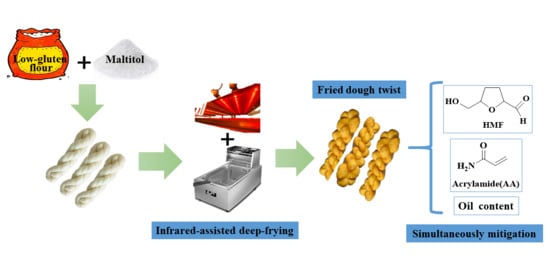

Simultaneously Mitigation of Acrylamide, 5-Hydroxymethylfurfural, and Oil Content in Fried Dough Twist via Different Ingredients Combination and Infrared-Assisted Deep-Frying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of FDT

2.3. Quantification of Acrylamide in FDT

2.4. Quantification of HMF in FDT

2.5. Analysis of Oil Content

2.6. Analysis of Moisture Content and Water Activity

2.7. Analysis of FDT Color

2.8. Analysis of FDT Texture

2.9. Statistical Analysis

3. Results and Discussion

3.1. Effect of Main Ingredients on Acrylamide and HMF in Fried Dough Twist (FDT)

3.2. Effect of Main Ingredients on Physicochemical of Fried Dough Twist (FDT)

3.3. Effect Infrared-Assisted Deep-Frying on Fried Dough Twist (FDT)

3.4. Comparison of the Effect of Deep-Frying and Infrared-Assisted Deep-Frying on Fried Dough Twist (FDT)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Li, J. Changes in glyoxal and methylglyoxal content in the fried dough twist during frying and storage. Eur. Food Res. Technol. 2014, 238, 323–331. [Google Scholar] [CrossRef]

- Zhuang, H.; Zhang, T.; Liu, J.; Yuan, Y. Detection of acrylamide content in traditional Chinese food by high-performance liquid chromatography tandem mass spectrometry method. CyTA J. Food 2012, 10, 36–41. [Google Scholar] [CrossRef] [Green Version]

- Müller, R.; Rappert, S. Pyrazines: Occurrence, formation and biodegradation. Appl. Microbiol. Biotechnol. 2010, 85, 1315–1320. [Google Scholar] [CrossRef]

- Starowicz, M.; Zieliński, H. How Maillard Reaction Influences Sensorial Properties (Color, Flavor and Texture) of Food Products? Food Rev. Int. 2019, 35, 707–725. [Google Scholar] [CrossRef]

- Zhou, P.; Guo, M.; Liu, D.; Liu, X.; Labuza, T.P. Maillard-Reaction-Induced Modification and Aggregation of Proteins and Hardening of Texture in Protein Bar Model Systems. J. Food Sci. 2013, 78, 437–444. [Google Scholar] [CrossRef]

- De Oliveira, F.C.; Coimbra, J.S.D.R.; de Oliveira, E.B.; Zuñiga, A.D.G.; Rojas, E.E.G. Food Protein-polysaccharide Conjugates Obtained via the Maillard Reaction: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1108–1125. [Google Scholar] [CrossRef] [PubMed]

- Mesias, M.; Holgado, F.; Márquez-Ruiz, G.; Morales, F.J. An investigation of process contaminants’ formation during the deep frying of breadcrumbs using a bread coat model. Food Funct. 2016, 7, 1645–1654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nguyen, H.T.; Van der Fels-Klerx, H.J.; Peters, R.J.B.; Van Boekel, M.A.J.S. Acrylamide and 5-hydroxymethylfurfural formation during baking of biscuits: Part I: Effects of sugar type. Food Chem. 2016, 192, 575–585. [Google Scholar] [CrossRef] [PubMed]

- Žilić, S.; Aktağ, I.G.; Dodig, D.; Filipović, M.; Gökmen, V. Acrylamide formation in biscuits made of different wholegrain flours depending on their free asparagine content and baking conditions. Food Res. Int. 2020, 132, 109109. [Google Scholar] [CrossRef]

