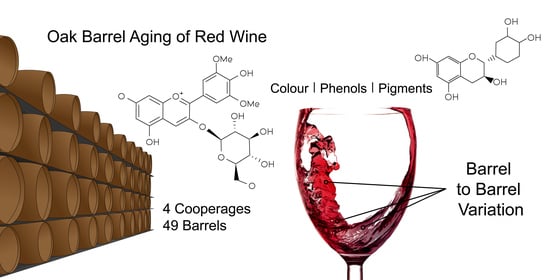

Effect of Barrel-to-Barrel Variation on Color and Phenolic Composition of a Red Wine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wine, Wooden Barrels, and Sampling

2.2. General Physical and Chemical Analysis

2.3. Color, Pigments, and Phenolic Composition

2.3.1. Chromatic Characteristics

2.3.2. Total Anthocyanins, Degree of Ionization of Anthocyanins, Ionized Anthocyanins, Total Pigments, Polymerization Index, Polymerized Pigments

2.3.3. Total Phenols, Flavonoid Phenols, Non-Flavonoid Phenols

2.3.4. Tanning Power

2.3.5. Color Due to Copigmentation

2.3.6. Flavanol Monomers and Proanthocyanidin According to Polymerization Degree

2.4. Statistical Analysis

3. Results and Discussion

3.1. Wine Aging

3.1.1. General Physical–Chemical Parameters

3.1.2. Pigments and Phenolic Composition

3.1.3. Chromatic Characteristics

3.2. Barrel-to-Barrel Variation

3.2.1. The Effect of the Cooperage

3.2.2. The Effect of the Barrel

3.3. Required Barrel Number

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Waterhouse, A.L.; Sacks, G.L.; Jeffery, D.W. Understanding Wine Chemistry, 1st ed.; John Wiley & Sons: Chichester, UK, 2016; ISBN 9781118627808. [Google Scholar]

- Ruiz De Adana, M.; López, L.M.; Sala, J.M. A Fickian model for calculating wine losses from oak casks depending on conditions in ageing facilities. Appl. Therm. Eng. 2005, 25, 709–718. [Google Scholar] [CrossRef]

- Cerdán, T.G.; Goñi, D.T.; Azpilicueta, C.A. Accumulation of volatile compounds during ageing of two red wines with different composition. J. Food Eng. 2004, 65, 349–356. [Google Scholar] [CrossRef]

- Chira, K.; Teissedre, P.L. Relation between volatile composition, ellagitannin content and sensory perception of oak wood chips representing different toasting processes. Eur. Food Res. Technol. 2013, 236, 735–746. [Google Scholar] [CrossRef]

- Morata, A.; López, C.; Tesfaye, W.; González, C.; Escott, C. Anthocyanins as Natural Pigments in Beverages. In Value-Added Ingredients and Enrichments of Beverages; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 383–428. ISBN 9780128166871. [Google Scholar]

- He, F.; Liang, N.N.; Mu, L.; Pan, Q.H.; Wang, J.; Reeves, M.J.; Duan, C.Q. Anthocyanins and their variation in red wines II. Anthocyanin derived pigments and their color evolution. Molecules 2012, 17, 1483–1519. [Google Scholar] [CrossRef] [Green Version]

- Es-Safi, N.E.; Cheynier, V. Flavanols and Anthocyanins as Potent Compounds in the Formation of New Pigments during Storage and Aging of Red Wine. In Red Wine Color: Revealing the Mysteries; Waterhouse, A.L., Kennedy, J.A., Eds.; American Chemical Society: Washington, WA, USA, 2004; pp. 143–159. [Google Scholar]

- Cheynier, V.; Dueñas-Paton, M.; Salas, E.; Maury, C.; Souquet, J.; Sarni-Manchado, P.; Fulcrand, H. Structure and Properties of Wine Pigments and Tannins. Am. J. Enol. Vitic. 2006, 57, 298–305. [Google Scholar]

- Escribano-Bailón, T.; Álvarez-García, M.; Rivas-Gonzalo, J.G.; Heredia, F.J.; Santos-Buelga, C. Color and stability of pigments derived from the acetaldehyde-mediated condensation between malvidin 3-O-glucoside and (+)-catechin. J. Agric. Food Chem. 2001, 49, 1213–1217. [Google Scholar] [CrossRef]

