Finite Element Analysis and Near-Infrared Hyperspectral Reflectance Imaging for the Determination of Blueberry Bruise Grading

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fruit Materials

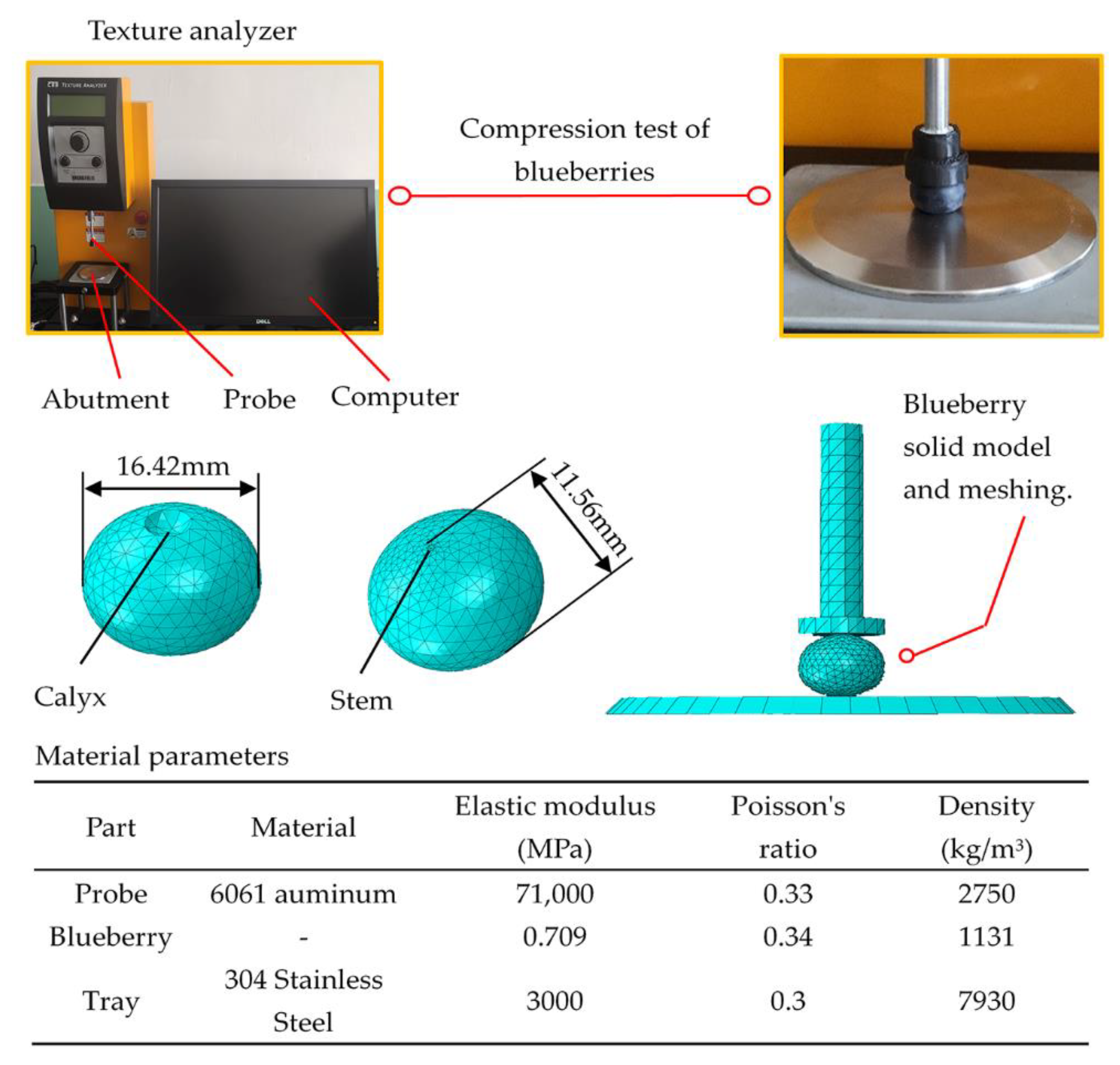

2.2. Blueberry Physical Parameters

2.3. Blueberry Borderline Failure and Bruise Simulation