- Robert, F.; Vuataz, G.; Pollien, P.; Saucy, F.; Alonso, M.-I.; Bauwens, I.; Blank, I. Acrylamide Formation from Asparagine under Low-Moisture Maillard Reaction Conditions. 1. Physical and Chemical Aspects in Crystalline Model Systems. J. Agric. Food Chem. 2004, 52, 6837–6842. [Google Scholar] [CrossRef]

- Koszucka, A.; Nowak, A.; Nowak, I.; Motyl, I. Acrylamide in human diet, its metabolism, toxicity, inactivation and the associated European Union legal regulations in food industry. Crit. Rev. Food Sci. 2020, 60, 1677–1692. [Google Scholar] [CrossRef] [PubMed]

- Pundir, C.S.; Yadav, N.; Chhillar, A.K. Occurrence, synthesis, toxicity and detection methods for acrylamide determination in processed foods with special reference to biosensors: A review. Trends Food Sci. Technol. 2019, 85, 211–225. [Google Scholar] [CrossRef]

- Mesías, M.; Morales, F.J. Effect of Different Flours on the Formation of Hydroxymethylfurfural, Furfural, and Dicarbonyl Compounds in Heated Glucose/Flour Systems. Foods 2017, 6, 14. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zou, Y.; Wu, T.; Huang, C.; Pei, K.; Zhang, G.; Lin, X.; Bai, W.; Ou, S. Chlorogenic acid increased 5-hydroxymethylfurfural formation when heating fructose alone or with aspartic acid at two pH levels. Food Chem. 2016, 190, 832–835. [Google Scholar] [CrossRef]

- Polovková, M.; Šimko, P. Determination and occurrence of 5-hydroxymethyl-2-furaldehyde in white and brown sugar by high performance liquid chromatography. Food Control. 2017, 78, 183–186. [Google Scholar] [CrossRef]

- Schouten, M.A.; Tappi, S.; Romani, S. Acrylamide in coffee: Formation and possible mitigation strategies—A review. Crit. Rev. Food Sci. 2020, 3807–3821. [Google Scholar] [CrossRef]

- Wang, S.; Yu, J.; Xin, Q.; Wang, S.; Copeland, L. Effects of starch damage and yeast fermentation on acrylamide formation in bread. Food Control. 2017, 73, 230–236. [Google Scholar] [CrossRef]

- Higley, J.; Kim, J.-Y.; Huber, K.C.; Smith, G. Added versus Accumulated Sugars on Color Development and Acrylamide Formation in French-Fried Potato Strips. J. Agric. Food Chem. 2012, 60, 8763–8771. [Google Scholar] [CrossRef]

- Xu, F.; Oruna-Concha, M.-J.; Elmore, J.S. The use of asparaginase to reduce acrylamide levels in cooked food. Food Chem. 2016, 210, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.T.; van der Fels-Klerx, H.J.; van Boekel, M.A.J.S. Acrylamide and 5-hydroxymethylfurfural formation during biscuit baking. Part II: Effect of the ratio of reducing sugars and asparagine. Food Chem. 2017, 230, 14–23. [Google Scholar] [CrossRef] [PubMed]

- Mogol, B.A.; Gokmen, V. Effect of chitosan on the formation of acrylamide and hydroxymethylfurfural in model, biscuit and crust systems. Food Funct. 2016, 7, 3431–3436. [Google Scholar] [CrossRef] [PubMed]

- Lumanlan, J.C.; Fernando, W.M.A.D.B.; Karnpanit, W.; Jayasena, V. Effects of food gums and pre-drying on fat content of fabricated fried chips. Int. J. Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Durán, M.; Pedreschi, F.; Moyano, P.; Troncoso, E. Oil partition in pre-treated potato slices during frying and cooling. J. Food Eng. 2007, 81, 257–265. [Google Scholar] [CrossRef]

