Effect of Quinoa (Chenopodium quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Quinoa Starch Extraction

2.2. Analysis of the Chemical Composition of Quinoa Starch

2.3. Preparation of Chicken Meatballs with Starch (Corn and Quinoa) and Quinoa Seeds

2.4. Water-Holding Capacity (WHC)

2.5. Determination of Total Volatile Basic Nitrogen (TVB-N)

- a: total volume of NaOH used to titrate for sample solution (mL)

- b: total volume of NaOH used to titrate for distilled water (mL)

- f: factor of 0.01 N NaOH, w: sample weight (g), d: dilution rate

2.6. Determination of Thiobarbituric Acid Reactive Substances (TBARS)

2.7. Determination of DPPH Free Radical Scavenging Activity

2.8. Instrumental Color Analysis

2.9. Texture Profile Analysis (TPA) of Chicken Meatballs

2.10. Acceptance Test of Chicken Meatballs

2.11. Statistical Analyses

3. Results and Discussion

3.1. Chemical Composition of Quinoa Starch and Water-Holding Capacity

3.2. Effect of Quinoa Seeds and Starch on Total Volatile Basic Nitrogen (TVB-N), Thiobarbituric Acid Reactive Substances (TBARS), and DPPH Free Radical Scavenging Activity

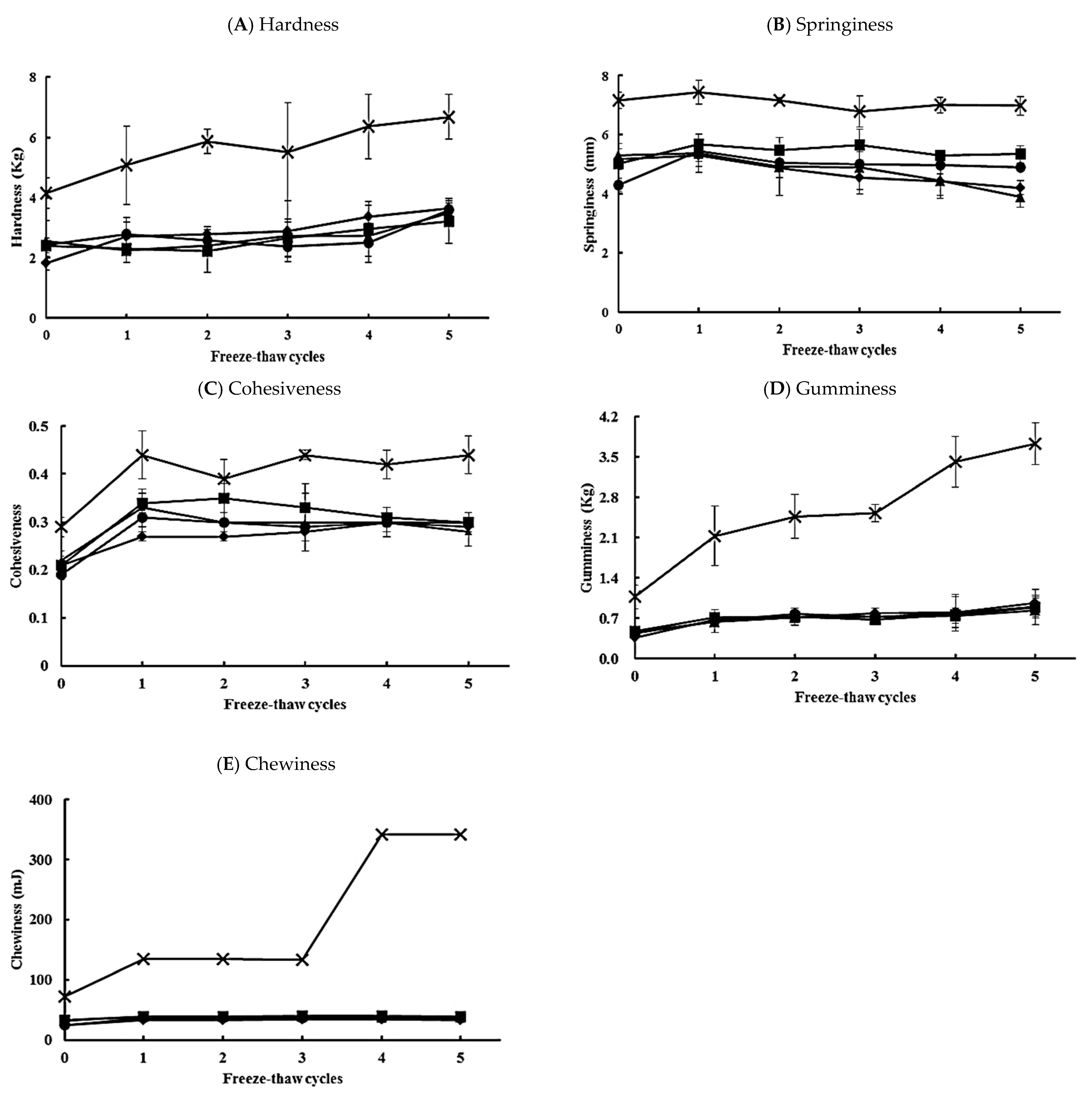

3.3. Effect of Quinoa Starch and Seeds on the Textural Properties of Chicken Meatballs

3.4. Effect of Quinoa Seeds and Starch on the Color of Chicken Meatballs during F-T Cycles

3.5. Effect of Quinoa Seeds and Starch on the Sensory Score

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giatrakou, V.; Ntzimani, A.; Savvaidis, I. Effect of chitosan and thyme oil on a ready to cook chicken product. Food Micro 2010, 27, 132–136. [Google Scholar] [CrossRef]

- Alexandrakis, D.; Downey, G.; Scannell, A.G. Rapid non-destructive detection of spoilage of intact chicken breast muscle using near-infrared and Fourier transform mid-infrared spectroscopy and multivariate statistics. Food Bioprocess. Technol. 2012, 5, 338–347. [Google Scholar] [CrossRef]