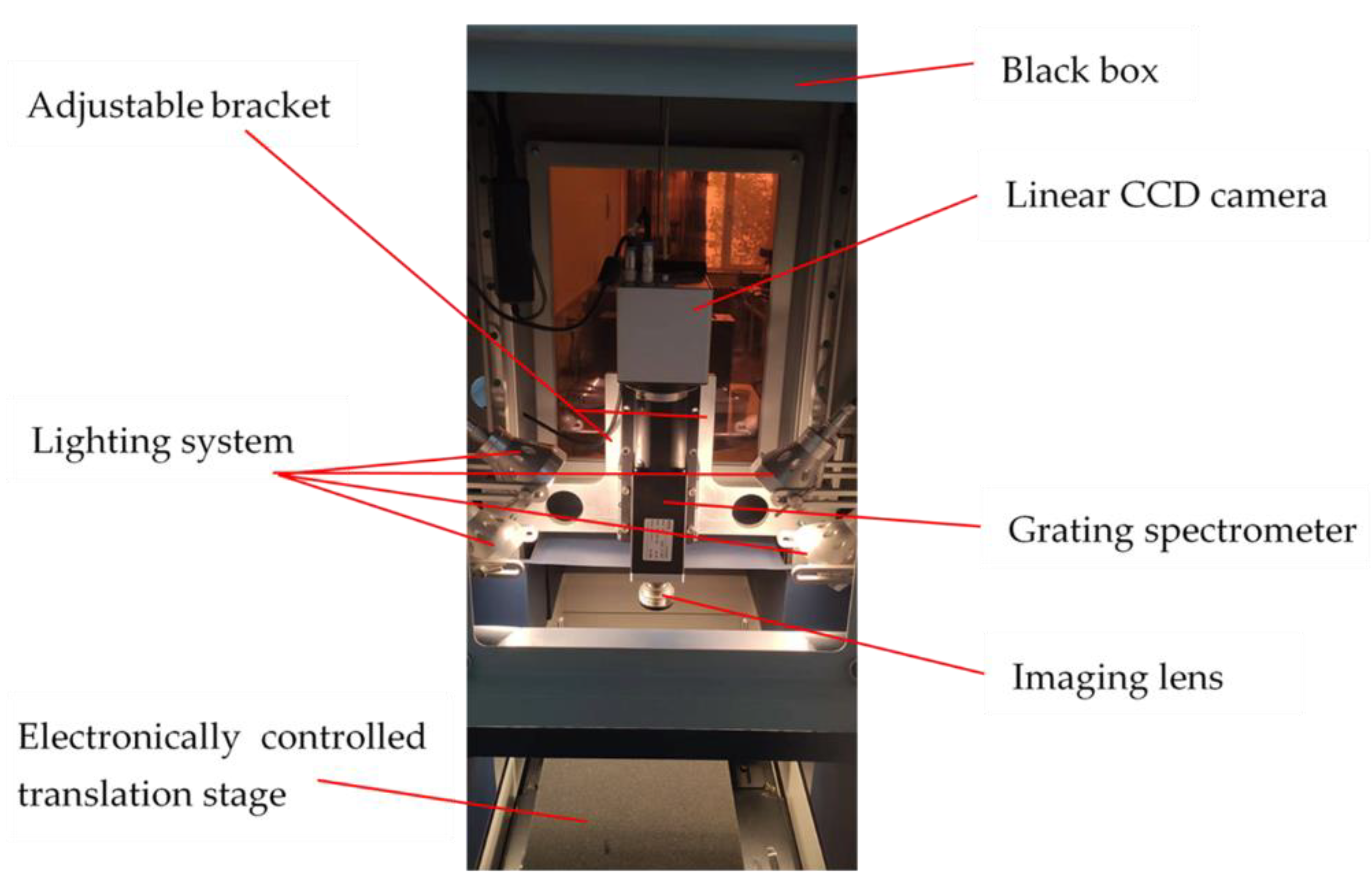

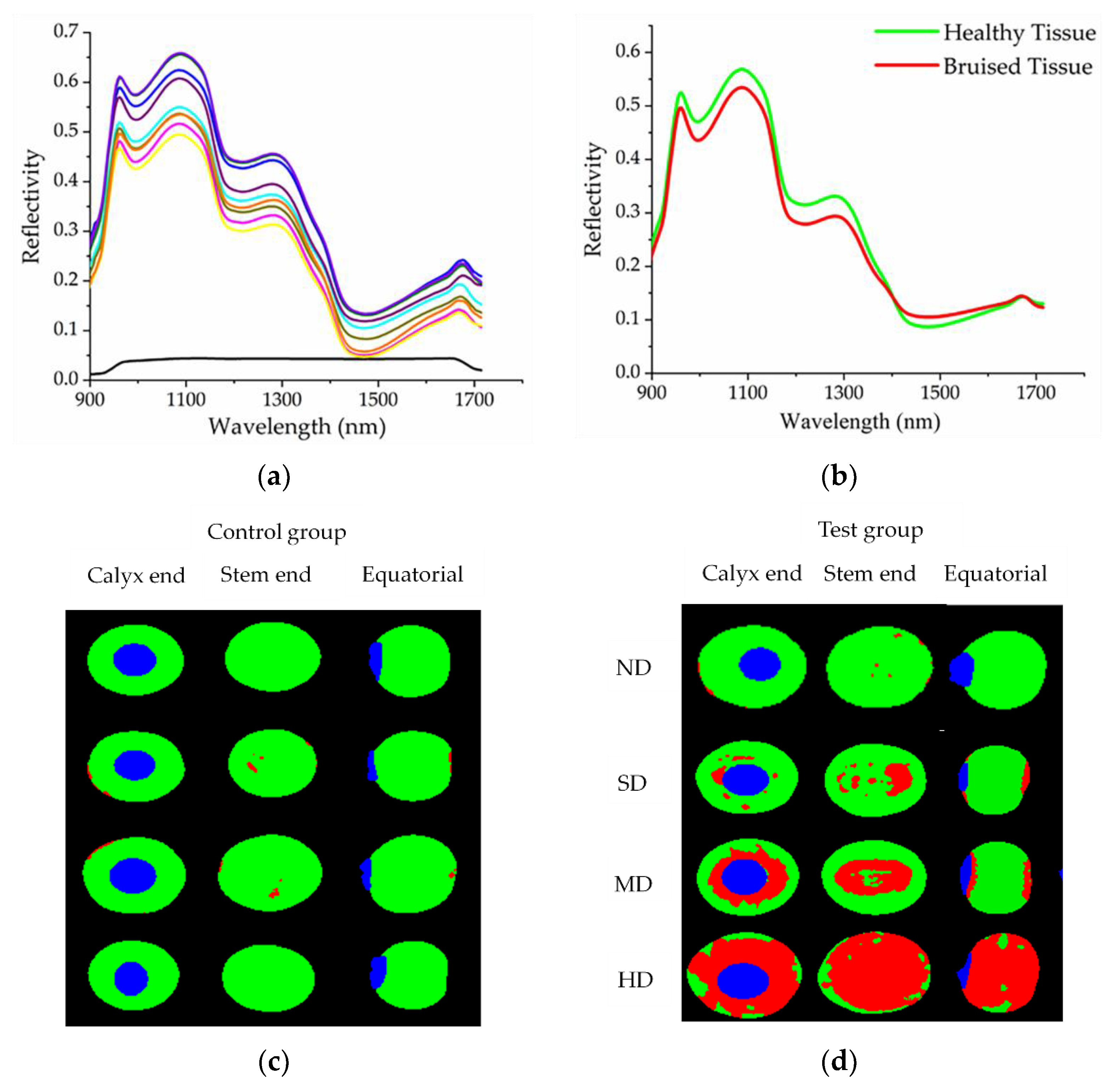

2.4. Bruise Damage Detection Based on Hyperspectral Reflectance Imaging

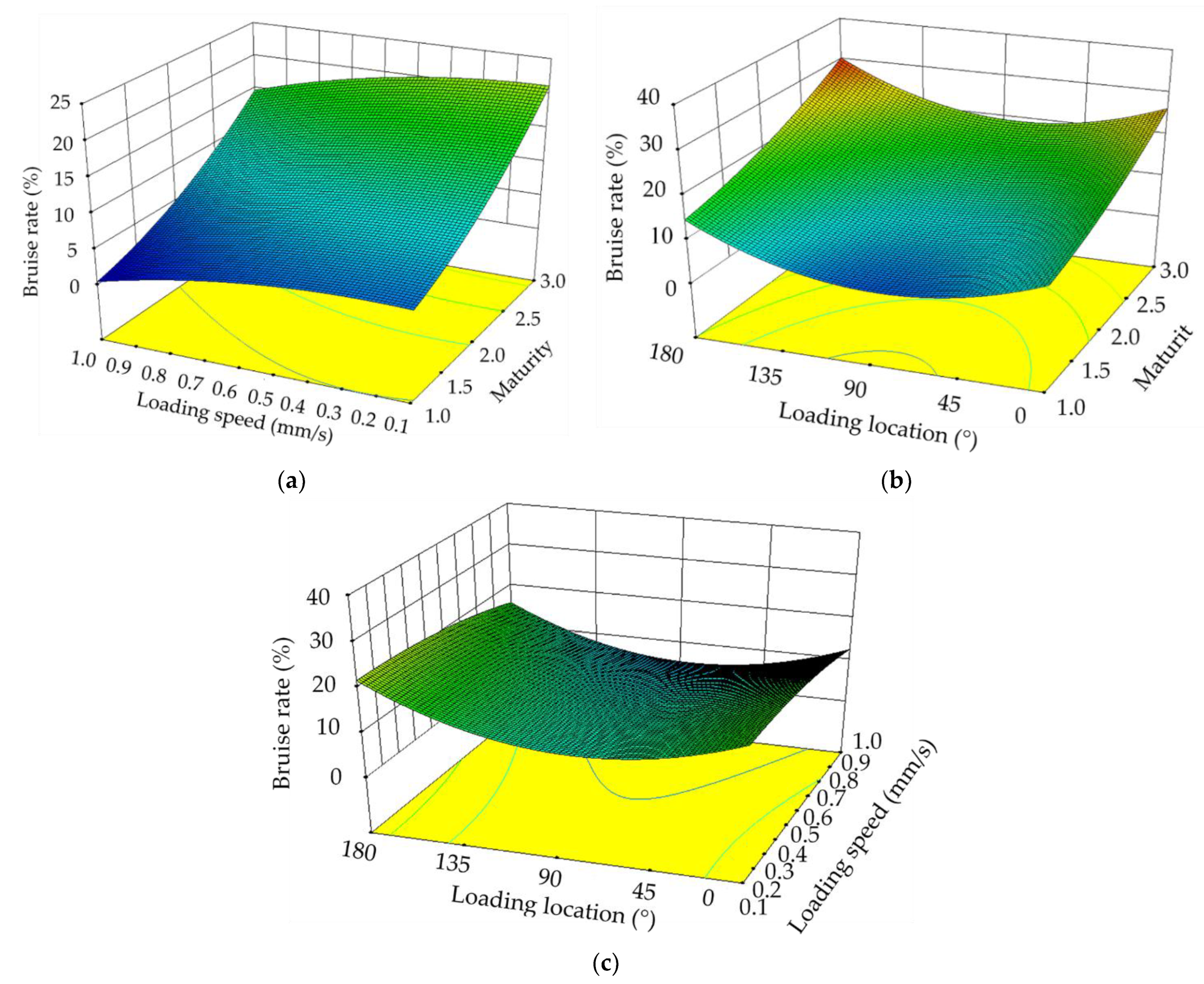

2.5. The Influence of Some Factors on Bruise Damage

3. Results and Discussion

3.1. Blueberry Parameters and Mechanical Simulation

3.2. Bruise Damage Standard Division

3.3. Analysis of Influencing Factors of Bruise Degree

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luteyn, J.L.; Sylva, D.S. “Murrí” (Antioquia Department, Colombia): Hotspot for Neotropical Blueberries (Ericaceae: Vaccinieae). Brittonia 1999, 51, 280–302. [Google Scholar] [CrossRef]

- Barnes, J.S.; Nguyen, H.P.; Shen, S.; Schug, K.A. General method for extraction of blueberry anthocyanins and identification using high performance liquid chromatography–electrospray ionization-ion trap-time of flight-mass spectrometry. J. Chromatogr. A 2009, 1216, 4728–4735. [Google Scholar] [CrossRef] [PubMed]

