Legume Seed Protein Digestibility as Influenced by Traditional and Emerging Physical Processing Technologies

Abstract

:1. Introduction

2. Assessment of Digestibility of Legume Seed Proteins

2.1. Methods Used in the Analyses of Legume Seed Protein Digestibility

2.2. Legume Protein Digestibility

3. Inhibition of Digestibility

3.1. Antinutrients

3.2. Mechanisms of Inhibition

3.3. Food Structure and Matrix Effect

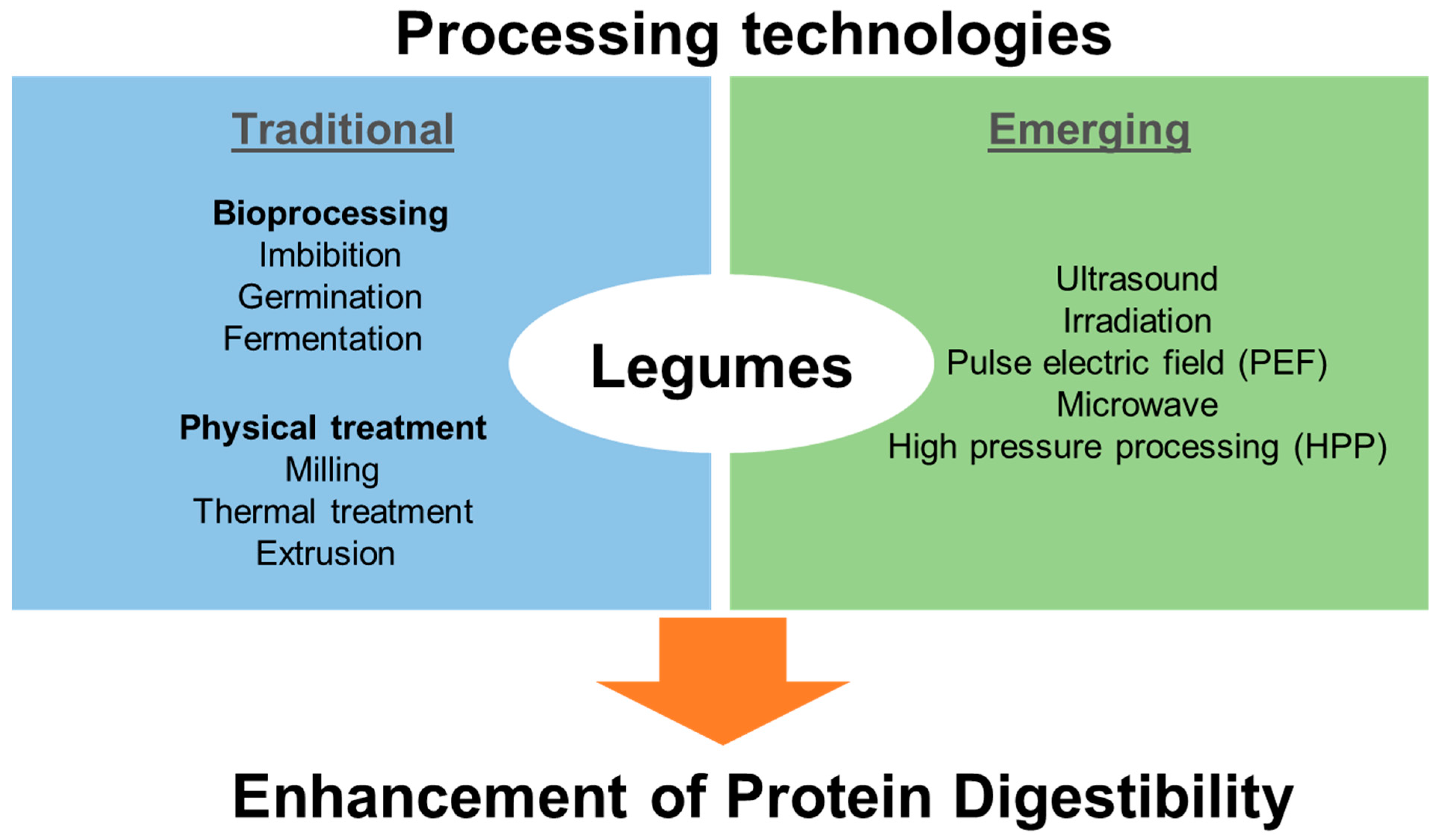

4. Effects of Traditional Processing Technologies on Protein Structure and Digestibility

4.1. Bioprocessing: Imbibition, Germination, and Fermentation

4.2. Physical Treatment: Milling, Thermal Treatment, and Extrusion

4.3. Combination of Bioprocessing and Physical Treatment

5. Emerging Processing Technologies on Protein Structure and Digestibility

5.1. High-Pressure Processing (HPP)

5.2. Ultrasound

5.3. Irradiation

5.4. Pulsed Electric Field (PEF)

5.5. Microwave Heating

6. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rivera-Piza, A.; Lee, S.J. Effects of Dietary Fibers and Prebiotics in Adiposity Regulation via Modulation of Gut Microbiota. Appl. Biol. Chem. 2020, 63, 2. [Google Scholar] [CrossRef]

- Peredo-Lovillo, A.; Romero-Luna, H.E.; Jiménez-Fernández, M. Health Promoting Microbial Metabolites Produced by Gut Microbiota after Prebiotics Metabolism. Food Res. Int. 2020, 136, 109473. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Sabate, R.; Badilla-Briones, Y.; Sabaté, J. Understanding Attitudes towards Reducing Meat Consumption for Environmental Reasons. A Qualitative Synthesis Review. Sustainability 2019, 11, 6295. [Google Scholar] [CrossRef] [Green Version]

- Sanchez-Sabate, R.; Sabaté, J. Consumer Attitudes towards Environmental Concerns of Meat Consumption: A Systematic Review. Int. J. Environ. Res. Public Health 2019, 16, 1220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ohanenye, I.C.; Tsopmo, A.; Ejike, C.E.C.; Udenigwe, C. Germination as a Bioprocess for Enhancing the Quality and Nutritional Prospects of Legume Proteins. Trends Food Sci. Technol. 2020, 101, 213–222. [Google Scholar] [CrossRef]

- Avilés-Gaxiola, S.; Chuck-Hernández, C.; Saldívar, S.O.S. Inactivation Methods of Trypsin Inhibitor in Legumes: A Review. J. Food Sci. 2018, 83, 17–29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giuberti, G.; Tava, A.; Mennella, G.; Pecetti, L.; Masoero, F.; Sparvoli, F.; Fiego, A.L.; Campion, B. Nutrients’ and Antinutrients’ Seed Content in Common Bean (Phaseolus vulgaris L.) Lines Carrying Mutations Affecting Seed Composition. Agronomy 2019, 9, 317. [Google Scholar] [CrossRef] [Green Version]

