Assessment of Quality Indices and Their Influence on the Texture Profile in the Dry-Aging Process of Beef

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical Materials

2.3. Methods

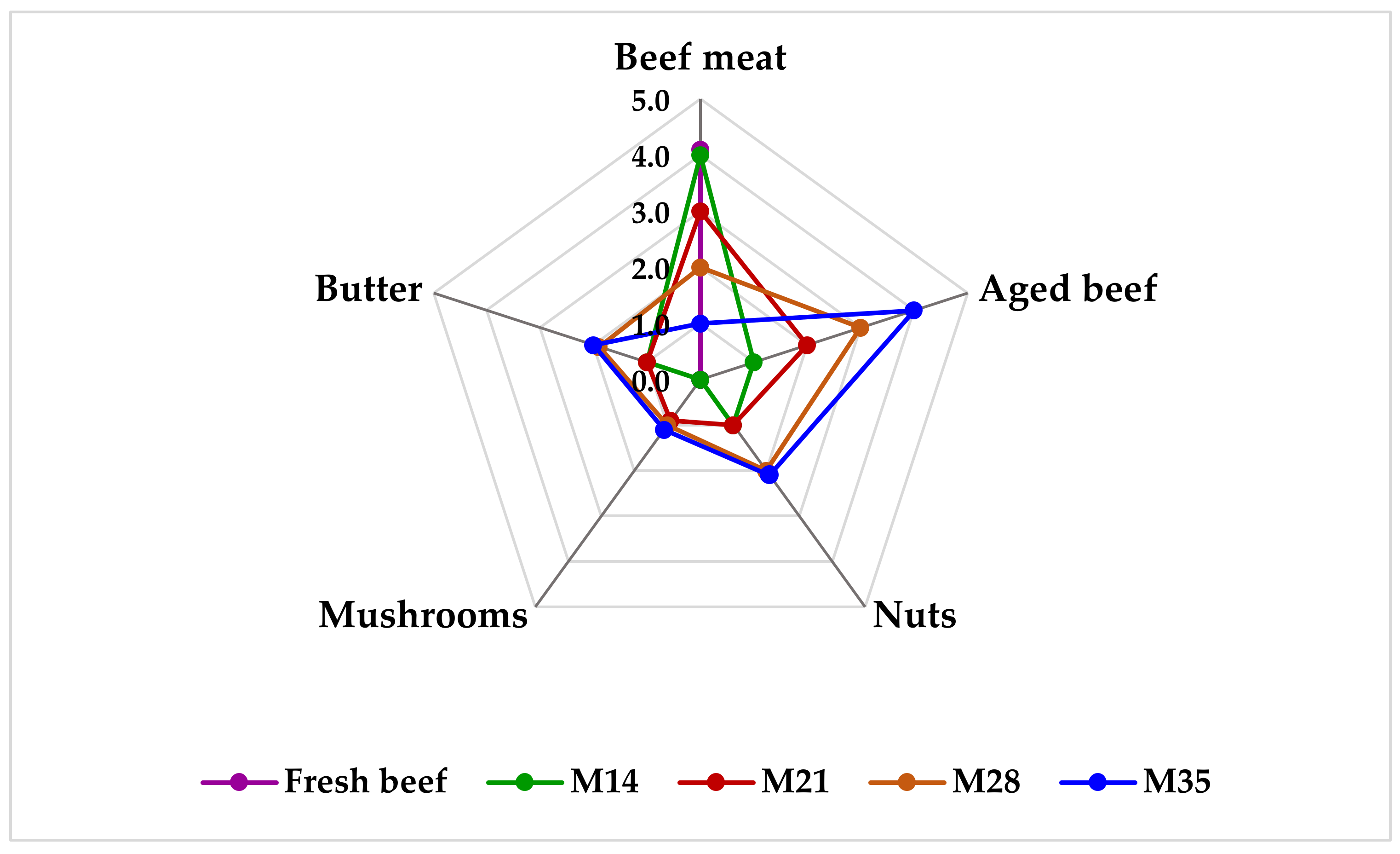

2.3.1. Sensory Analysis of Fresh and Aged Meat by Comparison with Unit Scoring Scales

2.3.2. Sensory Analysis of Fresh and Aged Meat by Constructing the Sensory Profile

2.3.3. Moisture Content

2.3.4. Fat Content

2.3.5. Total Protein Content

2.3.6. Protein Solubility

2.3.7. Total Collagen and Collagen Solubility

2.3.8. Determination of the Meat pH

2.3.9. Determination of Water Holding Capacity (WHC)

2.3.10. Texture Profile Analysis

2.4. Mathematical Modeling

2.5. Statistical Analysis

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Smet, S.; Vossen, E. Meat: The balance between nutrition and health. A review. Meat Sci. 2016, 120, 145–156. [Google Scholar] [CrossRef] [PubMed]

