High-Moisture Meat Analogues Produced from Yellow Pea and Faba Bean Protein Isolates/Concentrate: Effect of Raw Material Composition and Extrusion Parameters on Texture Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Protein Isolates from Pulses

2.3. Characterisation of Commercial and Local Protein Isolates/Concentrate

2.3.1. Proximate Analysis

2.3.2. Thermal Properties

2.3.3. Water-Holding Capacity

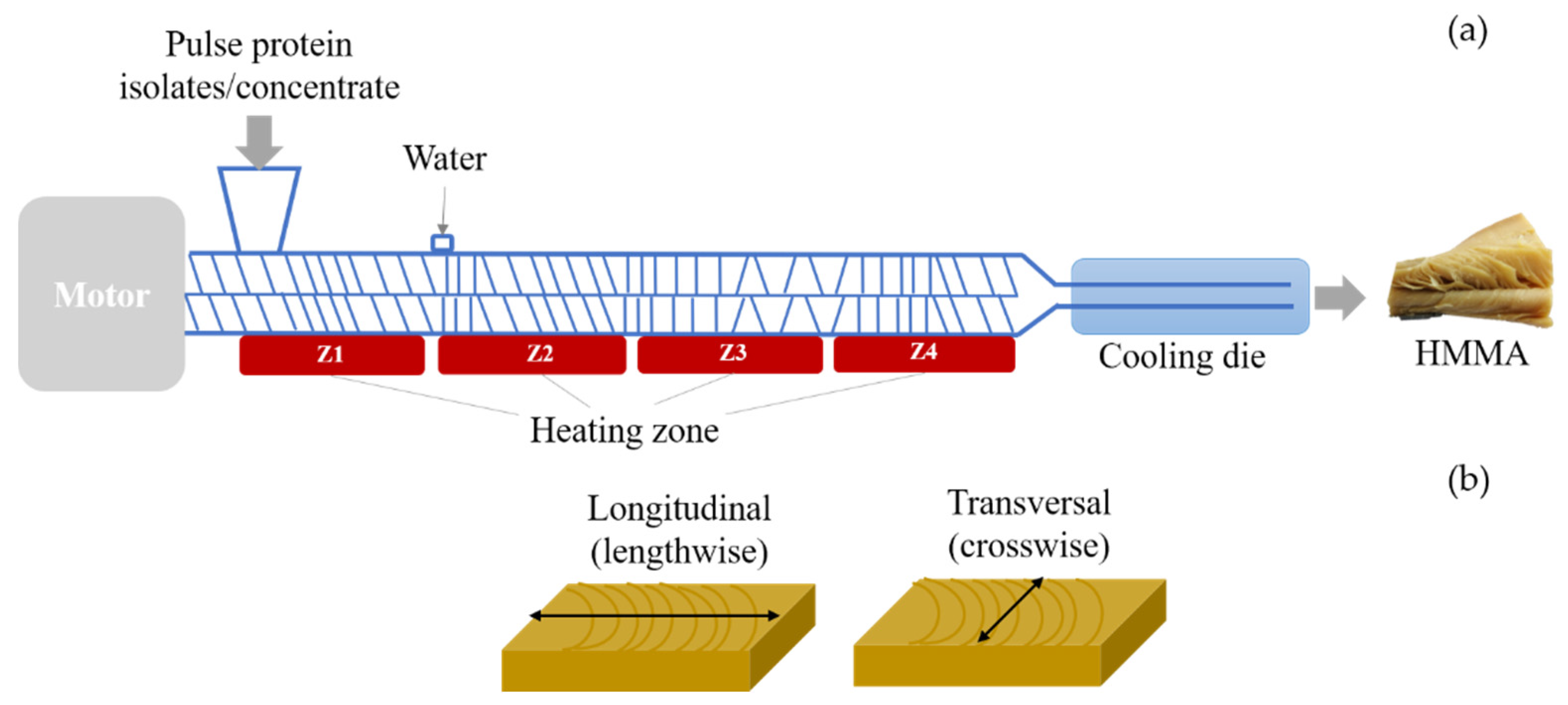

2.4. High-Moisture Extrusion Trials

Texture Properties of HMMA

2.5. Statistical Analysis

3. Results and Discussion

3.1. Characterisation of Protein Isolates/Concentrate from Pulses

3.2. High-Moisture Extrusion Trials

3.2.1. Preliminary Extrusion Trials

3.2.2. HMMA Production Using Local Pulse Protein Isolates

3.3. Effect of Protein Isolate/Concentrate Composition and Extrusion Parameters on HMMA Texture Properties

3.3.1. Effects of Protein Isolate/Concentrate Composition

3.3.2. Effect of Extrusion Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Target Moisture Content (%) | Screw Speed (rpm) | Processing Temperature Zone (°C) | |||

|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | ||

| 65 | 800 | 40 | 80 | 110 | 110 |

| 40 | 80 | 110 | 130 | ||

| 40 | 80 | 120 | 140 | ||

| 40 | 80 | 130 | 150 | ||

| 68 | 800 | 40 | 80 | 110 | 110 |

| 40 | 80 | 110 | 130 | ||

| 40 | 80 | 120 | 140 | ||

| 40 | 80 | 130 | 150 | ||

| 70 | 800 | 40 | 80 | 110 | 110 |

| 40 | 80 | 110 | 130 | ||