- Guan, H.; Diao, X.; Liu, D.; Han, J.; Kong, B.; Liu, D.; Gao, C.; Zhang, L. Effect of High-Pressure Processing Enzymatic Hydrolysates of Soy Protein Isolate on the Emulsifying and Oxidative Stability of Myofibrillar Protein-Prepared Oil-in-Water Emulsions. J. Sci. Food Agric. 2020, 100, 3910–3919. [Google Scholar] [CrossRef] [PubMed]

- Vanga, S.K.; Wang, J.; Orsat, V.; Raghavan, V. Effect of Pulsed Ultrasound, a Green Food Processing Technique, on the Secondary Structure and in-Vitro Digestibility of Almond Milk Protein. Food Res. Int. 2020, 137, 109523. [Google Scholar] [CrossRef]

- Vanga, S.K.; Wang, J.; Raghavan, V. Effect of Ultrasound and Microwave Processing on the Structure, in-Vitro Digestibility and Trypsin Inhibitor Activity of Soymilk Proteins. LWT 2020, 131, 109708. [Google Scholar] [CrossRef]

- Sun, X.; Ohanenye, I.C.; Ahmed, T.; Udenigwe, C.C. Microwave Treatment Increased Protein Digestibility of Pigeon Pea (Cajanus cajan) Flour: Elucidation of Underlying Mechanisms. Food Chem. 2020, 329, 127196. [Google Scholar] [CrossRef]

- Pateiro, M.; Munekata, P.E.S.; Tsatsanis, C.; Domínguez, R.; Zhang, W.; Barba, F.J.; Lorenzo, J.M. Evaluation of the Protein and Bioactive Compound Bioaccessibility/Bioavailability and Cytotoxicity of the Extracts Obtained from Aquaculture and Fisheries by-Products. Adv. Food Nutr. Res. 2020, 92, 97–125. [Google Scholar] [CrossRef] [PubMed]

- Coles, L.T.; Moughan, P.J.; Darragh, A.J. In Vitro Digestion and Fermentation Methods, Including Gas Production Techniques, as Applied to Nutritive Evaluation of Foods in the Hindgut of Humans and Other Simple-Stomached Animals. Anim. Feed Sci. Technol. 2005, 123–124 Pt 1, 421–444. [Google Scholar] [CrossRef]

- Bailey, H.M.; Stein, H.H. Raw and Roasted Pistachio Nuts (Pistacia vera L.) Are ‘Good’ Sources of Protein Based on Their Digestible Indispensable Amino Acid Score as Determined in Pigs. J. Sci. Food Agric. 2020, 100, 3878–3885. [Google Scholar] [CrossRef] [PubMed]

- Pandey, M.K.; Roorkiwal, M.; Singh, V.K.; Ramalingam, A.; Kudapa, H.; Thudi, M.; Chitikineni, A.; Rathore, A.; Varshney, R.K. Emerging Genomic Tools for Legume Breeding: Current Status and Future Prospects. Front. Plant Sci. 2016, 7, 455. [Google Scholar] [CrossRef] [Green Version]

- Afzal, M.; Alghamdi, S.S.; Migdadi, H.H.; Khan, M.A.; Nurmansyah; Mirza, S.B.; El-Harty, E. Legume Genomics and Transcriptomics: From Classic Breeding to Modern Technologies. Saudi J. Biol. Sci. 2020, 27, 543–555. [Google Scholar] [CrossRef] [PubMed]

- Nikolić, Z.; Đorđević, V.; Torbica, A.; Mikić, A. Legumes Seed Storage Proteins Characterization by SDS-PAGE and Lab-on-a-Chip Electrophoresis. J. Food Compos. Anal. 2012, 28, 75–80. [Google Scholar] [CrossRef]

- Crimarco, A.; Springfield, S.; Petlura, C.; Streaty, T.; Cunanan, K.; Lee, J.; Fielding-Singh, P.; Carter, M.M.; Topf, M.A.; Wastyk, H.C.; et al. A Randomized Crossover Trial on the Effect of Plant-Based Compared with Animal-Based Meat on Trimethylamine-N-Oxide and Cardiovascular Disease Risk Factors in Generally Healthy Adults: Study with Appetizing Plantfood-Meat Eating Alternative Trial (SWAP-MEAT). Am. J. Clin. Nutr. 2020, 112, 1188–1199. [Google Scholar] [CrossRef] [PubMed]

- Haddad, E.H. Vegetarian Diet and Risk of Cardiovascular Disease. In Vegetarian Nutrition and Wellness; Winston, J.C., Ed.; CRC Press: Boca Raton, CA, USA, 2018; p. 26. ISBN 9781315267012. [Google Scholar]

- Lima, A.I.G.; Mota, J.; Monteiro, S.A.V.S.; Ferreira, R.M.S.B. Legume Seeds and Colorectal Cancer Revisited: Protease Inhibitors Reduce MMP-9 Activity and Colon Cancer Cell Migration. Food Chem. 2016, 197, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Avramenko, N.A.; Low, N.H.; Nickerson, M.T. The Effects of Limited Enzymatic Hydrolysis on the Physicochemical and Emulsifying Properties of a Lentil Protein Isolate. Food Res. Int. 2013, 51, 162–169. [Google Scholar] [CrossRef]

- Toews, R.; Wang, N. Physicochemical and Functional Properties of Protein Concentrates from Pulses. Food Res. Int. 2013, 52, 445–451. [Google Scholar] [CrossRef]

- Berghout, J.A.M.; Venema, P.; Boom, R.M.; Van der Goot, A.J. Comparing Functional Properties of Concentrated Protein Isolates with Freeze-Dried Protein Isolates from Lupin Seeds. Food Hydrocoll. 2015, 51, 346–354. [Google Scholar] [CrossRef]

- Ladjal-Ettoumi, Y.; Boudries, H.; Chibane, M.; Romero, A. Pea, Chickpea and Lentil Protein Isolates: Physicochemical Characterization and Emulsifying Properties. Food Biophys. 2016, 11, 43–51. [Google Scholar] [CrossRef]

- Burger, T.G.; Zhang, Y. Recent Progress in the Utilization of Pea Protein as an Emulsifier for Food Applications. Trends Food Sci. Technol. 2019, 86, 25–33. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-Based Meat Analogues. In Sustainable Meat Production and Processing; Galankis, M.C., Ed.; Academic Press: London, UK, 2019; pp. 103–126. [Google Scholar]