- Pereira, P.M.; Vicente, A.F. Meat nutritional composition and nutritive role in the human diet. Meat Sci. 2013, 93, 586–592. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Becker, T. Defining meat quality. In Meat Processing. Improving Quality; Kerry, J., Kerry, J., Ledward, D., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2002; p. 464. [Google Scholar]

- Organisation for Economic Co-operation and Development (OECD). Available online: https://data.oecd.org (accessed on 1 April 2022).

- EUROSTAT. Available online: https://ec.europa.eu (accessed on 2 April 2022).

- Soren, N.M. Methods for nutritional quality analysis of meat. In Meat Quality Analysis Advanced Evaluation Methods, Techniques, and Technologies, 1st ed.; Biswas, A.K., Mandal, P., Eds.; Academic Press: London, UK, 2020; pp. 21–36. [Google Scholar]

- Listrat, A.; Lebret, B.; Louveau, I.; Astruc, T.; Bonnet, M.; Lefaucheur, L.; Picard, B.; Bugeon, J. How Muscle Structure and Composition Influence Meat and Flesh Quality. Sci. World J. 2016, 2016, 3182746. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scollan, N.; Hocquette, J.-F.; Nuernberg, K.; Dannenberger, D.; Richardson, I.; Moloney, A. Innovations in beef production systems that enhance the nutritional and health value of beef lipids and their relationship with meat quality. Meat Sci. 2006, 74, 17–33. [Google Scholar] [CrossRef]

- Ismail, I.; Hwang, Y.-H.; Bakhsh, A.; Joo, S.-T. The alternative approach of low temperature-long time cooking on bovine semitendinosus meat quality. Asian-Australas J. Anim. Sci. 2019, 32, 282–289. [Google Scholar] [CrossRef] [Green Version]

- Hocquette, J.-F.; Ellies-Oury, M.-P.; Lherm, M.; Pineau, C.; Deblitz, C.; Farmer, L. Current situation and future prospects for beef production in Europe—A review. Asian-Australas. J. Anim. Sci. 2018, 31, 1017–1035. [Google Scholar] [CrossRef] [Green Version]

- Bender, A. Meat and Meat Products in Human Nutrition in the Developing World. In Food and Nutrition Paper; FAO: Rome, Italy, 1992; p. 53. [Google Scholar]

- Banu, C.; Alexe, P.; Vizireanu, C. Industrial Meat Processing; Technical Publishing House: Bucuresti, Romania, 2003; p. 642. (In Romanian) [Google Scholar]

- Trbovich, V. The Effects of Sous Vide Cooking on Tenderness and Protein Concentration in Young Fed Beef and Cow Semitendinosus Muscles. Master Thesis, The Ohio State University, Columbus, OH, USA, 2017. [Google Scholar]

- Corbin, C.H.; O’Quinn, T.G.; Garmyn, A.J.; Legako, J.F.; Hunt, M.R.; Dinh, T.T.N.; Rathmann, R.J.; Brooks, J.C.; Miller, M.F. Sensory evaluation of tender beef strip loin steaks of varying marbling levels and quality treatments. Meat Sci. 2015, 100, 24–31. [Google Scholar] [CrossRef]

- Brooks, J.C.; Belew, J.B.; Griffin, B.D.; Gwartney, D.L.; Hale, D.S.; Henning, W.R.; Johnson, D.D.; Morgan, J.B.; Parrish, F.C., Jr.; Reagan, J.O.; et al. National beef tenderness survey—1998. J. Anim. Sci. 2000, 78, 1852–1860. [Google Scholar] [CrossRef]

