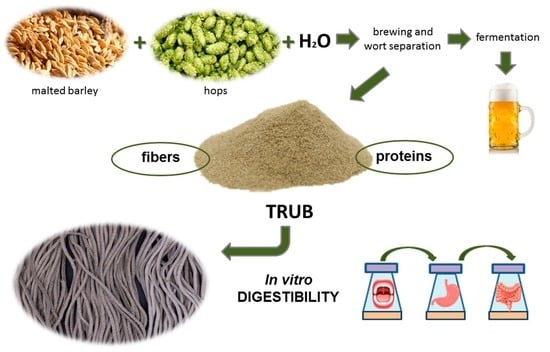

Durum Wheat Fresh Pasta Fortification with Trub, a Beer Industry By-Product

Abstract

:1. Introduction

2. Materials and Methods

2.1. Debittered Trub Powder Preparation

2.2. Preparation of Pasta with DTP

2.3. Proximate Composition

2.4. In Vitro Digestion of Pasta Samples for the Evaluation of Digestibility of Proteins

2.5. In Vitro Starch Digestion of Pasta Samples

2.6. Technological Properties

2.7. Texture Analysis

2.8. Color Analysis

2.9. Sensory Evaluation

2.10. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analyses

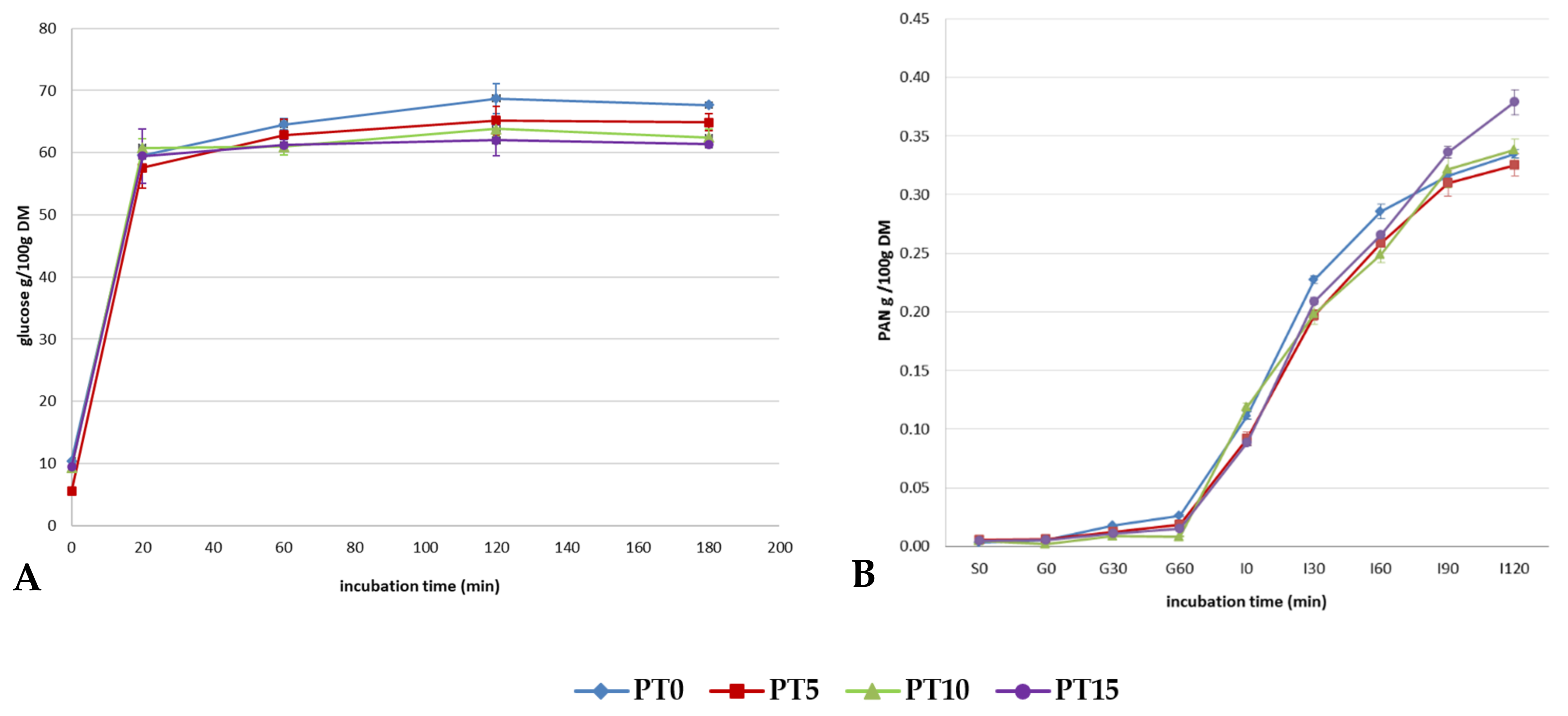

3.2. In Vitro Starch and Protein Digestion

3.3. Technological and Cooking Properties, and Texture of Pasta

3.4. Color Analysis

3.5. Sensory Evaluation

3.6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cimini, A.; Moresi, M. Circular economy in the brewing chain. Ital. J. Food Sci. 2021, 33, 47–69. [Google Scholar] [CrossRef]