- Kumar, A.; Agarwal, D.K.; Kumar, S.; Reddy, Y.M.; Chintagunta, A.D.; Saritha, K.V.; Pal, G.; Kumar, S.P.J. Nutraceuticals Derived from Seed Storage Proteins: Implications for Health Wellness. Biocatal. Agric. Biotechnol. 2019, 17, 710–719. [Google Scholar] [CrossRef]

- Bar-El Dadon, S.; Pascual, C.Y.; Eshel, D.; Teper-Bamnolker, P.; Paloma Ibáñez, M.D.; Reifen, R. Vicilin and the Basic Subunit of Legumin Are Putative Chickpea Allergens. Food Chem. 2013, 138, 13–18. [Google Scholar] [CrossRef]

- Rui, X.; Boye, J.I.; Ribereau, S.; Simpson, B.K.; Prasher, S.O. Comparative Study of the Composition and Thermal Properties of Protein Isolates Prepared from Nine Phaseolus vulgaris Legume Varieties. Food Res. Int. 2011, 44, 2497–2504. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, X.; Hou, W.; Li, P.; Sha, W.; Tian, Y. Structure and Function of Seed Storage Proteins in Faba Bean (Vicia faba L.). 3 Biotech 2017, 7, 74. [Google Scholar] [CrossRef] [Green Version]

- Hsu, H.W.; Vavak, D.L.; Satterlee, L.D.; Miller, G.A. A Multienzyme Technique for Estimating Protein Digestibility. J. Food Sci. 1977, 42, 1269–1273. [Google Scholar] [CrossRef]

- Oyeyinka, A.T.; Pillay, K.; Siwela, M. Full Title- In Vitro Digestibility, Amino Acid Profile and Antioxidant Activity of Cooked Bambara Groundnut Grain. Food Biosci. 2019, 31, 100428. [Google Scholar] [CrossRef]

- Tinus, T.; Damour, M.; Van Riel, V.; Sopade, P.A. Particle Size-Starch-Protein Digestibility Relationships in Cowpea (Vigna unguiculata). J. Food Eng. 2012, 113, 254–264. [Google Scholar] [CrossRef]

- Zhu, L.; Jie, C.; Tang, X.; Xiong, Y.L. Reducing, Radical Scavenging, and Chelation Properties of In Vitro Digests of Alcalase-Treated Zein Hydrolysate. J. Agric. Food Chem. 2008, 56, 2714–2721. [Google Scholar] [CrossRef] [PubMed]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carrière, F.; Boutrou, R.; Corredig, M.; Dupont, D.; et al. A Standardised Static In Vitro Digestion Method Suitable for Food-an International Consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sousa, R.; Portmann, R.; Dubois, S.; Recio, I.; Egger, L. Protein Digestion of Different Protein Sources Using the INFOGEST Static Digestion Model. Food Res. Int. 2020, 130, 108996. [Google Scholar] [CrossRef] [PubMed]

- Ménard, O.; Bourlieu, C.; De Oliveira, S.C.; Dellarosa, N.; Laghi, L.; Carrière, F.; Capozzi, F.; Dupont, D.; Deglaire, A. A First Step towards a Consensus Static In Vitro Model for Simulating Full-Term Infant Digestion. Food Chem. 2018, 240, 338–345. [Google Scholar] [CrossRef]

- Roux, L.L.; Chacon, R.; Dupont, D.; Jeantet, R.; Deglaire, A.; Nau, F. In Vitro Static Digestion Reveals How Plant Proteins Modulate Model Infant Formula Digestibility. Food Res. Int. 2020, 130, 108917. [Google Scholar] [CrossRef]

- Guerra, A.; Etienne-Mesmin, L.; Livrelli, V.; Denis, S.; Blanquet-Diot, S.; Alric, M. Relevance and Challenges in Modeling Human Gastric and Small Intestinal Digestion. Trends Biotechnol. 2012, 30, 591–600. [Google Scholar] [CrossRef]

- Jing, T.Z.; Qi, F.H.; Wang, Z.Y. Most Dominant Roles of Insect Gut Bacteria: Digestion, Detoxification, or Essential Nutrient Provision? Microbiome 2020, 8, 38. [Google Scholar] [CrossRef] [Green Version]

- Oliphant, K.; Allen-Vercoe, E. Macronutrient Metabolism by the Human Gut Microbiome: Major Fermentation by-Products and Their Impact on Host Health. Microbiome 2019, 7, 91. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Medina, G.; Franczyk, A.J.; Neufeld, J.; Appah, P.; Utioh, A.; Frohlich, P.; House, J.D. Effect of Processing on the In Vitro and In Vivo Protein Quality of Beans (Phaseolus vulgaris and Vicia faba). Nutrients 2018, 10, 671. [Google Scholar] [CrossRef] [Green Version]

- Gabriel, I.; Quillien, L.; Cassecuelle, F.; Marget, P.; Juin, H.; Lessire, M.; Sève, B.; Duc, G.; Burstin, J. Variation in Seed Protein Digestion of Different Pea (Pisum sativum L.) Genotypes by Cecectomized Broiler Chickens: 2. Relation between In Vivo Protein Digestibility and Pea Seed Characteristics, and Identification of Resistant Pea Polypeptides. Livest. Sci. 2008, 113, 262–273. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Medina, G.; Franczyk, A.J.; Neufeld, J.; Appah, P.; Utioh, A.; Frohlich, P.; House, J.D. Effect of Processing on the In Vitro and In Vivo Protein Quality of Red and Green Lentils (Lens culinaris). Food Chem. 2018, 240, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Almaas, H.; Eriksen, E.; Sekse, C.; Comi, I.; Flengsrud, R.; Holm, H.; Jensen, E.; Jacobsen, M.; Langsrud, T.; Vegarud, G.E. Antibacterial Peptides Derived from Caprine Whey Proteins, by Digestion with Human Gastrointestinal Juice. Br. J. Nutr. 2011, 106, 896–905. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tapal, A.; Vegarud, G.E.; Sreedhara, A.; Kaul Tiku, P. Nutraceutical Protein Isolate from Pigeon Pea (Cajanus cajan) Milling Waste by-Product: Functional Aspects and Digestibility. Food Funct. 2019, 10, 2710–2719. [Google Scholar] [CrossRef]

- Ambawat, S.; Khetarpaul, N. Comparative Assessment of Antioxidant, Nutritional and Functional Properties of Soybean and Its by-Product Okara. Ann. Phytomed. 2018, 7, 112–118. [Google Scholar] [CrossRef]

- Anitha, S.; Govindaraj, M.; Kane-Potaka, J. Balanced Amino Acid and Higher Micronutrients in Millets Complements Legumes for Improved Human Dietary Nutrition. Cereal Chem. 2020, 97, 74–84. [Google Scholar] [CrossRef] [Green Version]

