nutritional Composition, Enzyme Activities and Bioactive Compounds of Mung Bean (Vigna Radiata L.) Germinated under Dark and Light Conditions. LWT Food Sci. Technol. 2020, 133, 110100. [Google Scholar] [CrossRef]

- Yuwono, S.S.; Zulfiah, A.A. Formulation of Analogue Rice Based Mocaf and Maizena Flour with Addition CMC and Tofu Waste Flour. Jurnal Pangan dan Agroindustri 2014, 3, 1465–1472. [Google Scholar]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion Processing of Raw Food Materials and By-Products: A Review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.; Mahfuz, A.A. Low Temperature Dry Extrusion and High-Pressure Processing Prior to Enzyme-Assisted Aqueous Extraction of Full Fat Soybean Flakes. Food Chem. 2009, 114, 947–954. [Google Scholar] [CrossRef]

- Venkata, R.P.; Subramanyam, R. Evaluation of the Deleterious Health Effects of Consumption of Repeatedly Heated Vegetable Oil. Toxicol. Rep. 2016, 3, 636–643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wicaksono, A.; Rahmawan, A.; Matin, H.H.A.; Wardani, L.G.K.; Kusworo, T.D.; Sumardiono, S. The Effect of Pretreatment Using Sodium Hydroxide and Acetic Acid to Biogas Production from Rice Straw Waste. MATEC Web Conf. 2017, 101, 02011. [Google Scholar] [CrossRef] [Green Version]

- Sumardiono, S.; Riyanta, A.B.; Matin, H.H.A.; Kusworo, T.D.; Jos, B. Increasing Biogas Production from Sugar Cane Baggase by Anaerobic Co-Digestion with Animal Manure. MATEC Web Conf. 2017, 101, 02014. [Google Scholar] [CrossRef] [Green Version]

- Vasanthan, T.; Gaosong, J.; Yeung, J.; Li, J. Dietary Fiber Profile of Barley Flour as Affected by Extrusion Cooking. Food Chem. 2002, 77, 35–40. [Google Scholar] [CrossRef]

- Liu, H.; Hebb, R.L.; Putri, N.; Rizvi, S.S.H. Physical Properties of Supercritical Fluid Extrusion Products Composed of Milk Protein Concentrate with Carbohydrates. Int. J. Food Sci. Technol. 2018, 53, 847–856. [Google Scholar] [CrossRef]

- Omohimi, C.I.; Sobukola, O.P.; Sarafadeen, K.O.; Sanni, L.O. Effect of Process Parameters on The Proximate Composition, Functional and Sensory Properties. Int. J. Biol. Life Agric. Sci. 2013, 6. [Google Scholar] [CrossRef]

- Schutyser, M.A.I.; Pelgrom, P.J.M.; van der Goot, A.J.; Boom, R.M. Dry Fractionation for Sustainable Production of Functional Legume Protein Concentrates. Trends Food Sci. Technol. 2015, 45, 327–335. [Google Scholar] [CrossRef]

- Setiawati, N.P.; Santoso, J.; Purwaningsih, S. The Characteristics of Artificial Rice with Seaweed Eucheuma Cottonii Addition as A Dietary Fiber Source. Jurnal Ilmu dan Teknologi Kelautan Tropis 2014, 6. [Google Scholar] [CrossRef]

- Handayani, N.H. Study Characteristics of Analog Rice Made from Purple Sweet Potato (Ipomea Batatas) Flour and Starch. Jurnal Aplikasi Teknologi Pangan 2017, 6. [Google Scholar] [CrossRef]

- De Arcangelis, E.; Cuomo, F.; Trivisonno, M.C.; Marconi, E.; Messia, M.C. Gelatinization and Pasta Making Conditions for Buckwheat Gluten-Free Pasta. J. Cereal Sci. 2020, 95, 103073. [Google Scholar] [CrossRef]

- Noviasari, S.; Kusnandar, F.; Budijanto, S. Development of White Corn-Based Rice Analogues. Jurnal Teknologi dan Industri Pangan 2013, 24, 194–200. [Google Scholar] [CrossRef]

- Sharif, M.; Butt, M.; Sharif, H.; Nasir, M. Sensory Evaluation and Consumer Acceptability. In Handbook of Food Science and Technology; Taylor & Francis: Boca Raton, FL, USA, 2017; pp. 362–386. [Google Scholar]