- dos Santos Mathias, T.R.; de Mello, P.P.M.; Eliana, F.C.S. Solid wastes in brewing process: A review. J. Brew. Distill. 2014, 5, 1–9. [Google Scholar] [CrossRef]

- Rachwał, K.; Waśko, A.; Gustaw, K.; Polak-Berecka, M. Utilization of brewery wastes in food industry. PeerJ 2020, 8, e9427. [Google Scholar] [CrossRef] [PubMed]

- Saraiva, B.R.; Anjo, F.A.; Vital, A.C.P.; da Silva, L.H.M.; Ogawa, C.Y.L.; Sato, F.; Coimbra, L.B.; Matumoto-Pintro, P.T. Waste from brewing (trub) as a source of protein for the food industry. Int. J. Food Sci. Technol. 2019, 54, 1247–1255. [Google Scholar] [CrossRef]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, nutritional, and sensory properties of pasta fortified with agro-industrial by-products: A review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Wang, J.; Brennan, M.A.; Serventi, L.; Brennan, C.S. Impact of functional vegetable ingredients on the technical and nutritional quality of pasta. Crit. Rev. Food Sci. Nutr. 2021, 62, 6069–6080. [Google Scholar] [CrossRef]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta fortification with olive pomace: Effects on the technological characteristics and nutritional properties. LWT 2019, 114, 108368. [Google Scholar] [CrossRef]

- Rocchetti, G.; Rizzi, C.; Cervini, M.; Rainero, G.; Bianchi, F.; Giuberti, G.; Lucini, L.; Simonato, B. Impact of Grape Pomace Powder on the Phenolic Bioaccessibility and on In Vitro Starch Digestibility of Wheat Based Bread. Foods 2021, 10, 557. [Google Scholar] [CrossRef]

- Rocchetti, G.; Rizzi, C.; Pasini, G.; Lucini, L.; Giuberti, G.; Simonato, B. Effect of Moringa oleifera L. leaf powder addition on the phenolic bioaccessibility and on in vitro starch digestibility of durum wheat fresh pasta. Foods 2020, 9, 628. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; The Association of Official Analytical Chemist: Gaithersburg, MD, USA, 2007. [Google Scholar]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F.; et al. INFOGEST static in vitro simulation of gastrointestinal food digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar] [CrossRef]

- AACC. Approved Method of the AACC, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Cleary, L.; Brennan, C. The influence of a (1 → 3)(1 → 4)-β-D-glucan rich fraction from barley on the physico-chemical properties and in vitro reducing sugars release of durum wheat pasta. Int. J. Food Sci. Technol. 2006, 41, 910–918. [Google Scholar] [CrossRef]

- Rainero, G.; Bianchi, F.; Rizzi, C.; Cervini, M.; Giuberti, G.; Simonato, B. Breadsticks fortification with red grape pomace: Effect on nutritional, technological, and sensory properties. J. Sci. Food Agric. 2021, 102, 2545–2552. [Google Scholar] [CrossRef] [PubMed]

- Murray, J.C.; Kiszonas, A.M.; Morris, C.F. Influence of Soft Kernel Texture on Fresh Durum Pasta. J. Food Sci. 2018, 83, 2812–2818. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.; Giuberti, G.; Cervini, M.; Simonato, B. Fortification of Durum Wheat Fresh Pasta with Maqui (Aristotelia chilensis) and Its Effects on Technological, Nutritional, Sensory Properties, and Predicted Glycemic Index. Food Bioprocess Technol. 2022, 15, 1563–1572. [Google Scholar] [CrossRef]

- Simonato, B.; Tolve, R.; Rainero, G.; Rizzi, C.; Sega, D.; Rocchetti, G.; Lucini, L.; Giuberti, G. Technological, nutritional, and sensory properties of durum wheat fresh pasta fortified with Moringa oleifera L. leaf powder. J. Sci. Food Agric. 2020, 101, 1920–1925. [Google Scholar] [CrossRef] [PubMed]