- De Freitas, V.A.; Mateus, N. Updating Wine Pigments. In Recent Advances in Polyphenol Research; Wiley-Blackwell: Hoboken, NJ, USA, 2010; pp. 59–89. ISBN 9781405193993. [Google Scholar]

- Salas, E.; Atanasova, V.; Meudec, E.; Mazauric, J.P.; Cheynier, V. Demonstration of the occurrence of flavanol—anthocyanin adducts in wine and in model solutions. Anal. Chim. Acta 2004, 513, 325–332. [Google Scholar] [CrossRef]

- Vidal, S.; Cartalade, D.; Souquet, J.M.; Fulcrand, H.; Cheynier, V. Changes in proanthocyanidin chain length in winelike model solutions. J. Agric. Food Chem. 2002, 50, 2261–2266. [Google Scholar] [CrossRef] [PubMed]

- Boulton, R. The Copigmentation of Anthocyanins and Its Role in the Color of Red Wine: A Critical Review. Am. J. Enol. Vitic. 2001, 52, 67–87. [Google Scholar]

- Haslam, E. In vino veritas: Oligomeric procyanidins and the ageing of red wines. Phytochemistry 1980, 19, 2577–2582. [Google Scholar]

- Cheynier, V. Polyphenols in foods are more complex than often thought 1–3. Am. J. Clin. Nutr. 2005, 81, 223–229. [Google Scholar] [CrossRef] [Green Version]

- Chira, K.; Jourdes, M.; Teissedre, P. Cabernet sauvignon red wine astringency quality control by tannin characterization and polymerization during storage. Eur. Food Res. Technol. 2012, 253–261. [Google Scholar] [CrossRef]

- Organisation Internationale de la Vigne et du Vin (OIV). International Code of Oenological Practices; Organisation Internationale de la Vigne et du Vin (OIV): Paris, France, 2017; ISBN 9791091799737. [Google Scholar]

- Mosedale, J.R.; Puech, J.L.; Feuillat, F. The influence on wine flavor of the oak species and natural variation of heartwood components. Am. J. Enol. Vitic. 1999, 50, 503–512. [Google Scholar]

- Doussot, F.; Pardon, P.; Dedier, J.; De Jeso, B. Individual, species and geographic origin influence on cooperage oak extractible content (Quercus robur L. and Quercus petraea Liebl.). Analusis 2000, 28, 960–965. [Google Scholar] [CrossRef] [Green Version]

- Miller, D.P.; Howell, G.S.; Michealis, C.S.; Dickmann, D.I. The Content of Phenolic Acid and Aldehyde Flavor Components of White Oak as Affected by Site and Species. Am. J. Enol. Vitic. 1992, 43, 333–338. [Google Scholar]

- Martínez, J.; Cadahía, E.; Fernández De Simón, B.; Ojeda, S.; Rubio, P. Effect of the seasoning method on the chemical composition of oak heartwood to cooperage. J. Agric. Food Chem. 2008, 56, 3089–3096. [Google Scholar] [CrossRef] [PubMed]

- Chira, K.; Teissedre, P.L. Extraction of oak volatiles and ellagitannins compounds and sensory profile of wine aged with French winewoods subjected to different toasting methods: Behaviour during storage. Food Chem. 2013, 140, 168–177. [Google Scholar] [CrossRef] [PubMed]

- Towey, J.P.; Waterhouse, A.L. Barrel-to-Barrel Variation of Volatile Oak Extractives in Barrel-Fermented Chardonnay. Am. J. Enol. Vitic. 1996, 47, 17–20. [Google Scholar]

- Pilet, A.; De Sousa, R.B.; Ricardo-da-Silva, J.M.; Catarino, S. Barrel-to-barrel variation of phenolic and mineral composition of red wine. BIO Web Conf. 2019, 12, 02011. [Google Scholar] [CrossRef] [Green Version]

- Lima Ferreira, M. Automatização da análise de vinhos—FTIR-Manuel Lima Ferreira. In Química Enológica—Métodos Analíticos. Avanços Recentes No Controlo Da Qualidade de Vinhos e de Outros Produtos Vitivinícolas; Curvelo-Garcia, A.S., Barros, P., Eds.; Publindústria: Porto, Portugal, 2015; pp. 101–113. [Google Scholar]