- Heymann, H.; Lawless, H.T. Sensory Evaluation of Food: Principles and Practices; Springer Science & Business Media: New York, NY, USA, 2013; ISBN 978-1-4419-7452-5. [Google Scholar]

- Wahjuningsih, S.B.; Susanti, S. Chemical, Physical, and Sensory Characteristics of Analog Rice Developed from the Mocaf, Arrowroof, and Red Bean Flour. IOP Conf. Ser. Earth Env. Sci. 2018, 102, 012015. [Google Scholar] [CrossRef]

- Menis, M.E.C.; Milani, T.M.G.; Jordano, A.; Boscolo, M.; Conti-Silva, A.C. Extrusion of Flavored Corn Grits: Structural Characteristics, Volatile Compounds Retention and Sensory Acceptability. LWT Food Sci. Technol. 2013, 54, 434–439. [Google Scholar] [CrossRef] [Green Version]

- Macheix, J.; Sapis, J.; Fleuriet, A.; Lee, C.Y. Phenolic Compounds and Polyphenoloxidase in Relation to Browning in Grapes and Wines. Crit. Rev. Food Sci. Nutr. 1991, 30, 441–486. [Google Scholar] [CrossRef]

- Choe, E.; Huang, R.; Min, D.B. Chemical Reactions and Stability of Riboflavin in Foods. J. Food Sci. 2005, 70, R28–R36. [Google Scholar] [CrossRef]

- Delgado-Ospina, J.; Martuscelli, M.; Grande-Tovar, C.D.; Lucas-González, R.; Molina-Hernandez, J.B.; Viuda-Martos, M.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Chaves-López, C. Cacao Pod Husk Flour as an Ingredient for Reformulating Frankfurters: Effects on Quality Properties. Foods 2021, 10, 1243. [Google Scholar] [CrossRef] [PubMed]

- Budi, F.S.; Hariyadi, P.; Budijanto, S.; Syah, D. Extrusion Process Technology of Analog Rice. Jurnal Pangan 2013, 22, 263–274. [Google Scholar] [CrossRef]

- Hodgins, D. The Electronic Nose: Sensor Array-Based Instruments That Emulate the Human Nose. In Techniques for Analyzing; CRC Press: Boca Raton, FL, USA, 1997; ISBN 978-1-00-306757-3. [Google Scholar]

- Elzerman, J.E.; Hoek, A.C.; van Boekel, M.A.J.S.; Luning, P.A. Consumer Acceptance and Appropriateness of Meat Substitutes in a Meal Context. Food Qual. Prefer. 2011, 22, 233–240. [Google Scholar] [CrossRef] [Green Version]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical Properties, Modifications and Applications of Starches from Different Botanical Sources. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef] [Green Version]

- Sumardiono, S.; Jos, B.; Pudjihastuti, I.; Sari, R.J.; Kumala, W.D.N.; Cahyono, H. Effect of Chemical Modification, Drying Method, and Drying Temperature on Baking Expansion and the Physicochemical Properties of Cassava Starch. J. Food Process. Preserv. 2021, e16111. [Google Scholar] [CrossRef]

- Sumardiono, S.; Pudjihastuti, I.; Budiyono, B.; Hartanto, H.; Sophiana, I.C. Combination Process Method of Lactic Acid Hydrolysis and Hydrogen Peroxide Oxidation for Cassava Starch Modification. AIP Conf. Proc. 2017, 1840, 060006. [Google Scholar] [CrossRef]

- Wardhani, D.H.; Cahyono, H.; Dwinanda, M.F.H.; Nabila, P.R.; Aryanti, N.; Pangestuti, D.R. Performance of Deacetyled Glucomannan as Iron Encapsulation Excipient. MATEC Web Conf. 2018, 156, 01021. [Google Scholar] [CrossRef] [Green Version]

- Budi, F.S.; Hariyadi, P.; Budijanto, S.; Syah, D. Effect of Dough Moisture Content and Extrusion Temperature on Degree of Gelatinization and Crystallinity of Rice Analogues. J. Dev. Sus. Agr. 2015, 10, 91–100. [Google Scholar]

