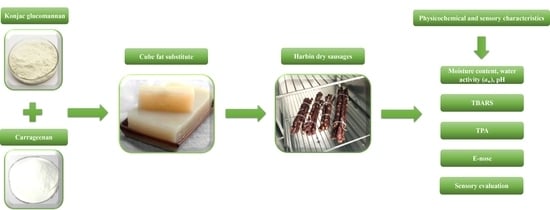

Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. CFS Preparation

2.3. Harbin Dry Sausage Preparation

2.4. Moisture Content and aw

2.5. pH and TBARS Values

2.6. Colour Measurement

2.7. Texture Profile Analysis

2.8. E-Nose Analysis

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content and aw

3.2. pH and TBARS Values

3.3. Colour Analysis

3.4. TPA

3.5. E-Nose Analysis

3.6. Sensory Analysis

3.7. HCA Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Q.; Kong, B.; Han, Q.; Xia, X.; Xu, L. The role of bacterial fermentation in lipolysis and lipid oxidation in Harbin dry sausages and its flavour development. LWT Food Sci. Technol. 2017, 77, 389–396. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Triki, M.; Herrero, A.; Rodriguez-Salas, L.; Jiménez-Colmenero, F. Konjac gel as pork backfat replacer in dry fermented sausages: Processing and quality characteristics. Meat Sci. 2012, 92, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Bray, G.A.; Paeratakul, S.; Popkin, B. Dietary fat and obesity: A review of animal, clinical and epidemiological studies. Physiol. Behav. 2004, 83, 549–555. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.-S.; Choi, J.-H.; Han, D.-J.; Kim, H.-Y.; Lee, M.-A.; Kim, H.-W.; Lee, J.-W.; Chung, H.-J.; Kim, C.-J. Optimization of replacing pork back fat with grape seed oil and rice bran fiber for reduced-fat meat emulsion systems. Meat Sci. 2010, 84, 212–218. [Google Scholar] [CrossRef]

- Chen, Y.; Jia, X.; Sun, F.; Jiang, S.; Liu, H.; Liu, Q.; Kong, B. Using a stable pre-emulsified canola oil system that includes porcine plasma protein hydrolysates and oxidized tannic acid to partially replace pork fat in frankfurters. Meat Sci. 2020, 160, 107968. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). Available online: https://www.who.int/publications/i/item/924120916X (accessed on 28 January 2002).

- Chinese Dietary Guidelines (CDG). Available online: http://dg.cnsoc.org/article/04/8a2389fd575f695101577a31ca7602d5.html (accessed on 30 September 2016).

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasaran, I.; Bloukas, J. Effect of fat level and partial replacement of pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Liaros, N.; Katsanidis, E.; Bloukas, J. Effect of the ripening time under vacuum and packaging film permeability on processing and quality characteristics of low-fat fermented sausages. Meat Sci. 2009, 83, 589–598. [Google Scholar] [CrossRef]

- Olivares, A.; Navarro, J.L.; Salvador, A.; Flores, M. Sensory acceptability of slow fermented sausages based on fat content and ripening time. Meat Sci. 2010, 86, 251–257. [Google Scholar] [CrossRef] [Green Version]

- Koutsopoulos, D.; Koutsimanis, G.; Bloukas, J. Effect of carrageenan level and packaging during ripening on processing and quality characteristics of low-fat fermented sausages produced with olive oil. Meat Sci. 2008, 79, 188–197. [Google Scholar] [CrossRef]

- Zhu, Y.; Guo, L.; Tang, W.; Yang, Q. Beneficial effects of Jerusalem artichoke powder and olive oil as animal fat replacers and natural healthy compound sources in Harbin dry sausages. Poult. Sci. 2020, 99, 7147–7158. [Google Scholar] [CrossRef]

- Al-Ghazzewi, F.H.; Khanna, S.; Tester, R.F.; Piggott, J. The potential use of hydrolysed konjac glucomannan as a prebiotic. J. Sci. Food Agric. 2007, 87, 1758–1766. [Google Scholar] [CrossRef]

- Wang, X.; Xie, Y.; Li, X.; Liu, Y.; Yan, W. Effects of partial replacement of pork back fat by a camellia oil gel on certain quality characteristics of a cooked style Harbin sausage. Meat Sci. 2018, 146, 154–159. [Google Scholar] [CrossRef]