- Organisation Internationale de la Vigne et du Vin (OIV). Compendium of International Methods of Wine and Must Analysis, 1st ed.; Organisation Internationale de la Vigne et du Vin (OIV): Paris, France, 2020; ISBN 978-2-85038-016-7. [Google Scholar]

- Somers, T.C.; Evans, M.E. Spectral evaluation of young red wines: Anthocyanin equilibria, total phenolics, free and molecular SO2, “chemical age”. J. Sci. Food Agric. 1977, 28, 279–287. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P. Les dosage des composés phénoliquestotaux dans les vins rouges. Anal. Chim. Acta 1970, 52, 627–631. [Google Scholar]

- Kramling, T.E.; Singleton, V.L. An Estimate of the Nonflavonoid Phenols in Wines. Am. J. Enol. Vitic. 1969, 20, 86–92. [Google Scholar]

- De Freitas, V.; Mateus, N. Structural features of procyanidin interactions with salivary proteins. J. Agric. Food Chem. 2001, 49, 940–945. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Ricardo-da-Silva, J.M.; Spranger, I. Critical Factors of Vanillin Assay for Catechins and Proanthocyanidins. J. Agric. Food Chem. 1998, 46, 4267–4274. [Google Scholar] [CrossRef]

- Sun, B.; Leandro, C.; Ricardo Da Silva, J.M.; Spranger, I. Separation of Grape and Wine Proanthocyanidins According to Their Degree of Polymerization. J. Agric. Food Chem. 1998, 46, 1390–1396. [Google Scholar] [CrossRef]

- Everitt, B.S.; Skrondal, A. The Cambridge Dictionary of Statistics, 4th ed.; Cambridge University Press: Cambridge, UK, 2010; ISBN 978-0-511-78827-7. [Google Scholar]

- Gelman, A.; Hill, J. Data Analysis Using Regression and Multilevel/Hierarchical Models; Cambridge University Press: Cambridge, UK, 2007; pp. 437–447. ISBN 978-0-521-86706-1. [Google Scholar]

- Geng, S.; Hills, F.J. Biometrics in Agricultural Science; Kendall/Hunt Publishing Co.: Dubuque, IA, USA, 1989; ISBN 9780840354372. [Google Scholar]

- Martínez-Pérez, M.P.; Bautista-Ortín, A.B.; Durant, V.; Gómez-Plaza, E. Evaluating alternatives to cold stabilization in wineries: The use of carboxymethyl cellulose, potassium polyaspartate, electrodialysis and ion exchange resins. Foods 2020, 9, 1275. [Google Scholar] [CrossRef] [PubMed]

- Chira, K.; Pacella, N.; Jourdes, M.; Teissedre, P.L. Chemical and sensory evaluation of Bordeaux wines (Cabernet-Sauvignon and Merlot) and correlation with wine age. Food Chem. 2011, 126, 1971–1977. [Google Scholar] [CrossRef]

- Jarauta, I.; Cacho, J.; Ferreira, V. Concurrent Phenomena Contributing to the Formation of the Aroma of Wine during Aging in Oak Wood: An Analytical Study. J. Agric. Food Chem. 2005, 4166–4177. [Google Scholar] [CrossRef] [PubMed]

- Garde-Cerdán, T.; Ancín-Azpilicueta, C. Review of quality factors on wine ageing in oak barrels. Trends Food Sci. Technol. 2006, 17, 438–447. [Google Scholar] [CrossRef]

- Rasines-Perea, Z.; Jacquet, R.; Jourdes, M.; Quideau, S.; Teissedre, P.L. Ellagitannins and flavano-ellagitannins: Red wines tendency in different areas, barrel origin and ageing time in barrel and bottle. Biomolecules 2019, 9, 316. [Google Scholar] [CrossRef] [Green Version]

- Gambuti, A.; Capuano, R.; Tiziana, M.; Daniela, L.; Luigi, S. Effect of aging in new oak, one-year-used oak, chestnut barrels and bottle on color, phenolics and gustative proWle of three monovarietal red wines. Eur. Food Res. Technol. 2010, 231, 455–465. [Google Scholar] [CrossRef]

