Potential Use of Vacuum Impregnation and High-Pressure Homogenization to Obtain Functional Products from Lulo Fruit (Solanum quitoense Lam.)

Abstract

1. Introduction

2. Materials and Methods

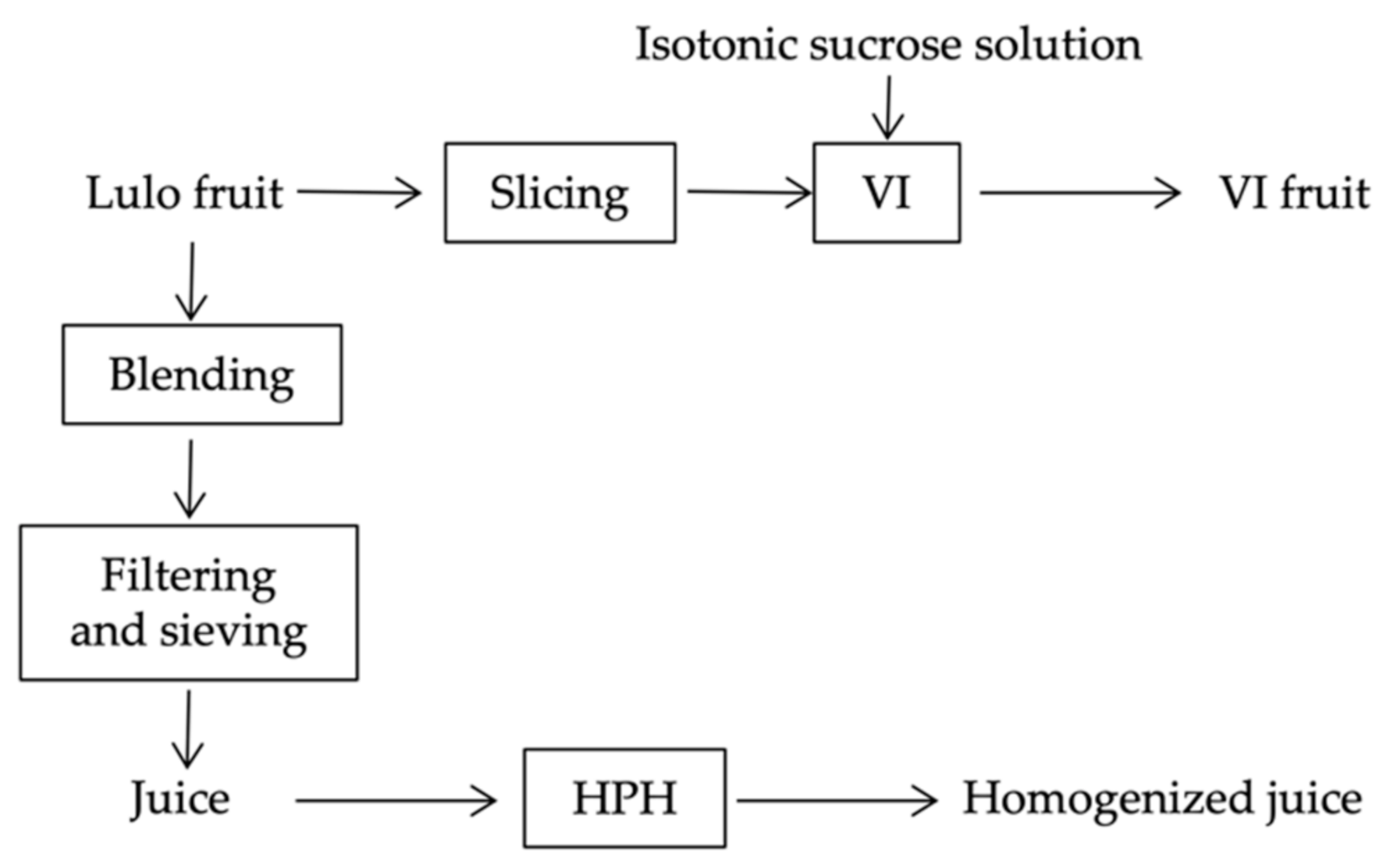

2.1. Food Materials and Sample Preparation

2.2. HPH Treatment

2.3. VI Experiments

2.4. Physicochemical Characterization

2.5. Antioxidant Properties

2.6. Statistical Analysis

3. Results and Discussion

3.1. Vacuum Impregnation Properties of Lulo Fruit

3.2. Physicochemical Characterization

3.3. Antioxidant Properties

3.4. Profile of Phenolic Compounds by High-Performance Liquid Chromatography Coupled to Mass Spectrometry (LC-MS/MS)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Contreras-Calderón, J.; Calderón-Jaimes, L.; Guerra-Hernández, E.; García-Villanova, B. Antioxidant capacity, phenolic content and vitamin C in pulp, peel and seed from 24 exotic fruits from Colombia. Food Res. Int. 2011, 44, 2047–2053. [Google Scholar] [CrossRef]

- Ministerio de Salud y Protección Social Análisis de Situación de Salud. Colombia. Available online: https://www.minsalud.gov.co/salud/publica/epidemiologia/Paginas/analisis-de-situacion-de-salud-.aspx (accessed on 25 August 2019).

- WHO Health Topics: Hypertension. Available online: https://www.who.int/news-room/fact-sheets/detail/hypertension (accessed on 2 January 2020).

- Ramírez, F.; Kallarackal, J.; Davenport, T.L. Lulo (Solanum quitoense Lam.) reproductive physiology: A review. Sci. Hortic. 2018, 238, 163–176. [Google Scholar] [CrossRef]