- Alejandre, M.; Poyato, C.; Ansorena, D.; Astiasarán, I. Linseed oil gelled emulsion: A successful fat replacer in dry fermented sausages. Meat Sci. 2016, 121, 107–113. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Ruiz-Capillas, C. Healthy oil combination stabilized in a konjac matrix as pork fat replacement in low-fat, PUFA-enriched, dry fermented sausages. LWT-Food Sci. Technol. 2013, 51, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Campagnol, P.C.B.; dos Santos, B.A.; Wagner, R.; Terra, N.N.; Pollonio, M.A.R. Amorphous cellulose gel as a fat substitute in fermented sausages. Meat Sci. 2012, 90, 36–42. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, S.C.; Jia, X.W.; Cao, C.A.; Kong, B.H.; Liu, Q. Effect of different gelling agents on the physical and chemical properties of cube fat analogue. Food Res. Develop. 2018, 39, 12–18. (In Chinese) [Google Scholar]

- Chen, Q.; Kong, B.; Sun, Q.; Dong, F.; Liu, Q. Antioxidant potential of a unique LAB culture isolated from Harbin dry sausage: In vitro and in a sausage model. Meat Sci. 2015, 110, 180–188. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Available online: https://www.aoac.org/?s=Association+of+Official+Analytical+Chemists (accessed on 16 November 1995).

- Chen, J.; Hu, Y.; Wen, R.; Liu, Q.; Chen, Q.; Kong, B. Effect of NaCl substitutes on the physical, microbial and sensory characteristics of Harbin dry sausage. Meat Sci. 2019, 156, 205–213. [Google Scholar] [CrossRef]

- Sun, Q.; Zhao, X.; Chen, H.; Zhang, C.; Kong, B. Impact of spice extracts on the formation of biogenic amines and the physicochemical, microbiological and sensory quality of dry sausage. Food Control. 2018, 92, 190–200. [Google Scholar] [CrossRef]

- Wen, R.; Hu, Y.; Zhang, L.; Wang, Y.; Chen, Q.; Kong, B. Effect of NaCl substitutes on lipid and protein oxidation and flavor development of Harbin dry sausage. Meat Sci. 2019, 156, 33–43. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Wen, R.; Sun, F.; Wang, Y.; Kong, B.; Chen, Q. Collaborative analysis on differences in volatile compounds of Harbin red sausages smoked with different types of woodchips based on gas chromatography–mass spectrometry combined with electronic nose. LWT Food Sci. Technol. 2021, 143, 111144. [Google Scholar] [CrossRef]

- Yin, X.; Lv, Y.; Wen, R.; Wang, Y.; Chen, Q.; Kong, B. Characterization of selected Harbin red sausages on the basis of their flavour profiles using HS-SPME-GC/MS combined with electronic nose and electronic tongue. Meat Sci. 2021, 172, 108345. [Google Scholar] [CrossRef]

- Kong, B.; Xiong, Y.L.; Fang, C.; Thompson, K.R.; Metts, L.S.; Muzinic, L.A.; Webster, C.D. Influence of Gender and Spawning on Meat Quality of Australian Red Claw Crayfish (Cherax quadricarinatus) Stored at 2 °C. J. Food Sci. 2006, 71, E320–E325. [Google Scholar] [CrossRef] [Green Version]

- International Standard Organisation (ISO). Available online: https://www.iso.org/standard/50125.html (accessed on 1 December 2014).

- International Standard Organisation (ISO). Available online: https://www.iso.org/standard/36385.html (accessed on 1 December 2007).

- Jiang, S.; Zhao, S.; Jia, X.; Wang, H.; Zhang, H.; Liu, Q.; Kong, B. Thermal gelling properties and structural properties of myofibrillar protein including thermo-reversible and thermo-irreversible curdlan gels. Food Chem. 2020, 311, 126018. [Google Scholar] [CrossRef]

- Bolin, H.R. Relation of Moisture to Water Acitivity in Prunes and Raisins. J. Food Sci. 1980, 45, 1190–1192. [Google Scholar] [CrossRef]

- García, M.L.; Dominguez, R.; Galvez, M.; Casas, C.; Selgas, M. Utilization of cereal and fruit fibres in low fat dry fermented sausages. Meat Sci. 2002, 60, 227–236. [Google Scholar] [CrossRef]

