A Novel Approach to Develop Lager Yeast with Higher NADH Availability to Improve the Flavor Stability of Industrial Beer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Strains and Chemicals

2.2. ARTP Mutagenesis

2.3. Beer Fermentation

2.4. Analytical Methods

3. Results

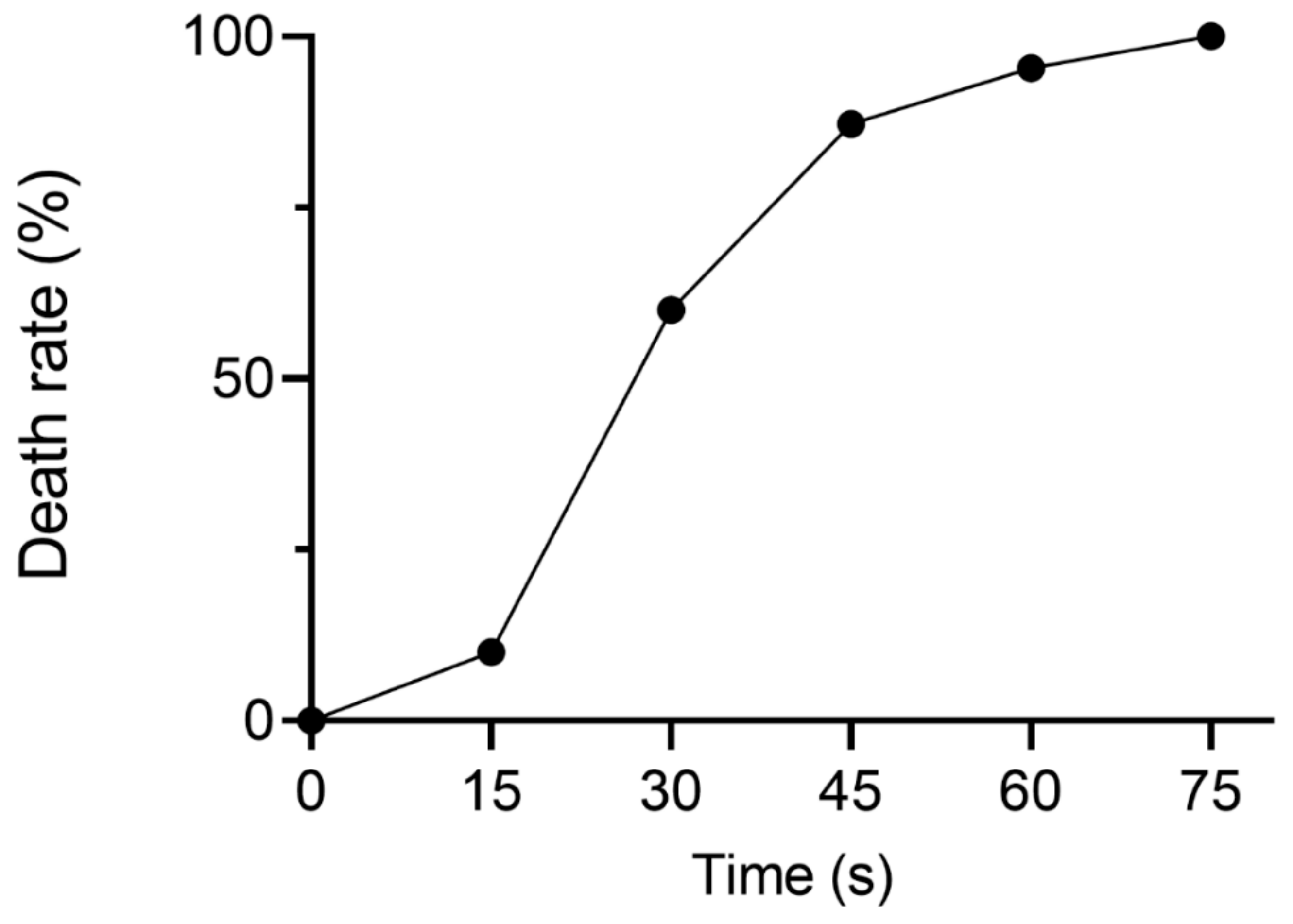

3.1. DNP Serves as a Selective Marker for the NADH Perturbation Variants

3.2. Screening the Optimal Strain with Industrial Potential

3.3. Pilot Scale Fermentation

3.4. Application of DNP Selection to Other Industrial Strain

4. Discussion

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Ethical Approval

References

- Kucharczyk, K.; Żyła, K.; Tuszyński, T. Simultaneous optimization of acetaldehyde and DMS concentrations for better sensory quality of beer fermented on an industrial scale. Foods 2020, 9, 1043. [Google Scholar] [CrossRef]

- Pires, E.J.; Teixeira, J.A.; Brányik, T.; Vicente, A.A. Yeast: The soul of beer’s aroma—A review of flavour-active esters and higher alcohols produced by the brewing yeast. Appl. Microbiol. Biotechnol. 2014, 98, 1937–1949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Z.; Bai, X.; He, X.; Zhang, B. Secretion expression of SOD1 and its overlapping function with GSH in brewing yeast strain for better flavor and anti-aging ability. J. Ind. Microbiol. Biotechnol. 2014, 41, 1415–1424. [Google Scholar] [CrossRef]

- Vanderhaegen, B.; Neven He Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Gil, M.I.; Tomás-Barberán, F.A.; Hess-Pierce, B.; Holcroft, D.M.; Kader, A.A. Antioxidant activity of pomegranate juice and its relationship with phenolic composition and processing. J. Agric. Food Chem. 2000, 48, 4581–4589. [Google Scholar] [CrossRef]

- Rakete, S.; Klaus, A.; Glomb, M.A. Investigations on the Maillard reaction of dextrins during aging of Pilsner type beer. J. Agric. Food Chem. 2014, 62, 9876–9884. [Google Scholar] [CrossRef]

