Olive Oil-Based Oleogel as Fat Replacer in a Sponge Cake: A Comparative Study and Optimization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

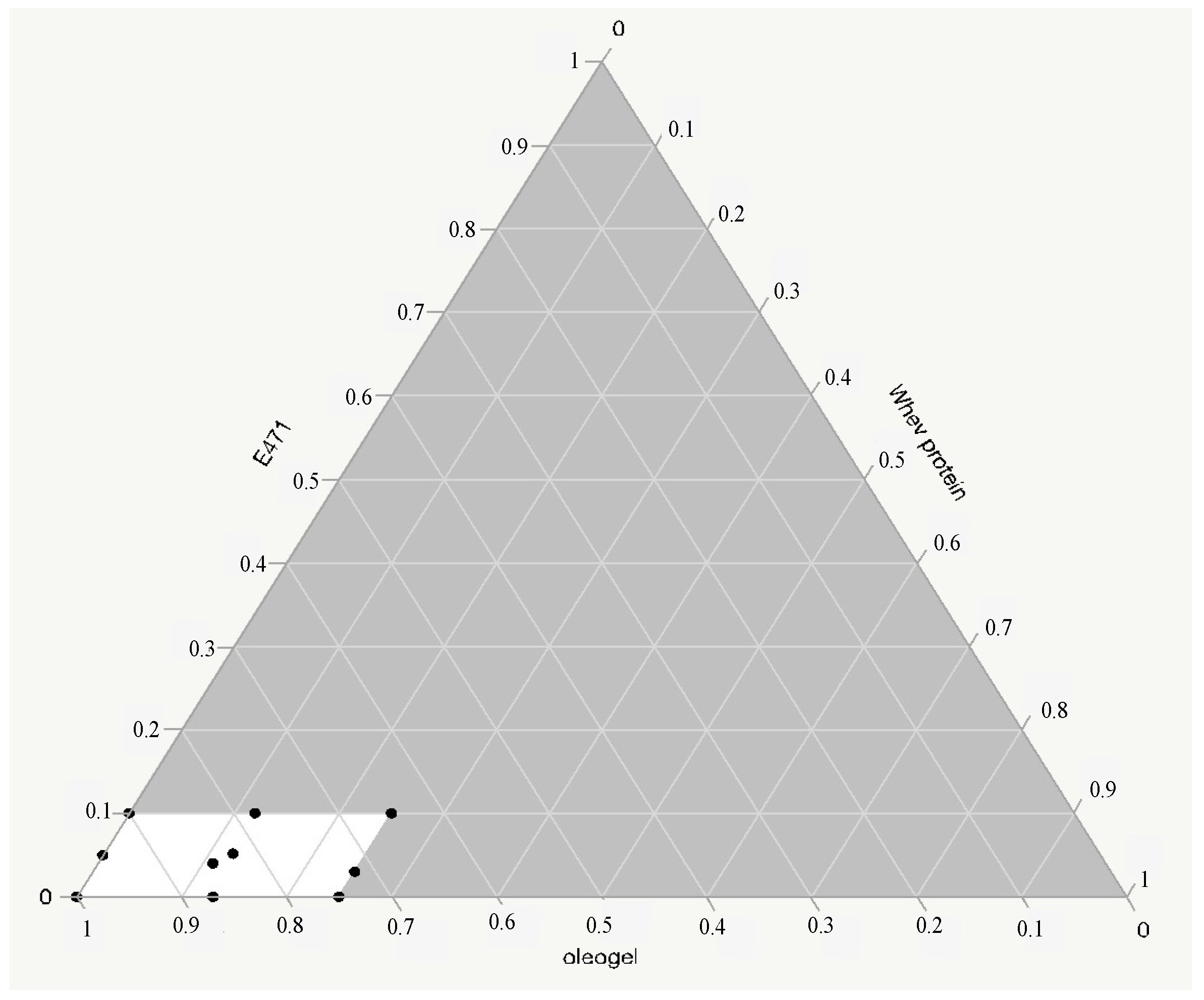

2.2. Experimental Design

2.3. Oleogel Preparation

2.4. Sample Preparation and Characterization

2.4.1. Crumb Porosity and Water Activity Evaluation

2.4.2. Texture Profile Analysis

2.4.3. Sensory Analysis

2.5. Statistical Analysis

2.6. Plumcake Storage

3. Results and Discussion

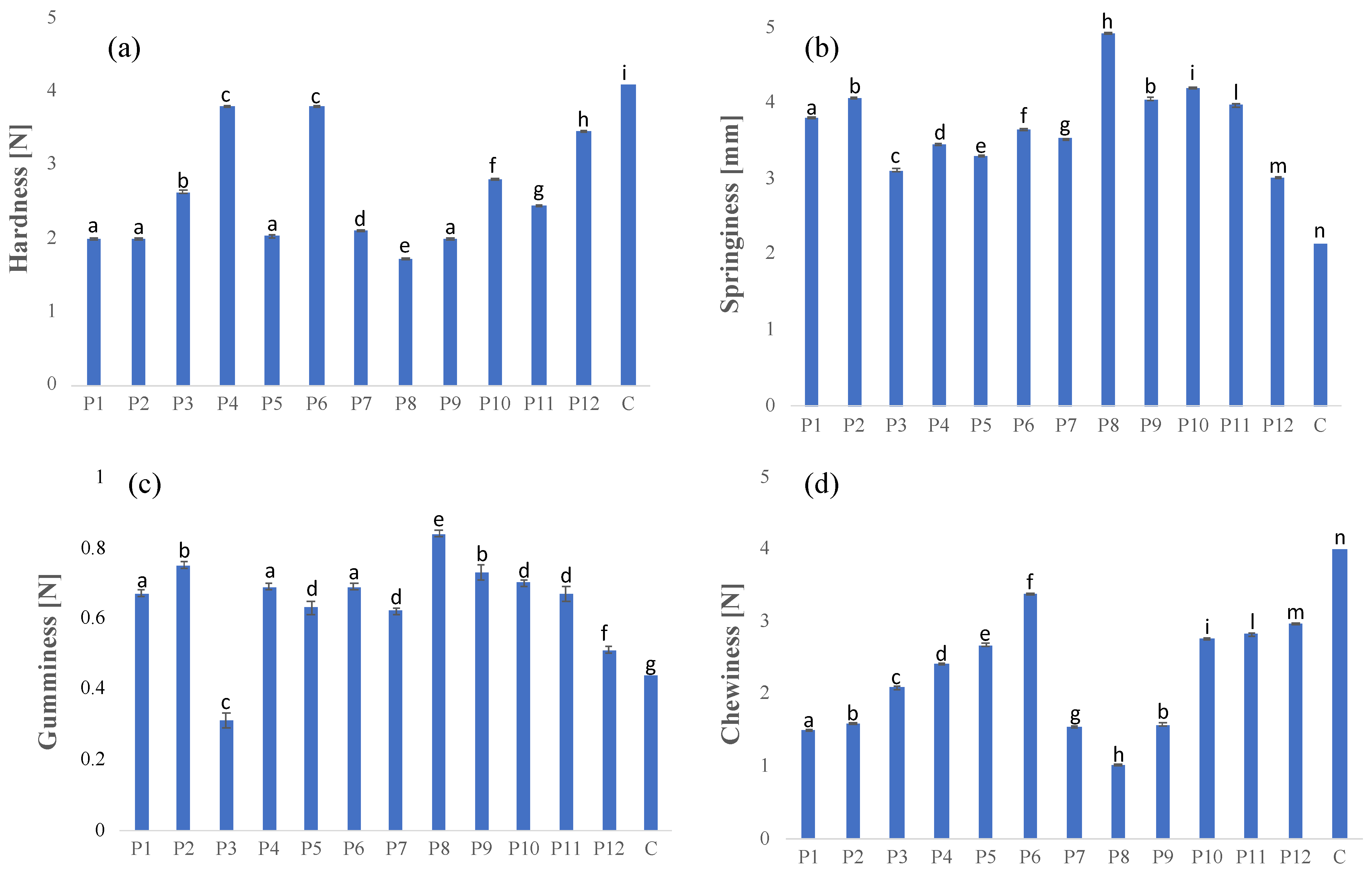