- Mendoza, E.; García, M.L.; Casas, C.; Selgas, M. Inulin as fat substitute in low fat, dry fermented sausages. Meat Sci. 2001, 57, 387–393. [Google Scholar] [CrossRef]

- Wang, Y.; Li, F.; Zhuang, H.; Chen, X.; Li, L.; Qiao, W.; Zhang, J. Effects of plant polyphenols and α-tocopherol on lipid oxidation, residual nitrites, biogenic amines, and N-nitrosamines formation during ripening and storage of dry-cured bacon. LWT-Food Sci. Technol. 2015, 60, 199–206. [Google Scholar] [CrossRef]

- Ulu, H. Evaluation of three 2-thiobarbituric acid methods for the measurement of lipid oxidation in various meats and meat products. Meat Sci. 2004, 67, 683–687. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Colmenero, F.J.; Ruiz-Capillas, C. Chilled storage characteristics of low-fat, n-3 PUFA-enriched dry fermented sausage reformulated with a healthy oil combination stabilized in a konjac matrix. Food Control. 2013, 31, 158–165. [Google Scholar] [CrossRef]

- Valencia, I.; Ansorena, D.; Astiasarán, I. Nutritional and sensory properties of dry fermented sausages enriched with n−3 PUFAs. Meat Sci. 2006, 72, 727–733. [Google Scholar] [CrossRef]

- Josquin, N.M.; Linssen, J.P.; Houben, J.H. Quality characteristics of Dutch-style fermented sausages manufactured with partial replacement of pork back-fat with pure, pre-emulsified or encapsulated fish oil. Meat Sci. 2012, 90, 81–86. [Google Scholar] [CrossRef]

- Škaljac, S.; Jokanović, M.; Tomović, V.; Ivić, M.; Tasić, T.; Ikonić, P.; Šojić, B.; Džinić, N.; Petrović, L. Influence of smoking in traditional and industrial conditions on colour and content of polycyclic aromatic hydrocarbons in dry fermented sausage “Petrovská klobása”. LWT Food Sci. Technol. 2018, 87, 158–162. [Google Scholar] [CrossRef]

- Liu, P.; Wang, S.; Zhang, H.; Wang, H.; Kong, B. Influence of glycated nitrosohaemoglobin prepared from porcine blood cell on physicochemical properties, microbial growth and flavour formation of Harbin dry sausages. Meat Sci. 2019, 148, 96–104. [Google Scholar] [CrossRef]

- Utrilla, M.; Ruiz, A.G.; Soriano, A. Effect of partial reduction of pork meat on the physicochemical and sensory quality of dry ripened sausages: Development of a healthy venison salchichon. Meat Sci. 2014, 98, 785–791. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Guàrdia, M.D.; Serra, X.; Gou, P.; Arnau, J. Sensory characterisation and consumer acceptability of potassium chloride and sunflower oil addition in small-caliber non-acid fermented sausages with a reduced content of sodium chloride and fat. Meat Sci. 2016, 112, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Mora-Gallego, H.; Serra, X.; Guàrdia, M.D.; Arnau, J. Effect of reducing and replacing pork fat on the physicochemical, instrumental and sensory characteristics throughout storage time of small caliber non-acid fermented sausages with reduced sodium content. Meat Sci. 2014, 97, 62–68. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Hu, Y.; Wen, R.; Wang, Y.; Qin, L.; Kong, B. Characterisation of the flavour profile of dry fermented sausages with different NaCl substitutes using HS-SPME-GC-MS combined with electronic nose and electronic tongue. Meat Sci. 2021, 172, 108338. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Cao, J.; Pei, Z.; Wei, P.; Xiang, D.; Cao, X.; Shen, X.; Li, C. Volatile flavour components and the mechanisms underlying their production in golden pompano (Trachinotus blochii) fillets subjected to different drying methods: A comparative study using an electronic nose, an electronic tongue and SDE-GC-MS. Food Res. Int. 2019, 123, 217–225. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Song, J.; Bi, J.; Meng, X.; Wu, X. Characterization of volatile profile from ten different varieties of Chinese jujubes by HS-SPME/GC–MS coupled with E-nose. Food Res. Int. 2018, 105, 605–615. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lin, R.; Cheng, S.; Tan, M. Water dynamics changes and protein denaturation in surf clam evaluated by two-dimensional LF-NMR T1-T2 relaxation technique during heating process. Food Chem. 2020, 320, 126622. [Google Scholar] [CrossRef] [PubMed]