- Kahraman, H.A.; Gurbuz, U. Aging Applications on Beef Meat. MANAS J. Eng. 2018, 6, 7–13. [Google Scholar]

- Campbell, R.E.; Hunt, M.C.; Levis, P.; Chambers, E. Dry-aging effects on palatability of beef longissimus muscle. J. Food Sci. 2001, 66, 196–199. [Google Scholar] [CrossRef]

- Kemp, C.M.; Sensky, P.L.; Bardsley, R.G.; Buttery, P.J.; Parr, T. Tenderness—An enzymatic view. Meat Sci. 2010, 84, 248–256. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Colle, M.J.; Richard, R.P.; Killinger, K.M.; Bohlscheid, J.C.; Gray, A.R.; Loucks, W.I.; Doumit, M.E. Influence of extended aging on beef quality characteristics and sensory perception of steaks from the biceps femoris and semimembranosus. Meat Sci. 2016, 119, 110–117. [Google Scholar] [CrossRef] [PubMed]

- Ahnstrom, M.L.; Seyfert, M.; Hunt, M.C.; Johnson, D.E. Dry aging of beef in a bag highly permeable to water vapor. Meat Sci. 2006, 73, 674–679. [Google Scholar] [CrossRef] [PubMed]

- Stenström, H.; Li, X.; Hunt, M.C.; Lundström, K. Consumer preference and effect of correct or misleading information after aging beef longissimus musclle using vacuum, dry aging, or a dry aging bag. Meat Sci. 2014, 96, 661–666. [Google Scholar] [CrossRef]

- Dashdorj, D.; Tripathi, V.K.; Cho, S.; Kim, Y.; Hwang, I. Dry aging of beef; Review. J. Anim. Sci. Technol. 2016, 58, 20. [Google Scholar] [CrossRef] [Green Version]

- Savell, J.W. Dry-Aging of Beef, Executive Summary; National Cattlemen’s Beef Association: Centennial, CO, USA, 2008; p. 16. [Google Scholar]

- Lee, H.J.; Choe, J.; Kim, K.T. Analysis of low-marbled Hanwoo cow meat aged with different dry-aging methods. Asian-Australas. J. Anim. Sci. 2017, 30, 1733–1738. [Google Scholar] [CrossRef]

- Schroeder, J.W.; Cramer, D.A.; Bowling, R.A.; Cook, C.A. Palatability, shelf life and chemical differences between forage-and grain-finished beef. Sci. J. Anim. Sci. 1980, 5, 852–859. [Google Scholar] [CrossRef]

- Miller, M.F.; Davis, G.W.; Ramsey, C.B. Effect of subprimal fabrication and packaging methods on palatability and retail case life of loin steaks from lean beef. J. Food Sci. 1985, 50, 1544–1560. [Google Scholar] [CrossRef]

- GD No. 696 from 04-08-2010 for the Approval of the Requirements Regarding the Production, Import and Placing on the Market of Meat—Raw Material. Available online: http://lex.justice.md/index.php?action=view&view=doc&id=335616 (accessed on 1 March 2022).

- ISO 6658:2017; Sensory Analysis—Methodology—General Guidance. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/65519.html (accessed on 2 March 2022).

- Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Delgado-Pando, G. Sensory Analysis and Consumer Research in New Meat Products Development. Foods 2021, 10, 429. [Google Scholar] [CrossRef]

- ISO 1442:1997(en); Meat and Meat Products—Determination of Moisture Content (Reference Method). International Organization for Standardization: Geneva, Switzerland, 1997.

- ISO 1443:1973(en); Meat and Meat Products—Determination of Total Fat Content. International Organization for Standardization: Geneva, Switzerland, 1973.

- ISO 937:1978; Meat and Meat Products—Determination of Nitrogen Content (Reference Method). International Organization for Standardization: Geneva, Switzerland, 1978.

- Joo, S.T.; Kaufman, R.G.; Kim, B.C.; Park, G.B. The relationship of sarcoplasmic and myofbrillar protein solubility to colour and water-holding capacity in porcine longissimus muscle. Meat Sci. 1999, 52, 291–297. [Google Scholar] [CrossRef]

- ISO 3496:1994; Meat and Meat Products—Determination of Hydroxyproline Content. International Organization for Standardization: Geneva, Switzerland, 1994.