- Routray, W.; Orsat, V. Blueberries and Their Anthocyanins: Factors Affecting Biosynthesis and Properties. Compr. Rev. Food Sci. Food Saf. 2011, 10, 303–320. [Google Scholar] [CrossRef]

- Silva, S.; Costa, E.M.; Veiga, M.; Morais, R.M.; Calhau, C.; Pintado, M. Health promoting properties of blueberries: A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 181–200. [Google Scholar] [CrossRef]

- Yu, P.; Li, C.; Takeda, F.; Krewer, G.; Rains, G.; Hamrita, T. Measurement of mechanical impacts created by rotary, slapper, and sway blueberry mechanical harvesters. Comput. Electron. Agric. 2014, 101, 84–92. [Google Scholar] [CrossRef]

- Xu, R.; Takeda, F.; Krewer, G.; Li, C. Measure of mechanical impacts in commercial blueberry packing lines and potential damage to blueberry fruit. Postharvest Biol. Technol. 2015, 110, 103–113. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. A new method for measuring impact related bruises in fruits. Postharvest Biol. Technol. 2015, 110, 131–139. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. The effect of drop height on bruising of selected apple varieties. Postharvest Biol. Technol. 2013, 85, 167–172. [Google Scholar] [CrossRef]

- Moggia, C.; Graell, J.; Lara, I.; González, G.; Lobos, G.A. Firmness at Harvest Impacts Postharvest Fruit Softening and Internal Browning Development in Mechanically Damaged and Non-damaged Highbush Blueberries (Vaccinium corymbosum L.). Front. Plant Sci. 2017, 8, 535. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Jiménez, F.; Castro-García, S.; Blanco-Roldán, G.L.; Agüera-Vega, J.; Gil-Ribes, J.A. Non-destructive determination of impact bruising on table olives using Vis–NIR spectroscopy. Biosyst. Eng. 2012, 113, 371–378. [Google Scholar] [CrossRef]

- Li, Z.G.; Li, P.P.; Liu, J.Z. Effect of mechanical damage on mass loss and water content in tomato fruits. Int. Agrophys. 2011, 25, 77–83. [Google Scholar]

- Thompson, J.F.; Slaughter, D.C.; Arpaia, M.L. Suspended Tray Package for Protecting Soft Fruit from Mechanical Damage. Appl. Eng. Agric. 2008, 24, 71–75. [Google Scholar] [CrossRef] [Green Version]

- Moggia, C.; Graell, J.; Lara, I.; Schmeda-Hirschmann, G.; Thomas-Valdés, S.; Lobos, G.A. Fruit characteristics and cuticle triterpenes as related to postharvest quality of highbush blueberries. Sci. Hortic. 2016, 211, 449–457. [Google Scholar] [CrossRef] [Green Version]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R. Measurement and analysis of vibration and mechanical damage to bananas during long-distance interstate transport by multi-trailer road trains. Postharvest Biol. Technol. 2019, 158, 110977. [Google Scholar] [CrossRef]

- Toivonen, P.M.; Hampson, C.; Stan, S.; McKenzie, D.-L.; Hocking, R. Factors affecting severity of bruises and degree of apparent bruise recovery in a yellow-skinned apple. Postharvest Biol. Technol. 2007, 45, 276–280. [Google Scholar] [CrossRef]

- Li, Z.; Andrews, J.; Wang, Y. Mathematical modelling of mechanical damage to tomato fruits. Postharvest Biol. Technol. 2017, 126, 50–56. [Google Scholar] [CrossRef]

- Dintwa, E.; Van Zeebroeck, M.; Ramon, H.; Tijskens, E. Finite element analysis of the dynamic collision of apple fruit. Postharvest Biol. Technol. 2008, 49, 260–276. [Google Scholar] [CrossRef]

- Du, D.; Wang, B.; Wang, J.; Yao, F.; Hong, X. Prediction of bruise susceptibility of harvested kiwifruit (Actinidia chinensis) using finite element method. Postharvest Biol. Technol. 2019, 152, 36–44. [Google Scholar] [CrossRef]