| Treatments | Lean Meat | Back Fat | CFS |

|---|---|---|---|

| Control | 900 | 100 | - |

| FS1 | 900 | 80 | 20 |

| FS2 | 900 | 60 | 40 |

| FS3 | 900 | 40 | 60 |

| FS4 | 900 | 20 | 80 |

| Sensors | Representative Material Species | Description |

|---|---|---|

| W1 C | Aromatic compounds | Sensitive to aromatic constituents, benzenes |

| W5 S | Broad range | Sensitive to nitrogen oxides |

| W3 C | Aromatic | Sensitive to aroma, ammonia |

| W6 S | Hydrogen | Sensitive to hydrides |

| W5 C | Arom-aliph | Sensitive to short-chain alkane aromatic components |

| W1 S | Broad-methane | Sensitive to methyl compounds |

| W1 W | Sulphur-organic | Sensitive to sulphides |

| W2 S | Broad-alcohol | Sensitive to alcohols, aldehydes and ketones |

| W2 W | Sulph-chlor | Sensitive to organic sulphides |

| W3 S | Methane-aliph | Sensitive to long-chain alkanes |

| Fermentation Time (d) | |||||

|---|---|---|---|---|---|

| 0 | 1 | 4 | 7 | ||

| moisture content (%) | Control | 62.52 ± 0.05 Ad | 53.39 ± 0.32 Ba | 38.37 ± 0.38 Ca | 28.57 ± 0.45 Da |

| FS1 | 63.32 ± 0.38 Ac | 52.06 ± 0.28 Bb | 37.12 ± 0.31 Ca | 27.31 ± 0.34 Da | |

| FS2 | 64.35 ± 0.25 Ab | 50.50 ± 0.38 Bc | 35.63 ± 0.43 Cb | 27.55 ± 0.39 Da | |

| FS3 | 64.88 ± 0.07 Ab | 48.35 ± 0.31 Bd | 32.64 ± 0.35 Cc | 24.36 ± 0.64 Db | |

| FS4 | 65.53 ± 0.18 Aa | 47.83 ± 0.22 Bd | 30.32 ± 0.74 Cd | 22.06 ± 0.46 Dc | |

| water activity (aw) | Control | 0.95 ± 0.01 Ab | 0.92 ± 0.01 Ba | 0.87 ± 0.01 Ca | 0.84 ± 0.01 Da |

| FS1 | 0.96 ± 0.01 Aab | 0.90 ± 0.01 Bb | 0.86 ± 0.01 Ca | 0.82 ± 0.01 Db | |

| FS2 | 0.96 ± 0.01 Aa | 0.91 ± 0.01 Bb | 0.84 ± 0.01 Cb | 0.81 ± 0.01 Db | |

| FS3 | 0.96 ± 0.01 Aa | 0.90 ± 0.01 Bbc | 0.83 ± 0.01 Cc | 0.79 ± 0.01 Dc | |

| FS4 | 0.97 ± 0.01 Aa | 0.90 ± 0.01 Bc | 0.80 ± 0.01 Cd | 0.78 ± 0.01 Dd | |

| Fermentation Time (d) | |||||

|---|---|---|---|---|---|

| 0 | 1 | 4 | 7 | ||

| L*-value | Control | 61.30 ± 1.01 Aa | 50.42 ± 0.71 Ba | 37.51 ± 1.29 Ca | 31.74 ± 0.61 Da |

| FS1 | 60.91 ± 0.70 Aa | 47.03 ± 0.25 Bb | 33.58 ± 0.71 Cb | 31.71 ± 0.36 Da | |

| FS2 | 60.58 ± 0.54 Aa | 45.68 ± 0.21 Bc | 32.54 ± 0.62 Cbc | 29.92 ± 0.58 Db | |

| FS3 | 60.69 ± 0.60 Aa | 43.68 ± 0.16 Bd | 30.40 ± 0.82 Ccd | 28.59 ± 0.66 Db | |

| FS4 | 60.28 ± 0.39 Aa | 43.27 ± 0.18 Bd | 29.49 ± 0.46 Cd | 26.81 ± 0.51 Dc | |

| a*-value | Control | 10.11 ± 0.04 Cd | 12.84 ± 0.04 Bb | 14.13 ± 0.14 Ac | 14.42 ± 0.12 Ac |