- Sen, A.R.; Naveena, B.M.; Muthukumar, M.; Vaithiyanathan, S. Colour, myoglobin denaturation and storage stability of raw and cooked mutton chops at different end point cooking temperature. J. Food Sci. Technol. 2014, 51, 970–975. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Overview of Texture Profile Analysis. Available online: https://texturetechnologies.com/resources/texture-profile-analysis#tpa-measurements. (accessed on 5 February 2022).

- Batina, L.; Gierlichs, B.; Prouff, E.; Rivain, M.; Standaert, F.-X.; Veyrat-Charvillon, N. Mutual Information Analysis: A Comprehensive Study. J. Cryptol. 2011, 24, 269–291. [Google Scholar] [CrossRef] [Green Version]

- Maqsood, S.; Abushelaibi, A.; Manheem, K.; Kadim, I.T. Characterisation of the lipid and protein fraction of fresh camel meat and the associated changes during refrigerated storage. J. Food Compos. Anal. 2015, 41, 212–220. [Google Scholar] [CrossRef]

- Huff-Lonergan, E.; Zhang, W.; Lonergan, S.M. Biochemistry of postmortem muscle, Lessons on mechanisms of meat tenderization. Meat Sci. 2010, 86, 184–195. [Google Scholar] [CrossRef] [PubMed]

- Feiner, G. Meat Products Handbook Practical Science and Technology, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2006; 648p. [Google Scholar]

- Kim, M.; Choe, J.; Lee, H.J.; Yoon, Y.; Yoon, S.; Jo, C. Effects of aging and aging method on physicochemical and sensory traits of different beef cuts. Food Sci. Anim. Resour. 2019, 39, 54–64. [Google Scholar] [CrossRef]

- Nishimura, T. Role of extracellular matrix in development of skeletal muscle and postmortem aging of meat. Meat Sci. 2015, 109, 48–55. [Google Scholar] [CrossRef]

- Warner, R.; Greenwood, P.; Pethick, D.; Ferguson, D. Genetic and environmental effects on meat quality. Meat Sci. 2010, 86, 171–183. [Google Scholar] [CrossRef] [Green Version]

- Koohmaraie, M.; Geesink, G. Contribution of postmortem muscle biochemistry to the delivery of consistent meat quality with particular focus on the calpain system. Meat Sci. 2006, 74, 34–43. [Google Scholar] [CrossRef] [Green Version]

- Ustuner, H.; Arrdicli, S.; Arslan, O. Determination of the alterations in quality parameters and consumer preference of dry-aged beef based on different periods of ageing using a purposive incubator. J. Hell. Vet. Med. Soc. 2021, 72, 2669–2676. [Google Scholar] [CrossRef]

- Ardicli, S. Impact of Genetic and Postmortem Mechanisms on Beef Colour Parameters. Uludag Univ. J. Fac. Vet. Med. 2018, 37, 49–59. (In Turkish) [Google Scholar]

- Perry, N. Dry aging beef. Inter. J. Gastron. Food Sci. 2012, 1, 78–80. [Google Scholar] [CrossRef] [Green Version]

- Spanier, A.M.; Flores, M.; McMilli, K.W.; Bidne, T.D. The effect of post-mortem aging on meat flavor quality in Brangus beef. Correlation of treatments, sensory, instrumental and chemical descriptors. Food Chem. 1997, 59, 531–538. [Google Scholar] [CrossRef]

- Cho, S.; Kang, S.M.; Kim, Y.S.; Kim, Y.C.; van Ba, H.; Seo, H.W.; Lee, E.M.; Seong, P.N.; Kim, J.H. Comparison of Drying Yield, Meat Quality, Oxidation Stability and Sensory Properties of Bone-in Shell Loin Cut by Different Dry-aging Conditions. Korean J. Food Sci. Anim. Resour. 2018, 38, 1131–1143. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.W.; Lee, S.H.; Min, Y.; Lee, S.; Jo, C.; Jung, S. Quality improvement of strip loin from Hanwoo with low quality grade by dry aging. Korean J. Food Nutr. 2015, 28, 415–421. [Google Scholar] [CrossRef] [Green Version]