- Debnath, S.; Bhat, K.K.; Rastogi, N.K. Effect of pre-drying on kinetics of moisture loss and oil uptake during deep fat frying of chickpea flour-based snack food. LWT Food Sci. Technol. 2003, 36, 91–98. [Google Scholar] [CrossRef]

- Han, Z.; Gao, J.; Wang, X.; Wang, W.; Dong, J.; Zhang, Y.; Wang, S. Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk. Molecules 2019, 24, 272. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.; Gao, J.; Li, J.; Zhang, Y.; Yang, Y.; Wang, S. Mitigation of 3-deoxyglucosone and 5-hydroxymethylfurfural in brown fermented milk via an alternative browning process based on the hydrolysis of endogenous lactose. Food Funct. 2019, 10, 2022–2029. [Google Scholar] [CrossRef]

- Roldan, M.; Loebner, J.; Degen, J.; Henle, T.; Antequera, T.; Ruiz-Carrascal, J. Advanced glycation end products, physico-chemical and sensory characteristics of cooked lamb loins affected by cooking method and addition of flavour precursors. Food Chem. 2015, 168, 487–495. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.J.; Perez-Palacios, T.; Ruiz-Carrascal, J. Physico-chemical and sensory characteristics of freeze-dried and air-dehydrated yogurt foam. LWT Food Sci. Tech. 2017, 80, 328–334. [Google Scholar] [CrossRef]

- Claus, A.; Schreiter, P.; Weber, A.; Graeff, S.; Herrmann, W.; Claupein, W.; Schieber, A.; Carle, R. Influence of Agronomic Factors and Extraction Rate on the Acrylamide Contents in Yeast-Leavened Breads. J. Agric. Food Chem. 2006, 54, 8968–8976. [Google Scholar] [CrossRef] [PubMed]

- Psimouli, V.; Oreopoulou, V. The effect of alternative sweeteners on batter rheology and cake properties. J. Sci. Food Agric. 2012, 92, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of Water Activity (aw) on Microbial Stability as a Hurdle in Food Preservation. In Water Activity in Foods: Fundamentals and Applications, 2nd ed.; Barbosa-Cánovas, G.V., Fontana, A.J., Jr., Eds.; Wiley Blackwell: Chicago, IL, USA, 2020; pp. 323–355. [Google Scholar]

- Zoulias, E.I.; Oreopoulou, V.; Kounalaki, E. Effect of fat and sugar replacement on cookie properties. J. Sci. Food Agric. 2002, 82, 1637–1644. [Google Scholar] [CrossRef]

- Purlis, E. Browning development in bakery products-A review. J. Food Eng. 2010, 99, 239–249. [Google Scholar] [CrossRef]

- Raymundo, A.; Fradinho, P.; Nunes, M.C. Effect of Psyllium fibre content on the textural and rheological characteristics of biscuit and biscuit dough. Bioact. Carbohyd. Diet. Fibre 2014, 3, 96–105. [Google Scholar] [CrossRef]

- Ajila, C.M.; Leelavathi, K.; Prasada Rao, U.J.S. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar] [CrossRef]

- Baxter, G.; Blanchard, C.; Zhao, J. Effects of glutelin and globulin on the physicochemical properties of rice starch and flour. J. Cereal Sci. 2014, 60, 414–420. [Google Scholar] [CrossRef]