- Islam, M.A.; Haque, M.A.; Ferdwsi, M.J.; Ali, M.Y.; Hashem, M.A. Formulation of value added chicken meatball with different level of wheat flour SAARC. J. Agric. 2018, 16, 205–213. [Google Scholar] [CrossRef]

- Ali, S.; Zhang, W.; Rajput, N.; Khan, M.A.; Li, C.B.; Zhou, G.H. Effect of multiple freeze–thaw cycles on the quality of chicken breast meat. Food Chem. 2015, 173, 808–814. [Google Scholar] [CrossRef]

- Rahman, M.H.; Hossain, M.M.; Rahman, S.M.E.; Hashem, M.A.; Oh, D.H. Effect of Repeated Freeze-Thaw Cycles on Beef Quality and Safety. Korean J. Food Sci. Anim. Resour. 2014, 34, 482–495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bobreneva, I.V.; Baioumy, A.A.; Tvorogova, A.A.; Shobanova, T.V. Possibility of using quinoa seeds (Chenopodium quinoa) in meat products and its impact on nutritional and organoleptic characteristics. Biosci. Res. 2018, 15, 3307–3315. [Google Scholar]

- Fernández-López, J.; Viuda-Martos, M.; Pérez-Alvarez, J.A. Quinoa and chia products as ingredients for healthier processed meat products: Technological strategies for their application and effects on the final product. Curr. Opin. Food Sci. 2021, 40, 26–32. [Google Scholar] [CrossRef]

- Pereira, E.; Encina-Zelada, C.; Barros, L.; Gonzales-Barron, U.; Cadavez, V.; Ferreira, I.C. Chemical and nutritional characterization of Chenopodium quinoa Willd. (quinoa) grains: A good alternative to nutritious food. Food Chem. 2019, 280, 110–114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vega-Galvez, A.; Miranda, M.; Vergara, J.; Uribe, E.; Puente, L.; Martinez, E.A. Nutrition facts and functional potential of quinoa (Chenopodium quinoa Willd.), an ancient Andean grain: A review. J. Sci. Food Agric. 2010, 90, 2541–2547. [Google Scholar] [CrossRef] [PubMed]