- Combrzyński, M.; Oniszczuk, T.; Kupryaniuk, K.; Wójtowicz, A.; Mitrus, M.; Milanowski, M.; Soja, J.; Budziak-Wieczorek, I.; Karcz, D.; Kamiński, D.; et al. Physical Properties, Spectroscopic, Microscopic, X-Ray, and Chemometric Analysis of Starch Films Enriched with Selected Functional Additives. Materials 2021, 14, 2673. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; An, D.; Li, L.; Liu, C.; Li, M.; Buckow, R.; Zheng, X.; Bian, K. Structural, Rheological and Gelatinization Properties of Wheat Starch Granules Separated from Different Noodle-Making Process. J. Cereal Sci. 2020, 91, 102897. [Google Scholar] [CrossRef]

| Analog Rice Sample Code | Sago Flour (%w/w) | Corn Starch (%w/w) | Mung Bean Flour (%w/w) | Skim Milk (%w/w) | CMC (%w/w) | Extrusion Temperature (°C) |

|---|---|---|---|---|---|---|

| AR-1 | 60 | 30 | 9.6 | - | 0.4 | 70 |

| AR-2 | 55 | 30 | 14.6 | - | 0.4 | 70 |

| AR-3 | 50 | 30 | 19.6 | - | 0.4 | 70 |

| AR-4 | 60 | 30 | 9.6 | 0.4 | - | 70 |

| AR-5 | 55 | 30 | 14.6 | 0.4 | - | 70 |

| AR-6 | 50 | 30 | 19.6 | 0.4 | - | 70 |

| AR-7 | 60 | 30 | 9.2 | 0.4 | 0.4 | 70 |

| AR-8 | 55 | 30 | 14.2 | 0.4 | 0.4 | 70 |

| AR-9 | 50 | 30 | 19.2 | 0.4 | 0.4 | 70 |

| AR-10 | 50 | 30 | 19.2 | 0.4 | 0.4 | 50 |

| AR-11 | 50 | 30 | 19.2 | 0.4 | 0.4 | 60 |

| AR-12 | 50 | 30 | 19.2 | 0.4 | 0.4 | 70 |

| AR-13 | 50 | 30 | 19.2 | 0.4 | 0.4 | 80 |

| AR-14 | 50 | 30 | 19.2 | 0.4 | 0.4 | 90 |

| Analog Rice Raw Material | Carbohydrates (%) | Protein (%) | Fat (%) | Crude Fiber (%) | Moisture Content (%) | Ash (%) |

|---|---|---|---|---|---|---|

| Sago flour | 83.92 ± 0.62 a | 0.92 ± 0.02 e | 0.994 ± 0.002 d | 0.87 ± 0.03 f | 6.80 ± 0.05 c | 7.370 ± 0.003 c |

| Bean flour | 58.33 ± 0.35 f | 22.44 ± 0.08 a | 2.693 ± 0.006 a | 3.68 ± 0.02 b | 7.55 ± 0.05 b | 8.994 ± 0.005 b |

| Cornstarch | 80.56 ± 0.73 d | 9.11 ± 0.04 b | 1.540 ± 0.003 b | 5.42 ± 0.04 a | 2.99 ± 0.05 e | 0.581 ± 0.001 e |

| Skim milk | 84.32 ± 0.58 b | 1.36 ± 0.01 d | 1.281 ± 0.001 c | 1.29 ± 0.02 e | 5.09 ± 0.05 d | 7.952 ± 0.004 d |

| CMC | 82.96 ± 0.24 c | 0.90 ± 0.01 e | 1.294 ± 0.002 c | 1.65 ± 0.02 d | 5.36 ± 0.05 d | 9.490 ± 0.006 a |

| IR64 (rice standard) | 78.10 ± 0.12 e | 7.18 ± 0.04 c | 0.360 ± 0.004 e | 3.29 ± 0.04 c | 13.88 ± 0.04 a | 0.560 ± 0.004 e |

| Analog Rice Sample Code | Carbohydrates (%) | Protein (%) | Fat (%) | Crude Fiber (%) | Moisture Content (%) | Ash (%) |

|---|---|---|---|---|---|---|

| AR-1 | 83.44 ± 0.20 b | 2.97 ± 0.03 c | 1.671 ± 0.003 d | 2.39 ± 0.04 fg | 10.55 ± 0.04 a | 1.374 ± 0.003 bc |

| AR-2 | 82.75 ± 0.30 c | 3.88 ± 0.07 b | 1.653 ± 0.002 d | 3.89 ± 0.05 c | 10.21 ± 0.07 b | 1.511 ± 0.002 b |

| AR-3 | 80.93 ± 0.90 e | 4.76 ± 0.07 a | 2.552 ± 0.006 a | 3.48 ± 0.07 d | 10.35 ± 0.03 ab | 1.481 ± 0.008 b |