- Baert, J.J.; De Clippeleer, J.; Hughes, P.S.; De Cooman, L.; Aerts, G. On the origin of free and bound staling aldehydes in beer. J. Agric. Food Chem. 2012, 60, 11449–11472. [Google Scholar] [CrossRef]

- Bustillo Trueba, P.; Jaskula-Goiris, B.; Ditrych, M.; Filipowska, W.; De Brabanter, J.; De Rouck, G.; De Clippeleer, J. Monitoring the evolution of free and cysteinylated aldehydes from malt to fresh and forced aged beer. Food Res. Int. 2021, 140, 110049. [Google Scholar] [CrossRef]

- Saison, D.; Schutter, D.; Uyttenhove, B.; Delvaux, F.; Delvaux, F.R. Contribution of staling compounds to the aged flavour of lager beer by studying their flavour thresholds. Food Chem. 2009, 114, 1206–1215. [Google Scholar] [CrossRef]

- Saison, D.; De Schutter, D.P.; Vanbeneden, N.; Daenen, L.; Delvaux, F.; Delvaux, F.R. Decrease of aged beer aroma by the reducing activity of brewing yeast. J. Agric. Food Chem. 2010, 58, 3107–3115. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Song, Y.; Guo, L.; Cheng, W.; Niu, C.; Wang, J.; Li, Q. Higher NADH availability of lager yeast increases the flavor stability of beer. J. Agric. Food Chem. 2020, 68, 584–590. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Niu, C.; Liu, C.; Li, Q. Unraveling the mechanisms for low-level acetaldehyde production during alcoholic fermentation in Saccharomyces pastorianus lager yeast. J. Agric. Food Chem. 2019, 67, 2020–2027. [Google Scholar] [CrossRef] [PubMed]

- Lv, Q.; Hu, M.; Tian, L.; Liu, F.; Wang, Q.; Xu, M.; Rao, Z. Enhancing l-glutamine production in Corynebacterium glutamicum by rational metabolic engineering combined with a two-stage pH control strategy. Bioresour. Technol. 2021, 341, 125799. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Guo, S.; Hua, Q.; Hu, F. Improved AP-3 production through combined ARTP mutagenesis, fermentation optimization, and subsequent genome shuffling. Biotechnol. Lett. 2021, 43, 1143–1154. [Google Scholar] [CrossRef] [PubMed]