- Forero, D.P.; Orrego, C.E.; Peterson, D.G.; Osorio, C. Chemical and sensory comparison of fresh and dried lulo (Solanum quitoense Lam.) fruit aroma. Food Chem. 2015, 169, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Gancel, A.L.; Alter, P.; Dhuique-Mayer, C.; Ruales, J.; Vaillant, F. Identifying carotenoids and phenolic compounds in naranjilla (Solanum quitoense Lam. var. Puyo hybrid), an Andean fruit. J. Agric. Food Chem. 2008, 56, 11890–11899. [Google Scholar] [CrossRef] [PubMed]

- Forero, D.P.; Masatani, C.; Fujimoto, Y.; Coy-Barrera, E.; Peterson, D.G.; Osorio, C. Spermidine derivatives in lulo (Solanum quitoense Lam.) fruit: Sensory (taste) versus biofunctional (ACE-inhibition) properties. J. Agric. Food Chem. 2016, 64, 5375–5383. [Google Scholar] [CrossRef]

- Mesa, J.; Hinestroza-Córdoba, L.I.; Barrera, C.; Seguí, L.; Betoret, E.; Betoret, N. High homogenization pressures to improve food quality, functionality and sustainability. Molecules 2020, 25, 3305. [Google Scholar] [CrossRef]

- Betoret, E.; Sentandreu, E.; Betoret, N.; Fito, P. Homogenization pressures applied to citrus juice manufacturing. Functional properties and application. J. Food Eng. 2012, 111, 28–33. [Google Scholar] [CrossRef]

- Betoret, E.; Betoret, N.; Vidal, D.; Fito, P. Functional foods development: Trends and technologies. Trends Food Sci. Technol. 2011, 22, 498–508. [Google Scholar] [CrossRef]

- Betoret, E.; Betoret, N.; Rocculi, P.; Dalla Rosa, M. Strategies to improve food functionality: Structure-property relationships on high pressures homogenization, vacuum impregnation and drying technologies. Trends Food Sci. Technol. 2015, 46, 1–12. [Google Scholar] [CrossRef]

- Betoret, E.; Sentandreu, E.; Betoret, N.; Codoñer-Franch, P.; Valls-Bellés, V.; Fito, P. Technological development and functional properties of an apple snack rich in flavonoid from mandarin juice. Innov. Food Sci. Emerg. Technol. 2012, 16, 298–304. [Google Scholar] [CrossRef]