- Gordillo-Bastidas, E.; Díaz-Rizzolo, D.A.; Roura, E.; Massanés, T.; Gomis, R. Quinoa (Chenopodium quinoa Willd.), from Nutritional Value to Potential Health Benefits: An Integrative Review. J. Nutr. Food Sci. 2016, 6, 1000497. [Google Scholar] [CrossRef] [Green Version]

- Hirose, Y.; Fujita, T.; Ishii, T.; Ueno, N. Antioxidative properties and flavonoid composition of Chenopodium quinoa seeds cultivated in Japan. Food Chem. 2010, 119, 1300–1306. [Google Scholar] [CrossRef]

- Steffolani, M.E.; León, A.E.; Pérez, G.T. Study of the physicochemical and functional characterization of quinoa and kañiwa starches. Starch Stärke 2013, 65, 976–983. [Google Scholar] [CrossRef]

- Lindeboom, N.; Chang, P.R.; Tyler, R.T. Analytical, biochemical and physicochemical aspects of starch granule size, with emphasis on small granule starches: A review. Starch Stärke 2004, 56, 89–99. [Google Scholar] [CrossRef]

- Jiang, F.; Du, C.; Guo, Y.; Fu, J.; Jiang, W.; Du, S.K. Physicochemical and structural properties of starches isolated from quinoa varieties. Food Hydrocoll. 2020, 101, 105515. [Google Scholar] [CrossRef]

- Li, G.; Zhu, F. Quinoa starch: Structure, properties, and applications. Carbohydr. Polym. 2018, 181, 851–861. [Google Scholar] [CrossRef]

- Ahamed, N.T.; Singhal, R.S.; Kulkarni, P.R.; Pal, M. Physicochemical and functional properties of Chenopodium quinoa starch. Carbohydr. Polym. 1996, 31, 99–103. [Google Scholar] [CrossRef]

- Lindeboom, N. Studies on the Characterization, Biosynthesis, and Isolation of Starch and Protein from Quinoa (Chenopodium quinoa Willd.). Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 25 June 2005. [Google Scholar]

- Contreras-Jiménez, B.; Torres-Vargas, O.L.; Rodríguez-García, M.E. Physicochemical characterization of quinoa (Chenopodium quinoa) flour and isolated starch. Food Chem. 2019, 298, 124982. [Google Scholar] [CrossRef] [PubMed]

- Shokry, A.M. The usage of quinoa flour as a potential ingredient in production of meat burger with functional proterties. Middle East. J. Appl. Sci. 2016, 6, 1128–1137. [Google Scholar]

- Özer, C.O.; Seçen, S.M. Effects of quinoa flour on lipid and protein oxidation in raw and cooked beef burger during long term frozen storage. Food Sci. Technol. 2018, 38, 221–227. [Google Scholar] [CrossRef] [Green Version]

- Bagdatli, A. The influence of quinoa (Chenopodium quinoa Willd.) flour on the physicochemical, textural and sensorial properties of beef meatball. Ital. J. Food Sci. 2018, 30, 280–288. [Google Scholar] [CrossRef]

- Bahmanyar, F.; Hosseini, S.M.; Mirmoghtadaie, L.; Shojaee-Aliabadi, S. Effects of replacing soy protein and bread crumb with quinoa and buckwheat flour in functional beef burger formulation. Meat Sci. 2021, 172, 108305. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Lee, Y.J.; Kim, Y.H.; Yoon, K.S. Antioxidant and antimicrobial activities of quinoa (Chenopodium quinoa Willd.) seeds cultivated in Korea. Prev. Nutr. Food Sci. 2017, 22, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, S.; Zhu, F. Physicochemical properties of quinoa starch. Carbohydr. Polym. 2016, 137, 328–338. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis of AOAC, 17th ed.; International Association of Official Analytical Communities: Gakthersburg, MD, USA, 2000; Available online: http://www.eoma.aoac.org (accessed on 15 March 2020).