- Grundlingh, J.; Dargan, P.I.; El-Zanfaly, M.; Wood, D.M. 2,4-dinitrophenol (DNP): A weight loss agent with significant acute toxicity and risk of death. J. Med. Toxicol. 2011, 7, 205–212. [Google Scholar] [CrossRef] [Green Version]

- Ludwig, N.; Yerneni, S.S.; Menshikova, E.V.; Gillespie, D.G.; Jackson, E.K.; Whiteside, T.L. Simultaneous inhibition of glycolysis and oxidative phosphorylation triggers a multi-fold increase in secretion of exosomes: Possible Role of 2′3′-cAMP. Sci. Rep. 2020, 10, 6948. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Yang, X.; Zhang, S.; Wang, X.; Guo, C.; Guo, X.; Xiao, D. Development of Saccharomyces cerevisiae producing higher levels of sulfur dioxide and glutathione to improve beer flavor stability. Appl. Biochem. Biotechnol. 2012, 166, 402–413. [Google Scholar] [CrossRef]

- Wang, J.; Shen, N.; Yin, H.; Liu, C.; Li, Y.; Li, Q. Development of industrial brewing yeast with low acetaldehyde production and improved flavor stability. Appl. Biochem. Biotechnol. 2013, 169, 1016–1025. [Google Scholar] [CrossRef]

- Liu, C.; Li, Q.; Niu, C.; Zheng, F.; Zhao, Y. Simultaneous determination of diethylacetal and acetaldehyde during beer fermentation and storage process. J. Sci. Food Agric. 2018, 98, 4733–4741. [Google Scholar] [CrossRef]

- Yang, F.; Luan, B.; Sun, Z.; Yang, C.; Yu, Z.; Li, X. Application of chitooligosaccharides as antioxidants in beer to improve the flavour stability by protecting against beer staling during storage. Biotechnol. Lett. 2017, 39, 305–310. [Google Scholar] [CrossRef]

- Lei, H.; Feng, L.; Peng, F.; Xu, H. Amino acid supplementations enhance the stress resistance and fermentation performance of lager yeast during high gravity fermentation. Appl. Biochem. Biotechnol. 2019, 187, 540–555. [Google Scholar] [CrossRef] [PubMed]

- Piddocke, M.P.; Kreisz, S.; Heldt-Hansen, H.P.; Nielsen, K.F.; Olsson, L. Physiological characterization of brewer’s yeast in high-gravity beer fermentations with glucose or maltose syrups as adjuncts. Appl. Microbiol. Biotechnol. 2009, 84, 453–464. [Google Scholar] [CrossRef]

- Shi, T.T.; Li, P.; Chen, S.J.; Chen, Y.F.; Guo, X.W.; Xiao, D.G. Reduced production of diacetyl by overexpressing BDH2 gene and ILV5 gene in yeast of the lager brewers with one ILV2 allelic gene deleted. J. Ind. Microbiol. Biotechnol. 2017, 44, 397–405. [Google Scholar] [CrossRef]

- Liu, C.; Li, Q.; Niu, C.; Tian, Y.; Zhao, Y.; Yin, X. The use of atmospheric and room temperature plasma mutagenesis to create a brewing yeast with reduced acetaldehyde production. J. Inst. Brew. 2018, 124, 236–243. [Google Scholar] [CrossRef] [Green Version]

- Shen, N.; Wang, J.; Liu, C.; Li, Y.; Li, Q. Domesticating brewing yeast for decreasing acetaldehyde production and improving beer flavor stability. Eur. Food Res. Technol. 2014, 238, 347–355. [Google Scholar] [CrossRef]

- Bamforth, C.W. A critical control point analysis for flavor stability of beer. Tech. Q. Mbaa Commun. 2004, 14, 97–103. [Google Scholar]

- Yasui, T.; Matsuura, C.; Hori, T.; Ogawa, Y.; Ohkochi, M. Importance of raw materials and the wort production process on trans-2-nonenal formation in beer. In EBC Symposium “Flavour and Flavour Stability”; Fachverlag Hans Carl: Nuürnberg, Germany, 2001; Volume 8, pp. 1–12. [Google Scholar]