| 40 | 80 | 120 | 140 | ||

| 40 | 80 | 130 | 150 | ||

| Target Moisture Content (%) | Processing Temperature Zone (°C) | SME 2 (kJ/kg) | Texture Properties | Cutting Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | Hardness (g) | Springiness | Chewiness (g) | Crosswise (g) | Lengthwise (g) | ||

| 65 | 40 | 80 | 110 | 110 | 1179 ± 47 a | 3996 ± 273 a | 0.9 ± 0.06 a | 3408 ± 197 a | 2529 ± 191 b | 2914 ± 57 a |

| 40 | 80 | 110 | 130 | 1152 ± 47 ab | 3638 ± 176 a | 0.9 ± 0.02 a | 3219 ± 153 a | 3184 ± 127 a | 2731 ± 78 a | |

| 40 | 80 | 120 | 140 | 1125 ± 81 ab | 2199 ± 230 b | 0.9 ± 0.05 a | 1935 ± 165 b | 3378 ± 193 a | 2674 ± 79 a | |

| 40 | 80 | 130 | 150 | 1018 ± 46 b | 2003 ± 56 b | 0.9 ± 0.05 a | 1813 ± 49 b | 2977 ± 295 ab | 2542 ± 326 a | |

| 68 | 40 | 80 | 110 | 110 | 1152 ± 123 a | 3059 ± 126 a | 0.9 ± 0.07 a | 2569 ± 85 a | 1708 ± 152 a | 1597 ± 83 b |

| 40 | 80 | 110 | 130 | 1018 ± 46 a | 2092 ± 114 b | 0.9 ± 0.02 a | 1856 ± 132 b | 1842 ± 130 a | 1951 ± 178 a | |

| 40 | 80 | 120 | 140 | 992 ± 46 a | 2760 ± 159 a | 0.9 ± 0.07 a | 2364 ± 86 a | 1811 ± 37 a | 1547 ± 114 b | |

| 40 | 80 | 130 | 150 | 992 ± 46 a | 1428 ± 88 c | 0.9 ± 0.02 a | 1261 ± 69 c | 1740 ± 193 a | 1744 ± 61 ab | |

| 70 | 40 | 80 | 110 | 110 | 1259 ± 46 a | 2835 ± 143 a | 0.9 ± 0.07 a | 2393 ± 122 a | 1486 ± 72 a | 1494 ± 54 a |

| 40 | 80 | 110 | 130 | 1179 ± 47 a | 2495 ± 253 a | 0.9 ± 0.05 a | 2093 ± 207 a | 1514 ± 131 a | 1553 ± 18 a | |