- Quaglieri, C.; Jourdes, M.; Waffo-Teguo, P.; Teissedre, P.L. Updated knowledge about pyranoanthocyanins: Impact of oxygen on their contents, and contribution in the winemaking process to overall wine color. Trends Food Sci. Technol. 2017, 67, 139–149. [Google Scholar] [CrossRef]

- Kyraleou, M.; Kallithraka, S.; Chira, K.; Tzanakouli, E.; Ligas, I.; Kotseridis, Y. Differentiation of wines treated with wood chips based on their phenolic content, volatile composition, and sensory parameters. J. Food Sci. 2015, 80, C2701–C2710. [Google Scholar] [CrossRef] [PubMed]

- Llaudy, M.D.C.; Canals, R.; González-Manzano, S.; Canals, J.M.; Santos-Buelga, C.; Zamora, F. Influence of micro-oxygenation treatment before oak aging on phenolic compounds composition, astringency, and color of red wine. J. Agric. Food Chem. 2006, 54, 4246–4252. [Google Scholar] [CrossRef] [PubMed]

- Fulcrand, H.; Atanasova, V.; Salas, E. The Fate of Anthocyanins in Wine: Are There Determining Factors? In Red Wine Color: Revealing the Mysteries; Waterhouse, A.L., Kennedy, J.A., Eds.; American Chemical Society: Washington, WA, USA, 2004; pp. 68–88. [Google Scholar]

- Fulcrand, H.; Dueñas, M.; Salas, E.; Cheynier, V. Phenolic Reactions during Winemaking and Aging. Am. J. Enol. Vitic. 2006, 57, 289–297. [Google Scholar]

- Cheynier, V.; Remy, S.; Fulcrand, H. Mechanisms of Anthocyanin and Tannin Changes during Winemaking and Aging. In Proceedings of the ASEV 50th Anniversary Annual Meeting, Washington, WA, USA, 19–23 June 2000; pp. 337–344. [Google Scholar]

- Spillmann, P.J.; Sefton, M.A.; Gawel, R. The effect of oak wood source, location of seasoning and coopering on the composition of volatile compounds in oak-matured wines. Aust. J. Grape Wine Res. 2008, 10, 216–226. [Google Scholar] [CrossRef]

- Sánchez-Gómez, R.; del Alamo-Sanza, M.; Martínez-Martínez, V.; Nevares, I. Study of the role of oxygen in the evolution of red wine colour under different ageing conditions in barrels and bottles. Food Chem. 2020, 328, 127040. [Google Scholar] [CrossRef] [PubMed]

- Del Alamo-Sanza, M.; Nevares, I. Oak wine barrel as an active vessel: A critical review of past and current knowledge. Crit. Rev. Food Sci. Nutr. 2018, 58, 2711–2726. [Google Scholar] [CrossRef]

| Analytical Parameter | Cooperage Effect | Cooperage A | Cooperage B | Cooperage C | Cooperage D | Average (A, B, C, D) | Bottle Matured |

|---|---|---|---|---|---|---|---|

| Density (g/mL) | ** | 0.9917 ± 0.0001 ab | 0.9918 ± 0.0001 a | 0.9918 ± 0.0001 a | 0.9916 ± 0.0001 b | 0.9917 ± 0.0001 | 0.9909 ± 0.0000 |

| Alcoholic Strength (% vol.) | ** | 13.4 ± 0.1 ab | 13.4 ± 0.0 ab | 13.3 ± 0.1 b | 13.4 ± 0.0 a | 13.4 ± 01 | 13.0 ± 0.0 |

| Total Dry Matter (g/L) | ** | 29.7 ± 0.2 b | 29.9 ± 0.2 a | 29.7 ± 0.1 ab | 29.7 ± 0.1 b | 29.7 ± 0.2 | 27.3 ± 0.0 |

| Residual Sugar (g/L) | *** | 1.8 ± 0.2 a | 1.5 ± 0.1 b | 2.0 ± 0.1 a | 1.9 ± 0.2 a | 1.8 ± 0.2 | 3.7 ± 0.1 |

| Total Acidity (g tartaric acid/L) | *** | 5.67 ± 0.10 b | 5.91 ± 0.02 a | 5.65 ± 0.08 b | 5.63 ± 0.10 b | 5.71 ± 0.07 | 5.71 ± 0.00 |