- Kabas, O.; Vlăduţ, V. Determination of Drop-Test Behavior of a Sample Peach Using Finite Element Method. Int. J. Food Prop. 2015, 18, 2584–2592. [Google Scholar] [CrossRef]

- Pascoal-Faria, P.; Alves, N. Studying apple bruise using a finite element method analysis. In Proceedings of the International Conference on Numerical Analysis and Applied Mathematics 2016 (Icnaam-2016), Rhodes, Greece, 19–25 September 2016; Simos, T., Tsitouras, C., Eds.; AIP: Rhodes, Greece, 2017; 1863. [Google Scholar] [CrossRef]

- Kabas, O. Methods of Measuring Bruise Volume of Pear (Pyrus communis L.). Int. J. Food Prop. 2010, 13, 1178–1186. [Google Scholar] [CrossRef] [Green Version]

- Seyedabadi, E.; Khojastehpour, M.; Sadrnia, H. Predicting Cantaloupe Bruising Using Non-Linear Finite Element Method. Int. J. Food Prop. 2015, 18, 2015–2025. [Google Scholar] [CrossRef]

- Yousefi, S.; Farsi, H.; Kheiralipour, K. Drop test of pear fruit: Experimental measurement and finite element modelling. Biosyst. Eng. 2016, 147, 17–25. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y. A multiscale finite element model for mechanical response of tomato fruits. Postharvest Biol. Technol. 2016, 121, 19–26. [Google Scholar] [CrossRef]

- McGlone, V.A.; Fraser, D.G.; Jordan, R.B.; Künnemeyer, R. Internal Quality Assessment of Mandarin Fruit by vis/NIR Spectroscopy. J. Near Infrared Spectrosc. 2003, 11, 323–332. [Google Scholar] [CrossRef]

- Tavakolian, M.S.S.; Silaghi, F.A.; Fabbri, A.; Molari, G.; Giunchi, A.; Guarnieri, A. Differentiation of post harvest date fruit varieties non-destructively using FT-NIR spectroscopy. Int. J. Food Sci. Technol. 2013, 48, 1282–1288. [Google Scholar] [CrossRef]

- Wu, Y.; Li, L.; Liu, L.; Liu, Y. Nondestructive measurement of internal quality attributes of apple fruit by using NIR spectroscopy. Multimedia Tools Appl. 2019, 78, 4179–4195. [Google Scholar] [CrossRef]

- Moscetti, R.; Haff, R.P.; Monarca, D.; Cecchini, M.; Massantini, R. Near-infrared spectroscopy for detection of hailstorm damage on olive fruit. Postharvest Biol. Technol. 2016, 120, 204–212. [Google Scholar] [CrossRef]

- Xiong, J.; Lin, R.; Bu, R.; Liu, Z.; Yang, Z.; Yu, L. A Micro-Damage Detection Method of Litchi Fruit Using Hyperspectral Imaging Technology. Sensors 2018, 18, 700. [Google Scholar] [CrossRef] [Green Version]

- Siedliska, A.; Baranowski, P.; Zubik, M.; Mazurek, W.; Sosnowska, B. Detection of fungal infections in strawberry fruit by VNIR/SWIR hyperspectral imaging. Postharvest Biol. Technol. 2018, 139, 115–126. [Google Scholar] [CrossRef]

- Liu, D.-H.; Zhang, S.-J.; Wang, B.; Yu, K.-Q.; Zhao, Y.-R.; He, Y. Detection of hawthorn fruit defects using hyperspectral imaging. Spectrosc. Spect. Anal. 2015, 35, 3167–3171. [Google Scholar] [CrossRef]

- Yang, L.; Gao, H.; Meng, L.; Fu, X.; Du, X.; Wu, D.; Huang, L. Nondestructive measurement of pectin polysaccharides using hyperspectral imaging in mulberry fruit. Food Chem. 2021, 334, 127614. [Google Scholar] [CrossRef] [PubMed]

- Firouzjaei, R.A.; Minaei, S.; Beheshti, B. Sweet lemon mechanical damage detection using image processing technique and UV radiation. J. Food Meas. Charact. 2018, 12, 1513–1518. [Google Scholar] [CrossRef]