- Fito, P.; Chiralt, A.; Barat, J.; Martinez-Monzo, J. Vacuum Impregnation in Fruit Processing. In Food Preservation Technology; Lozano, J., Añon, C., Parada.Aries, E., Barbosa-Cánovas, P., Eds.; Gustavo Trends in Food Engineering, Technomic Publishing Company: Lancaster, PA, USA, 2000; pp. 149–164. ISBN 1-56676-991-4. [Google Scholar]

- Fito, P.; Andrés, A.; Chiralt, A.; Pardo, P. Coupling of Hydrodynamic Mechanism and Deformation-Relaxation Phenomena during Vacuum Treatments in Solid Porous Food-Liquid Systems. J. Food Eng. 1996, 27, 229–240. [Google Scholar] [CrossRef]

- AOAC. Official Method 973.18 Official Methods of Analysis of the Association of Official Analytical Chemists, 18th ed.; Association of Official Analytical Chemist: Arlington, VA, USA, 2000. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Wolfe, K.L.; Liu, R.H. Apple peels as a value-added food ingredient. J. Agric. Food Chem. 2003, 51, 1676–1683. [Google Scholar] [CrossRef] [PubMed]

- Luximon-Ramma, A.; Bahorun, T.; Soobrattee, M.A.; Aruoma, O.I. Antioxidant activities of phenolic, proanthocyanidin, and flavonoid components in extracts of Cassia fistula. J. Agric. Food Chem. 2002, 50, 5042–5047. [Google Scholar] [CrossRef]

- Kuskoski, E.M.; Asuero, A.G.; Troncoso, A.M.; Mancini-Filho, J.; Fett, R. Aplicación de diversos métodos químicos para determinar actividad antioxidante en pulpa de frutos. Ciência Tecnol. Aliment. 2005, 25, 726–732. [Google Scholar] [CrossRef]

- Stratil, P.; Klejdus, B.; Kubáň, V. Determination of total content of phenolic compounds and their antioxidant activity in vegetables—Evaluation of spectrophotometric methods. J. Agric. Food Chem. 2006, 54, 607–616. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Rodrigues, E.; Mariutti, L.R.B.; Mercadante, A.Z. Carotenoids and phenolic compounds from Solanum sessiliflorum, an unexploited amazonian fruit, and their scavenging capacities against reactive oxygen and nitrogen species. J. Agric. Food Chem. 2013, 61, 3022–3029. [Google Scholar] [CrossRef]

- Svobodova, B.; Barros, L.; Sopik, T.; Calhelha, R.C.; Heleno, S.; Alves, M.J.; Walcott, S.; Kuban, V.; Ferreira, I.C.F.R. Non-edible parts of Solanum stramoniifolium Jacq.-a new potent source of bioactive extracts rich in phenolic compounds for functional foods. Food Funct. 2017, 8, 2013–2021. [Google Scholar] [CrossRef]

- Cortéz Rodriguez, M.; Herrera Herrera, E.A.; Gil González, J.H. Impregnación de Uchua (Physalis peruviana L.) de forma Semiesférica con una Emunsión Fortificante. Biotecnol. Sect. Agropecu. Agroind. 2016, 14, 27. [Google Scholar] [CrossRef]

- Fito, P.; Chiralt, A.; Barat, J.M.; Andrés, A.; Martínez-Monzó, J.; Martínez-Navarrete, N. Vacuum impregnation for development of new dehydrated products. J. Food Eng. 2001, 49, 297–302. [Google Scholar] [CrossRef]

- Wellala, C.K.D.; Bi, J.; Liu, X.; Liu, J.; Lyu, J.; Zhou, M.; Marszałek, K.; Trych, U. Effect of high pressure homogenization combined with juice ratio on water-soluble pectin characteristics, functional properties and bioactive compounds in mixed juices. Innov. Food Sci. Emerg. Technol. 2020, 60, 102279. [Google Scholar] [CrossRef]

- Cerdán-Calero, M.; Izquierdo, L.; Sentandreu, E. Valencia Late orange juice preserved by pulp reduction and high pressure homogenization: Sensory quality and gas chromatography-mass spectrometry analysis of volatiles. LWT—Food Sci. Technol. 2013, 51, 476–483. [Google Scholar] [CrossRef]