| FS1 | 10.23 ± 0.05 Cd | 13.04 ± 0.10 Bb | 14.29 ± 0.13 Ac | 14.43 ± 0.22 Ac | |

| FS2 | 10.52 ± 0.14 Cc | 13.41 ± 0.49 Bab | 14.77 ± 0.11 ABb | 14.96 ± 0.07 Ab | |

| FS3 | 12.07 ± 0.06 Cb | 14.00 ± 0.15 Ba | 15.62 ± 0.20 Aa | 15.77 ± 0.12 Aa | |

| FS4 | 12.34 ± 0.04 Ca | 13.97 ± 0.05 Ba | 15.84 ± 0.14 Aa | 15.95 ± 0.10 Aa | |

| b*-value | Control | 14.04 ± 0.10 Cc | 14.07 ± 0.28 Cc | 14.28 ± 0.12 Bd | 14.88 ± 0.03 Ac |

| FS1 | 14.17 ± 0.15 Cbc | 14.15 ± 0.17 Cbc | 14.41 ± 0.08 Bc | 14.95 ± 0.07 Ac | |

| FS2 | 14.26 ± 0.23 Cb | 14.31 ± 0.20 Cb | 14.66 ± 0.18 Bb | 15.13 ± 0.12 Ab | |

| FS3 | 14.67 ± 0.08 Ca | 14.97 ± 0.03 Ba | 14.92 ± 0.10 Ba | 15.83 ± 0.11 Aa | |

| FS4 | 14.64 ± 0.22 Ca | 14.96 ± 0.13 Ba | 14.86 ± 0.04 Ba | 15.67 ± 0.23 Aa | |

| Fermentation Time (d) | Treatments | Hardness (N) | Springiness | Chewiness (N) | Resilience |

|---|---|---|---|---|---|

| 0 | Control | 13.61 ± 1.07 Ba | 0.63 ± 0.02 Aa | 4.45 ± 0.37 Ba | 0.23 ± 0.01 Aa |

| FS1 | 13.98 ± 0.71 Ba | 0.62 ± 0.05 Aa | 4.34 ± 0.31 Ba | 0.20 ± 0.01 Aab | |

| FS2 | 12.71 ± 0.68 Bab | 0.61 ± 0.06 Aab | 4.15 ± 0.22 Bab | 0.19 ± 0.01 Ab | |

| FS3 | 12.28 ± 0.63 Bab | 0.58 ± 0.04 Ab | 3.73 ± 0.27 Bb | 0.17 ± 0.01 Ac | |

| FS4 | 11.16 ± 0.84 Bb | 0.58 ± 0.05 Ab | 3.47 ± 0.17 Bb | 0.16 ± 0.01 Ad | |

| 7 | Control | 60.73 ± 1.17 Ac | 0.59 ± 0.04 Ba | 17.99 ± 0.13 Ac | 0.17 ± 0.01 Ba |

| FS1 | 61.66 ± 0.67 Ac | 0.58 ± 0.03 Ba | 18.53 ± 0.39 Ab | 0.16 ± 0.01 Ba | |

| FS2 | 63.17 ± 1.16 Abc | 0.56 ± 0.04 Bb | 18.65 ± 0.53 Ab | 0.16 ± 0.01 Ba | |

| FS3 | 64.66 ± 1.34 Aab | 0.54 ± 0.07 Bc | 21.24 ± 0.67 Aa | 0.13 ± 0.01 Bb | |

| FS4 | 67.34 ± 0.95 Aa | 0.55 ± 0.05 Bc | 22.32 ± 0.41 Aa | 0.11 ± 0.01 Bc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhao, J.; Li, X.; Liu, Q.; Kong, B. Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages. Foods 2021, 10, 1460. https://doi.org/10.3390/foods10071460

Chen J, Zhao J, Li X, Liu Q, Kong B. Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages. Foods. 2021; 10(7):1460. https://doi.org/10.3390/foods10071460

Chicago/Turabian StyleChen, Jiaxin, Jinhai Zhao, Xin Li, Qian Liu, and Baohua Kong. 2021. "Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages" Foods 10, no. 7: 1460. https://doi.org/10.3390/foods10071460

APA StyleChen, J., Zhao, J., Li, X., Liu, Q., & Kong, B. (2021). Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages. Foods, 10(7), 1460. https://doi.org/10.3390/foods10071460