- Carbonaro, M.; Maselli, P.; Nucara, A. Relationship between Digestibility and Secondary Structure of Raw and Thermally Treated Legume Proteins: A Fourier Transform Infrared (FT-IR) Spectroscopic Study. Amino Acids 2012, 43, 911–921. [Google Scholar] [CrossRef]

- Carbonaro, M.; Maselli, P.; Nucara, A. Structural Aspects of Legume Proteins and Nutraceutical Properties. Food Res. Int. 2015, 76, 19–30. [Google Scholar] [CrossRef]

- Ribeiro, I.C.; Leclercq, C.C.; Simões, N.; Toureiro, A.; Duarte, I.; Freire, J.B.; Chaves, M.M.; Renaut, J.; Pinheiro, C. Identification of Chickpea Seed Proteins Resistant to Simulated In Vitro Human Digestion. J. Proteom. 2017, 169, 143–152. [Google Scholar] [CrossRef]

- Kimura, A.; Takako, F.; Meili, Z.; Shiori, M.; Maruyama, N.; Utsumi, S. Comparison of Physicochemical Properties of 7S and 11S Globulins from Pea, Fava Bean, Cowpea, and French Bean with Those of Soybean-French Bean 7S Globulin Exhibits Excellent Properties. J. Agric. Food Chem. 2008, 56, 10273–10279. [Google Scholar] [CrossRef]

- Melito, C.; Tovar, J. Cell Walls Limit In Vitro Protein Digestibility in Processed Legume Seeds. Food Chem. 1995, 53, 305–307. [Google Scholar] [CrossRef]

- Bhattarai, R.R.; Dhital, S.; Wu, P.; Chen, X.D.; Gidley, M.J. Digestion of Isolated Legume Cells in a Stomach-Duodenum Model: Three Mechanisms Limit Starch and Protein Hydrolysis. Food Funct. 2017, 8, 2573–2582. [Google Scholar] [CrossRef]

- Zahir, M.; Fogliano, V.; Capuano, E. Food Matrix and Processing Modulate: In Vitro Protein Digestibility in Soybeans. Food Funct. 2018, 9, 6326–6336. [Google Scholar] [CrossRef]

- Ohanenye, I.; Sun, X.; Sarteshnizi, R.A.; Udenigwe, C.C. Germination Alters the Microstructure, In Vitro Protein Digestibility, α -Glucosidase and Dipeptidyl Peptidase-IV Inhibitory Activities of Bioaccessible Fraction of Pigeon Pea (Cajanus cajan) Seeds. Legum. Sci. 2021, 3, e79. [Google Scholar] [CrossRef]

- Stone, A.K.; Nosworthy, M.G.; Chiremba, C.; House, J.D.; Nickerson, M.T. A Comparative Study of the Functionality and Protein Quality of a Variety of Legume and Cereal Flours. Cereal Chem. 2019, 96, 1159–1169. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Franczyk, A.J.; Medina, G.; Neufeld, J.; Appah, P.; Utioh, A.; Frohlich, P.; House, J.D. Effect of Processing on the In Vitro and In Vivo Protein Quality of Yellow and Green Split Peas (Pisum sativum). J. Agric. Food Chem. 2017, 65, 7790–7796. [Google Scholar] [CrossRef] [PubMed]

- Nosworthy, M.G.; Neufeld, J.; Frohlich, P.; Young, G.; Malcolmson, L.; House, J.D. Determination of the Protein Quality of Cooked Canadian Pulses. Food Sci. Nutr. 2017, 5, 896–903. [Google Scholar] [CrossRef]

- Gilani, G.S.; Xiao, C.W.; Cockell, K.A. Impact of Antinutritional Factors in Food Proteins on the Digestibility of Protein and the Bioavailability of Amino Acids and on Protein Quality. Br. J. Nutr. 2012, 108, S315–S332. [Google Scholar] [CrossRef] [PubMed]

- Patterson, C.A.; Curran, J.; Der, T. Effect of Processing on Antinutrient Compounds in Pulses. Cereal Chem. 2017, 94, 2–10. [Google Scholar] [CrossRef]

- Joye, I. Protein Digestibility of Cereal Products. Foods 2019, 8, 199. [Google Scholar] [CrossRef] [Green Version]

- Samtiya, M.; Aluko, R.E.; Dhewa, T. Plant Food Anti-Nutritional Factors and Their Reduction Strategies: An Overview. Food Prod. Process. Nutr. 2020, 2, 6. [Google Scholar] [CrossRef]

- Nørgaard, J.V.; Malla, N.; Dionisio, G.; Madsen, C.K.; Pettersson, D.; Lærke, H.N.; Hjortshøj, R.L.; Brinch-Pedersen, H. Exogenous Xylanase or Protease for Pigs Fed Barley Cultivars with High or Low Enzyme Inhibitors. Anim. Feed Sci. Technol. 2019, 248, 59–66. [Google Scholar] [CrossRef]

- El-Hady, E.A.A.; Habiba, R.A. Effect of Soaking and Extrusion Conditions on Antinutrients and Protein Digestibility of Legume Seeds. LWT—Food Sci. Technol. 2003, 36, 285–293. [Google Scholar] [CrossRef]

- Cristina Oliveira de Lima, V.; Piuvezam, G.; Leal Lima Maciel, B.; Heloneida de Araújo Morais, A. Trypsin Inhibitors: Promising Candidate Satietogenic Proteins as Complementary Treatment for Obesity and Metabolic Disorders? J. Enzyme Inhib. Med. Chem. 2019, 34, 405–419. [Google Scholar] [CrossRef]

- Nissar, J.; Ahad, T.; Naik, H.R.; Hussain, S.Z. A Review Phytic Acid: As Antinutrient or Nutraceutical. J. Pharmacogn. Phytochem. 2017, 6, 1554–1560. [Google Scholar]

- Cirkovic Velickovic, T.D.; Stanic-Vucinic, D.J. The Role of Dietary Phenolic Compounds in Protein Digestion and Processing Technologies to Improve Their Antinutritive Properties. Compr. Rev. Food Sci. Food Saf. 2018, 17, 82–103. [Google Scholar] [CrossRef] [Green Version]

- Singh, N. Pulses: An Overview. J. Food Sci. Technol. 2017, 54, 853–857. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parmar, N.; Singh, N.; Kaur, A.; Virdi, A.S.; Shevkani, K. Protein and Microstructure Evaluation of Harder-to-Cook and Easy-to-Cook Grains from Different Kidney Bean Accessions. LWT—Food Sci. Technol. 2017, 79, 487–495. [Google Scholar] [CrossRef]