- Betoret, E.; Betoret, N.; Carbonell, J.V.; Fito, P. Effects of pressure homogenization on particle size and the functional properties of citrus juices. J. Food Eng. 2009, 92, 18–23. [Google Scholar] [CrossRef]

- Castagnini, J.M. Estudio del Proceso de Obtención de Zumo de Arándanos y su Utilización Como Ingrediente Para la Obtención de un Alimento Funcional por Impregnación a Vacío. Ph.D. Thesis, Universitat Politécnica de Valéncia, Valencia, Spain, 2014. [Google Scholar]

- Leite, T.S.; Augusto, P.E.D.; Cristianini, M. The use of high pressure homogenization (HPH) to reduce consistency of concentrated orange juice (COJ). Innov. Food Sci. Emerg. Technol. 2014, 26, 124–133. [Google Scholar] [CrossRef]

- Silva, V.M.; Sato, A.C.K.; Barbosa, G.; Dacanal, G.; Ciro-Velásquez, H.J.; Cunha, R.L. The effect of homogenisation on the stability of pineapple pulp. Int. J. Food Sci. Technol. 2010, 45, 2127–2133. [Google Scholar] [CrossRef]

- Lopez-Sanchez, P.; Svelander, C.; Bialek, L.; Schumm, S.; Langton, M. Rheology and Microstructure of Carrot and Tomato Emulsions as a Result of High-Pressure Homogenization Conditions. J. Food Sci. 2011, 76. [Google Scholar] [CrossRef]

- Chiralt, A.; Martinez-Navarrete, N.; González, C.; Talens, P.; Moraga, G. Propiedades Reológicas de Alimentos. Reología de Alimentos Fluidos. En: Propiedades Físicas de los Alimentos, 1st ed.; Universitat Politécnica de Valéncia-España: Valencia, Spain, 2012; Chapter 4. [Google Scholar]

- Del Caro, A.; Piga, A.; Vacca, V.; Agabbio, M. Changes of flavonoids, vitamin C and antioxidant capacity in minimally processed citrus segments and juices during storage. Food Chem. 2004, 84, 99–105. [Google Scholar] [CrossRef]

- Hinestroza-Córdoba, L.I.; Serna, S.D.; Seguí, L.; Barrera, C.; Betoret, N. Characterization of powdered lulo (Solanum quitoense) bagasse as a functional food ingredient. Foods 2020, 9, 723. [Google Scholar] [CrossRef]

- Betoret, E.; Calabuig-Jiménez, L.; Patrignani, F.; Lanciotti, R.; Dalla Rosa, M. Effect of high pressure processing and trehalose addition on functional properties of mandarin juice enriched with probiotic microorganisms. LWT—Food Sci. Technol. 2017, 85, 418–422. [Google Scholar] [CrossRef]

- Igual, M.; Ramires, S.; Mosquera, L.H.; Martínez-Navarrete, N. Optimization of spray drying conditions for lulo (Solanum quitoense L.) pulp. Powder Technol. 2014, 256, 233–238. [Google Scholar] [CrossRef]

- Vasco, C.; Ruales, J.; Kamal-Eldin, A. Total phenolic compounds and antioxidant capacities of major fruits from Ecuador. Food Chem. 2008, 111, 816–823. [Google Scholar] [CrossRef]

- Nagar, E.; Berenshtein, L.; Okun, Z.; Shpigelman, A. The structure-dependent influence of high pressure processing on polyphenol-cell wall material (CWM) interactions and polyphenol-polyphenol association in model systems: Possible implication to accessibility. Innov. Food Sci. Emerg. Technol. 2020, 66, 102538. [Google Scholar] [CrossRef]

- Suárez-Jacobo, Á.; Rüfer, C.E.; Gervilla, R.; Guamis, B.; Roig-Sagués, A.X.; Saldo, J. Influence of ultra-high pressure homogenisation on antioxidant capacity, polyphenol and vitamin content of clear apple juice. Food Chem. 2011, 127, 447–454. [Google Scholar] [CrossRef]