- Saraiva, B.R.; Zancheta, J.C.; Gibin, M.S.; Anjo, F.A.; Lazzari, A.; Ribeiro, E.; Filho, M.; Sato, F.; Matumoto-pintro, P. Brewing by-product valorisation: Trub debittered for nutritional and quality improvement of pasta. Int. J. Food Sci. Nutr. 2022, 1–12. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Simonato, B.; Curioni, A.; Pasini, G. Digestibility of pasta made with three wheat types: A preliminary study. Food Chem. 2015, 174, 219–225. [Google Scholar] [CrossRef]

- Ding, L.; Xie, Z.; Fu, X.; Wang, Z.; Huang, Q.; Zhang, B. Structural and in vitro starch digestion properties of potato parenchyma cells: Effects of gelatinization degree. Food Hydrocoll. 2021, 113, 106464. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of Grape Pomace Addition on the Technological, Sensory, and Nutritional Properties of Durum Wheat Pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef]

- Rakhesh, N.; Fellows, C.M.; Sissons, M. Evaluation of the technological and sensory properties of durum wheat spaghetti enriched with different dietary fibres. J. Sci. Food Agric. 2015, 95, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Messia, M.C.; Cuomo, F.; Falasca, L.; Trivisonno, M.C.; De Arcangelis, E.; Marconi, E. Nutritional and technological quality of high protein pasta. Foods 2021, 10, 589. [Google Scholar] [CrossRef] [PubMed]

- Sykut-Domańska, E.; Zarzycki, P.; Sobota, A.; Teterycz, D.; Wirkijowska, A.; Blicharz-Kania, A.; Andrejko, D.; Mazurkiewicz, J. The potential use of by-products from coconut industry for production of pasta. J. Food Process. Preserv. 2020, 44, e14490. [Google Scholar] [CrossRef]

- Zarzycki, P.; Sykut-Domańska, E.; Sobota, A.; Teterycz, D.; Krawęcka, A.; Blicharz-Kania, A.; Andrejko, D.; Zdybel, B. Flaxseed enriched pasta—chemical composition and cooking quality. Foods 2020, 9, 404. [Google Scholar] [CrossRef] [PubMed]

- Pasini, G.; Cullere, M.; Vegro, M.; Simonato, B.; Dalle Zotte, A. Potentiality of protein fractions from the house cricket (Acheta domesticus) and yellow mealworm (Tenebrio molitor) for pasta formulation. LWT 2022, 164, 113638. [Google Scholar] [CrossRef]

- Sant’Anna, V.; Christiano, F.D.P.; Marczak, L.D.F.; Tessaro, I.C.; Thys, R.C.S. The effect of the incorporation of grape marc powder in fettuccini pasta properties. LWT 2014, 58, 497–501. [Google Scholar] [CrossRef]

- Nocente, F.; Natale, C.; Galassi, E.; Taddei, F.; Gazza, L. Using einkorn and tritordeum brewers’ spent grain to increase the nutritional potential of durum wheat pasta. Foods 2021, 10, 502. [Google Scholar] [CrossRef]

- Gaita, C.; Alexa, E.; Moigradean, D.; Conforti, F.; Poiana, M.A. Designing of high value-added pasta formulas by incorporation of grape pomace skins. Rom. Biotechnol. Lett. 2020, 25, 1607–1614. [Google Scholar] [CrossRef]

- Michalak-Majewska, M.; Teterycz, D.; Muszyński, S.; Radzki, W.; Sykut-Domańska, E. Influence of onion skin powder on nutritional and quality attributes of wheat pasta. PLoS ONE 2020, 15, e0227942. [Google Scholar] [CrossRef]

- De Pasquale, I.; Verni, M.; Verardo, V.; Gómez-Caravaca, A.M.; Rizzello, C.G. Nutritional and functional advantages of the use of fermented black chickpea flour for semolina-pasta fortification. Foods 2021, 10, 182. [Google Scholar] [CrossRef]

- Kim, B.R.; Kim, S.; Bae, G.S.; Chang, M.B.; Moon, B.K. Quality characteristics of common wheat fresh noodle with insoluble dietary fiber from kimchi by-product. LWT 2017, 85, 240–245. [Google Scholar] [CrossRef]

- Bustos, M.C.; Pérez, G.T.; León, A.E. Effect of four types of dietary fiber on the technological quality of pasta. Food Sci. Technol. Int. 2011, 17, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, A.R.; Madeira, T.; Botelho, G.; Martins, D.; Ferreira, R.M.; Silva, A.M.S.; Cardoso, S.M.; Costa, R. Brown Algae Fucus vesiculosus in Pasta: Effects on Textural Quality, Cooking Properties, and Sensorial Traits. Foods 2022, 11, 1561. [Google Scholar] [CrossRef]