| Volatile Acidity (g acetic acid /L) | ** | 0.80 ± 0.05 ab | 0.73 ± 0.05 b | 0.83 ± 0.07 a | 0.75 ± 0.05 b | 0.78 ± 0.05 | 0.78 ± 0.00 |

| Total SO2 (mg/L) | ** | 86 ± 1 a | 83 ± 1 b | 86 ± 1 a | 86 ± 1 a | 86 ± 1 | 88 ± 1 |

| pH | ns | 3.44 ± 0.01 | 3.45 ± 0.01 | 3.45 ± 0.02 | 3.44 ± 0.01 | 3.44 ± 0.01 | 3.44 ± 0.00 |

| Ash (g/L) | ** | 3.30 ± 0.05 b | 3.37 ± 0.02 a | 3.29 ± 0.06 b | 3.28 ± 0.06 b | 3.31 ± 0.06 | 3.09 ± 0.03 |

| Sulfates (mg/L) | ns | 0.99 ± 0.01 | 0.98 ± 0.02 | 0.99 ± 0.01 | 0.99 ± 0.01 | 0.99 ± 0.01 | 0.38 ± 0.00 |

| Chloride (mg/L) | *** | 0.065 ± 0.001 b | 0.069 ± 0.001 a | 0.0645 ± 0.001 b | 0.065 ± 0.001 b | 0.066 ± 0.001 | 0.069 ± 0.001 |

| Analytical Parameter | Cooperage Effect | Cooperage A | Cooperage B | Cooperage C | Cooperage D | Average (A, B, C, D) | Bottle Matured |

|---|---|---|---|---|---|---|---|

| Total Phenols (mg/L gallic acid) | *** | 2050 ± 57 a | 1864 ± 65 b | 2081 ± 88 a | 2093 ± 33 a | 2022 ± 61 | 1948 ± 14 |

| Flavonoids (mg/L gallic acid) | *** | 1904 ± 56 a | 1724 ± 66 b | 1934 ± 88 a | 1946 ± 26 a | 1877 ± 59 | 1701 ± 13 |

| Non-flavonoids (mg/L gallic acid) | ns | 145 ± 12 | 140 ± 3 | 147 ± 5 | 147 ± 9 | 145 ± 7 | 248 ± 1 |

| Flavanol Monomers (mg/L) | ns | 14 ± 3 | 15 ± 3 | 16 ± 2 | 19 ± 5 | 16 ± 3 | 12 ± 4 |

| Oligomeric Proanthocyanidins (mg/L) | ns | 64 ± 20 | 57 ± 11 | 63 ± 21 | 71 ± 20 | 64 ± 18 | 38 ± 13 |

| Polymeric Proanthocyanidins (mg/L) | ns | 438 ± 66 | 585 ± 128 | 512 ± 58 | 576 ± 66 | 528 ± 80 | 462 ± 60 |

| Total Condensed Tannins (mg/L) | ns | 516 ± 76 | 658 ± 141 | 591 ± 62 | 667 ± 91 | 608 ± 93 | 512 ± 49 |

| Tanning Power (NTU/mL) | ** | 534 ± 24 ab | 504 ± 24 b | 540 ± 20 a | 541 ± 21 a | 530 ± 22 | 467 ± 16 |

| Total Pigments (a.u.) | ns | 15.1 ± 0.9 | 14 ± 2 | 15 ± 1 | 16.4 ± 0.8 | 15 ± 1 | 12.8 ± 0.2 |

| Polymerization Index (%) | ns | 54 ± 4 | 52 ± 3 | 54 ± 6 | 50 ± 4 | 52 ± 4 | 46 ± 1 |

| Polymerized Pigments (a.u.) | ** | 8.1 ± 0.2 a | 7.4 ± 0.9 b | 8.1 ± 0.2 a | 8.2 ± 0.3 a | 8.0 ± 0.4 | 5.9 ± 0.0 |

| Total Anthocyanins (mg/L malvidin 3-O-glucoside) | ns | 59 ± 21 | 63 ± 20 | 62 ± 33 | 83 ± 24 | 67 ± 24 | 80 ± 4 |

| Degree of Ionization of Anthocyanins (%) | ns | 60 ± 17 | 60 ± 20 | 64 ± 22 | 50 ± 8 | 58 ± 17 | 57 ± 5 |