- Velázquez-Estrada, R.M.; Hernández-Herrero, M.M.; Rüfer, C.E.; Guamis-López, B.; Roig-Sagués, A.X. Influence of ultra high pressure homogenization processing on bioactive compounds and antioxidant activity of orange juice. Innov. Food Sci. Emerg. Technol. 2013, 18, 89–94. [Google Scholar] [CrossRef]

- Minatel, I.O.; Borges, C.V.; Ferreira, M.I.; Gomez, H.A.G.; Chen, C.-Y.O.; Lima, G.P.P. Phenolic Compounds: Functional Properties, Impact of Processing and Bioavailability. In Phenolic Compounds—Biological Activity; Soto-Hernandez, M., Palma-Tenango, M., del Rosario Garcia Mateos, M., Eds.; InTech: Nappanee, IN, USA, 2017. [Google Scholar] [CrossRef]

- Persic, M.; Mikulic-Petkovsek, M.; Slatnar, A.; Veberic, R. Chemical composition of apple fruit, juice and pomace and the correlation between phenolic content, enzymatic activity and browning. LWT—Food Sci. Technol. 2017, 82, 23–31. [Google Scholar] [CrossRef]

- Capanoglu, E.; De Vos, R.C.H.; Hall, R.D.; Boyacioglu, D.; Beekwilder, J. Changes in polyphenol content during production of grape juice concentrate. Food Chem. 2013, 139, 521–526. [Google Scholar] [CrossRef]

- Morais, M.G.; Saldanha, A.A.; Costa Rodrigues, J.P.; Cotta Mendes, I.; Ferreira, L.M.; Avelar Amado, P.; de Souza Farias, K.; Samúdio Santos Zanuncio, V.; Brentan da Silva, D.; Carmo Horta Pinto, F.; et al. Chemical composition, antioxidant, anti-inflammatory and antinociceptive activities of the ethanol extract of ripe fruits of Solanum lycocarpum St. Hil. (Solanaceae). J. Ethnopharmacol. 2020, 262, 113125. [Google Scholar] [CrossRef]

- More, G.K. A review of the ethnopharmacology, phytochemistry and pharmacological relevance of the South African weed Solanum sisymbriifolium Lam. (Solanaceae). Environ. Dev. Sustain. 2019, 21, 37–50. [Google Scholar] [CrossRef]

- Rios, R.; da Silva, H.B.F.; Carneiro, N.V.Q.; Pires, A.d.O.; Carneiro, T.C.B.; Costa, R.d.S.; Marques, C.R.; Machado, M.S.S.; Velozo, E.d.S.; Silva, T.M.G.d.; et al. Solanum paniculatum L. decreases levels of inflammatory cytokines by reducing NFKB, TBET and GATA3 gene expression in vitro. J. Ethnopharmacol. 2017, 209, 32–40. [Google Scholar] [CrossRef] [PubMed]

- Da Costa, G.A.F.; Morais, M.G.; Saldanha, A.A.; Assis Silva, I.C.; Aleixo, Á.A.; Ferreira, J.M.S.; Soares, A.C.; Duarte-Almeida, J.M.; Lima, L.A.R.D.S. Antioxidant, Antibacterial, Cytotoxic, and Anti-Inflammatory Potential of the Leaves of Solanum lycocarpum A. St. Hil. (Solanaceae). Evid.-Based Complement. Altern. Med. 2015, 2015. [Google Scholar] [CrossRef]

- Ismail, B.B.; Pu, Y.; Guo, M.; Ma, X.; Liu, D. LC-MS/QTOF identification of phytochemicals and the effects of solvents on phenolic constituents and antioxidant activity of baobab (Adansonia digitata) fruit pulp. Food Chem. 2019, 277, 279–288. [Google Scholar] [CrossRef]