- Capuano, E.; Pellegrini, N. An Integrated Look at the Effect of Structure on Nutrient Bioavailability in Plant Foods. J. Sci. Food Agric. 2018, 99, 493–498. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drulyte, D.; Orlien, V. The Effect of Processing on Digestion of Legume Proteins. Foods 2019, 8, 224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rovalino-Córdova, A.M.; Fogliano, V.; Capuano, E. The Effect of Cell Wall Encapsulation on Macronutrients Digestion: A Case Study in Kidney Beans. Food Chem. 2019, 286, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Holland, C.; Ryden, P.; Edwards, C.H.; Grundy, M.M.L. Plant Cell Walls: Impact on Nutrient Bioaccessibility and Digestibility. Foods 2020, 9, 201. [Google Scholar] [CrossRef] [Green Version]

- Zahir, M.; Fogliano, V.; Capuano, E. Effect of Soybean Processing on Cell Wall Porosity and Protein Digestibility. Food Funct. 2020, 11, 285–296. [Google Scholar] [CrossRef] [Green Version]

- Ranawana Viren, V.; Henry, C.J.K.; Pratt Megan, M. Degree of Habitual Mastication Seems to Contribute to Interindividual Variations in the Glycemic Response to Rice but Not to Spaghetti. Nutr. Res. 2010, 30, 382–391. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; House, J.D. Factors Influencing the Quality of Dietary Proteins: Implications for Pulses. Cereal Chem. 2017, 94, 49–57. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Xie, Q.F.; Che, L. ming Effects of Gamma Irradiation on Aflatoxin B1 Levels in Soybean and on the Properties of Soybean and Soybean Oil. Appl. Radiat. Isot. 2018, 139, 224–230. [Google Scholar] [CrossRef] [PubMed]

- Lima, D.C.; Miano, A.C.; Augusto, P.E.D.; Arthur, V. Gamma Irradiation of Common Beans: Effect on Nutritional and Technological Properties. LWT 2019, 116, 108539. [Google Scholar] [CrossRef]

- Siddhuraju, P.; Makkar, H.P.S.; Becker, K. The Effect of Ionising Radiation on Antinutritional Factors and the Nutritional Value of Plant Materials with Reference to Human and Animal Food. Food Chem. 2002, 78, 187–205. [Google Scholar] [CrossRef]

- Tresina, P.S.; Paulpriya, K.; Veerabahu Ramasamy Mohan, S.J. Effect of Gamma Irradiation on the Nutritional and Antinutritional Qualities of Vigna aconitifolia (Jacq.) Marechal: An Underutilized Food Legume. Biocatal. Agric. Biotechnol. 2017, 10, 30–37. [Google Scholar] [CrossRef]

- Tresina, P.S.; Mohan, V.R. Effect of Gamma Irradiation on Physicochemical Properties, Proximate Composition, Vitamins and Antinutritional Factors of the Tribal Pulse Vigna unguiculata subsp. unguiculata. Int. J. Food Sci. Technol. 2011, 46, 1739–1746. [Google Scholar] [CrossRef]

- Hassan, A.B.; Mahmoud, N.S.; Elmamoun, K.; Adiamo, O.Q.; Mohamed Ahmed, I.A. Effects of Gamma Irradiation on the Protein Characteristics and Functional Properties of Sesame (Sesamum indicum L.) Seeds. Radiat. Phys. Chem. 2018, 144, 85–91. [Google Scholar] [CrossRef]

- Bamidele, O.; Akanbi, C. Effect of Gamma Irradiation on Amino Acids Profile, Minerals and Some Vitamins Content in Pigeon Pea (Cajanus cajan) Flour. Br. J. Appl. Sci. Technol. 2015, 5, 90–98. [Google Scholar] [CrossRef]

- Khatkar, A.B.; Kaur, A.; Khatkar, S.K. Restructuring of Soy Protein Employing Ultrasound: Effect on Hydration, Gelation, Thermal, In-Vitro Protein Digestibility and Structural Attributes. LWT 2020, 132, 109781. [Google Scholar] [CrossRef]

- Martínez-Velasco, A.; Alvarez-Ramirez, J.; Rodríguez-Huezo, E.; Meraz-Rodríguez, M.; Vernon-Carter, E.; Lobato-Calleros, C. Effect of the Preparation Method and Storage Time on the In Vitro Protein Digestibility of Maize Tortillas. J. Cereal Sci. 2018, 84, 7–12. [Google Scholar] [CrossRef]

- Linsberger-Martin, G.; Weiglhofer, K.; Thi Phuong, T.P.; Berghofer, E. High Hydrostatic Pressure Influences Antinutritional Factors and In Vitro Protein Digestibility of Split Peas and Whole White Beans. LWT—Food Sci. Technol. 2013, 51, 331–336. [Google Scholar] [CrossRef]

- Laguna, L.; Picouet, P.; Guàrdia, M.D.; Renard, C.M.G.C.; Sarkar, A. In Vitro Gastrointestinal Digestion of Pea Protein Isolate as a Function of PH, Food Matrices, Autoclaving, High-Pressure and Re-Heat Treatments. LWT—Food Sci. Technol. 2017, 84, 511–519. [Google Scholar] [CrossRef]

- Lee, H.; Ha, M.J.; Shahbaz, H.M.; Kim, J.U.; Jang, H.; Park, J. High Hydrostatic Pressure Treatment for Manufacturing of Red Bean Powder: A Comparison with the Thermal Treatment. J. Food Eng. 2018, 238, 141–147. [Google Scholar] [CrossRef]

- Zhong, Y.; Wang, Z.; Zhao, Y. Impact of Radio Frequency, Microwaving, and High Hydrostatic Pressure at Elevated Temperature on the Nutritional and Antinutritional Components in Black Soybeans. J. Food Sci. 2015, 80, C2732–C2739. [Google Scholar] [CrossRef]

- Vagadia, B.H.; Vanga, S.K.; Singh, A.; Gariepy, Y.; Raghavan, V. Comparison of Conventional and Microwave Treatment on Soymilk for Inactivation of Trypsin Inhibitors and In Vitro Protein Digestibility. Foods 2018, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Boye, J.I.; Hu, X. In Vitro Digestibility, Protein Composition and Techno-Functional Properties of Saskatchewan Grown Yellow Field Peas (Pisum sativum L.) as Affected by Processing. Food Res. Int. 2017, 92, 64–78. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Cartier, A.; Obielodan, M.; Jordan, K.; Hairston, T.; Shannon, A.; Sismour, E. Nutritional and Anti-Nutritional Composition, and In Vitro Protein Digestibility of Kabuli Chickpea (Cicer arietinum L.) as Affected by Differential Processing Methods. J. Food Meas. Charact. 2016, 10, 625–633. [Google Scholar] [CrossRef]