- Gong, S.; Xu, B.; Gu, X.; Li, W.; Yu, Y.; Zhang, W.; Wang, Z. Study on the effects of sugar alcohols and Angelica keiskei flour on cookie quality, antioxidant, and nutrition. Cereal Chem. 2020, 97, 714–722. [Google Scholar] [CrossRef]

| Wheat Flours | Polyol Sweeteners | Frying Oil | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Low-Gluten Flour | Medium-Gluten Flour | Strong-Gluten Flour | Sucrose | Maltitol | Lactitol | Sorbitol | Palm Oil | Soybean Oil | Rapeseed Oil | |

| Moisture content (%) | 3.05 ± 0.26a | 2.88 ± 0.17ab | 2.56 ± 0.20b | 3.05 ± 0.26a | 3.18 ± 0.23a | 3.25 ± 0.24a | 3.03 ± 0.25a | 3.05 ± 0.26a | 2.92 ± 0.27a | 2.88 ± 0.19a |

| Water activity (aw) | 0.61 ± 0.01a | 0.64 ± 0.03a | 0.61 ± 0.03a | 0.61 ± 0.01a | 0.64 ± 0.02a | 0.59 ± 0.03a | 0.63 ± 0.01a | 0.61 ± 0.01a | 0.62 ± 0.02a | 0.60 ± 0.02a |

| a * | 16.37 ± 0.14a | 15.81 ± 0.64a | 15.69 ± 0.51a | 16.37 ± 0.14a | 15.31 ± 1.18a | 15.43 ± 1.04a | 16.69 ± 0.42a | 16.37 ± 0.14a | 16.91 ± 1.22a | 14.87 ± 0.72a |

| b * | 29.05 ± 1.05c | 31.84 ± 0.42b | 32.74 ± 0.65a | 29.05 ± 2.45a | 20.41 ± 2.26b | 22.26 ± 1.79b | 20.97 ± 1.42b | 29.05 ± 2.45a | 30.30 ± 1.58a | 32.59 ± 0.85a |

| L * | 35.69 ± 3.16a | 32.71 ± 0.81a | 32.41 ± 0.54a | 35.69 ± 3.16a | 26.78 ± 2.14b | 29.50 ± 3.72b | 27.49 ± 0.52b | 35.69 ± 3.16a | 34.15 ± 3.15a | 37.59 ± 1.31a |

| ΔE * | - | 4.12 ± 0.64b | 4.98 ± 1.07b | - | 12.45 ± 1.23a | 9.27 ± 2.06a | 11.52 ± 1.43a | - | 2.06 ± 1.16b | 4.29 ± 1.28b |

| BI | 109.00 ± 1.64c | 122.08 ± 1.19b | 124.82 ± 0.97a | 109.00 ± 1.64a | 106.72 ± 1.48b | 105.17 ± 1.05b | 107.43 ± 1.69ab | 109.00 ± 1.64a | 116.69 ± 1.70a | 113.75 ± 1.01a |

| Oil content (%) | 21.1 ± 1.4a | 19.3 ± 1.8a | 20.6 ± 1.5a | 21.1 ± 1.4a | 20.6 ± 0.8a | 19.6 ± 1.5a | 21.9 ± 1.4a | 21.1 ± 1.4a | 20.1 ± 1.1a | 21.5 ± 1.5a |

| Infrared-Assisted Temperature | Infrared-Assisted Time (min) | Moisture Content (%) | Water Activity | a * | b * | L * | ΔE * | BI | Hardness(g) | Fracturability (N) |

|---|---|---|---|---|---|---|---|---|---|---|

| 80 °C | 1 | 3.11 ± 0.25a | 0.64 ± 0.03a | 15.64 ± 1.13a | 20.41 ± 0.97a | 41.47 ± 0.29a | - | 84.45 ± 2.28a | 2914.25 ± 60.74a | 12.56 ± 0.72a |

| 2 | 3.02 ± 0.32ab | 0.58 ± 0.02a | 14.80 ± 1.08a | 24.66 ± 1.75b | 38.20 ± 0.55b | 5.43 ± 1.23b | 94.23 ± 1.37b | 3325.73 ± 38.19b | 12.45 ± 0.79a | |

| 3 | 2.85 ± 0.28ab | 0.59 ± 0.01a | 14.65 ± 0.56a | 27.92 ± 2.32c | 35.76 ± 0.62c | 9.48 ± 1.43c | 104.81 ± 2.35c | 3484.33 ± 45.28b | 13.15 ± 0.35ab | |