- Pinela, J.; Montoya, C.; Carvalho, A.M.; Martins, V.; Rocha, F.; Barata, A.M.; Barros, L.; Ferreira, I.C.F.R. Phenolic composition and antioxidant properties of ex-situ conserved tomato (Solanum lycopersicum L.) germplasm. Food Res. Int. 2019, 125, 108545. [Google Scholar] [CrossRef]

- Díaz-García, M.C.; Obón, J.M.; Castellar, M.R.; Collado, J.; Alacid, M. Quantification by UHPLC of total individual polyphenols in fruit juices. Food Chem. 2013, 138, 938–949. [Google Scholar] [CrossRef]

- Brahem, M.; Renard, C.M.G.C.; Eder, S.; Loonis, M.; Ouni, R.; Mars, M.; Le Bourvellec, C. Characterization and quantification of fruit phenolic compounds of European and Tunisian pear cultivars. Food Res. Int. 2017, 95, 125–133. [Google Scholar] [CrossRef]

- Kolniak-Ostek, J. Content of bioactive compounds and antioxidant capacity in skin tissues of pear. J. Funct. Foods 2016, 23, 40–51. [Google Scholar] [CrossRef]

- Chanforan, C.; Loonis, M.; Mora, N.; Caris-Veyrat, C.; Dufour, C. The impact of industrial processing on health-beneficial tomato microconstituents. Food Chem. 2012, 134, 1786–1795. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Romero, M.; Segura-Carretero, A.; Fernández-Gutiérrez, A. Metabolite profiling and quantification of phenolic compounds in methanol extracts of tomato fruit. Phytochemistry 2010, 71, 1848–1864. [Google Scholar] [CrossRef] [PubMed]

- Hokkanen, J.; Mattila, S.; Jaakola, L.; Pirttilä, A.M.; Tolonen, A. Identification of phenolic compounds from lingonberry (Vaccinium vitis-idaea L.), Bilberry (Vaccinium myrtillus L.) andHybrid Bilberry (Vaccinium x intermedium Ruthe L.) Leaves. J. Agric. Food Chem. 2009, 57, 9437–9447. [Google Scholar] [CrossRef] [PubMed]

- Park, J.B. 5-Caffeoylquinic acid and caffeic acid orally administered suppress P-selectin expression on mouse platelets. J. Nutr. Biochem. 2009, 20, 800–805. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.P.A.; Angolini, C.F.F.; Paulino, B.N.; Lauretti, L.B.C.; Orlando, E.A.; Silva, J.G.S.; Neri-Numa, I.A.; Souza, J.D.R.P.; Pallone, J.A.L.; Eberlin, M.N.; et al. A comprehensive characterization of Solanum lycocarpum St. Hill and Solanum oocarpum Sendtn: Chemical composition and antioxidant properties. Food Res. Int. 2018, 1–9. [Google Scholar] [CrossRef]

- Gutiérrez Ortiz, A.L.; Berti, F.; Navarini, L.; Monteiro, A.; Resmini, M.; Forzato, C. Synthesis of p-coumaroylquinic acids and analysis of their interconversion. Tetrahedron Asymmetry 2017, 28, 419–427. [Google Scholar] [CrossRef]

- Mikulic-Petkovsek, M.; Schmitzer, V.; Jakopic, J.; Cunja, V.; Veberic, R.; Munda, A.; Stampar, F. Phenolic compounds as defence response of pepper fruits to Colletotrichum coccodes. Physiol. Mol. Plant Pathol. 2013, 84, 138–145. [Google Scholar] [CrossRef]

- Rodríguez-Medina, I.C.; Segura-Carretero, A.; Fernández-Gutiérrez, A. Use of high-performance liquid chromatography with diode array detection coupled to electrospray-Qq-time-of-flight mass spectrometry for the direct characterization of the phenolic fraction in organic commercial juices. J. Chromatogr. A 2009, 1216, 4736–4744. [Google Scholar] [CrossRef]

- Liu, P.; Li, L.; Song, L.; Sun, X.; Yan, S.; Huang, W. Characterisation of phenolics in fruit septum of Juglans regia Linn. by ultra performance liquid chromatography coupled with Orbitrap mass spectrometer. Food Chem. 2019, 286, 669–677. [Google Scholar] [CrossRef]