- AACC. International Methods, 11st ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2000; Available online: http://methods.aaccnet.org/default.aspx (accessed on 12 March 2020).

- Williams, P.C.; Kuzina, F.D.; Hlynka, I. Rapid Colorimetric Procedure for Estimating the Amylose Content of Starches and Flours. Available online: https://www.cerealsgrains.org/publications/cc/backissues/1970/Documents/CC1970a58.html (accessed on 12 March 2020).

- Ministry of Food and Drug Safety (MFDS). Korean Food Code. Available online: http://foodsafetykorea.go.kr/foodcode/index.jsp. (accessed on 13 October 2020).

- Ryu, K.S.; Shim, K.S.; Shin, D. Effect of grape pomace powder addition on TBARS and color of cooked pork sausages during storage. Food Sci. Anim. Resour. 2014, 34, 200–206. [Google Scholar] [CrossRef] [Green Version]

- Qwele, K.; Hugo, A.; Oyedemi, S.O.; Moyo, B.; Masika, P.J.; Muchenje, V. Chemical composition, fatty acid content and antioxidant potential of meat from goats supplemented with Moringa (Moringa oleifera) leaves, sunflower cake, and grass hay. Meat Sci. 2013, 93, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Watanabe, K.; Mitsunaga, T. Characterization of storage starches from quinoa, barley and adzuki seeds. Carbohydr. Polym. 2002, 49, 13–22. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Li-Chan, E.C.Y. Binding and textural properties of beef gels as affected by protein, κ-carrageenan and microbial transglutaminase addition. Food Res. Int. 2002, 35, 91–98. [Google Scholar] [CrossRef]

- Ikhlas, B.; Huda, N.; Noryati, I. Chemical composition and physicochemical properties of meatballs prepared from mechanically deboned quail meat using various types of flour. Int. J. Poult. Sci. 2011, 10, 30–37. [Google Scholar] [CrossRef] [Green Version]

- Ali, S.; Rajput, N.; Li, C.; Zhang, W.; Zhou, G. Effect of freeze-that cycles on lipid oxidation and myowater in broiler chickens. Braz. J. Poult. Sci. 2016, 18, 35–40. [Google Scholar] [CrossRef] [Green Version]

- Prestes, R.C.; Silva, L.B.; Torri, A.M.P.; Kubota, E.H.; Rosa, C.S.; Roman, S.S.; Kempka, A.P.; Demiate, I.M. Sensory and physicochemical evaluation of low-fat chicken mortadella with added native and modified starches. J. Food Sci. Technol. 2015, 52, 4360–4368. [Google Scholar] [CrossRef] [Green Version]

- Rolland-Sabaté, A.; Sfánchez, T.; Buléon, A.; Colonna, P.; Jaillais, B.; Ceballos, H.; Dufour, D. Structural characterization of novel cassava starches with low and high- amylose contents in comparison with other commercial sources. Food Hydrocoll. 2012, 27, 161–174. [Google Scholar] [CrossRef]

- Petracci, M.; Bianchi, M.; Mudalal, S.; Cavani, C. Functional ingredients for poultry meat products. Trends Food Sci. Technol. 2013, 33, 27–39. [Google Scholar] [CrossRef]

- Vinci, G.; Antonelli, M.L. Biogenic amines: Quality index of freshness in red and white meat. Food Control. 2002, 13, 519–524. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Zhao, J.; Wu, M. Nondestructive detection of total volatile basic nitrogen (TVB-N) content in pork meat by integrating hyperspectral imaging and colorimetric sensor combined with a nonlinear data fusion. Food Sci. Technol. 2015, 63, 268–274. [Google Scholar] [CrossRef]

- Patsias, A.; Badeka, A.V.; Savvaidis, I.N.; Kontominas, M.G. Combined effect of freeze chilling and MAP on quality parameters of raw chicken fillets. Food Microbiol. 2008, 25, 575–581. [Google Scholar] [CrossRef] [PubMed]