- Laster, M.A.; Smith, R.D.; Nicholson, K.L.; Nicholson, J.D.W.; Harris, K.B.; Miller, R.K.; Griffin, D.B.; Savell, J.W. Dry versus wet aging of beef: Retail cutting yields and consumer sensory attribute evaluations of steaks from ri-beyes, strip loins, and top sirloins from two quality grade groups. Meat Sci. 2008, 80, 795–804. [Google Scholar] [CrossRef]

- Kim, Y.H.B.; Kemp, R.; Samuelsson, L.M. Effects of dry-aging on meat quality attributes and metabolite profiles of beef loins. Meat Sci. 2016, 111, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.M.; Harris, K.B.; Griffin, D.B.; Miller, R.K.; Kerth, C.R.; Savell, J.W. Retail yields and palatability evaluations of individual muscles from wet-aged and dry-aged beef ribeyes and top sirloin butts that were merchandised innovatively. Meat Sci. 2014, 97, 21–26. [Google Scholar] [CrossRef]

- Page, J.; Wulf, D.; Schwotzer, T. A survey of beef muscle color and pH. J. Anim. Sci 2001, 79, 678–687. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Jang, M.; Park, S.; Jeong, J.; Shim, Y.; Kim, J. Determination of Indicators for Dry Aged Beef Quality. Food Sci. Anim. Resour. 2019, 39, 934–942. [Google Scholar] [CrossRef] [Green Version]

- Obuz, E.; Akkaya, L.; Gök, V.; Dikeman, M.E. Effects of blade tenderization, aging method and aging time on meat quality charaxterisitcs of Longissimus lumborum steaks from cull Holstein cows. Meat Sci. 2014, 96, 1227–1232. [Google Scholar] [CrossRef]

- Alexe, P. Transforming the Living Animal into Meat; Mirtun Publishing House: Bucuresti, Romania, 2000. (In Romanian) [Google Scholar]

- Mudalal, S.; Babini, E.; Cavani, C.; Petracci, M. Quantity and functionality of protein fractions in chicken breast fillets affected by white striping. Poult. Sci. J. 2014, 93, 2108–2116. [Google Scholar] [CrossRef] [PubMed]

- Iida, F.; Miyazaki, Y.; Tsuyuki, R.; Kato, K.; Egusa, A.; Ogoshi, H.; Nishimura, T. Changes in taste compounds, breaking properties, and sensory attributes during dry aging of beef from Japanese black cattle. Meat Sci. 2016, 112, 46–51. [Google Scholar] [CrossRef] [PubMed]

- Banu, C.; Ionescu, A.; Bahrim, G.; Dorin, S.S.; Vizireanu, C. Meat Biochemistry, Microbiology and Parasitology; Publishing House AGIR: Bucuresti, Romania, 2006. (In Romanian) [Google Scholar]

- Colle, M.J.; Richard, R.P.; Killinger, K.M.; Bohlscheid, J.C.; Gray, A.R.; Loucks, W.I.; Day, R.N.; Cochran, A.S.; Nasados, J.A.; Doumit, M.E. Influence of extended aging on beef quality characteristics and sensory perception of steaks from the gluteus medius and longissimus lumborum. Meat Sci. 2015, 110, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kim, T.K.; Shin, D.M.; Kim, H.W.; Kim, Y.B.; Choi, Y.S. Comparative effects of dry-aging and wet-aging on physicochemical properties and digestibility of Hanwoo beef. Asian-Australas J. Anim. Sci. 2020, 33, 501–505. [Google Scholar] [CrossRef]

- Maqsood, S.; Manheem, K.; Gani, A.; Abushelaibi, A. Degradation of myofibrillar, sarcoplasmic and connective tissue proteins by plant proteolytic enzymes and their impact on camel meat tenderness. J. Food Sci. Technol. 2018, 55, 3427–3438. [Google Scholar] [CrossRef]

- Toldra, F. Proteolysis and lipolysis in flavour development of dry-cured meat products. Meat Sci. 1998, 49S, 101–110. [Google Scholar] [CrossRef]

- Claeys, E.; de Smet, S.; Balcaen, A.; Raes, K.; Demeyer, D. Quantification of fresh meat peptides by SDS–PAGE in relation to ageing time and taste intensity. Meat Sci. 2004, 67, 281–288. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Campo, M.M.; Santolaria, P.; Sañudo, C.; Lepetit, J.J.; Olleta, L.; Panea, B.; Albertí, P. Assessment of breed type and ageing time effects on beef meat quality using two different texture devices. Meat Sci. 2000, 55, 371–378. [Google Scholar] [CrossRef]

