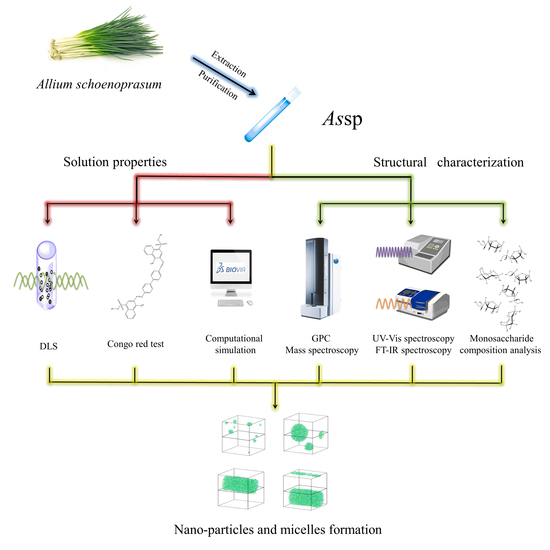

Purification, Characterization, and Self-Assembly of the Polysaccharide from Allium schoenoprasum

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Methods

2.2.1. Extraction and Purification of AssP

2.2.2. Gel Permeation Chromatography

2.2.3. Mass Spectroscopy

2.2.4. Monosaccharide Composition Analysis

2.2.5. UV-Vis Spectroscopy

2.2.6. FT-IR Spectroscopy

2.2.7. Dynamic Light Scattering

2.2.8. Congo-Red Test

2.2.9. Computational Hydrodynamic Behavior Simulation

3. Results

3.1. Extraction, Purification, and Molecular Weight Characterization of AssP

3.2. Structural Characterization of AssP

3.3. Tertiary Structure and Solution Behavior of AssP

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stajner, D.; Canadanovic-Brunet, J.; Pavlovic, A. Allium schoenoprasum L., as a natural antioxidant. Phytother. Res. 2004, 18, 522–524. [Google Scholar] [CrossRef]

- Stajner, D.; Popovic, B.M.; Calic-Dragosavac, D.; Malencic, D.; Zdravkovic-Korac, S. Comparative study on Allium schoenoprasum cultivated plant and Allium schoenoprasum tissue culture organs antioxidant status. Phytother. Res. 2011, 25, 1618–1622. [Google Scholar] [CrossRef]

- Bezmaternykh, K.V.; Shirshova, T.I.; Beshlei, I.V.; Matistov, N.V.; Smirnova, G.V.; Oktyabr’skii, O.N.; Volodin, V.V. Antioxidant Activity of Extracts from Allium schoenoprasum L. and Rubus chamaemorus L. Growing in the Komi Republic. Pharm. Chem. J. 2014, 48, 116–120. [Google Scholar] [CrossRef]

- Kucekova, Z.; Mlcek, J.; Humpolicek, P.; Rop, O.; Valasek, P.; Saha, P. Phenolic compounds from Allium schoenoprasum, Tragopogon pratensis and Rumex acetosa and their antiproliferative effects. Molecules 2011, 16, 9207–9217. [Google Scholar] [CrossRef] [PubMed]

- Timite, G.; Mitaine-Offer, A.C.; Miyamoto, T.; Tanaka, C.; Mirjolet, J.F.; Duchamp, O.; Lacaille-Dubois, M.A. Structure and cytotoxicity of steroidal glycosides from Allium schoenoprasum. Phytochemistry 2013, 88, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Shirshova, T.I.; Beshlei, I.V.; Deryagina, V.P.; Ryzhova, N.I.; Matistov, N.V. Chemical composition of Allium schoenoprasum leaves and inhibitory effect of their extract on tumor growth in mice. Pharm. Chem. J. 2013, 46, 672–675. [Google Scholar] [CrossRef]

- Shirshova, T.I.; Beshlei, I.V.; Deryagina, V.P.; Ryzhova, N.I. The Component Composition of Steroid Glycosides Extracted from the Fruits of Allium schoenoprasum L. and Assessment of Their Effects on the Growth of Transplanted Tumors in Mice. Pharm. Chem. J. 2014, 48, 328–331. [Google Scholar] [CrossRef]

- Barazani, O.; Dudai, N.; Khadka, U.R.; Golan-Goldhirsh, A. Cadmium accumulation in Allium schoenoprasum L. grown in an aqueous medium. Chemosphere 2004, 57, 1213–1218. [Google Scholar] [CrossRef]