| 4 | 2.62 ± 0.24b | 058 ± 0.03a | 13.65 ± 2.60a | 29.72 ± 1.28d | 33.21 ± 0.78c | 12.60 ± 0.95d | 115.89 ± 1.46d | 3633.84 ± 61.32b | 14.03 ± 0.27b | |

| 100 °C | 1 | 2.93 ± 0.23a | 0.60 ± 0.03a | 15.75 ± 0.69a | 21.02 ± 0.43a | 40.05 ± 1.22a | 1.55 ± 1.02a | 86.66 ± 2.42a | 3179.11 ± 51.72a | 13.13 ± 1.34a |

| 2 | 2.62 ± 0.41ab | 0.61 ± 0.02a | 14.99 ± 0.37b | 25.73 ± 0.15b | 36.78 ± 0.49b | 6.91 ± 1.49b | 98.56 ± 2.37b | 3470.09 ± 31.16b | 12.28 ± 0.70a | |

| 3 | 2.76 ± 0.35ab | 0.56 ± 0.04a | 14.32 ± 0.42c | 28.17 ± 0.65c | 35.46 ± 1.32b | 9.90 ± 1.27c | 106.19 ± 3.28c | 3691.82 ± 62.13c | 13.23 ± 0.14a | |

| 4 | 2.39 ± 0.29b | 0.58 ± 0.03a | 14.08 ± 0.34c | 31.83 ± 0.96d | 34.93 ± 0.46b | 13.27 ± 1.19d | 117.47 ± 2.34d | 3891.71 ± 74.31d | 14.89 ± 0.23b | |

| 120 ° | 1 | 2.83 ± 0.27a | 0.58 ± 0.04a | 14.13 ± 0.51a | 22.82 ± 1.10a | 38.00 ± 0.77a | 1.97 ± 0.86a | 90.87 ± 1.49a | 3195.79 ± 57.18a | 12.48 ± 0.89a |

| 2 | 2.51 ± 0.19ab | 0.55 ± 0.03a | 13.91 ± 0.75a | 28.72 ± 0.77b | 39.26 ± 1.13a | 3.67 ± 1.30b | 99.9 ± 2.23b | 3533.89 ± 43.91b | 13.61 ± 0.79ab | |

| 3 | 2.45 ± 0.31ab | 0.54 ± 0.05a | 13.91 ± 0.73a | 33.49 ± 1.78c | 38.72 ± 1.29a | 6.68 ± 1.54b | 112.28 ± 3.35c | 3624.33 ± 24.56c | 13.82 ± 0.38ab | |

| 4 | 2.21 ± 0.33b | 0.56 ± 0.03a | 15.89 ± 1.20b | 35.46 ± 0.93c | 37.64 ± 2.09a | 14.64 ± 1.32d | 121.22 ± 4.64d | 3972.35 ± 69.88d | 14.20 ± 0.53b |

| Infrared-Assisted Condition | Deep-Frying Time (min) | a * | b * | L * | ΔE * | BI | Hardness (g) | Fracturability (N) |

|---|---|---|---|---|---|---|---|---|

| 100 °C for 3 min | 3 | 14.19 ± 0.60a | 23.73 ± 0.64a | 40.78 ± 0.68a | - | 89.17 ± 3.12a | 2914.25 ± 60.74a | 12.56 ± 0.22a |

| 4 | 14.63 ± 1.32a | 25.85 ± 0.58b | 34.78 ± 0.72b | 6.38 ± 1.35a | 102.23 ± 1.32b | 3179.11 ± 51.72b | 13.13 ± 0.24ab | |

| 5 | 14.32 ± 0.42a | 28.17 ± 0.65c | 35.46 ± 1.32b | 6.93 ± 1.17a | 106.19 ± 3.28b | 3691.82 ± 62.13c | 13.23 ± 0.14b | |

