Antimicrobial and Functional Properties of Duckweed (Wolffia globosa) Protein and Peptide Extracts Prepared by Ultrasound-Assisted Extraction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composition Analyses of Dried W. globosa

2.3. Microorganisms

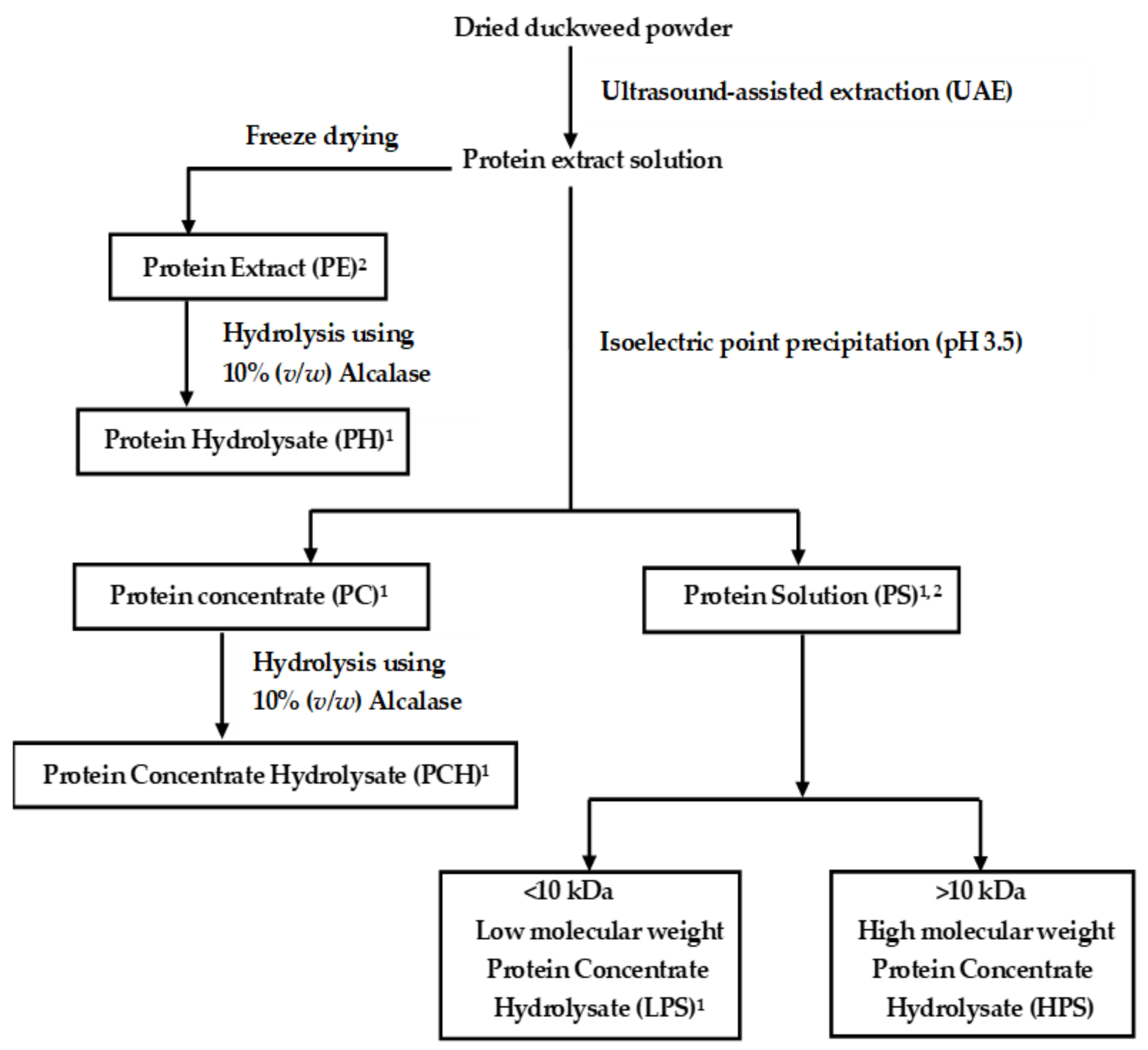

2.4. Preparation of Protein Fractions

2.5. Antimicrobial Assay

2.5.1. Preparation of Test Microorganisms

2.5.2. Antimicrobial Test

2.6. Determination of Functional Properties

2.6.1. Protein Solubility

2.6.2. Emulsifying Capacity (EC) and Emulsifying Stability (ES)

2.7. Characterization of Proteins and Peptides

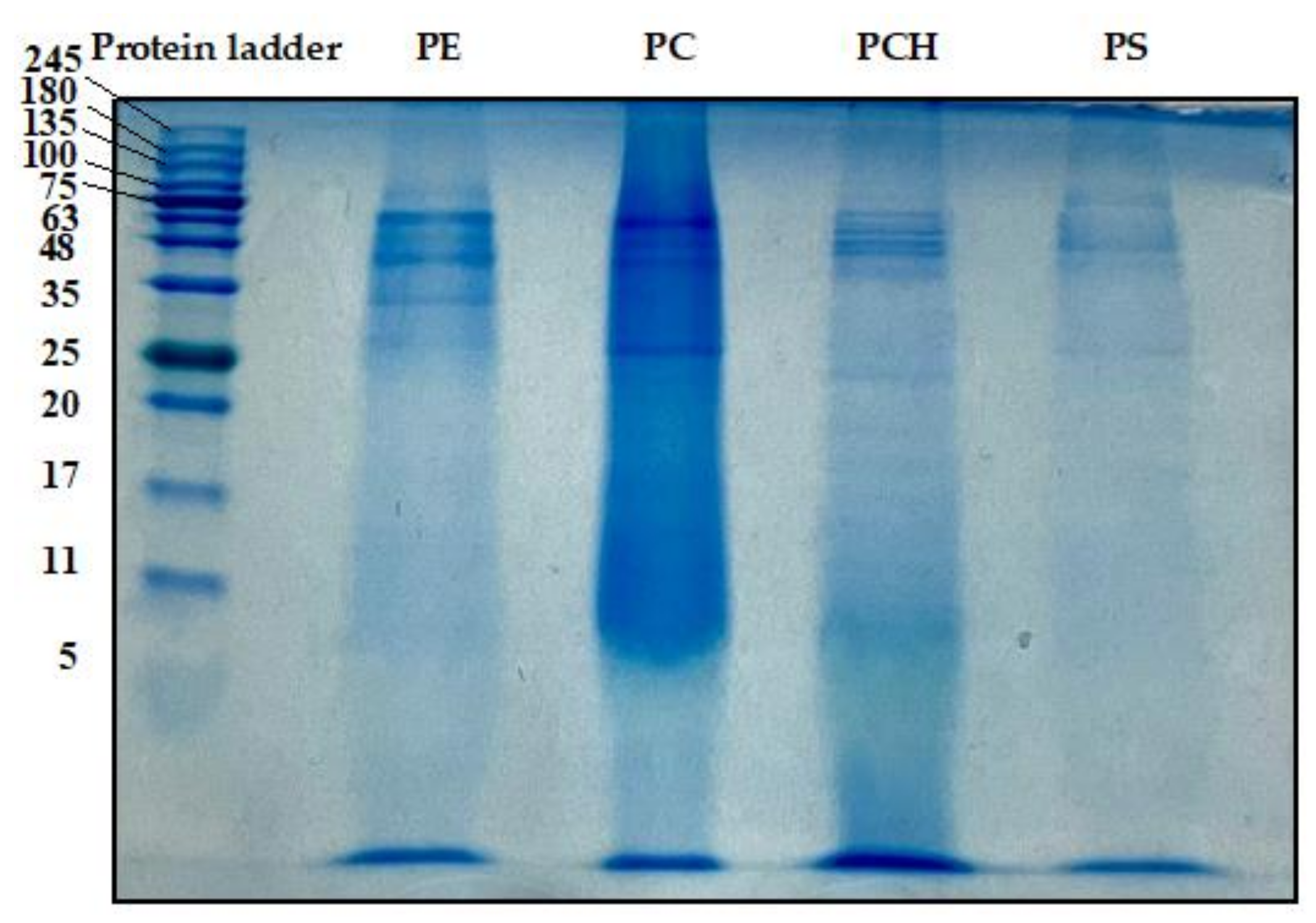

2.7.1. Molecular Weight (Mw) Determination of Proteins and Peptides

2.7.2. Amino Acid Composition Analysis

2.8. Statistical Analysis

3. Results

3.1. The Compositions of Dried W. globosa

3.2. Antimicrobial Properties

3.3. Functional Properties of Duckweed Protein

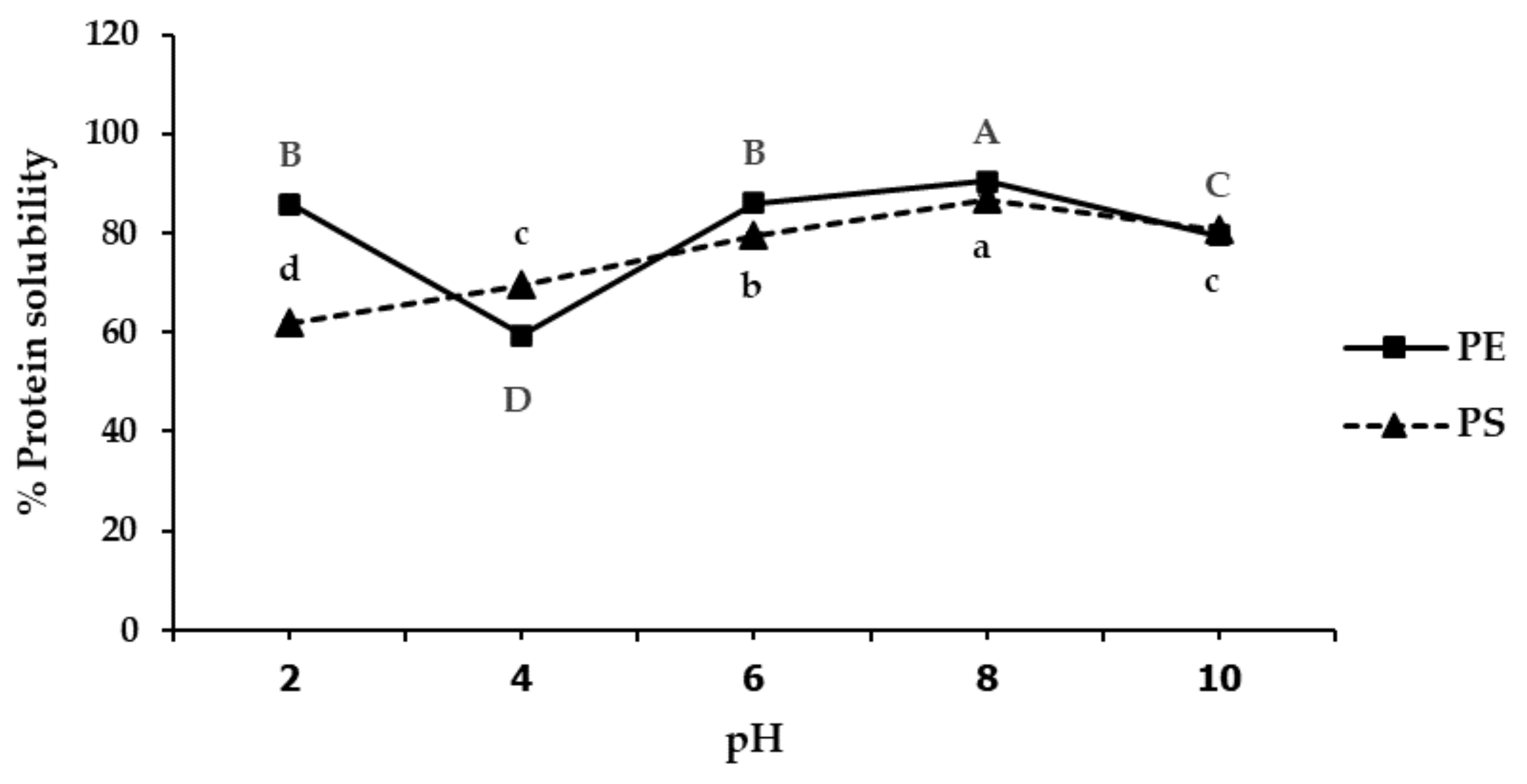