| 40 | 80 | 120 | 140 | 1072 ± 46 b | 2407 ± 227 a | 0.8 ± 0.04 a | 2035 ± 211 a | 1797 ± 51 a | 1621 ± 149 a | |

| 40 | 80 | 130 | 150 | 992 ± 46 c | 1795 ± 86 b | 0.9 ± 0.07 a | 1599 ± 105 b | 2386 ± 269 b | 1091 ± 27 b | |

| Raw Material | Processing Temperature Zone (°C) | Target Moisture Content (%) | Screw Speed (rpm) | |||

|---|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | |||

| Yellow pea isolate commercial (YPI-com) | 40 | 80 | 130 | 150 | 66 | 400 |

| 600 | ||||||

| 800 | ||||||

| 67 | 400 | |||||

| 40 | 80 | 130 | 150 | 600 | ||

| 800 | ||||||

| 68 | 400 | |||||

| 40 | 80 | 130 | 150 | 600 | ||

| 800 | ||||||

| 69 | 400 | |||||

| 40 | 80 | 130 | 150 | 600 | ||

| 800 | ||||||

| 70 | 400 | |||||

| 40 | 80 | 130 | 150 | 600 | ||

| 800 | ||||||

| Yellow pea isolate local (YPI-local) | 40 | 80 | 130 | 150 | 67 | 400 |

| 600 | ||||||

| 800 | ||||||

| Faba bean concentrate commercial (FBC-com) | 40 | 60 | 130 | 150 | 58 | 400 |

| 600 | ||||||

| 800 | ||||||

| 40 | 60 | 130 | 150 | 60 | 400 | |

| 600 | ||||||

| 800 | ||||||

| 40 | 60 | 130 | 150 | 62 | 400 | |

| 600 | ||||||

| 800 | ||||||

| Faba bean isolate local (FBI-local) | 40 | 60 | 110 | 130 | 62 | 800 |

| 64 | 800 | |||||

| 66 | 800 | |||||

| 68 | 800 | |||||

Appendix C

| ID | Target Moisture Content (%) | Screw Speed (rpm) | SME 3 (kJ/kg) | Texture Profile Analysis 2 | Cutting Strength 2 | |||

|---|---|---|---|---|---|---|---|---|

| Hardness (g) | Springiness | Chewiness (g) | Crosswise (g) | Lengthwise (g) | ||||

| Yellow pea isolate commercial (YPI-com) 1 | ||||||||

| 1 | 66% | 400 | 583 ± 35 d | 2229 ± 237 e | 0.9 ± 0.09 ab | 1950 ± 167 fg | 2402 ± 3 bcd | 2001 ± 107 d |

| 2 | 600 | 1085 ± 91 c | 2534 ± 250 e | 1.0 ± 0.01 a | 2201 ± 237 f | 2297 ± 43 cd | 2053 ± 308 d | |

| 3 | 800 | 1527 ± 69 a | 2682 ± 168 e | 0.9 ± 0.04 ab | 2354 ± 147 f | 2508 ± 187 bc | 1545 ± 221 e | |

| 4 | 67% | 400 | 583 ± 35 d | 2389 ± 123 e | 0.8 ± 0.04 ab | 2021 ± 164 fg | 2237 ± 47 cd | 1749 ± 55 de |

| 5 | 600 | 995 ± 91 c | 1824 ± 147 efg | 0.9 ± 0.02 ab | 1570 ± 94 hi | 1427 ± 70 efg | 1466 ± 163 ef | |

| 6 | 800 | 1447 ± 121 a | 2131 ± 139 efg | 0.9 ± 0.02 ab | 1818 ± 103 gh | 1623 ± 59 ef | 1260 ± 71 f | |

| 7 | 68% | 400 | 563 ± 35 d | 1986 ± 133 efg | 0.9± 0.02 ab | 1986 ± 133 fg | 2091 ± 105 de | 1706 ± 87 de |

| 8 | 600 | 904 ± 1 c | 1774 ± 105 fg | 1.0 ± 0.01 a | 1544 ± 80 hi | 1756 ± 102 def | 1169 ± 93 f | |