| Ionized Anthocyanins (mg/L malvidin 3-O-glucoside) | ns | 33 ± 7 a | 36 ± 12 a | 35 ± 10 a | 40 ± 6 a | 36 ± 9 | 45 ± 2 |

| Color Intensity (a.u.) | *** | 20.03 ± 0.63 a | 18.71 ± 0.89 b | 20.22 ± 0.53 a | 20.48 ± 0.26 a | 19.86 ± 0.58 | 16.52 ± 0.16 |

| Tonality | ** | 0.674 ± 0.007 a | 0.645 ± 0.02 b | 0.668 ± 0.012 ab | 0.671 ± 0.006 a | 0.664 ± 0.011 | 0.627 ± 0.004 |

| Color due to Copigmentation (%) | ns | 51 ± 2 | 51 ± 1 | 51 ± 2 | 51 ± 2 | 51 ± 1 | 52 ± 1 |

| L*, Clarity (a.u.) [0 = black, 100 = colorless] | * | 52.4 ± 0.8 ab | 53.8 ± 1.1 a | 52.0 ± 1.0 ab | 51.3 ± 0.7 b | 52.4 ± 0.9 | 55.7 ± 0.1 |

| a*, Green-Red (a.u.) [green < 0 > red] | * | 44 ± 1 ab | 42 ± 1 b | 44 ± 2 ab | 45 ± 1 a | 44 ± 1 | 41 ± 0.0 |

| b*, Blue-Yellow (a.u.) [blue < 0 > yellow] | *** | 9.1 ± 1.1 a | 6.6 ± 1.2 b | 8.4 ± 0.9 ab | 9.6 ± 0.8 a | 8.5 ± 1.0 | −1.2 ± 0.0 |

| C*, Chroma (a.u.) | * | 44.5 ± 1.3 ab | 42.8 ± 1.3 b | 44.7 ± 1.6 a | 45.8 ± 0.9 a | 44.5 ± 1.3 | 41.3 ± 0.0 |

| H*, Tone or Angle of HUE (0–360°) | *** | 4.8 ± 0.6 b | 6.5 ± 1.0 a | 5.2 ± 0.5 b | 4.6 ± 0.4 b | 5.3 ± 0.7 | −33.7 ± 2.5 |

| Analytical Parameter | Analytical Method Variation (%) | Coefficient of Variation (CV) (%) and the Barrel Number Required for Results within the Called Percentage of the True Population Mean | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooperage A | Cooperage B | Cooperage C | Cooperage D | Average CV | ||||||||||||||

| CV | 5% | 10% | 15% | CV | 5% | 10% | 15% | CV | 5% | 10% | 15% | CV | 5% | 10% | 15% | |||

| Density (g/mL) | 0.1 | 0.0 | 1 | 1 | 1 | 0.0 | 1 | 1 | 1 | 0.0 | 1 | 1 | 1 | 0.0 | 1 | 1 | 1 | 0.0 ± 0.0 |

| pH | 0.1 | 0.4 | 1 | 1 | 1 | 0.4 | 1 | 1 | 1 | 0.3 | 1 | 1 | 1 | 0.5 | 1 | 1 | 1 | 0.4 ± 0.1 |

| Alcoholic Strength (% vol.) | 0.1 | 0.6 | 1 | 1 | 1 | 0.3 | 1 | 1 | 1 | 0.4 | 1 | 1 | 1 | 0.5 | 1 | 1 | 1 | 0.5 ± 0.1 |

| Total Dry Matter (g/L) | 0.1 | 0.6 | 1 | 1 | 1 | 0.3 | 1 | 1 | 1 | 0.6 | 1 | 1 | 1 | 0.4 | 1 | 1 | 1 | 0.5 ± 0.1 |

| Sulfates (mg/L) | 0.6 | 1.0 | 1 | 1 | 1 | 0.9 | 1 | 1 | 1 | 1.4 | 1 | 1 | 1 | 0.9 | 1 | 1 | 1 | 1 ± 0.2 |

| Total SO2 (mg/L) | 0.4 | 1.3 | 1 | 1 | 1 | 1.0 | 1 | 1 | 1 | 1.4 | 1 | 1 | 1 | 1.2 | 1 | 1 | 1 | 1.2 ± 0.2 |