- Rivera, N.V.; Gómez-Sanchis, J.; Pérez, J.J.C.; Carrasco, J.J.; Millán-Giraldo, M.; Lorente, D.; Cubero, S.; Blasco, J. Early detection of mechanical damage in mango using NIR hyperspectral images and machine learning. Biosyst. Eng. 2014, 122, 91–98. [Google Scholar] [CrossRef]

- Siedliska, A.; Baranowski, P.; Zubik, M.; Mazurek, W. Detection of pits in fresh and frozen cherries using a hyperspectral system in transmittance mode. J. Food Eng. 2017, 215, 61–71. [Google Scholar] [CrossRef]

- Zhang, M.; Li, C.; Takeda, F.; Yang, F. Detection of Internally Bruised Blueberries Using Hyperspectral Transmittance Imaging. Trans. ASABE 2017, 60, 1489–1502. [Google Scholar] [CrossRef]

- Fan, S.; Li, C.; Huang, W.; Chen, L. Detection of blueberry internal bruising over time using NIR hyperspectral reflectance imaging with optimum wavelengths. Postharvest Biol. Technol. 2017, 134, 55–66. [Google Scholar] [CrossRef]

- Yu, P.; Li, C.; Takeda, F.; Krewer, G. Visual bruise assessment and analysis of mechanical impact measurement in southern highbush blueberries. Appl. Eng. Agric. 2014, 30, 29–37. [Google Scholar]

- Aliasgarian, S.; Ghassemzadeh, H.R.; Moghaddam, M.; Ghaffari, H. Mechanical Damage Of Strawberry During Harvest And Postharvest Operations. Acta Technol. Agric. 2015, 18, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Shahgholi, G.; Latifi, M.; Jahanbakhshi, A. Potato creep analysis during storage using experimental measurement and finite element method (FEM). J. Food Process Eng. 2020, 43, e13522. [Google Scholar] [CrossRef]

- de Oliveira, G.H.H.; Corrêa, P.C.; Botelho, F.M.; de Oliveira, A. Mechanical Properties of Tomatoes Subjected to an Induced Compression during Storage. J. Texture Stud. 2015, 46, 293–301. [Google Scholar] [CrossRef]

- Prussia, S.E.; Tetteh, M.K.; Verma, B.P.; Nesmith, D.S. Apparent modulus of elasticity from firmtech 2 firmness measurements of blueberries. Trans. ASABE 2006, 49, 113–121. [Google Scholar] [CrossRef]

- Ashebir, D.; Jezik, K.; Weingartemann, H.; Gretzmacher, R. Change in color and other fruit quality characteristics of tomato cultivars after hot-air drying at low final-moisture content. Int. J. Food Sci. Nutr. 2009, 60, 308–315. [Google Scholar] [CrossRef] [PubMed]

- Dehghannya, J.; Gorbani, R.; Ghanbarzadeh, B. Shrinkage of Mirabelle Plum during Hot Air Drying as Influenced by Ultrasound-Assisted Osmotic Dehydration. Int. J. Food Prop. 2016, 19, 1093–1103. [Google Scholar] [CrossRef]

- Elmas, F.; Varhan, E.; Koç, M. Drying characteristics of jujube (Zizyphus jujuba) slices in a hot air dryer and physicochemical properties of jujube powder. J. Food Meas. Charact. 2019, 13, 70–86. [Google Scholar] [CrossRef]

- Koyuncu, T.; Pinar, Y.; Lule, F. Convective drying characteristics of azarole red (Crataegus monogyna Jacq.) and yellow (Crataegus aronia Bosc.) fruits. J. Food Eng. 2007, 78, 1471–1475. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, J.; Tian, W.; Zhang, C.; An, Z. Finite element analysis of blueberry stack damage. J. Food Process Eng. 2021, 44, e13840. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, C.; Takeda, F. Nondestructive Detection and Quantification of Blueberry Bruising using Near-infrared (NIR) Hyperspectral Reflectance Imaging. Sci. Rep. 2016, 6, 35679. [Google Scholar] [CrossRef] [Green Version]