| 9 | 800 | 1487 ± 69 a | 1760 ± 114 fg | 0.9 ± 0.09 ab | 1524 ± 75 hi | 1657 ± 74 ef | 1326 ± 83 f | |

| 10 | 69% | 400 | 563 ± 35 d | 1930 ± 67 efg | 0.9± 0.04 ab | 1642 ± 45 gh | 1818 ± 44 def | 1674 ± 29 def |

| 11 | 600 | 1085 ± 91 c | 2016 ± 133 efg | 1.0 ± 0.01 a | 1785 ± 107 gh | 1833 ± 71 de | 2011 ± 216 d | |

| 12 | 800 | 1487 ± 69 a | 2433 ± 27 e | 0.9 ± 0.06 ab | 2075 ± 18 fg | 1969 ± 160 de | 2112 ± 204 d | |

| 13 | 70% | 400 | 643 ± 35 d | 1493 ± 153 g | 0.9± 0.05 ab | 1259 ± 119 hi | 930 ± 28 h | 702 ± 132 g |

| 14 | 600 | 1176 ± 91 c | 1702 ± 84 fg | 0.9 ± 0.02 ab | 1446 ± 98 hi | 1270 ± 164 g | 1277 ± 47 f | |

| 15 | 800 | 1567 ± 121 a | 2426 ± 101 e | 0.9 ± 0.06 ab | 2028 ± 31 fg | 1599 ± 16 efg | 1325 ± 74 f | |

| Yellow pea isolate local (YPI-local) 1 | ||||||||

| 16 | 67% | 400 | 502 ± 35 d | 2177 ± 175 efg | 0.9 ± 0.09 ab | 1805 ± 176 gh | 1846 ± 140 def | 1451 ± 220 f |

| 17 | 600 | 1025 ± 52 c | 2252 ± 210 ef | 0.9 ± 0.09 ab | 1796 ± 148 gh | 1828 ± 275 def | 1780 ± 32 def | |

| 800 | ||||||||

| Faba bean concentrate commercial (FBC-com) 1 | ||||||||

| 18 | 58% | 400 | 643 ± 35 d | 6136 ± 190 a | 0.9 ± 0.01 ab | 5185 ± 174 a | 3149 ± 94 a | 2730 ± 71 c |

| 19 | 600 | 1146 ± 53 c | 6120 ± 245 a | 0.9 ± 0.06 ab | 5264 ± 254 a | 3041 ± 45 a | 2679 ± 159 cd | |

| 20 | 800 | 1567 ± 121 b | 4637 ± 325 c | 0.9 ± 0.08 ab | 4039 ± 244 c | 2817 ± 32 ab | 2293 ± 94 d | |

| 21 | 60% | 400 | 603 ± 60 d | 5475 ± 225 b | 0.9 ± 0.04 ab | 4806 ± 187 a | 3107 ± 157 a | 2659 ± 74 cd |

| 22 | 600 | 995 ± 2 c | 4496 ± 185 c | 0.9 ± 0.05 ab | 3914 ± 188 bc | 2336 ± 97 cd | 2212 ± 99 d | |

| 23 | 800 | 1607 ± 70 b | 5222 ± 241 b | 0.9 ± 0.02 ab | 4420 ± 240 ab | 2570 ± 183 bc | 2317 ± 142 cd | |

| 24 | 62% | 400 | 583 ± 35 d | 3780 ± 160 d | 0.9 ± 0.01 ab | 3002 ± 222 d | 1520 ± 51 fg | 1644 ± 61 ef |

| 25 | 600 | 1146 ± 53 c | 4522 ± 74 c | 0.9 ± 0.01 ab | 3631 ± 21 cd | 1697 ± 27 def | 1813 ± 61 de | |

| 26 | 800 | 1567 ± 121 b | 4009 ± 93 cd | 0.9 ± 0.07 ab | 3339 ± 90 d | 1788 ± 44 def | 1547 ± 14 ef | |