3.3.1. Effect of pH on Protein Solubility

3.3.2. Effect of pH on Emulsifying Property

3.4. Characterization of Duckweed Proteins and Peptides

3.4.1. Determination of Molecular Weight (Mw)

3.4.2. Amino Acid Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sha, L.; Xiong, Y.L. Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Colgrave, M.L.; Dominik, S.; Tobin, A.B.; Stockmann, R.; Simon, C.; Howitt, C.A.; Belobrajdic, D.P.; Paull, C.; Vanhercke, T. Perspectives on Future Protein Production. J. Agric. Food Chem. 2021, 69, 15076–15083. [Google Scholar] [CrossRef] [PubMed]

- Boye, J.I. Food allergies in developing and emerging economies: Need for comprehensive data on prevalence rates. Clin. Transl. Allergy 2012, 2, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, J.; Shen, Y.; Zheng, Y.; Smith, G.; Sun, X.S.; Wang, D.; Zhao, Y.; Zhang, W.; Li, Y. Duckweed (Lemnaceae) for potentially nutritious human food: A review. Food Rev. Int. 2021, 37, 1–15. [Google Scholar] [CrossRef]

- Ruekaewma, N. Optimal Conditions for Production of Khai-nam Wolffia globosa. Ph.D. Thesis, Chulalongkorn University, Bangkok, Thailand, 2011. [Google Scholar]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Wouters, A.G.; Rombouts, I.; Legein, M.; Fierens, E.; Brijs, K.; Blecker, C.; Delcour, J.A. Air-water interfacial properties of enzymatic wheat gluten hydrolyzates determine their foaming behavior. Food Hydrocoll. 2016, 55, 155–162. [Google Scholar] [CrossRef]

- Kadam, S.U.; Álvarez, C.; Tiwari, B.K.; O'Donnell, C.P. Extraction and characterization of protein from Irish brown seaweed Ascophyllum nodosum. Food Res. Int. 2017, 99, 1021–1027. [Google Scholar] [CrossRef]

- Görgüç, A.; Gençdağ, E.; Yılmaz, F.M. Bioactive peptides derived from plant origin by-products: Biological activities and techno-functional utilizations in food developments-A review. Food Res. Int. 2020, 136, 109504. [Google Scholar] [CrossRef]

- Nwachukwu, I.D.; Aluko, R.E. CHAPTER 1: Food Protein Structures, Functionality and Product Development. In Food Proteins and Peptides: Emerging Biofunctions, Food and Biomaterial Applications, 1st ed.; The Royal Society of Chemistry: London, UK, 2021; pp. 1–33. [Google Scholar]

- Burgos-Diaz, C.; Piornos, J.A.; Wandersleben, T.; Ogura, T.; Hernandez, X.; Rubilar, M. Emulsifying and Foaming Properties of Different Protein Fractions Obtained from a Novel Lupin Variety AluProt-CGNA((R)) (Lupinus luteus). J. Food Sci. 2016, 81, C1699–C1706. [Google Scholar] [CrossRef]

- Burgos-Díaz, C.; Hernández, X.; Wandersleben, T.; Barahona, T.; Medina, C.; Quiroz, A.; Rubilar, M. Influence of multilayer O/W emulsions stabilized by proteins from a novel lupin variety AluProt-CGNA and ionic polysaccharides on d-limonene retention during spray-drying. Colloids Surf. A Physicochem. Eng. Asp. 2018, 536, 234–241. [Google Scholar] [CrossRef]