- Dorta, E.; González, M.; Lobo, M.G.; Sánchez-Moreno, C.; de Ancos, B. Screening of phenolic compounds in by-product extracts from mangoes (Mangifera indica L.) by HPLC-ESI-QTOF-MS and multivariate analysis for use as a food ingredient. Food Res. Int. 2014, 57, 51–60. [Google Scholar] [CrossRef]

- Fu, L.; Xu, B.T.; Xu, X.R.; Gan, R.Y.; Zhang, Y.; Xia, E.Q.; Li, H. Bin Antioxidant capacities and total phenolic contents of 62 fruits. Food Chem. 2011, 129, 345–350. [Google Scholar] [CrossRef]

- Phenol-Explorer; USA Database Phenol-Explorer. Available online: http://phenol-explorer.eu/compounds (accessed on 18 February 2020).

- Baret, P.; Septembre-Malaterre, A.; Rigoulet, M.; Lefebvre d’Hellencourt, C.; Priault, M.; Gonthier, M.-P.; Devin, A. Dietary polyphenols preconditioning protects 3T3-L1 preadipocytes from mitochondrial alterations induced by oxidative stress. Int. J. Biochem. Cell Biol. 2013, 45, 167–174. [Google Scholar] [CrossRef]

- Asgary, S.; Sahebkar, A.; Afshani, M.R.; Keshvari, M.; Haghjooyjavanmard, S.; Rafieian-Kopaei, M. Clinical Evaluation of Blood Pressure Lowering, Endothelial Function Improving, Hypolipidemic and Anti-Inflammatory Effects of Pomegranate Juice in Hypertensive Subjects. Phyther. Res. 2014, 28, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.B.; Meyer, R.S.; Whitaker, B.D.; Litt, A.; Kennelly, E.J. A new liquid chromatography-mass spectrometry-based strategy to integrate chemistry, morphology, and evolution of eggplant (Solanum) species. J. Chromatogr. A 2013, 1314, 154–172. [Google Scholar] [CrossRef] [PubMed]

- Santiago-Silva, P.; Labanca, R.A.; Gloria, M.B.A. Functional potential of tropical fruits with respect to free bioactive amines. Food Res. Int. 2011, 44, 1264–1268. [Google Scholar] [CrossRef]

- Bomtempo, L.L.; Costa, M.A.; Lima, H.; Engeseth, N.; Gloria, M.B.A. Bioactive amines in Passiflora are affected by species and fruit development. Food Res. Int. 2016, 89, 733–738. [Google Scholar] [CrossRef] [PubMed]

| Batch | aw | °Brix | X1 | γ1 | X | γ | Ɛe |

|---|---|---|---|---|---|---|---|

| 1 | 0.995 ± 0.001 a | 8.73 ± 0.06 a | 5 ± 7 a | 5 ± 4 a | 8.8 ± 1.6 a | 3 ± 3 a | 6 ± 4 a |

| 2 | 0.996 ± 0.003 a | 8.93 ± 0.06 a | 2 ± 4 a | 5 ± 2 a | 11 ± 2 a | 3.7 ± 0.9 a | 8 ± 2 a |

| 3 | 0.994 ± 0.002 a | 8.70 ± 0.17 a | 2.5 ± 1.3 a | 7.1 ± 1.0 a | 8.6 ± 0.9 a | 2.9 ± 0.8 a | 6.3 ± 1.2 a |

| Fruit | Nonhomogenized | 50 MPa | 100 MPa | 150 MPa | |

|---|---|---|---|---|---|

| Xw (%) | 91.2 ± 0.4 | - | - | - | - |

| aw | 0.994 ± 0.003 a | 0.994 ± 0.003 a | 0.997 ± 0.003 a | 0.995 ± 0.001 a | 0.996± 0.000 a |

| Brix | 8.88 ± 0.17 b | 6.57 ± 0.12 a | 6.4 ± 0.4 a | 6.33 ± 0.15 a | 6.4 ± 0.4 a |