- Kapolna, E.; Fodor, P. Bioavailability of selenium from selenium-enriched green onions (Allium fistulosum) and chives (Allium schoenoprasum) after ‘in vitro’ gastrointestinal digestion. Int. J. Food Sci. Nutr. 2007, 58, 282–296. [Google Scholar] [CrossRef]

- Eisazadeh, S.; Asadi Kapourchal, S.; Homaee, M.; Noorhosseini, S.A.; Damalas, C.A. Chive (Allium schoenoprasum L.) response as a phytoextraction plant in cadmium-contaminated soils. Environ. Sci. Pollut. Res. Int. 2019, 26, 152–160. [Google Scholar] [CrossRef]

- Zhang, Y.; Shi, X.P.; Zhang, W.M. Study on the optimization of extraction technology and antioxidation activity of Fistular onion stalk (Allium schoenoprasum L.) polysaccharide. Sci. Technol. Food Ind. 2010, 31, 255–258. [Google Scholar]

- Zhang, Y.; Shi, X.P.; Jiang, H.F.; Zhang, W.M.; Jin, J.H. Study on Reducing Blood Lipid and Prevention of Alcohol Liver of Fistular Onion Stalk (Allium schoenoprasum L.) Polysaccharides. J. Food Sci. Biotechnol. 2010, 29, 521–525. [Google Scholar]

- Chen, Y.; Mao, W.; Wang, B.; Zhou, L.; Gu, Q.; Chen, Y.; Zhao, C.; Li, N.; Wang, C.; Shan, J.; et al. Preparation and characterization of an extracellular polysaccharide produced by the deep-sea fungus Penicillium griseofulvum. Bioresour. Technol. 2013, 132, 178–181. [Google Scholar] [CrossRef] [PubMed]

- Goo, B.G.; Baek, G.; Choi, D.J.; Park, Y.I.; Synytsya, A.; Bleha, R.; Seong, D.H.; Lee, C.G.; Park, J.K. Characterization of a renewable extracellular polysaccharide from defatted microalgae Dunaliella tertiolecta. Bioresour. Technol. 2013, 129, 343–350. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.; Xia, F.; Feng, K.; Sun, G.; Gao, X.; Sun, L.; Jiang, R.; Tian, D.; Sun, X. Structural characterization and in vitro antitumor activity of a novel polysaccharide isolated from the fruiting bodies of Pleurotus ostreatus. Bioresour. Technol. 2009, 100, 1682–1686. [Google Scholar] [CrossRef]

- Sun, Y.; Liang, H.; Zhang, X.; Tong, H.; Liu, J. Structural elucidation and immunological activity of a polysaccharide from the fruiting body of Armillaria mellea. Bioresour. Technol. 2009, 100, 1860–1863. [Google Scholar] [CrossRef] [PubMed]

- Rout, S.; Banerjee, R. Free radical scavenging, anti-glycation and tyrosinase inhibition properties of a polysaccharide fraction isolated from the rind from Punica granatum. Bioresour. Technol. 2007, 98, 3159–3163. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Zhou, F.; Yang, D. Curdlan conformation change during its hydrolysis by multi-domain beta-1,3-glucanases. Food Chem. 2019, 287, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Han, Y.; Sun, C.; Dai, L.; Yang, S.; Wei, Y.; Mao, L.; Yuan, F.; Gao, Y. Effect of molecular weight of hyaluronan on zein-based nanoparticles: Fabrication, structural characterization and delivery of curcumin. Carbohydr. Polym. 2018, 201, 599–607. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.J.; Lv, Q.Q.; Zhang, B.; Chen, H.Q. Structural characterization and hepatoprotective activities of polysaccharides from the leaves of Toona sinensis (A. Juss) Roem. Carbohydr. Polym. 2019, 212, 89–101. [Google Scholar] [CrossRef]

- Zhao, Y.; You, L.Y.; Lu, Z.Y.; Sun, C.C. Dissipative particle dynamics study on the multicompartment micelles self-assembled from the mixture of diblock copolymer poly(ethyl ethylene)-block-poly(ethylene oxide) and homopolymer poly(propylene oxide) in aqueous solution. Polymer 2009, 50, 5333–5340. [Google Scholar] [CrossRef]

- Groot, R.D.; Warren, P.B. Dissipative particle dynamics: Bridging the gap between atomistic and mesoscopic simulation. J. Chem. Phys. 1997, 107, 4423–4435. [Google Scholar] [CrossRef]