| Faba bean isolate local (FBI-local) 1 | ||||||||

| 27 | 62% | 800 | 1889 ± 121 a | 2648 ± 188 e | 0.9 ± 0.02 ab | 2309 ± 152 f | 2423 ± 109 cd | 3397 ± 180 ab |

| 28 | 64% | 800 | 1809 ± 70 ab | 3301 ± 274 d | 0.9 ± 0.05 ab | 2808 ± 216 e | 2249 ± 184 cd | 2479 ± 136 cd |

| 29 | 66% | 800 | 1728 ± 121 ab | 3524 ± 150 d | 0.9 ± 0.09 ab | 2992 ± 133 de | 2019 ± 92 de | 1933 ± 29 de |

| 30 | 70% | 800 | 1809 ± 69 ab | 2578 ± 26 e | 0.9 ± 0.08 ab | 2128 ± 48 fg | 1204 ± 146 g | 1553 ± 102 ef |

| References | ||||||||

| 31 | Commercial soybean HMMA | 500 ± 45 h | 0.9 ± 0.08 ab | 408 ± 39 j | 1204 ± 119 g | 1553 ± 52 ef | ||

| 32 | Boiled chicken | 2332 ± 148 e | 0.8 ± 0.09 b | 1679 ± 86 gh | 2102 ± 131 d | 3207 ± 227 b | ||

| 33 | Boiled beef | 1645 ± 238 g | 0.9 ± 0.12 ab | 1087 ± 113 i | 1821 ± 383 ef | 3743 ± 123 a | ||

References

- Shepon, A.; Eshel, G.; Noor, E.; Milo, R. Energy and Protein Feed-to-Food Conversion Efficiencies in the US and Potential Food Security Gains from Dietary Changes. Environ. Res. Lett. 2016, 11, 1005002. [Google Scholar] [CrossRef]

- Röös, E.; Bajželj, B.; Smith, P.; Patel, M.; Little, D.; Garnett, T. Greedy or Needy? Land Use and Climate Impacts of Food in 2050 under Different Livestock Futures. Glob. Environ. Chang. 2017, 47, 1–12. [Google Scholar] [CrossRef]

- EAT-Lancet Commission. Healthy Diets from Sustainable Food Systems: Food Planet Health; EAT: Stockholm, Sweden, 2019. [Google Scholar]

- Campos-Vega, R.; Loarca-Piña, G.; Oomah, B.D. Minor Components of Pulses and Their Potential Impact on Human Health. Food Res. Int. 2010, 43, 461–482. [Google Scholar] [CrossRef]

- Hoek, A.C.; Elzerman, J.E.; Hageman, R.; Kok, F.J.; Luning, P.A.; de Graaf, C. Are Meat Substitutes Liked Better over Time? A Repeated in-Home Use Test with Meat Substitutes or Meat in Meals. Food Qual. Prefer. 2013, 28, 253–263. [Google Scholar] [CrossRef]

- Elzerman, J.E.; van Boekel, M.A.J.S.; Luning, P.A. Exploring Meat Substitutes: Consumer Experiences and Contextual Factors. Br. Food J. 2013, 115, 700–710. [Google Scholar] [CrossRef]

- Maung, T.; Ryu, G. Asian Perspective on High-Moisture Extrusion. Cereal Foods World 2020, 65. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High Moisture Extrusion Cooking of Pea Protein Isolates: Raw Material Characteristics, Extruder Responses, and Texture Properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Eisner, P.; Schweiggert-Weisz, U. Effect of High Moisture Extrusion Cooking on Protein-Protein Interactions of Pea (Pisum sativum L.) Protein Isolates. Int. J. Food Sci. Technol. 2015, 50, 1390–1396. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Boom, R.M.; van der Goot, A.J. Structuring Processes for Meat Analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Vatansever, S.; Tulbek, M.C.; Riaz, M.N. Low- and High-Moisture Extrusion of Pulse Proteins as Plant-Based Meat Ingredients: A Review. Cereal Foods World 2020, 65. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Y.; Dreisoerner, J.; Wei, Y. The Effects of Screw Configuration on the Screw Fill Degree and Special Mechanical Energy in Twin-Screw Extruder for High-Moisture Texturised Defatted Soybean Meal. J. Food Eng. 2015, 157, 77–83. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Zhang, B.; Drago, S.R.; Zhang, J. Relationships between the Gelatinization of Starches and the Textural Properties of Extruded Texturized Soybean Protein-Starch Systems. J. Food Eng. 2016, 174, 29–36. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B. Chemical Cross-Linking and Molecular Aggregation of Soybean Protein during Extrusion Cooking at Low and High Moisture Content. LWT Food Sci. Technol. 2011, 44, 957–962. [Google Scholar] [CrossRef]