- Nocente, F.; Taddei, F.; Galassi, E.; Gazza, L. Upcycling of brewers’ spent grain by production of dry pasta with higher nutritional potential. LWT 2019, 114, 108421. [Google Scholar] [CrossRef]

| Samples | T | DTP | PT0 | PT5 | PT10 | PT15 |

|---|---|---|---|---|---|---|

| Ash | 3.3 ± 0.01 | 4.2 ± 0.03 | 0.5 ± 0.01 a | 0.6 ± 0.01 b | 0.9 ± 0.01 c | 1.0 ± 0.03 d |

| Fat | 5.0 ± 0.1 | 6.1 ± 0.2 | 1.2 ± 0.1 a | 1.4 ± 0.1 b | 1.7 ± 0.1 c | 1.9 ± 0.11 d |

| Sugar | 17.3 ± 0.2 | 0.0 | 2.0 ± 0.0 a | 1.8 ± 0.0 b | 1.7 ± 0.1 c | 1.9 ± 0.1 b |

| Protein | 23.2 ± 0.70 | 28.0 ± 0.10 | 12.9 ± 0.3 a | 13.5 ± 0.06 b | 14.2 ± 0.2 c | 14.9 ± 0.17 d |

| Total dietary fiber | 26.9 ± 1.4 | 59.5 ± 1.6 | 3.4 ± 0.1 a | 11.0 ± 0.2 b | 11.8 ±0.1 b | 12.9 ± 0.2 c |

| Total starch | 22.9 ± 0.3 | 1.6 ± 0.10 | 52.0 ± 0.5 a | 49.8 ± 0.16 b | 47.0 ± 0.2 c | 46.2 ± 0.2 d |

| Pasta Samples | Fully-Cooked Time (min) | Cooking Loss (%) | Swelling Index (g Water/g Dry Pasta) | Firmness (N) | Adhesiveness (N) |

|---|---|---|---|---|---|

| PT0 | 6.5 | 5.45 ± 0.17 a | 1.62 ± 0.06 a | 135.02 ± 14.53 a | −3.97 ± 0,62 a |

| PT5 | 3.75 | 6.16 ± 0.19 b | 1.17 ± 0.02 b | 216.47 ± 27.21 b | −11.53 ± 1.57 b |

| PT10 | 3 | 6.55 ± 0.12 c | 1.23 ± 0.007 b | 253.72 ± 21.87 c | −21.02 ± 2.47 c |

| PT15 | 6.75 | 10.92 ± 0.05 d | 1.71 ± 0.04 a | 129.36 ± 3.64 a | −7.60 ± 0.28 a |

| Pasta Sample | Cooked/Uncooked | L* | a* | b* |

|---|---|---|---|---|

| PT0 | Uncooked | 82.81 ± 1.69 a | 1.06 ± 0.56 c | 8.50 ± 2.97 a,b |

| Cooked | 81.88 ± 0.75 a | −1.21 ± 0.48 d | 10.25 ± 2.25 a | |

| PT5 | Uncooked | 68.47 ± 3.25 b | 3.94 ± 0.73 b | −2.87 ± 0.91 e |

| Cooked | 38.26 ± 3.02 e | 7.36 ±0.86 a | 6.86 ± 1.64 b,c | |

| PT10 | Uncooked | 62.48 ± 3.85 c | 3.98 ± 0.89 b | −1.09 ± 1.25 e |

| Cooked | 23.55 ± 3.67 f | 7.23 ± 1.01 a | 3.63 ± 1.24 c,d | |

| PT15 | Uncooked | 54.91 ± 5.08 d | 4.39 ± 0.32 b | −1.42 ± 1.98 e |

| Cooked | 23.43 ± 2.51 f | 7.93 ± 1.27 a | 4.86 ± 1.56 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lomuscio, E.; Bianchi, F.; Cervini, M.; Giuberti, G.; Simonato, B.; Rizzi, C. Durum Wheat Fresh Pasta Fortification with Trub, a Beer Industry By-Product. Foods 2022, 11, 2496. https://doi.org/10.3390/foods11162496

Lomuscio E, Bianchi F, Cervini M, Giuberti G, Simonato B, Rizzi C. Durum Wheat Fresh Pasta Fortification with Trub, a Beer Industry By-Product. Foods. 2022; 11(16):2496. https://doi.org/10.3390/foods11162496

Chicago/Turabian StyleLomuscio, Elisabetta, Federico Bianchi, Mariasole Cervini, Gianluca Giuberti, Barbara Simonato, and Corrado Rizzi. 2022. "Durum Wheat Fresh Pasta Fortification with Trub, a Beer Industry By-Product" Foods 11, no. 16: 2496. https://doi.org/10.3390/foods11162496

APA StyleLomuscio, E., Bianchi, F., Cervini, M., Giuberti, G., Simonato, B., & Rizzi, C. (2022). Durum Wheat Fresh Pasta Fortification with Trub, a Beer Industry By-Product. Foods, 11(16), 2496. https://doi.org/10.3390/foods11162496