- Zhang, S.X.; Farouk, M.M.; Young, O.A.; Wieliczko, K.J.; Podmore, C. Functional stability of frozen normal and high pH beef. Meat Sci. 2005, 69, 765–772. [Google Scholar] [CrossRef]

- Olivera, D.F.; Bambicha, R.; Laporte, G.; Cárdenas, F.C.; Mestorino, N. Kinetics of colour and texture changes of beef during storage. J. Food Sci. Technol. 2013, 50, 821–825. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Weston, A.R.; Rogers, R.W.; Althen, T.G. Review: The Role of Collagen in Meat Tenderness. Prof. Anim. Sci. 2002, 18, 107–111. [Google Scholar] [CrossRef]

- Ripoll, G.; Alcalde, M.J.; Córdoba, M.G.; Casquete, R.; Argüello, A.; Ruiz-Moyano, S.; Panea, B. Influence of the Use of Milk Replacers and pH on the Texture Profiles of Raw and Cooked Meat of Suckling Kids. Foods 2019, 8, 589. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vasanthi, C.; Venkataramanujam, V.; Dushyanthan, K. Effect of cooking temperature and time on the physico-chemical, histological and sensory properties of female carabeef (buffalo). Meat Sci. 2007, 76, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Pematilleke, N.; Kaur, M.; Adhikari, B.; Torley, P.J. Relationship between instrumental and sensory texture profile of beef semitendinosus muscles with different textures. J. Texture Stud. 2022, 53, 232–241. [Google Scholar] [CrossRef] [PubMed]

- Bao, G.; Zhang, L.; Sun, B.; Xie, P.; Wang, L.; Niu, J.; Ma, J. The Correlation Research on Yak Meat Texture Profile Analysis (Tpa) And Freshness Parameters During Refrigerated Storage. MOJ Food Process. Technol. 2015, 1, 00020. [Google Scholar]

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Niculaua, M. Rose hips, a valuable source of antioxidants to improve gingerbread characteristics. Molecules 2020, 25, 5659. [Google Scholar] [CrossRef]

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Padureanu, S.; Deseatnicova, O.; Turculet, N.; Boestean, O.; Niculaua, M. Potential Application of Hippophae Rhamnoides in Wheat Bread Production. Molecules 2020, 25, 1272. [Google Scholar] [CrossRef] [Green Version]

| Sensory Characteristics | Product Description |

|---|---|

| Appearance | Wet surface, elastic muscle tissue, regular edges, no deep cuts. |

| Color | The color of the muscles is dark red, and the color of the adipose tissue is white without signs of rancidity, specific to beef. |

| Consistency | Elastic, firm, the dimple disappears faster. |

| Flavor | The characteristic flavor of beef is not perceived, a balanced aroma characteristic of matured meat, without a foreign smell. |

| Indicators | Samples | ||||

|---|---|---|---|---|---|

| Fresh Beef | M14 | M21 | M28 | M35 | |

| Sensory indicators | |||||

| Average score of sensory profile | 4.15 ± 0.05 a | 4.43 ± 0.05 b | 4.80 ± 0.04 c,d | 4.92 ± 0.05 d,e | 5.00 ± 0.00 e |

| Appearance | 4.26 ± 0.04 a | 4.66 ± 0.03 b | 4.92 ± 0.01 c | 4.95 ± 0.03 c | 5.00 ± 0.00 c |

| Color | 4.30 ± 0.04 a | 4.57 ± 0.04 b | 4.88 ± 0.03 c | 4.92 ± 0.03 c,d | 5.00 ± 0.00 d |

| Consistency | 4.05 ± 0.03 a | 4.36 ± 0.02 b | 4.82 ± 0.05 c,d | 4.95 ± 0.03 d | 5.00 ± 0.00 d |

| Flavor | 4.00 ± 0.01 a | 4.13 ± 0.03 b | 4.57 ± 0.01 c | 4.84 ± 0.02 d | 5.00 ± 0.00 e |