- Wu, M.; Sun, Y.; Bi, C.; Ji, F.; Li, B.; Xing, J. Effects of Extrusion Conditions on the Physicochemical Properties of Soy Protein/Gluten Composite. Int. J. Agric. Biol. Eng. 2018, 11, 205–210. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B.; Ojokoh, A.O. System Parameters and Product Properties Response of Soybean Protein Extruded at Wide Moisture Range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and Chemical Characteristics of Soy Protein Meat Analog Extruded at High Moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion Process Parameters, Sensory Characteristics, and Structural Properties of a High Moisture Soy Protein Meat Analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Liu, K.S.; Hsieh, F.H. Protein-Protein Interactions in High Moisture-Extruded Meat Analogs and Heat-Induced Soy Protein Gels. JAOCS J. Am. Oil Chem. Soc. 2007, 84, 741–748. [Google Scholar] [CrossRef]

- Röös, E.; Carlsson, G.; Ferawati, F.; Hefni, M.; Stephan, A.; Tidåker, P.; Witthöft, C. Less Meat, More Legumes: Prospects and Challenges in the Transition toward Sustainable Diets in Sweden. Renew. Agric. Food Syst. 2020, 35, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Murillo, J.L.S.; Osen, R.; Hiermaier, S.; Ganzenmüller, G. Towards Understanding the Mechanism of Fibrous Texture Formation during High-Moisture Extrusion of Meat Substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Taehoon, K. Texturization of Pulse Proteins: Peas, Lentils, and Faba Beans. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, May 2018. [Google Scholar]

- AOAC. AOAC Official Method 990:03: Protein (Crude) in Animal Feed. Combustion Method. In Official Methods of Analysis of AOAC International; AOAC International: Washington, DC, USA, 2002. [Google Scholar]

- AOAC. AOAC Official Method 920.39: Fat (Crude) or Ether Extract in Animal Feed. Gravimetric. In Official Methods of Analysis of AOAC International; AOAC International: Washington, DC, USA, 2002. [Google Scholar]

- AOAC. AOAC Official Method 991.43: Total, Soluble and Insoluble Dietary Fiber in Foods. Gravimetric. In Official Methods of Analysis of AOAC International; AOAC International: Washington, DC, USA, 2002. [Google Scholar]

- AOAC. AOAC Official Method 934.01: Proximate Analysis and Calculations Moisture. In Official Methods of Analysis of AOAC International; AOAC International: Washington, DC, USA, 2002. [Google Scholar]

- AOAC. AOAC Official Method 923.03: Ash of Flour. Gravimetric; AOAC International: Washington, DC, USA, 2002. [Google Scholar]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef]

- AACC. AACC Method 56-30.01. Water Hydration Capacity of Protein Materials. In AACC Approved Methods of Analysis, 11th ed.; AACC: Arnold, MD, USA, 2010; Available online: http://methods.aaccnet.org/summaries/56-30-01.aspx (accessed on 21 February 2021).