- De Souza Rocha, T.; Hernandez, L.M.R.; Chang, Y.K.; de Mejía, E.G. Impact of Germination and Enzymatic Hydrolysis of Cowpea Bean (Vigna Unguiculata) on the Generation of Peptides Capable of Inhibiting Dipeptidyl Peptidase IV. Food Res. Int. 2014, 64, 799–809. [Google Scholar] [CrossRef] [PubMed]

- Di Stefano, E.; Tsopmo, A.; Oliviero, T.; Fogliano, V.; Udenigwe, C.C. Bioprocessing of Common Pulses Changed Seed Microstructures, and Improved Dipeptidyl Peptidase-IV and α-Glucosidase Inhibitory Activities. Sci. Rep. 2019, 9, 15308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- González-Montoya, M.; Hernández-Ledesma, B.; Mora-Escobedo, R.; Martínez-Villaluenga, C. Bioactive Peptides from Germinated Soybean with Anti-Diabetic Potential by Inhibition of Dipeptidyl Peptidase-IV, α-Amylase, and α-Glucosidase Enzymes. Int. J. Mol. Sci. 2018, 19, 2883. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dipnaik, K.; Bathere, D. Effect of Soaking and Sprouting on Protein Content and Transaminase Activity in Pulses. Int. J. Res. Med. Sci. 2017, 5, 4271. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Singh, A.; Singh, B. Effect on Germination Time and Temperature on Techno-Functional Properties and Protein Solubility of Pigeon Pea (Cajanus cajan) Flour. Qual. Assur. Saf. Crop. Foods 2019, 11, 305–312. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, A.; Singh, B. Characterization of In Vitro Antioxidant Activity, Bioactive Components, and Nutrient Digestibility in Pigeon Pea (Cajanus cajan) as Influenced by Germination Time and Temperature. J. Food Biochem. 2019, 43, e12706. [Google Scholar] [CrossRef]

- Gänzle, M.G. Food Fermentations for Improved Digestibility of Plant Foods–an Essential Ex Situ Digestion Step in Agricultural Societies? Curr. Opin. Food Sci. 2020, 32, 124–132. [Google Scholar] [CrossRef]

- Oghbaei, M.; Prakash, J. Effect of Primary Processing of Cereals and Legumes on Its Nutritional Quality: A Comprehensive Review. Cogent Food Agric. 2016, 2, 1136015. [Google Scholar] [CrossRef] [Green Version]

- Park, S.J.; Kim, T.; Baik, B.K. Relationship between Proportion and Composition of Albumins, and In Vitro Protein Digestibility of Raw and Cooked Pea Seeds (Pisum sativum L.). J. Sci. Food Agric. 2010, 90, 1719–1725. [Google Scholar] [CrossRef]

- Mojica, L.; Chen, K.; de Mejía, E.G. Impact of Commercial Precooking of Common Bean (Phaseolus vulgaris) on the Generation of Peptides, After Pepsin-Pancreatin Hydrolysis, Capable to Inhibit Dipeptidyl Peptidase-IV. J. Food Sci. 2015, 80, H188–H198. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Boye, J.I.; Simpson, B.K.; Prasher, S.O.; Monpetit, D.; Malcolmson, L. Thermal Processing Effects on the Functional Properties and Microstructure of Lentil, Chickpea, and Pea Flours. Food Res. Int. 2011, 44, 2534–2544. [Google Scholar] [CrossRef]

- Boye, J.I.; Aksay, S.; Roufik, S.; Ribéreau, S.; Mondor, M.; Farnworth, E.; Rajamohamed, S.H. Comparison of the Functional Properties of Pea, Chickpea and Lentil Protein Concentrates Processed Using Ultrafiltration and Isoelectric Precipitation Techniques. Food Res. Int. 2010, 43, 537–546. [Google Scholar] [CrossRef]

- Frias, J.; Giacomino, S.; Peñas, E.; Pellegrino, N.; Ferreyra, V.; Apro, N.; Carrión, O.O.; Vidal-Valverde, C. Assessment of the Nutritional Quality of Raw and Extruded Pisum sativum L. var. laguna Seeds. LWT—Food Sci. Technol. 2011, 44, 1303–1308. [Google Scholar] [CrossRef] [Green Version]

- Roy, F.; Boye, J.I.; Simpson, B.K. Bioactive Proteins and Peptides in Pulse Crops: Pea, Chickpea and Lentil. Food Res. Int. 2010, 43, 432–442. [Google Scholar] [CrossRef]

- Batista, K.A.; Prudêncio, S.H.; Fernandes, K.F. Changes in the Functional Properties and Antinutritional Factors of Extruded Hard-to-Cook Common Beans (Phaseolus vulgaris, L.). J. Food Sci. 2010, 75, 286–290. [Google Scholar] [CrossRef]

- Simons, C.W.; Hall, C.; Tulbek, M.; Mendis, M.; Heck, T.; Ogunyemi, S. Acceptability and Characterization of Extruded Pinto, Navy and Black Beans. J. Sci. Food Agric. 2015, 95, 2287–2291. [Google Scholar] [CrossRef]

- Torres, J.; Rutherfurd, S.M.; Muñoz, L.S.; Peters, M.; Montoya, C.A. The Impact of Heating and Soaking on the In Vitro Enzymatic Hydrolysis of Protein Varies in Different Species of Tropical Legumes. Food Chem. 2016, 194, 377–382. [Google Scholar] [CrossRef]

- Singhal, A.; Karaca, A.C.; Tyler, R.; Nickerson, M. Pulse Proteins: From Processing to Structure-Function Relationships. In Grain Legumes; IntechOpen: London, UK, 2016. [Google Scholar]

- Kalpanadevi, V.; Mohan, V.R. Effect of Processing on Antinutrients and In Vitro Protein Digestibility of the Underutilized Legume, Vigna unguiculata (L.) Walp Subsp. Unguiculata. LWT—Food Sci. Technol. 2013, 51, 455–461. [Google Scholar] [CrossRef]

- Gemede, H.F.; Ratta, N. Antinutritional Factors in Plant Foods: Potential Health Benefits and Adverse Effects. Int. J. Nutr. Food Sci. 2014, 3, 284. [Google Scholar] [CrossRef] [Green Version]

- Porzucek, H.; Duszkiewicz-Reinhard, W.; Piecyk, M.; Klepacka, I.; Gniewosz, M. Changes of Flatulence-Causing Sugars in Legume Protein Samples by High Hydrostatic Pressure. Electron. Pol. Agric. Ser. Food Sci. Technol. 2002, 5, 7. [Google Scholar]

- Ahmed, J.; Al-Ruwaih, N.; Mulla, M.; Rahman, M.H. Effect of High Pressure Treatment on Functional, Rheological and Structural Properties of Kidney Bean Protein Isolate. LWT—Food Sci. Technol. 2018, 91, 191–197. [Google Scholar] [CrossRef]