- Al-kahtani, H.A.; Abu-tarboush, H.M.; Bajaber, A.S.; Atia, M.; Abou-Arab, A.A.; El-mojaddidi, M.A. Chemical changes after irradiation and post-irradiation storage in tilapia and Spanish mackerel. J. Food Sci. 1996, 61, 729–733. [Google Scholar] [CrossRef]

- Song, L.; Gao, T.; Ma, R.X.; Jiang, Y.; Zhang, L.; Li, J.L.; Zhang, X.; Gao, F.; Zhou, G.H. Effect of different frozen storage temperatures and periods on the quality of chicken meatballs. J. Food Process. Pres. 2017, 41. [Google Scholar] [CrossRef]

- Alvarez-Jubete, L.; Wijngaard, H.; Arendt, E.K.; Gallagher, E. Polyphenol composition and in vitro antioxidant activity of amaranth, quinoa, buckwheat and wheat as affected by sprouting and baking. Food Chem. 2010, 119, 770–778. [Google Scholar] [CrossRef]

- Yael, B.; Liel, G.; Hana, B.; Ran, H.; Shmuel, G. Total phenolic content and antioxidant activity of red and yellow quinoa (Chenopodium quinoa Willd.) seed as affected by baking and cooking conditions. Food Nutr. Sci. 2012, 3, 1150–1155. [Google Scholar] [CrossRef] [Green Version]

- Nickel, J.; Spanier, L.P.; Botelho, F.T.; Gularte, M.A.; Helbig, E. Effect of different types of processing on the total phenolic compound content, antioxidant capacity, and saponin content of Chenopodium quinoa Willd. grains. Food Chem. 2016, 209, 139–143. [Google Scholar] [CrossRef]

- Wang, S.J. Starch Structure, Functionality, and Application in Foods; Springer Singapore: Singapore, 2020; Volume 179. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Singh, N. Some properties of corn starches II: Physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem. 2007, 101, 1499–1507. [Google Scholar] [CrossRef]

- Stikic, R.; Glamoclija, D.; Demin, M.; Vucelic-Radovic, B.; Jovanovic, Z.; Milojkovic- Opsenica, D.; Jacobsen, S.; Milovanovic, M. Agronomical and nutritional evaluation of quinoa seeds (Chenopodium quinoa Willd.) as an ingredient in bread formulations. J. Cereal Sci. 2012, 55, 132–138. [Google Scholar] [CrossRef]

- Schumacher, A.B.; Brandelli, A.; Macedo, F.C.; Pieta, L.; Klug, T.V.; de Jong, E.V. Chemical and sensory evaluation of dark chocolate with the addition of quinoa (Chenopodium quinoa Willd.). J. Food Sci. Technol. 2010, 47, 202–206. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Ingredient (g) | CS | QS | Q | CS-Q | QS-Q |

|---|---|---|---|---|---|

| Chicken breast meat | 77.95 | 77.95 | 70.45 | 67.95 | 67.95 |

| Quinoa seeds | 0 | 0 | 10 | 10 | 10 |

| Corn starch | 2.5 | - | - | 2.5 | - |

| quinoa starch | - | 2.5 | - | - | 2.5 |

| F-T Cycles | CS | QS | Q | CS-Q | QS-Q | |

|---|---|---|---|---|---|---|

| Cooking loss (%) | 0 | 15.30 ± 0.35 B | 15.35 ± 0.59 B | 25.87 ± 0.73 A | 14.03 ± 0.77 C | 13.86 ± 0.43 C |

| Drip loss (%) | 1 | 1.15 ± 0.03 Abc | 1.10 ± 0.06 Acd | 0.80 ± 0.26 Bc | 0.95 ± 0.06 ABc | 0.70 ± 0.18 Bc |

| 2 | 1.10 ± 0.11 Ac | 1.03 ± 0.04 Ad | 1.19 ± 0.03 Ab | 1.12 ± 0.12 Abc | 1.03 ± 0.13 Ab | |

| 3 | 1.27 ± 0.17 Abc | 1.24 ± 0.08 Abc | 1.37 ± 0.19 Ab | 1.21 ± 0.21 Aabc | 1.14 ± 0.10 Aab | |