- Palanisamy, M.; Franke, K.; Berger, R.G.; Heinz, V.; Töpfl, S. High Moisture Extrusion of Lupin Protein: Influence of Extrusion Parameters on Extruder Responses and Product Properties. J. Sci. Food Agric. 2019, 99, 2175–2185. [Google Scholar] [CrossRef] [PubMed]

- Vogelsang-O’Dwyer, M.; Petersen, I.L.; Joehnke, M.S.; Sørensen, J.C.; Bez, J.; Detzel, A.; Busch, M.; Krueger, M.; O’Mahony, J.A.; Arendt, E.K.; et al. Comparison of Faba Bean Protein Ingredients Produced Using Dry Fractionation and Isoelectric Precipitation: Techno-Functional, Nutritional and Environmental Performance. Foods 2020, 9, 322. [Google Scholar] [CrossRef] [Green Version]

- Saldanha do Carmo, C.; Silventoinen, P.; Nordgård, C.T.; Poudroux, C.; Dessev, T.; Zobel, H.; Holtekjølen, A.K.; Draget, K.I.; Holopainen-Mantila, U.; Knutsen, S.H.; et al. Is Dehulling of Peas and Faba Beans Necessary Prior to Dry Fractionation for the Production of Protein- and Starch-Rich Fractions? Impact on Physical Properties, Chemical Composition and Techno-Functional Properties. J. Food Eng. 2020, 278. [Google Scholar] [CrossRef]

- Rempel, C.; Geng, X.; Zhang, Y. Industrial Scale Preparation of Pea Flour Fractions with Enhanced Nutritive Composition by Dry Fractionation. Food Chem. 2019, 276, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Shand, P.; Ya, H.; Pietrasik, Z.; Wanasundara, P. Physicochemical and Textural Properties of Heat-Induced Pea Protein Isolate Gels. Food Chem. 2007, 102, 1119–11130. [Google Scholar] [CrossRef]

- Sharan, S.; Zanghelini, G.; Zotzel, J.; Bonerz, D.; Aschoff, J.; Saint-Eve, A.; Maillard, M.N. Fava Bean (Vicia faba L.) for Food Applications: From Seed to Ingredient Processing and Its Effect on Functional Properties, Antinutritional Factors, Flavor, and Color. Compr. Rev. Food Sci. Food Saf. 2021, 20, 401–428. [Google Scholar] [CrossRef] [PubMed]

- Lam, A.C.Y.; Can Karaca, A.; Tyler, R.T.; Nickerson, M.T. Pea Protein Isolates: Structure, Extraction, and Functionality. Food Rev. Int. 2018, 34, 126–147. [Google Scholar] [CrossRef]

- De Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; Squeo, G.; Summo, C. Physicochemical and Sensorial Evaluation of Meat Analogues Produced from Dry-Fractionated Pea and Oat Proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef]

- Thiébaud, M.; Dumay, E.; Cheftel, J.C. Influence of Process Variables on the Characteristics of a High Moisture Fish Soy Protein Mix Texturized by Extrusion Cooking. LWT Food Sci. Technol. 1996, 29, 526–535. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, B.; Wei, Y. Effects of the Specific Mechanical Energy on the Physicochemical Properties of Texturized Soy Protein during High-Moisture Extrusion Cooking. J. Food Eng. 2014, 121, 32–38. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, B.; Boom, R.; van der Goot, A.J. Air Bubbles in Calcium Caseinate Fibrous Material Enhances Anisotropy. Food Hydrocoll. 2019, 87, 497–505. [Google Scholar] [CrossRef]

- Rahate, K.A.; Madhumita, M.; Prabhakar, P.K. Nutritional Composition, Anti-Nutritional Factors, Pretreatments-Cum-Processing Impact and Food Formulation Potential of Faba Bean (Vicia faba L.): A Comprehensive Review. LWT Food Sci. Technol. 2021, 138, 110796. [Google Scholar] [CrossRef]

- FAO. FAO/INFOODS Databases FAO/INFOODS Global Food Composition Database for Pulses Version 1.0 (PulsesDM1.0) uPulses Database. 2017. Available online: http://www.fao.org/infoods/infoods/tables-and-databases/faoinfoods-databases/en (accessed on 21 February 2021).