- Peyrano, F.; Speroni, F.; Avanza, M.V. Physicochemical and Functional Properties of Cowpea Protein Isolates Treated with Temperature or High Hydrostatic Pressure. Innov. Food Sci. Emerg. Technol. 2016, 33, 38–46. [Google Scholar] [CrossRef]

- Karki, B.; Lamsal, B.P.; Jung, S.; van Leeuwen, J.H.; Pometto, A.L.; Grewell, D.; Khanal, S.K. Enhancing Protein and Sugar Release from Defatted Soy Flakes Using Ultrasound Technology. J. Food Eng. 2010, 96, 270–278. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Smith, B.; Guo, Y. Ultrasound-Microwave Assisted Extraction of Pectin from Fig (Ficus Carica L.) Skin: Optimization, Characterization and Bioactivity. Carbohydr. Polym. 2019, 222, 114992. [Google Scholar] [CrossRef]

- Rathod, R.P.; Annapure, U.S. Effect of Extrusion Process on Antinutritional Factors and Protein and Starch Digestibility of Lentil Splits. LWT—Food Sci. Technol. 2016, 66, 114–123. [Google Scholar] [CrossRef]

- Navarro del Hierro, J.; Herrera, T.; García-Risco, M.R.; Fornari, T.; Reglero, G.; Martin, D. Ultrasound-Assisted Extraction and Bioaccessibility of Saponins from Edible Seeds: Quinoa, Lentil, Fenugreek, Soybean and Lupin. Food Res. Int. 2018, 109, 440–447. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Liu, X.; Ren, X.; Huang, Y.; Huang, C.; Zhang, K. Swirling Cavitation Improves the Emulsifying Properties of Commercial Soy Protein Isolate. Ultrason. Sonochem. 2018, 42, 471–481. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Ding, J.; Andrade, J.; Rababah, T.M.; Almajwal, A.; Abulmeaty, M.M.; Feng, H. Modifying the Physicochemical Properties of Pea Protein by PH-Shifting and Ultrasound Combined Treatments. Ultrason. Sonochem. 2017, 38, 835–842. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Murray, B.; Flynn, C.; Norton, I. Comparison of Batch and Continuous Ultrasonic Emulsification Processes. J. Food Eng. 2015, 167, 114–121. [Google Scholar] [CrossRef] [Green Version]

- O’Sullivan, J.; Beevers, J.; Park, M.; Greenwood, R.; Norton, I. Comparative Assessment of the Effect of Ultrasound Treatment on Protein Functionality Pre- and Post-Emulsification. Colloids Surf. A Physicochem. Eng. Asp. 2015, 484, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Han, I.H.; Swanson, B.G.; Baik, B.K. Protein Digestibility of Selected Legumes Treated with Ultrasound and High Hydrostatic Pressure during Soaking. Cereal Chem. 2007, 84, 518–521. [Google Scholar] [CrossRef]

- Rivera del Rio, A.; Opazo-Navarrete, M.; Cepero-Betancourt, Y.; Tabilo-Munizaga, G.; Boom, R.M.; Janssen, A.E.M. Heat-Induced Changes in Microstructure of Spray-Dried Plant Protein Isolates and Its Implications on In Vitro Gastric Digestion. LWT 2020, 118, 108795. [Google Scholar] [CrossRef]

- Byanju, B.; Rahman, M.M.; Hojilla-Evangelista, M.P.; Lamsal, B.P. Effect of High-Power Sonication Pretreatment on Extraction and Some Physicochemical Properties of Proteins from Chickpea, Kidney Bean, and Soybean. Int. J. Biol. Macromol. 2020, 145, 712–721. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, H.; Zhu, X.; Hu, T.; Cheung, I.W.Y.; Pan, S.; Li-Chan, E.C.Y. Effect of Ultrasound Pre-Treatment on Formation of Transglutaminase-Catalysed Soy Protein Hydrogel as a Riboflavin Vehicle for Functional Foods. J. Funct. Foods 2015, 19, 182–193. [Google Scholar] [CrossRef]

- Xiong, T.; Xiong, W.; Ge, M.; Xia, J.; Li, B.; Chen, Y. Effect of High Intensity Ultrasound on Structure and Foaming Properties of Pea Protein Isolate. Food Res. Int. 2018, 109, 260–267. [Google Scholar] [CrossRef]

- Bhat, R.; Sridhar, K.R.; Tomita-Yokotani, K. Effect of Ionizing Radiation on Antinutritional Features of Velvet Bean Seeds (Mucuna pruriens). Food Chem. 2007, 103, 860–866. [Google Scholar] [CrossRef]

- Brigide, P.; Canniatti-Brazaca, S.G. Antinutrients and “In Vitro” Availability of Iron in Irradiated Common Beans (Phaseolus vulgaris). Food Chem. 2006, 98, 85–89. [Google Scholar] [CrossRef]

- Osman, A.M.A.; Hassan, A.B.; Osman, G.A.M.; Mohammed, N.; Rushdi, M.A.H.; Diab, E.E.; Babiker, E.E. Effects of Gamma Irradiation and/or Cooking on Nutritional Quality of Faba Bean (Vicia faba L.) Cultivars Seeds. J. Food Sci. Technol. 2014, 51, 1554–1560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jombo, T.Z.; Emmambux, M.N.; Taylor, J.R.N. Modification of the Functional Properties of Hard-to-Cook Cowpea Seed Flours and Cooked Prepared Pastes by γ-Irradiation. J. Food Sci. Technol. 2020, 58, 22–23. [Google Scholar] [CrossRef]

- Akbarian, A.; Khorvash, M.; Ghorbani, G.R.; Ghasemi, E.; Dehghan-Banadaky, M.; Shawrang, P.; Hosseini Ghaffari, M. Effects of Roasting and Electron Beam Irradiating on Protein Characteristics, Ruminal Degradability and Intestinal Digestibility of Soybean and the Performance of Dairy Cows. Livest. Sci. 2014, 168, 45–52. [Google Scholar] [CrossRef]

- Kumar Dixit, A.; Kumar, V.; Rani, A.; Manjaya, J.G.; Bhatnagar, D. Effect of Gamma Irradiation on Lipoxygenases, Trypsin Inhibitor, Raffinose Family Oligosaccharides and Nutritional Factors of Different Seed Coat Colored Soybean (Glycine max L.). Radiat. Phys. Chem. 2011, 80, 597–603. [Google Scholar] [CrossRef]

- Mallikarjunan, N.; Marathe, S.; Rajalakshmi, D.; Mahesh, S.; Jamdar, S.N.; Sharma, A. Effect of Ionizing Radiation on Structural and Functional Attributes of Red Kidney Bean (Phaseolus vulgaris L.) Lectin. LWT—Food Sci. Technol. 2014, 59, 300–307. [Google Scholar] [CrossRef]