- AOAC. Methods of Analysis; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Duangjarus, N.; Chaiworapuek, W.; Ritthiruangdej, P.; Sae-tan, S.; Charoensiddhi, S. Ultrasound-assisted extraction for the recovery of proteins from duckweed (Wolffia globosa) using response surface methodology. In Proceedings of the 59th Kasetsart University Annual Conference, Bangkok, Thailand, 10–12 March 2021. [Google Scholar]

- Silva, F.G.D.; Hernández-Ledesma, B.; Amigo, L.; Netto, F.M.; Miralles, B. Identification of peptides released from flaxseed (Linum usitatissimum) protein by Alcalase® hydrolysis: Antioxidant activity. LWT Food Sci. Technol. 2017, 76, 140–146. [Google Scholar] [CrossRef] [Green Version]

- Wikler, M.A. Methods for dilution antimicrobial susceptibility tests for bacteria that grow aerobically: Approved standard. CLSI 2006, 26, M7-A1. [Google Scholar]

- Piornos, J.A.; Burgos-Díaz, C.; Ogura, T.; Morales, E.; Rubilar, M.; Maureira-Butler, I.; Salvo-Garrido, H. Functional and physicochemical properties of a protein isolate from AluProt-CGNA: A novel protein-rich lupin variety (Lupinus luteus). Food Res. Int. 2015, 76, 719–724. [Google Scholar] [CrossRef] [PubMed]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef] [PubMed]

- Gorissen, S.H.; Crombag, J.J.; Senden, J.M.; Waterval, W.; Bierau, J.; Verdijk, L.B.; van Loon, L.J. Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids 2018, 50, 1685–1695. [Google Scholar] [CrossRef] [Green Version]

- Lordelo, M.; Gaspar, A.; Le Bellego, L.; Freire, J.P.B. Isoleucine and valine supplementation of a low-protein corn-wheat-soybean meal-based diet for piglets: Growth performance and nitrogen balance. J. Anim. Sci. 2008, 86, 2936–2941. [Google Scholar] [CrossRef]

- Dandare, S.U.; Ezeonwumelu, I.J.; Shinkafi, T.S.; Magaji, U.F.; Adio, A.A.I.; Ahmad, K. L-alanine supplementation improves blood glucose level and biochemical indices in alloxan-induced diabetic rats. J. Food Biochem. 2021, 45, e13590. [Google Scholar] [CrossRef]

- Thalacker-Mercer, A.E.; Gheller, M.E. Benefits and adverse effects of histidine supplementation. J. Nutr. 2020, 150 (Suppl. 1), 2588S–2592S. [Google Scholar] [CrossRef]

- Sánchez-Vioque, R.; Clemente, A.; Vioque, J.; Bautista, J.; Millán, F. Protein isolates from chickpea (Cicer arietinum L.): Chemical composition, functional properties and protein characterization. Food Chem. 1999, 64, 237–243. [Google Scholar] [CrossRef]

- Bora, P.S. Functional properties of native and succinylated lentil (Lens culinaris) globulins. Food Chem. 2002, 77, 171–176. [Google Scholar] [CrossRef]

- Sironi, E.; Sessa, F.; Duranti, M. A simple procedure of lupin seed protein fractionation for selective food applications. Eur. Food Res. Technol. 2005, 221, 145–150. [Google Scholar] [CrossRef]

- Duranti, M.; Gius, C.; Sessa, F.; Vecchio, G. The Saccharide Chain of Lupin Seed Conglutin γ is not Responsible for the Protection of the Native Protein from Degradation by Trypsin, but Facilitates the Refolding of the Acid-Treated Protein to the Resistant Conformation. FEBS J. 1995, 230, 886–891. [Google Scholar]

- Lestari, D.; Mulder, W.J.; Sanders, J.P. Jatropha seed protein functional properties for technical applications. Biochem. Eng. J. 2011, 53, 297–304. [Google Scholar] [CrossRef]

- Chavan, U.; McKenzie, D.; Shahidi, F. Functional properties of protein isolates from beach pea (Lathyrus maritimus L.). Food Chem. 2001, 74, 177–187. [Google Scholar] [CrossRef]