- Wang, H.; Li, Q.; Kuang, X.; Xiao, D.; Han, X.; Hu, X.; Ma, M. Functions of aldehyde reductases from Saccharomyces cerevisiae in detoxification of aldehyde inhibitors and their biotechnological applications. Appl. Microbiol. Biotechnol. 2018, 102, 10439–10456. [Google Scholar] [CrossRef]

- Issekutz, B., Jr. Effect of propranolol in dinitrophenol poisoning. Arch. Int. Pharm. 1984, 272, 310–319. [Google Scholar]

- Rognstad, R.; Katz, J. The effect of 2,4-dinitrophenol on adipose-tissue metabolism. Biochem. J. 1969, 111, 431–444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Colman, E. Dinitrophenol and obesity: An early twentieth-century regulatory dilemma. Regul. Toxicol. Pharm. 2007, 48, 115–117. [Google Scholar] [CrossRef]

| YJ-002 | YDR63 | M14 | MDR17 | |

|---|---|---|---|---|

| Real attenuation (%) | 68.73 ± 0.12 | 69.29 ± 0.08 * | 65.49 ± 0.19 | 65.04 ± 0.05 * |

| Diacetyl (mg/L) | 0.08 ± 0.01 | 0.07 ± 0.01 | 0.05 ± 0.01 | 0.06 ± 0.01 |

| Ethanol (%) | 6.21 ± 0.16 | 6.31 ± 0.09 | 5.56 ± 0.15 | 5.52 ± 0.03 |

| Acetaldehyde (mg/L) | 10.56 ± 0.04 | 4.89 ± 0.03 * | 14.16 ± 0.03 | 5.14 ± 0.05 * |

| Ethyl acetate (mg/L) | 18.42 ± 0.11 | 17.33 ± 0.17 * | 13.24 ± 0.08 | 13.17 ± 0.05 |

| Isoamyl acetate (mg/L) | 1.27 ± 0.03 | 1.59 ± 0.05 * | 0.35 ± 0.04 | 0.33 ± 0.05 |

| n-Propanol (mg/L) | 13.82 ± 0.21 | 12.78 ± 0.23 * | 8.23 ± 0.25 | 8.57 ± 0.18 |

| Isoamyl alcohol (mg/L) | 54.55 ± 0.23 | 50.35 ± 0.20 * | 40.62 ± 0.26 | 41.91 ± 0.37 * |

| Isobutanol (mg/L) | 9.17 ± 0.18 | 6.98 ± 0.13 * | 6.43 ± 0.05 | 6.71 ± 0.08 * |

| RSV | 50.23 | 100.37 * | 61.55 | 133.24 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Niu, C.; Liu, C.; Wang, J.; Zheng, F.; Li, Q. A Novel Approach to Develop Lager Yeast with Higher NADH Availability to Improve the Flavor Stability of Industrial Beer. Foods 2021, 10, 3057. https://doi.org/10.3390/foods10123057

Xu X, Niu C, Liu C, Wang J, Zheng F, Li Q. A Novel Approach to Develop Lager Yeast with Higher NADH Availability to Improve the Flavor Stability of Industrial Beer. Foods. 2021; 10(12):3057. https://doi.org/10.3390/foods10123057

Chicago/Turabian StyleXu, Xin, Chengtuo Niu, Chunfeng Liu, Jinjing Wang, Feiyun Zheng, and Qi Li. 2021. "A Novel Approach to Develop Lager Yeast with Higher NADH Availability to Improve the Flavor Stability of Industrial Beer" Foods 10, no. 12: 3057. https://doi.org/10.3390/foods10123057

APA StyleXu, X., Niu, C., Liu, C., Wang, J., Zheng, F., & Li, Q. (2021). A Novel Approach to Develop Lager Yeast with Higher NADH Availability to Improve the Flavor Stability of Industrial Beer. Foods, 10(12), 3057. https://doi.org/10.3390/foods10123057