- Li, Y. Effect of High Intensity Pulsed Electric Field on Inactivation of Soybean Trypsin Inhibitor. J. Anhui Agric. Sci. 2006, 34, 3800. [Google Scholar]

- Bhat, Z.F.; Morton, J.D.; Mason, S.L.; Bekhit, A.E.D.A. Pulsed Electric Field Improved Protein Digestion of Beef during In-Vitro Gastrointestinal Simulation. LWT 2019, 102, 45–51. [Google Scholar] [CrossRef]

- Simonetti, A.; Gambacorta, E.; Perna, A. Antioxidative and Antihypertensive Activities of Pig Meat before and after Cooking and In Vitro Gastrointestinal Digestion: Comparison between Italian Autochthonous Pig Suino Nero Lucano and a Modern Crossbred Pig. Food Chem. 2016, 212, 590–595. [Google Scholar] [CrossRef]

- Freedman, K.J.; Haq, S.R.; Edel, J.B.; Jemth, P.; Kim, M.J. Single Molecule Unfolding and Stretching of Protein Domains inside a Solid-State Nanopore by Electric Field. Sci. Rep. 2013, 3, 1638. [Google Scholar] [CrossRef] [Green Version]

- Kala, B.K.; Mohan, V.R. Effect of Microwave Treatment on the Antinutritional Factors of Two Accessions of Velvet Bean, Mucuna pruriens (L.) DC. var. utilis (Wall. Ex Wight) Bak. Ex Burck. Int. Food Res. J. 2012, 19, 961–969. [Google Scholar]

- Deng, Y.; Padilla-Zakour, O.; Zhao, Y.; Tao, S. Influences of High Hydrostatic Pressure, Microwave Heating, and Boiling on Chemical Compositions, Antinutritional Factors, Fatty Acids, In Vitro Protein Digestibility, and Microstructure of Buckwheat. Food Bioprocess Technol. 2015, 8, 2235–2245. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, K.; Hasjim, J.; Li, E.; Flanagan, B.M.; Gidley, M.J.; Dhital, S. Freeze-Drying Changes the Structure and Digestibility of B-Polymorphic Starches. J. Agric. Food Chem. 2014, 62, 1482–1491. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Wang, S.; Guo, J.; Wang, S. Modification of Glutenin and Associated Changes in Digestibility Due to Methylglyoxal during Heat Processing. J. Agric. Food Chem. 2019, 67, 10734–10743. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, Z.; Wang, R.; Sui, X.; Qi, B.; Han, F.; Li, Y.; Jiang, L. Secondary Structure and Subunit Composition of Soy Protein In Vitro Digested by Pepsin and Its Relation with Digestibility. Biomed Res. Int. 2016, 2016, 5498639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yalcin, S.; Basman, A. Effects of Infrared Treatment on Urease, Trypsin Inhibitor and Lipoxygenase Activities of Soybean Samples. Food Chem. 2015, 169, 203–210. [Google Scholar] [CrossRef] [PubMed]

| Technology | Legume Type | Treatment Conditions | IVPD Outcome | Process Advantages | Process Disadvantages | Reference |

|---|---|---|---|---|---|---|

| Irradiation | Soybean | 4.8, 9.2, 15.3, and 21.2 kGy | + | Increases isoflavone, phenol, and anthocyanin content | May induce vitamin C reduction. | [78] |

| Carioca beans | 10 kGy | + | [79] | |||

| Faba beans | 0.5 and 1.0 kGy | + | [80] | |||

| Moth beans | 2, 5, 10, 15, and 25 kGy | + | [81] | |||

| Cow pea | 2, 5, 10, 15, and 25 kGy | + | [82] | |||

| Sesame seed | 0.5 and 1.0 kGy | + | [83] | |||

| Pigeon pea | 20 kGy | + | [84] | |||

| Ultrasound | Soybean | 20 kHz and amplitude (20–40%), 10–20 min | + | Selective method | Energy-demanding | [85] |

| Soybean | 25 kHz, 400 W, 1–16 min | + | [10] | |||

| Fava bean | 20 kHz, 750 W | − | [86] | |||

| High-pressure processing | Split peas White beans | 600 MPa, 60 °C, different time intervals | + |

| It should be used in combination with other methods to achieve high effectiveness | [87] |

| Peas | 600 MPa, 25–28 °C, 5 min | + | [88] | |||

| Red bean | 600 MPa, 25 °C, 5 min | + | [89] | |||

| Black soybean | 600 MPa, 60 °C, 30 min | + | [90] | |||

| Microwave heating | Soybean | 2450 MHz, 2–10 min 70–100 °C, | + |

|

| [10] |

| Soybean | 2450 MHz, 1000 Watts | + | [91] | |||

| Yellow field pea seeds | 1200 W, 25 min | + | [92] | |||

| Pigeon pea | Cook mode, 3 min | + | [11] | |||

| Chickpea | 2450 MHz, 15 min | + | [93] | |||

| Radiofrequency heating | Black soybean | 2450 MHz, 30 min | No effect |

|

| [90] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ohanenye, I.C.; Ekezie, F.-G.C.; Sarteshnizi, R.A.; Boachie, R.T.; Emenike, C.U.; Sun, X.; Nwachukwu, I.D.; Udenigwe, C.C. Legume Seed Protein Digestibility as Influenced by Traditional and Emerging Physical Processing Technologies. Foods 2022, 11, 2299. https://doi.org/10.3390/foods11152299

Ohanenye IC, Ekezie F-GC, Sarteshnizi RA, Boachie RT, Emenike CU, Sun X, Nwachukwu ID, Udenigwe CC. Legume Seed Protein Digestibility as Influenced by Traditional and Emerging Physical Processing Technologies. Foods. 2022; 11(15):2299. https://doi.org/10.3390/foods11152299

Chicago/Turabian StyleOhanenye, Ikenna C., Flora-Glad C. Ekezie, Roghayeh A. Sarteshnizi, Ruth T. Boachie, Chijioke U. Emenike, Xiaohong Sun, Ifeanyi D. Nwachukwu, and Chibuike C. Udenigwe. 2022. "Legume Seed Protein Digestibility as Influenced by Traditional and Emerging Physical Processing Technologies" Foods 11, no. 15: 2299. https://doi.org/10.3390/foods11152299

APA StyleOhanenye, I. C., Ekezie, F.-G. C., Sarteshnizi, R. A., Boachie, R. T., Emenike, C. U., Sun, X., Nwachukwu, I. D., & Udenigwe, C. C. (2022). Legume Seed Protein Digestibility as Influenced by Traditional and Emerging Physical Processing Technologies. Foods, 11(15), 2299. https://doi.org/10.3390/foods11152299