- Pietsch, V.L.; Bühler, J.M.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein Concentrate: Influence of Thermomechanical Treatment on Protein-Protein Interactions and Rheological Properties. J. Food Eng. 2019, 251, 11–18. [Google Scholar] [CrossRef]

- Singh, J.; Beniwal, A.S.; Hardacre, A.; Singh, H. Meat Analogs: Protein Restructuring during Thermomechanical Processing. Compr. Rev. Food Sci. Food Saf. 2021, 1–29. [Google Scholar] [CrossRef]

- Eriksson, J. Extruded Vegetable Proteins—An Investigation of the Influence of Selected Additives upon the Texturization Process of Pea Protein Isolate during High Moisture Food Extrusion. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2019. [Google Scholar]

- Mazaheri Tehrani, M.; Ehtiati, A.; Sharifi Azghandi, S. Application of Genetic Algorithm to Optimize Extrusion Condition for Soy-Based Meat Analogue Texturization. J. Food Sci. Technol. 2017, 54, 1119–1125. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singhal, A.; Karaca, A.C.; Tyler, R.; Singhal, A.; Karaca, A.C.; Tyler, R.; Nickerson, M. Pulse Proteins: From Pulse from Processing to Structure-Function Relationships. In Grain Legumes; Goyal, A., Ed.; Intech Open: London, UK, 2016. [Google Scholar]

- Zhang, J.; Liu, L.; Liu, H.; Yoon, A.; Rizvi, S.S.H.; Wang, Q. Changes in Conformation and Quality of Vegetable Protein during Texturization Process by Extrusion. Crit. Rev. Food Sci. Nutr. 2019, 59, 3267–3280. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Yellow Pea | Faba Bean | ||

|---|---|---|---|---|

| Isolate Commercial | Isolate Local | Concentrate Commercial | Isolate Local | |

| Moisture (%) | 6 ± 0.2 b | 2 ± 0.1 c | 9 ± 0.2 a | 2 ± 0.3 c |

| Ash (%) | 4 ± 0.1 d | 5 ± 0.1 c | 6 ± 0.1 a | 5 ± 0.1 b |

| Protein (%) | 79 ± 1 c | 81 ± 1 b | 56 ± 1 d | 88 ± 1 a |

| Fat (%) | 0.2 ± 0.0 d | 3 ± 0.1 b | 3 ± 0.1 a | 0.3 ± 0.0 c |

| Carbohydrate, by difference (%) | 9.2 ± 0.7 b | 7.6 ± 0.4 c | 15 ± 1 a | 2.9 ± 0.5 d |

| Total dietary fibre (%) | 1.6 ± 0.1 b | 1.6 ± 0.1 b | 10 ± 0.4 a | 1.3 ± 0.2 b |

| WHC (mL/g) | 3 ± 0.1 b | 4 ± 0.1 a | 1 ± 0.0 d | 3 ± 0.1 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferawati, F.; Zahari, I.; Barman, M.; Hefni, M.; Ahlström, C.; Witthöft, C.; Östbring, K. High-Moisture Meat Analogues Produced from Yellow Pea and Faba Bean Protein Isolates/Concentrate: Effect of Raw Material Composition and Extrusion Parameters on Texture Properties. Foods 2021, 10, 843. https://doi.org/10.3390/foods10040843

Ferawati F, Zahari I, Barman M, Hefni M, Ahlström C, Witthöft C, Östbring K. High-Moisture Meat Analogues Produced from Yellow Pea and Faba Bean Protein Isolates/Concentrate: Effect of Raw Material Composition and Extrusion Parameters on Texture Properties. Foods. 2021; 10(4):843. https://doi.org/10.3390/foods10040843

Chicago/Turabian StyleFerawati, Ferawati, Izalin Zahari, Malin Barman, Mohammed Hefni, Cecilia Ahlström, Cornelia Witthöft, and Karolina Östbring. 2021. "High-Moisture Meat Analogues Produced from Yellow Pea and Faba Bean Protein Isolates/Concentrate: Effect of Raw Material Composition and Extrusion Parameters on Texture Properties" Foods 10, no. 4: 843. https://doi.org/10.3390/foods10040843