| 4 | 1.37 ± 0.01 Aab | 1.29 ± 0.15 Ab | 1.45 ± 0.16 Ab | 1.33 ± 0.14 Aab | 1.28 ± 0.13 Aab | |

| 5 | 1.53 ± 0.17 Ba | 1.49 ± 0.11 Ba | 1.96 ± 0.27 Aa | 1.48 ± 0.27 Ba | 1.42 ± 0.23 Ba | |

| Reheating loss (%) | 1 | 21.71 ± 0.35 Ce | 21.34 ± 0.41 Cc | 26.30 ± 0.51 Ae | 23.45 ± 0.53 Bc | 23.80 ± 0.58 Bc |

| 2 | 22.48 ± 0.59 Cd | 23.22 ± 0.62 Bb | 27.29 ± 0.88 Ad | 23.44 ± 0.26 BCc | 24.07 ± 0.06 Bbc | |

| 3 | 24.80 ± 0.15 Bc | 23.72 ± 1.09 Cb | 28.61 ± 0.35 Ac | 23.39 ± 0.21 Cc | 24.41 ± 0.41 BCbc | |

| 4 | 25.65 ± 0.37 Bb | 24.51 ± 0.86 Cb | 30.14 ± 0.35 Ab | 24.66 ± 0.28 Cb | 24.72 ± 0.29 Cb | |

| 5 | 28.75 ± 0.22 Ba | 28.48 ± 0.36 Ba | 31.41 ± 0.25 Aa | 28.22 ± 0.26 Ba | 28.71 ± 0.32 Ba |

| F-T Cycles | CS | QS | Q | CS-Q | QS-Q | |

|---|---|---|---|---|---|---|

| TVB-N (mg %) | 0 | 10.10 ± 0.69 d | 10.73 ± 0.81 b | 0.94 ± 2.28 b | 10.52 ± 0.84 c | 9.68 ± 0.49 d |

| 1 | 12.41 ± 0.81 c | 12.94 ± 0.40 a | 13.05 ± 1.09 a | 13.05 ± 0.77 b | 12.20 ± 1.09 c | |

| 2 | 13.05 ± 0.60 bc | 13.15 ± 0.40 a | 13.68 ± 1.26 a | 13.68 ± 1.06 ab | 13.26 ± 0.42 bc | |

| 3 | 13.68 ± 0.54 ab | 13.68 ± 1.26 a | 13.89 ± 0.49 a | 13.36 ± 0.72 ab | 13.57 ± 0.99 bc | |

| 4 | 13.99 ± 0.63 ab | 13.78 ± 0.63 a | 14.10 ± 0.81 a | 13.05 ± 0.49 b | 15.26 ± 1.83 a | |

| 5 | 14.73 ± 0.60 a | 14.39 ± 2.90 a | 14.52 ± 0.42 a | 14.52 ± 0.42 a | 14.62 ± 0.40 ab | |

| TBARS (mg malonaldehyde/kg of sample) | 0 | 0.11 ± 0.01 Af | 0.09 ± 0.01 Bf | 0.11 ± 0.03 Ad | 0.11 ± 0.01 Ad | 0.12 ± 0.02 Ad |

| 1 | 0.30 ± 0.01 Be | 0.32 ± 0.01 Be | 0.31 ± 0.03 Bc | 0.36 ± 0.02 Ac | 0.31 ± 0.01 Bc | |

| 2 | 0.38 ± 0.08 Ad | 0.39 ± 0.04 Ad | 0.38 ± 0.04 Ac | 0.39 ± 0.05 Ac | 0.33 ± 0.06 Ac | |

| 3 | 0.67 ± 0.07 Ac | 0.67 ± 0.04 Ac | 0.65 ± 0.09 Ab | 0.70 ± 0.14 Ab | 0.69 ± 0.08 Ab | |

| 4 | 0.74 ± 0.06 ABb | 0.73 ± 0.04 ABb | 0.69 ± 0.06 Bb | 0.78 ± 0.08 Aab | 0.72 ± 0.05 ABb | |