| Total Acidity (g tartaric acid/L) | 0.2 | 1.7 | 1 | 1 | 1 | 1.8 | 1 | 1 | 1 | 0.3 | 1 | 1 | 1 | 1.4 | 2 | 1 | 1 | 1.3 ± 0.6 |

| Ash (g/L) | 0.9 | 1.5 | 1 | 1 | 1 | 1.8 | 1 | 1 | 1 | 0.7 | 2 | 1 | 1 | 1.9 | 2 | 1 | 1 | 1.5 ± 0.5 |

| Chloride (mg/L) | 0.3 | 1.8 | 2 | 1 | 1 | 1.8 | 1 | 1 | 1 | 0.8 | 1 | 1 | 1 | 1.8 | 2 | 1 | 1 | 1.5 ± 0.4 |

| L*, Clarity (a.u.) [0 = black, 100 = colorless] | 0.2 | 1.6 | 1 | 1 | 1 | 2.0 | 2 | 1 | 1 | 2.0 | 2 | 1 | 1 | 1.4 | 1 | 1 | 1 | 1.7 ± 0.3 |

| Tonality | 0.7 | 1.0 | 1 | 1 | 1 | 3.0 | 3 | 1 | 1 | 1.9 | 2 | 1 | 1 | 0.9 | 1 | 1 | 1 | 1.7 ± 0.9 |

| Color due to Copigmentation (%) | 1.1 | 3.6 | 5 | 2 | 1 | 0.6 | 1 | 1 | 1 | 3.2 | 4 | 1 | 1 | 3.3 | 4 | 1 | 1 | 2.7 ± 1.2 |

| a*, Green-Red (a.u.) [green < 0 > red] | 0.2 | 2.7 | 3 | 1 | 1 | 2.7 | 3 | 1 | 1 | 3.5 | 4 | 1 | 1 | 1.8 | 2 | 1 | 1 | 2.7 ± 0.6 |

| C*, Chroma (a.u.) | 0.2 | 2.9 | 3 | 1 | 1 | 3.0 | 3 | 1 | 1 | 3.6 | 5 | 2 | 1 | 1.9 | 2 | 1 | 1 | 2.9 ± 0.6 |

| Color Intensity (a.u.) | 0.5 | 3.2 | 4 | 1 | 1 | 4.7 | 8 | 2 | 1 | 2.6 | 3 | 1 | 1 | 1.2 | 1 | 1 | 1 | 2.9 ± 1.3 |

| Total Phenols (mg/L gallic acid) | 1.3 | 2.8 | 3 | 1 | 1 | 3.5 | 4 | 1 | 1 | 4.2 | 6 | 2 | 1 | 1.6 | 1 | 1 | 1 | 3 ± 1 |

| Flavonoids (mg/L gallic acid) | 1.3 | 3.0 | 3 | 1 | 1 | 3.8 | 5 | 2 | 1 | 4.5 | 7 | 2 | 1 | 1.4 | 1 | 1 | 1 | 3.2 ± 1.2 |

| Tanning Power (NTU/mL) | 2.7 | 4.4 | 7 | 2 | 1 | 4.7 | 7 | 2 | 1 | 3.7 | 5 | 2 | 1 | 3.9 | 5 | 2 | 1 | 4.2 ± 0.4 |

| Non-flavonoids (mg/L gallic acid) | 2.3 | 8.5 | 23 | 6 | 3 | 2.4 | 2 | 1 | 1 | 3.5 | 4 | 1 | 1 | 5.8 | 11 | 3 | 2 | 5.1 ± 2.3 |

| Polymerized Pigments (a.u.) | 0.9 | 2.9 | 3 | 1 | 1 | 12.3 | 48 | 12 | 6 | 2.6 | 3 | 1 | 1 | 3.7 | 5 | 2 | 1 | 5.3 ± 4 |

| Volatile Acidity (g acetic acid/L) | 0.2 | 6.1 | 12 | 3 | 2 | 6.7 | 14 | 4 | 2 | 6.5 | 20 | 5 | 3 | 7.9 | 15 | 4 | 2 | 6.8 ± 0.7 |

| Polymerization Index (%) | 2.9 | 7.6 | 19 | 5 | 3 | 6.6 | 14 | 4 | 2 | 11.8 | 44 | 11 | 5 | 8.0 | 21 | 6 | 3 | 8.5 ± 2 |