- Adebowale, K.O.; Olu-Owolabi, B.I.; kehinde Olawumi, E.; Lawal, O.S. Functional properties of native, physically and chemically modified breadfruit (Artocarpus artilis) starch. Ind. Crops Prod. 2005, 21, 343–351. [Google Scholar] [CrossRef]

- Dee, K.C.; Puleo, D.A.; Bizios, R. Protein-surface interactions. In An Introduction to Tissue-Biomaterial Interactions, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2002; pp. 37–52. [Google Scholar]

- Ye, A. Complexation between milk proteins and polysaccharides via electrostatic interaction: Principles and applications-a review. Int. J. Food Sci. 2008, 43, 406–415. [Google Scholar] [CrossRef]

- Bouyer, E.; Mekhloufi, G.; Rosilio, V.; Grossiord, J.-L.; Agnely, F. Proteins, polysaccharides, and their complexes used as stabilizers for emulsions: Alternatives to synthetic surfactants in the pharmaceutical field? Int. J. Pharm. 2012, 436, 359–378. [Google Scholar] [CrossRef]

- Garcia-Vaquero, M.; Lopez-Alonso, M.; Hayes, M. Assessment of the functional properties of protein extracted from the brown seaweed Himanthalia elongata (Linnaeus) S. F. Gray. Food Res. Int. 2017, 99 Pt 3, 971–978. [Google Scholar] [CrossRef] [Green Version]

- Nasir, S.; Sarbon, N.M. Angiotensin converting enzyme (ACE), antioxidant activity and functional properties of shortfin scad (Decapterus macrosoma) muscle protein hydrolysate at different molecular weight variations. Biocatal. Agric. Biotechnol. 2019, 20, 101254. [Google Scholar] [CrossRef]

- Nieuwland, M.; Geerdink, P.; Engelen-Smit, N.P.E.; van der Meer, I.M.; America, A.H.P.; Mes, J.J.; Kootstra, A.M.J.; Henket, J.T.M.M.; Mulder, W.J. Isolation and Gelling Properties of Duckweed Protein Concentrate. ACS Food Sci. Technol. 2021, 1, 908–916. [Google Scholar] [CrossRef]

- Dashper, S.G.; O'Brien-Simpson, N.M.; Cross, K.J.; Paolini, R.A.; Hoffmann, B.; Catmull, D.V.; Malkoski, M.; Reynolds, E.C. Chemotherapy, Divalent metal cations increase the activity of the antimicrobial peptide kappacin. Antimicrob. Agents Chemother. 2005, 49, 2322–2328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Components | Dried W. globosa Powder (% Dry Basis) |