| 5 | 0.90 ± 0.03 Aa | 0.84 ± 0.03 ABa | 0.85 ± 0.10 ABa | 0.81 ± 0.07 Ba | 0.79 ± 0.04 Ba | |

| DPPH free radical-scavenging activity (%) | 0 | 20.28 ± 0.58 Ba | 20.73 ± 0.29 Ba | 34.51 ± 0.63 Aa | 34.84 ± 0.34 Aa | 34.41 ± 0.21 Aa |

| 1 | 18.42 ± 1.69 Cb | 17.26 ± 0.97 Cb | 33.33 ± 1.03 Bb | 33.60 ± 0.67 ABb | 34.82 ± 0.47 Aa | |

| 2 | 17.72 ± 0.48 Cb | 18.16 ± 0.84 Cb | 25.25 ± 0.54 Ac | 25.23 ± 0.97 Ac | 22.23 ± 0.72 Bb | |

| 3 | 15.95 ± 1.21 Cc | 15.95 ± 1.21 Cc | 22.08 ± 0.80 Ad | 20.43 ± 1.48 Bd | 19.36 ± 1.03 Bc | |

| 4 | 5.42 ± 0.80 Cd | 8.06 ± 1.73 Bd | 20.85 ± 0.34 Ae | 20.31 ± 1.37 Ad | 19.24 ± 1.84 Ac | |

| 5 | ND | ND | 12.22 ± 1.78 Af | 11.04 ± 0.73 Ae | 10.87 ± 0.65 Ad |

| F-T Cycles | CS | QS | Q | CS-Q | QS-Q | |

|---|---|---|---|---|---|---|

| L* (lightness) | 0 | 79.53 ± 0.22 Ab | 79.47 ± 0.13 Aab | 73.82 ± 0.09 Bd | 74.00 ± 0.41 Bd | 73.89 ± 0.46 Bd |

| 1 | 79.50 ± 0.43 Ab | 79.55 ± 0.39 Aab | 75.15 ± 0.61 Bc | 75.01 ± 0.53 Bc | 74.59 ± 0.38 Bc | |

| 2 | 80.08 ± 1.10 Ab | 79.63 ± 0.28 Aa | 75.72 ± 0.03 Bb | 75.92 ± 0.56 Bb | 75.52 ± 0.41 Bb | |

| 3 | 81.27 ± 0.19 Aa | 79.93 ± 0.06 Ba | 75.87 ± 0.18 Cb | 76.35 ± 0.58 Cb | 75.20 ± 0.10 Db | |

| 4 | 81.24 ± 0.06 Aa | 79.15 ± 0.20 Bb | 76.82 ± 0.07 Da | 77.44 ± 0.28 Ca | 75.28 ± 0.12 Eb | |

| 5 | 81.67 ± 0.15 Aa | 79.54 ± 0.25 Bab | 76.20 ± 0.04 Eb | 77.67 ± 0.19 Ca | 76.50 ± 0.06 Da | |

| C* (chroma/ intensity) | 0 | 14.34 ± 0.27 Ca | 15.09 ± 0.12 BCa | 15.87 ± 0.14 ABa | 15.61 ± 0.34 ABa | 16.66 ± 1.26 Aa |

| 1 | 14.13 ± 0.05 Da | 15.01 ± 0.14 BCab | 15.50 ± 0.30 ABb | 14.81 ± 0.28 Cc | 15.67 ± 0.58 Aabc | |

| 2 | 13.74 ± 0.04 Cb | 14.99 ± 0.31 Bab | 15.38 ± 0.14 Ab | 14.81 ± 0.06 Bc | 15.34 ± 0.05 Abc | |

| 3 | 13.52 ± 0.11 Cb | 15.17 ± 0.07 Ba | 15.53 ± 0.22 ABb | 15.18 ± 0.04 Bb | 15.74 ± 0.47 Aab | |

| 4 | 13.64 ± 0.18 Db | 14.95 ± 0.06 Bab | 15.48 ± 0.01 Ab | 14.62 ± 0.09 Cc | 15.08 ± 0.13 Bbc | |