- Golunski, S.; Astolfi, V.; Carniel, N.; de Oliveira, D.; Di Luccio, M.; Mazutti, M.A.; Treichel, H. Ethanol precipitation and ultrafiltration of inulinases from Kluyveromyces marxianus. Sep. Purif. Technol. 2011, 78, 261–265. [Google Scholar] [CrossRef]

- Zhang, Y. Study on Extraction, Purification and Biological Activity of Fistular Onion Stalk (Allium schoenoprasum L.) Polysaccharides. Master Thesis, Nanjing Agricultural University, Nanjing, China, 2009. [Google Scholar]

- Yan, J.K.; Wang, Y.Y.; Qiu, W.Y.; Shao, N. Three-phase partitioning for efficient extraction and separation of polysaccharides from Corbicula fluminea. Carbohydr. Polym. 2017, 163, 10–19. [Google Scholar] [CrossRef]

- Liu, Q.; Yao, C.; Sun, Y.; Chen, W.; Tan, H.; Cao, X.; Xue, S.; Yin, H. Production and structural characterization of a new type of polysaccharide from nitrogen-limited Arthrospira platensis cultivated in outdoor industrial-scale open raceway ponds. Biotechnol. Biofuels 2019, 12, 131. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Liu, J.; Zheng, P.; Li, M.; Zhou, Y.; Huang, L.; Chen, L.; Shuai, L. Promoting enzymatic hydrolysis of lignocellulosic biomass by inexpensive soy protein. Biotechnol. Biofuels 2019, 12, 51. [Google Scholar] [CrossRef]

- Smith, P.J.; Wang, H.T.; York, W.S.; Pena, M.J.; Urbanowicz, B.R. Designer biomass for next-generation biorefineries: Leveraging recent insights into xylan structure and biosynthesis. Biotechnol. Biofuels 2017, 10, 286. [Google Scholar] [CrossRef]

- Zeng, Y.; Himmel, M.E.; Ding, S.Y. Visualizing chemical functionality in plant cell walls. Biotechnol. Biofuels 2017, 10, 263. [Google Scholar] [CrossRef]

- Hartig, S.M.; Greene, R.R.; DasGupta, J.; Carlesso, G.; Dikov, M.M.; Prokop, A.; Davidson, J.M. Multifunctional nanoparticulate polyelectrolyte complexes. Pharm. Res. 2007, 24, 2353–2369. [Google Scholar] [CrossRef]

- Verma, M.L.; Dhanya, B.S.; Sukriti; Rani, V.; Thakur, M.; Jeslin, J.; Kushwaha, R. Carbohydrate and protein based biopolymeric nanoparticles: Current status and biotechnological applications. Int. J. Biol. Macromol. 2020, 154, 390–412. [Google Scholar] [CrossRef]

- Rajaonarivony, M.; Vauthier, C.; Couarraze, G.; Puisieux, F.; Couvreur, P. Development of a New Drug Carrier Made from Alginate. J. Pharm. Sci. 1993, 82, 912–917. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Wu, X.S. Preparation and characterization of agarose hydrogel nanoparticles for protein and peptide drug delivery. Pharm. Dev. Technol. 1997, 2, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Calvo, P.; RemunanLopez, C.; VilaJato, J.L.; Alonso, M.J. Novel hydrophilic chitosan-polyethylene oxide nanoparticles as protein carriers. J. Appl. Polym. Sci. 1997, 63, 125–132. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Zheng, J.; Li, Z.; Cai, Z.; Wang, F.; Yang, D. Purification, Characterization, and Self-Assembly of the Polysaccharide from Allium schoenoprasum. Foods 2021, 10, 1352. https://doi.org/10.3390/foods10061352

Zhang F, Zheng J, Li Z, Cai Z, Wang F, Yang D. Purification, Characterization, and Self-Assembly of the Polysaccharide from Allium schoenoprasum. Foods. 2021; 10(6):1352. https://doi.org/10.3390/foods10061352

Chicago/Turabian StyleZhang, Fengrui, Jun Zheng, Zeyu Li, Zixuan Cai, Fengqiao Wang, and Dong Yang. 2021. "Purification, Characterization, and Self-Assembly of the Polysaccharide from Allium schoenoprasum" Foods 10, no. 6: 1352. https://doi.org/10.3390/foods10061352

APA StyleZhang, F., Zheng, J., Li, Z., Cai, Z., Wang, F., & Yang, D. (2021). Purification, Characterization, and Self-Assembly of the Polysaccharide from Allium schoenoprasum. Foods, 10(6), 1352. https://doi.org/10.3390/foods10061352