| 120 °C for 2 min | 3 | 13.08 ± 0.83a | 23.89 ± 0.42a | 42.48 ± 1.65a | 2.04 ± 1.52b | 87.09 ± 2.34a | 3325.73 ± 38.19a | 12.45 ± 0.59a |

| 4 | 14.03 ± 1.57a | 26.8 ± 0.51b | 38.12 ± 0.91b | 4.07 ± 1.37a | 98.04 ± 2.19b | 3470.09 ± 31.16b | 12.28 ± 0.70ab | |

| 5 | 13.91 ± 0.75a | 28.72 ± 0.77c | 39.26 ± 1.13b | 5.22 ± 1.28a | 99.9 ± 2.23b | 3533.89 ± 43.91c | 13.61 ± 0.79b |

| Deep-Frying (Sucrose) | Deep-Frying (Maltitol) | Infrared-Assisted Deep-Frying (Maltitol) | |

|---|---|---|---|

| Moisture content (%) | 3.05 ± 0.26a | 3.18 ± 0.23a | 2.73 ± 0.29b |

| Water activity | 0.61 ± 0.01a | 0.64 ± 0.02a | 0.59 ± 0.05a |

| a * | 16.37 ± 0.14a | 15.31 ± 1.18a | 14.63 ± 1.32a |

| b * | 29.05 ± 1.05a | 20.41 ± 2.26a | 25.85 ± 0.58c |

| L * | 35.69 ± 3.16a | 26.78 ± 2.14b | 34.78 ± 0.72a |

| ΔE * | - | 17.68 ± 1.78a | 30.18 ± 2.28b |

| BI | 109.00 ± 1.64a | 106.72 ± 1.48a | 102.23 ± 1.32b |

| Hardness (g) | 2852.63 ± 22.51a | 2922.5 ± 27.19b | 3179.11 ± 51.72c |

| Fracturability (N) | 12.89 ± 0.28a | 12.38 ± 1.23ab | 13.13 ± 0.24b |

| Oil content (%) | 21.1 ± 1.4a | 20.6 ± 0.8a | 15.3 ± 0.5b |

| Acrylamide (μg/kg) | 206.1 ± 87.49a | 85.68 ± 13.38b | 78.53 ± 13.52c |

| HMF (μg/kg) | 1054.19 ± 29.14a | 474.08 ± 26.16b | 380.32 ± 23.36c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Z.; Gao, J.; Zhang, S.; Zhang, Y.; Wang, S. Simultaneously Mitigation of Acrylamide, 5-Hydroxymethylfurfural, and Oil Content in Fried Dough Twist via Different Ingredients Combination and Infrared-Assisted Deep-Frying. Foods 2021, 10, 604. https://doi.org/10.3390/foods10030604

Han Z, Gao J, Zhang S, Zhang Y, Wang S. Simultaneously Mitigation of Acrylamide, 5-Hydroxymethylfurfural, and Oil Content in Fried Dough Twist via Different Ingredients Combination and Infrared-Assisted Deep-Frying. Foods. 2021; 10(3):604. https://doi.org/10.3390/foods10030604

Chicago/Turabian StyleHan, Zhonghui, Jianxin Gao, Shunyang Zhang, Yan Zhang, and Shuo Wang. 2021. "Simultaneously Mitigation of Acrylamide, 5-Hydroxymethylfurfural, and Oil Content in Fried Dough Twist via Different Ingredients Combination and Infrared-Assisted Deep-Frying" Foods 10, no. 3: 604. https://doi.org/10.3390/foods10030604

APA StyleHan, Z., Gao, J., Zhang, S., Zhang, Y., & Wang, S. (2021). Simultaneously Mitigation of Acrylamide, 5-Hydroxymethylfurfural, and Oil Content in Fried Dough Twist via Different Ingredients Combination and Infrared-Assisted Deep-Frying. Foods, 10(3), 604. https://doi.org/10.3390/foods10030604