| AR-4 | 84.15 ± 0.50 a | 2.73 ± 0.06 d | 1.561 ± 0.007 de | 2.11 ± 0.02 g | 10.17 ± 0.07 b | 1.310 ± 0.009 c |

| AR-5 | 82.50 ± 0.80 cd | 3.83 ± 0.02 b | 2.081 ± 0.003 c | 3.01 ± 0.03 e | 10.28 ± 0.06 ab | 1.330 ± 0.006 c |

| AR-6 | 81.66 ± 0.10 d | 4.8 ± 0.01 a | 1.981 ± 0.005 cd | 4.45 ± 0.01 b | 10.28 ± 0.08 ab | 1.460 ± 0.009 b |

| AR-7 | 84.31 ± 0.40 a | 2.66 ± 0.02 d | 1.354 ± 0.007 e | 2.62 ± 0.05 f | 10.33 ± 0.03 ab | 1.362 ± 0.005 bc |

| AR-8 | 82.63 ± 0.70 c | 4.03 ± 0.04 ab | 1.702 ± 0.006 d | 2.06 ± 0.06 g | 10.49 ± 0.04 a | 1.452 ± 0.007 b |

| AR-9 | 80.73 ± 0.50 e | 4.83 ± 0.02 a | 2.280 ± 0.003 b | 5.57 ± 0.07 a | 10.51 ± 0.02 a | 1.650 ± 0.007 a |

| Analog Rice Sample Code | Extrusion Temperature (°C) | Carbohydrates (%) | Protein (%) | Fat (%) | Crude Fiber (%) | Moisture Content (%) | Ash (%) |

|---|---|---|---|---|---|---|---|

| AR-10 | 50 | 80.80 ± 0.50 b | 4.15 ± 0.01 a | 2.514 ± 0.003 a | 4.38 ± 0.06 a | 13.89 ± 0.05 a | 1.980 ± 0.001 a |

| AR-11 | 60 | 81.48 ± 0.30 b | 4.06 ± 0.04 a | 2.262 ± 0.002 a | 4.39 ± 0.02 a | 13.09 ± 0.02 b | 1.810 ± 0.003 b |

| AR-12 | 70 | 82.57 ± 0.20 a | 3.71 ± 0.06 b | 2.572 ± 0.007 a | 3.90 ± 0.04 b | 11.07 ± 0.07 c | 1.951 ± 0.002 a |

| AR-13 | 80 | 82.67 ± 0.60 a | 3.66 ± 0.02 b | 1.722 ± 0.002 b | 3.96 ± 0.05 b | 10.78 ± 0.08 d | 1.873 ± 0.005 a |

| AR-14 | 90 | 83.02 ± 0.70 a | 3.76 ± 0.04 b | 1.931 ± 0.004 b | 4.28 ± 0.02 a | 10.65 ± 0.04 d | 1.741 ± 0.007 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sumardiono, S.; Budiyono, B.; Kusumayanti, H.; Silvia, N.; Luthfiani, V.F.; Cahyono, H. Production and Physicochemical Characterization of Analog Rice Obtained from Sago Flour, Mung Bean Flour, and Corn Flour Using Hot Extrusion Technology. Foods 2021, 10, 3023. https://doi.org/10.3390/foods10123023

Sumardiono S, Budiyono B, Kusumayanti H, Silvia N, Luthfiani VF, Cahyono H. Production and Physicochemical Characterization of Analog Rice Obtained from Sago Flour, Mung Bean Flour, and Corn Flour Using Hot Extrusion Technology. Foods. 2021; 10(12):3023. https://doi.org/10.3390/foods10123023

Chicago/Turabian StyleSumardiono, Siswo, Budiyono Budiyono, Heny Kusumayanti, Nada Silvia, Virginia Feren Luthfiani, and Heri Cahyono. 2021. "Production and Physicochemical Characterization of Analog Rice Obtained from Sago Flour, Mung Bean Flour, and Corn Flour Using Hot Extrusion Technology" Foods 10, no. 12: 3023. https://doi.org/10.3390/foods10123023

APA StyleSumardiono, S., Budiyono, B., Kusumayanti, H., Silvia, N., Luthfiani, V. F., & Cahyono, H. (2021). Production and Physicochemical Characterization of Analog Rice Obtained from Sago Flour, Mung Bean Flour, and Corn Flour Using Hot Extrusion Technology. Foods, 10(12), 3023. https://doi.org/10.3390/foods10123023