| Physicochemical indicators | |||||

| Moisture content, % | 59.55 ± 0.45 d | 55.98 ± 0.55 c | 55.80 ± 0.37 c | 54.67 ± 0.38 b | 53.31 ± 0.16 a |

| Activ acidity pH, c.u. | 5.50 ± 0.01 a | 5.54 ± 0.01 b | 5.56 ± 0.01 b | 5.65 ± 0.01 c,d | 5.66 ± 0.01 c,d |

| Water holding capacity, % | 66.41 ± 0.41 a | 84.42 ± 0.98 b | 91.11 ± 0.40 c | 91.17 ± 0.46 c | 91.20 ± 0.49 c |

| Fat content, % | 6.40 ± 0.20 a | 8.56 ± 0.07 b | 9.02 ± 0.18 b,c | 9.34 ± 0.21 c | 9.50 ± 0.12 c |

| Total collagen content, % | 0.41 ± 0.010 a | 0.47 ± 0.006 b | 0.48 ± 0.005 b | 0.52 ± 0.004 c | 0.52 ± 0.006 c |

| Soluble colagen content, % | 0.05 ± 0.004 a | 0.11 ± 0.006 b | 0.12 ± 0.005 b,c | 0.12 ± 0.003 b,c | 0.13 ± 0.002 c |

| Protein content, % | 24.64 ± 0.07 d | 23.78 ± 0.36 c,d | 23.59 ± 0.45 b,c,d | 22.99 ± 0.34 a,b,c | 22.79 ± 0.36 a |

| Soluble protein content, % | 2.61 ± 0.02 a | 2.98 ± 0.05 b | 2.99 ± 0.01 b | 3.00 ± 0.01 b | 3.01 ± 0.004 b |

| Sarcoplasmatic protein content, % | 1.22 ± 0.02 a | 1.59 ± 0.06 b | 1.68 ± 0.05 b,c | 1.79 ± 0.03 c | 1.99 ± 0.02 d |

| Miofibrilar protein content, % | 1.39 ± 0.03 d | 1.38 ± 0.04 c,d | 1.32 ± 0.03 c | 1.10 ± 0.03 a,b | 1.02 ± 0.02 a |