|---|---|

| Moisture | 8.61 ± 0.02 |

| Protein | 33.16 ± 1.91 |

| Carbohydrate | 36.73 ± 2.03 |

| Ash | 14.58 ± 0.10 |

| Crude fiber | 12.49 ± 0.17 |

| Fat | 3.03 ± 0.19 |

| Sample | Log Reduction | |

|---|---|---|

| V. parahaemolyticus | C. albicans | |

| PH | 0.12 ± 0.46 ns | NI |

| PC | NI | 0.31 ± 0.22 b |

| PCH | 0.43 ± 1.31 ns | 3.70 ± 0.11 a |

| PS | 0.21 ± 0.17 ns | NI |

| LPS | NI | NI |

| Amino Acid | Amount (mg/g) | ||

|---|---|---|---|

| PE | PCH | PS | |

| Lys | 6.58 | 11.04 | 5.50 |

| His | 8.79 | 12.76 | 8.83 |

| Arg | 6.57 | 12.40 | 7.07 |

| Asp | 37.20 | 22.85 | 24.58 |

| Glu | 34.80 | 28.89 | 21.67 |

| Ser | 6.57 | 9.18 | 3.98 |

| Thr | 5.70 | 8.61 | 3.12 |

| Ala | 16.21 | 15.57 | 10.65 |

| Val | 14.94 | 16.90 | 9.51 |

| Ile | 7.86 | 9.60 | 4.65 |

| Leu | 15.19 | 19.56 | 8.46 |

| Met | 0.33 | 0.15 | 0.21 |

| Phe | 8.47 | 11.21 | 5.05 |

| Tyr | 1.67 | 5.58 | 2.35 |

| Cys | 0.00 | 0.00 | 0.00 |

| Gly | 11.92 | 12.28 | 7.11 |

| Pro | 7.04 | 7.19 | 2.89 |

| Total amino acids | 189.84 | 203.77 | 125.63 |

| Amino Acid | Percentage | |||||||

|---|---|---|---|---|---|---|---|---|

| PE | PCH | PS | Micro-Algae | Soy | Pea | Lupin | Oat | |

| Lys | 3.66 | 5.37 | 4.72 | 9.68 | 6.59 | 8.13 | 5.08 | 3.40 |

| His | 4.70 | 6.34 | 7.08 | 1.88 | 2.91 | 2.77 | 2.91 | 2.36 |

| Arg | 3.66 | 5.85 | 5.50 | 9.14 | 9.30 | 10.21 | 13.32 | 8.12 |

| Asp | 19.34 | 11.22 | 19.65 | NA | NA | NA | NA | NA |

| Glu | 18.30 | 14.15 | 17.30 | 15.32 | 24.03 | 22.32 | 30.02 | 28.80 |

| Ser | 3.66 | 4.83 | 3.14 | 5.65 | 6.59 | 6.23 | 6.05 | 5.76 |

| Thr | 3.14 | 4.39 | 2.36 | 5.65 | 4.46 | 4.33 | 3.87 | 3.93 |

| Ala | 8.36 | 7.80 | 8.65 | 10.75 | 5.43 | 5.54 | 4.12 | 5.76 |

| Val | 7.84 | 8.29 | 7.86 | 5.65 | 4.26 | 4.67 | 3.39 | 5.24 |

| Ile | 4.18 | 4.88 | 3.93 | 3.23 | 3.68 | 3.98 | 3.63 | 3.40 |

| Leu | 7.84 | 9.27 | 6.29 | 10.75 | 9.69 | 9.86 | 7.75 | 9.95 |

| Met | 0.16 | 0.05 | 0.16 | 0.00 | 0.58 | 0.52 | 0.48 | 0.26 |

| Phe | 4.18 | 5.37 | 3.93 | 5.65 | 6.20 | 6.40 | 4.36 | 7.07 |

| Tyr | 1.05 | 2.93 | 1.57 | 3.23 | 4.26 | 4.50 | 4.60 | 3.93 |

| Cys | 0.00 | 0.00 | 0.00 | 0.27 | 0.39 | 0.35 | 0.48 | 1.05 |

| Gly | 6.27 | 5.85 | 5.50 | 6.99 | 5.23 | 4.84 | 5.08 | 4.45 |

| Pro | 3.66 | 3.41 | 2.36 | 6.18 | 6.40 | 5.36 | 4.84 | 6.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duangjarus, N.; Chaiworapuek, W.; Rachtanapun, C.; Ritthiruangdej, P.; Charoensiddhi, S. Antimicrobial and Functional Properties of Duckweed (Wolffia globosa) Protein and Peptide Extracts Prepared by Ultrasound-Assisted Extraction. Foods 2022, 11, 2348. https://doi.org/10.3390/foods11152348

Duangjarus N, Chaiworapuek W, Rachtanapun C, Ritthiruangdej P, Charoensiddhi S. Antimicrobial and Functional Properties of Duckweed (Wolffia globosa) Protein and Peptide Extracts Prepared by Ultrasound-Assisted Extraction. Foods. 2022; 11(15):2348. https://doi.org/10.3390/foods11152348

Chicago/Turabian StyleDuangjarus, Natchaya, Weerachai Chaiworapuek, Chitsiri Rachtanapun, Pitiporn Ritthiruangdej, and Suvimol Charoensiddhi. 2022. "Antimicrobial and Functional Properties of Duckweed (Wolffia globosa) Protein and Peptide Extracts Prepared by Ultrasound-Assisted Extraction" Foods 11, no. 15: 2348. https://doi.org/10.3390/foods11152348