| pH | 3.13 ± 0.16 a | 3.31 ± 0.01 a | 3.12 ± 0.02 a | 3.18 ± 0.03 a | 3.18 ± 0.03 a |

| ρ (g/cm3) | 1.16 ± 0.07 b | 1.036 ± 0.018 a | 1.06 ± 0.04 a,b | 1.07 ± 0.02 a,b | 1.090 ± 0.013 a,b |

| Particle size | |||||

| D [4,3] | - | 251 ± 5 d | 124 ± 3 c | 75.5 ± 1.2 b | 57.94 ± 0.14 a |

| D [3,2] | - | 102.3 ± 0.5 d | 49.9 ± 1.5 c | 35.28 ± 0.07 b | 26.83 ± 0.19 a |

| d10 (μm) | - | 75.8 ± 0.3 d | 25.7 ± 1.1 c | 18.94 ± 0.11 b | 15.63 ± 0.03 a |

| d50 (μm) | - | 184.2 ± 1.6 d | 99.82 ± 0.09 c | 60.01 ± 0.11 b | 45.02 ± 0.19 a |

| d90 (μm) | - | 524 ± 17 d | 247 ± 3 c | 153.7 ± 2.0 b | 114.2 ± 0.5 a |

| Rheological properties | |||||

| K (Pa.sn) | - | 0.39 ± 0.12 a | 0.9 ± 0.4 b | 0.79 ± 0.02 a,b | 1.3 ± 0.5 b |

| n | - | 0.44 ± 0.06 b | 0.37 ± 0.04 a | 0.37 ± 0.00 a | 0.34 ± 0.04 a |

| R2 | 0.99 | 0.98 | 0.96 | 0.98 | |

| Color | |||||

| L* | - | 40.4 ± 0.4 b | 40.16 ± 0.11 a,b | 39.409 ± 0.012 a | 39.44 ± 0.08 a |

| a* | - | 9.5 ± 0.2 b | 9.08 ± 0.07 a | 9.15 ± 0.01 a,b | 8.829 ± 0.011 a |

| b* | - | 34.9 ± 1.4 a | 35.4 ± 0.5 a | 34.54 ± 0.01 a | 33.8 ± 0.2 a |

| Cab* | - | 36.2 ± 1.3 a | 36.5 ± 0.5 a | 35.73 ± 0.01 a | 34.9 ± 0.2 a |

| hab* | - | 74.7 ± 0.2 a | 75.61 ± 0.09 b | 75.16 ± 0.01 a,b | 75.37 ± 0.13 a,b |

| ΔE | - | - | 0.8 ± 0.2 a | 1.250 ± 0.014 a,b | 1.74 ± 0.13 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hinestroza-Córdoba, L.I.; Barrera, C.; Seguí, L.; Betoret, N. Potential Use of Vacuum Impregnation and High-Pressure Homogenization to Obtain Functional Products from Lulo Fruit (Solanum quitoense Lam.). Foods 2021, 10, 817. https://doi.org/10.3390/foods10040817

Hinestroza-Córdoba LI, Barrera C, Seguí L, Betoret N. Potential Use of Vacuum Impregnation and High-Pressure Homogenization to Obtain Functional Products from Lulo Fruit (Solanum quitoense Lam.). Foods. 2021; 10(4):817. https://doi.org/10.3390/foods10040817

Chicago/Turabian StyleHinestroza-Córdoba, Leidy Indira, Cristina Barrera, Lucía Seguí, and Noelia Betoret. 2021. "Potential Use of Vacuum Impregnation and High-Pressure Homogenization to Obtain Functional Products from Lulo Fruit (Solanum quitoense Lam.)" Foods 10, no. 4: 817. https://doi.org/10.3390/foods10040817

APA StyleHinestroza-Córdoba, L. I., Barrera, C., Seguí, L., & Betoret, N. (2021). Potential Use of Vacuum Impregnation and High-Pressure Homogenization to Obtain Functional Products from Lulo Fruit (Solanum quitoense Lam.). Foods, 10(4), 817. https://doi.org/10.3390/foods10040817