| Texture Parameters | Samples | ||||

|---|---|---|---|---|---|

| Fresh Beef | M14 | M21 | M28 | M35 | |

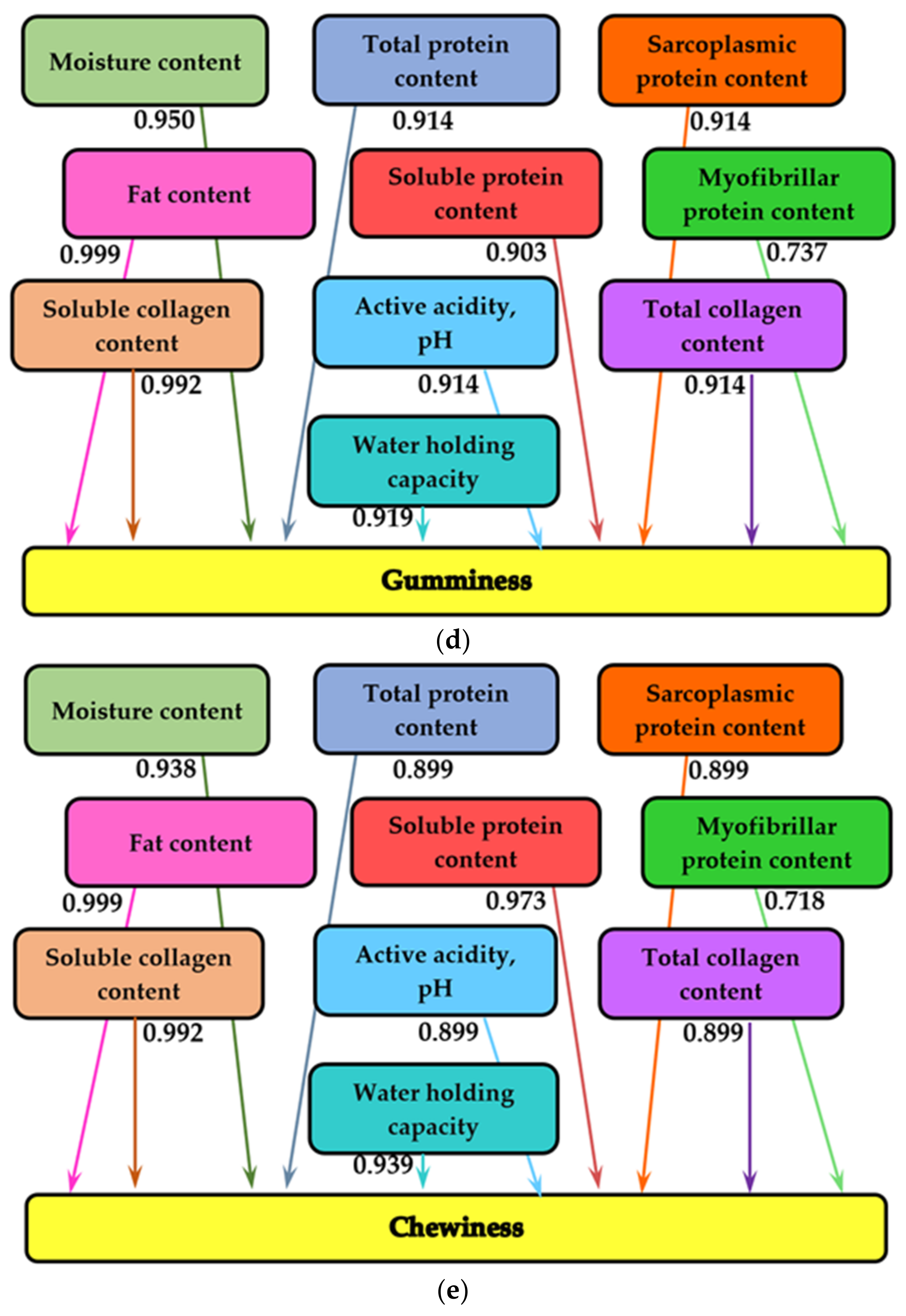

| Hardness, g | 1592.55 ± 48.11 c | 500.53 ± 13.75 b | 331.58 ± 34.87 b | 310.77 ± 40.12 b | 224.12 ± 32.98 a |

| Cohesiveness, % | 0.520 ± 0.006 d | 0.426 ± 0.008 c | 0.403 ± 0.008 b | 0.400 ± 0.007 b | 0.371 ± 0.009 a |

| Springiness, % | 0.705 ± 0.004 a | 0.745 ± 0.007 b | 0.752 ± 0.006 b | 0.766 ± 0.002 c | 0.802 ± 0.001 d |

| Gumminess, g | 828.13 ± 28.56 c | 231.22 ± 21.98 b | 133.63 ± 10.24 a | 124.31 ± 4.12 a | 83.15 ± 1.89 a |

| Chewiness, g | 583.83 ± 12.04 c | 158.85 ± 10.47 b | 100.48 ± 13.54 a | 95.21 ± 11.57 a | 66.68 ± 4.23 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulgaru, V.; Popescu, L.; Netreba, N.; Ghendov-Mosanu, A.; Sturza, R. Assessment of Quality Indices and Their Influence on the Texture Profile in the Dry-Aging Process of Beef. Foods 2022, 11, 1526. https://doi.org/10.3390/foods11101526

Bulgaru V, Popescu L, Netreba N, Ghendov-Mosanu A, Sturza R. Assessment of Quality Indices and Their Influence on the Texture Profile in the Dry-Aging Process of Beef. Foods. 2022; 11(10):1526. https://doi.org/10.3390/foods11101526

Chicago/Turabian StyleBulgaru, Viorica, Liliana Popescu, Natalia Netreba, Aliona Ghendov-Mosanu, and Rodica Sturza. 2022. "Assessment of Quality Indices and Their Influence on the Texture Profile in the Dry-Aging Process of Beef" Foods 11, no. 10: 1526. https://doi.org/10.3390/foods11101526

APA StyleBulgaru, V., Popescu, L., Netreba, N., Ghendov-Mosanu, A., & Sturza, R. (2022). Assessment of Quality Indices and Their Influence on the Texture Profile in the Dry-Aging Process of Beef. Foods, 11(10), 1526. https://doi.org/10.3390/foods11101526