| 5 | 13.80 ± 0.17 Bb | 14.72 ± 0.06 Ab | 14.78 ± 0.05 Ac | 14.49 ± 0.16 Ac | 14.71 ± 0.18 Ac | |

| h* (hue) | 0 | 84.96 ± 0.71 Ba | 85.74 ± 0.19 Aa | 85.88 ± 0.05 Aa | 83.71 ± 0.20 Ca | 85.08 ± 0.04 Bb |

| 1 | 85.17 ± 0.96 Aa | 85.99 ± 0.08 Aa | 85.56 ± 0.58 Aa | 84.00± 0.51 Ba | 85.83 ± 0.54 Aa | |

| 2 | 85.74 ± 0.11 Aa | 86.02 ± 0.38 Aa | 85.56 ± 0.59 Aa | 83.81 ± 0.05 Ba | 84.31 ± 0.21 Bc | |

| 3 | 85.72 ± 0.26 Aa | 85.92 ± 0.17 Aa | 85.53 ± 0.01 Aa | 83.34 ± 0.63 Ca | 84.32 ± 0.23 Bc | |

| 4 | 85.67 ± 0.03 Aa | 86.05 ± 0.45 Aa | 85.52 ± 0.18 Aa | 83.32 ± 0.83 Ba | 83.99 ± 0.10 Bcd | |

| 5 | 85.60 ± 0.07 Aa | 86.11 ± 0.38 Aa | 85.38 ± 0.84 Aa | 83.30 ± 0.08 Ba | 83.64 ± 0.43 Bd | |

| ΔE* | 2.21 | 0.39 | 2.62 | 3.84 | 3.28 | |

| Sensory Properties 1 | CS | QS | Q | CS-Q | QS-Q |

|---|---|---|---|---|---|

| Appearance | 6.34 ± 1.47 a | 6.40 ± 1.56 a | 5.23 ± 1.70 b | 5.31 ± 1.75 b | 5.37 ± 1.83 b |

| Color | 5.97 ± 1.40 a | 6.09 ± 1.60 a | 5.66 ± 1.85 a | 5.69 ± 1.83 a | 5.91 ± 1.79 a |

| Flavor | 5.89 ± 1.59 a | 5.91 ± 1.70 a | 5.34 ± 1.41 a | 5.60 ± 1.75 a | 6.09 ± 1.52 a |

| Taste | 6.03 ± 1.44 a | 5.83 ± 1.56 a | 4.69 ± 1.62 b | 5.43 ± 1.63 ab | 5.97 ± 1.87 a |

| Texture | 5.57 ± 1.72 ab | 5.60 ± 1.63 ab | 5.23 ± 1.85 b | 5.71 ± 1.66 ab | 6.17 ± 1.99 a |

| Overall acceptability | 5.77 ± 1.54 a | 5.89 ± 1.53 a | 4.77 ± 1.44 b | 5.80 ± 1.51 a | 6.46 ± 1.77 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-H.; Lee, Y.-J.; Lim, J.-G.; Jeon, J.-H.; Yoon, K.-S. Effect of Quinoa (Chenopodium quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage. Foods 2021, 10, 1601. https://doi.org/10.3390/foods10071601

Park J-H, Lee Y-J, Lim J-G, Jeon J-H, Yoon K-S. Effect of Quinoa (Chenopodium quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage. Foods. 2021; 10(7):1601. https://doi.org/10.3390/foods10071601

Chicago/Turabian StylePark, Jin-Hwa, Yun-Jin Lee, Jeong-Gyu Lim, Ji-Hye Jeon, and Ki-Sun Yoon. 2021. "Effect of Quinoa (Chenopodium quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage" Foods 10, no. 7: 1601. https://doi.org/10.3390/foods10071601

APA StylePark, J.-H., Lee, Y.-J., Lim, J.-G., Jeon, J.-H., & Yoon, K.-S. (2021). Effect of Quinoa (Chenopodium quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage. Foods, 10(7), 1601. https://doi.org/10.3390/foods10071601