| Residual Sugar (g/L) | 2.5 | 12.6 | 51 | 13 | 6 | 8.7 | 6 | 2 | 1 | 4.0 | 17 | 5 | 2 | 7.3 | 24 | 6 | 3 | 8.2 ± 3.1 |

| Total Pigments (a.u.) | 3.6 | 5.9 | 11 | 3 | 2 | 13.2 | 55 | 14 | 7 | 9.5 | 29 | 8 | 4 | 4.7 | 7 | 2 | 1 | 8.3 ± 3.3 |

| H*, Tone or Angle of HUE (0–360°) | 0.7 | 12.8 | 52 | 13 | 6 | 16.1 | 104 | 26 | 12 | 10.4 | 34 | 9 | 4 | 8.4 | 23 | 6 | 3 | 11.9 ± 2.9 |

| b*, Blue-Yellow (a.u.) [blue < 0 > yellow] | 0.6 | 12.6 | 51 | 13 | 6 | 18.1 | 104 | 26 | 12 | 11.5 | 42 | 11 | 5 | 8.8 | 25 | 7 | 3 | 12.8 ± 3.4 |

| Polymeric Proanthocyanidins (mg/L) | 12.3 | 15.0 | 71 | 18 | 8 | 21.9 | 151 | 38 | 17 | 11.4 | 41 | 11 | 5 | 11.4 | 42 | 11 | 5 | 14.9 ± 4.3 |

| Total Condensed Tannins (mg/L) | 10.6 | 14.8 | 69 | 18 | 8 | 21.4 | 145 | 37 | 17 | 10.5 | 35 | 9 | 4 | 13.6 | 59 | 15 | 7 | 15.1 ± 4 |

| Flavanol Monomers (mg/L) | 13.8 | 20.0 | 125 | 32 | 14 | 22.5 | 160 | 40 | 18 | 12.9 | 53 | 14 | 6 | 27.0 | 229 | 58 | 26 | 20.6 ± 5.1 |

| Ionized Anthocyanins (mg/L malvidin 3-O-glucoside) | 17.4 | 21.4 | 144 | 36 | 16 | 33.5 | 353 | 89 | 40 | 29.4 | 271 | 68 | 31 | 15.8 | 79 | 20 | 9 | 25 ± 6.9 |

| Degree of Ionization of Anthocyanins (%) | 9.0 | 28.6 | 257 | 65 | 29 | 33.1 | 344 | 86 | 39 | 33.7 | 357 | 90 | 40 | 16.1 | 82 | 21 | 10 | 27.9 ± 7.1 |

| Oligomeric Proanthocyanidins (mg/L) | 15.4 | 30.9 | 310 | 76 | 34 | 19.2 | 116 | 29 | 13 | 33.7 | 356 | 89 | 40 | 28.3 | 252 | 63 | 28 | 28 ± 5.5 |

| Total Anthocyanins (mg/L malvidin 3-O-glucoside) | 15.9 | 35.6 | 398 | 100 | 45 | 30.9 | 299 | 75 | 34 | 53.8 | 908 | 227 | 101 | 28.35 | 253 | 64 | 29 | 37.2 ± 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfahl, L.; Catarino, S.; Fontes, N.; Graça, A.; Ricardo-da-Silva, J. Effect of Barrel-to-Barrel Variation on Color and Phenolic Composition of a Red Wine. Foods 2021, 10, 1669. https://doi.org/10.3390/foods10071669

Pfahl L, Catarino S, Fontes N, Graça A, Ricardo-da-Silva J. Effect of Barrel-to-Barrel Variation on Color and Phenolic Composition of a Red Wine. Foods. 2021; 10(7):1669. https://doi.org/10.3390/foods10071669

Chicago/Turabian StylePfahl, Leonard, Sofia Catarino, Natacha Fontes, António Graça, and Jorge Ricardo-da-Silva. 2021. "Effect of Barrel-to-Barrel Variation on Color and Phenolic Composition of a Red Wine" Foods 10, no. 7: 1669. https://doi.org/10.3390/foods10071669

APA StylePfahl, L., Catarino, S., Fontes, N., Graça, A., & Ricardo-da-Silva, J. (2021). Effect of Barrel-to-Barrel Variation on Color and Phenolic Composition of a Red Wine. Foods, 10(7), 1669. https://doi.org/10.3390/foods10071669