- Fan, S.X.; Li, C.Y.; Huang, W.Q.; Chen, L.P. Data Fusion of Two Hyperspectral Imaging Systems with Complementary Spectral Sensing Ranges for Blueberry Bruising Detection. Sensors 2018, 18, 4463. [Google Scholar] [CrossRef] [Green Version]

| 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | |

|---|---|---|---|---|---|---|---|---|---|

| 0.6428 | 0.5736 | 0.5000 | 0.4226 | 0.3420 | 0.2588 | 0.1736 | 0.0872 | 0.0000 | |

| K | 1.198 | 1.235 | 1.267 | 1.293 | 1.314 | 1.331 | 1.342 | 1.349 | 1.351 |

| Degree of Bruise | Bruise Rate (%) | Compression刘Distance (mm) | Load (N) |

|---|---|---|---|

| ND | 0–7 | 0.0–0.5 | 0.00–1.17 |

| SD | 7–35 | 0.5–2.5 | 1.17–7.26 |

| MD | 35–70 | 2.5–4.0 | 7.26–12.27 |

| HD | 70–100 | 4.0–5.0 | 12.27–16.22 |

| Codes | Maturity | Speed (mm/s) | Load Location (°) |

|---|---|---|---|

| −1 | 1 | 0.1 | 0 |

| 0 | 2 | 0.5 | 90 |

| 1 | 3 | 1.0 | 180 |

| No. | Y | |||

|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 5.06 |

| 2 | 1 | −1 | 0 | 20.31 |

| 3 | −1 | 1 | 0 | 1.13 |

| 4 | 1 | 1 | 0 | 14.69 |

| 5 | −1 | 0 | −1 | 10.93 |

| 6 | 1 | 0 | −1 | 27.12 |

| 7 | −1 | 0 | 1 | 14.69 |

| 8 | 1 | 0 | 1 | 31.42 |

| 9 | 0 | −1 | −1 | 18.13 |

| 10 | 0 | 1 | −1 | 12.57 |

| 11 | 0 | −1 | 1 | 22.13 |

| 12 | 0 | 1 | 1 | 15.63 |

| 13 | 0 | 0 | 0 | 10.35 |

| 14 | 0 | 0 | 0 | 11.76 |

| 15 | 0 | 0 | 0 | 9.18 |

| 16 | 0 | 0 | 0 | 11.32 |

| 17 | 0 | 0 | 0 | 8.13 |

| Items | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 928.07 | 9 | 103.12 | 61.07 | <0.0001 *** |

| 470.18 | 1 | 470.18 | 278.43 | <0.0001 *** | |

| 58.37 | 1 | 58.37 | 34.57 | 0.0006 *** | |

| 27.99 | 1 | 27.99 | 16.58 | 0.0047 ** | |

| 0.91 | 1 | 0.91 | 0.54 | 0.4857 | |

| 0.073 | 1 | 0.073 | 0.043 | 0.8413 | |

| 0.25 | 1 | 0.25 | 0.15 | 0.7139 | |

| 17.48 | 1 | 17.48 | 10.35 | 0.0147 * | |

| 10.54 | 1 | 10.54 | 6.24 | 0.0411 * | |

| 330.13 | 1 | 330.13 | 195.50 | <0.0001 *** | |

| Residual | 11.82 | 7 | 1.69 | ||

| Lack of fit | 2.80 | 3 | 0.93 | 0.41 | 0.7529 |

| Pure error | 9.02 | 4 | 2.26 | ||

| Cor total | 939.89 | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; An, Z.; Liu, X.; Chen, J.; Wang, Y. Finite Element Analysis and Near-Infrared Hyperspectral Reflectance Imaging for the Determination of Blueberry Bruise Grading. Foods 2022, 11, 1899. https://doi.org/10.3390/foods11131899

Zheng Z, An Z, Liu X, Chen J, Wang Y. Finite Element Analysis and Near-Infrared Hyperspectral Reflectance Imaging for the Determination of Blueberry Bruise Grading. Foods. 2022; 11(13):1899. https://doi.org/10.3390/foods11131899

Chicago/Turabian StyleZheng, Zhaoqi, Zimin An, Xinyu Liu, Jinghui Chen, and Yonghong Wang. 2022. "Finite Element Analysis and Near-Infrared Hyperspectral Reflectance Imaging for the Determination of Blueberry Bruise Grading" Foods 11, no. 13: 1899. https://doi.org/10.3390/foods11131899