3.1. Influence of Fat Replacement with Olive Oil-Based Oleogel on the Plum Cake’s Texture Profile

3.2. Crumb Structure Evaluation

3.3. Water Activity Evaluation

3.4. Evaluation of Sensory Attributes

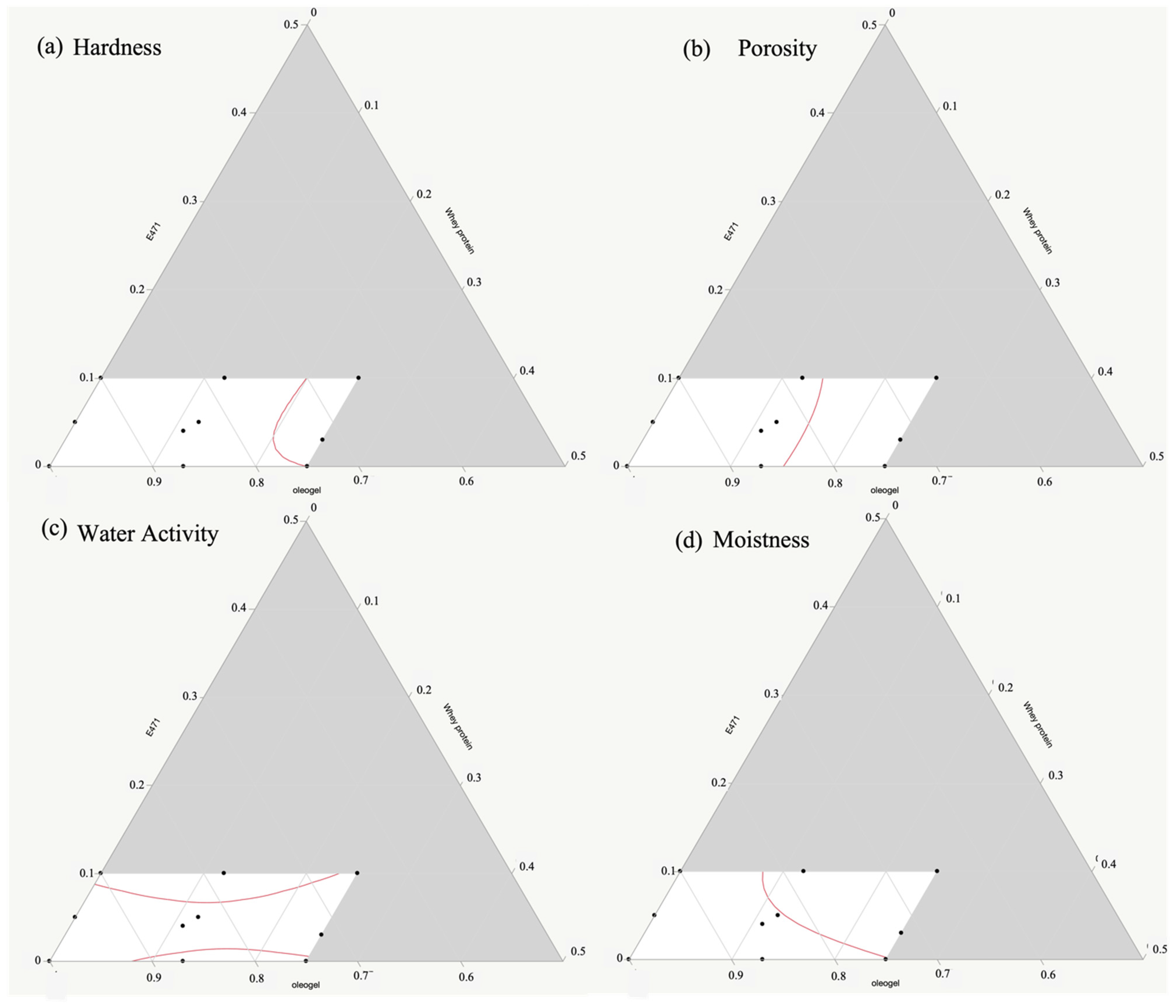

3.5. Mixture Optimization to Produce a Plum Cake with Desired Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Demirkesen, I.; Mert, B. Utilization of Beeswax Oleogel-Shortening Mixtures in Gluten-Free Bakery Products. J. Am. Oil. Chem. Soc. 2019, 96, 545–554. [Google Scholar] [CrossRef]

- Mert, B.; Demirkese, I. Reducing saturated fat with oleogel/shortening blends in a baked product. Food Chem. 2016, 199, 809–816. [Google Scholar] [CrossRef]

- Manzoor, S.; Masoodi, F.A.; Naqash, F.; Rashid, R. Oleogels: Promising alternatives to solid fats for food applications. Food Hydrocoll. 2022, 2, 100058. [Google Scholar] [CrossRef]

- Puscas, A.; Muresan, V.; Socaciu, C.; Muste, S. Oleogels in Food: A review of current and potential applications. Foods 2019, 9, 70. [Google Scholar] [CrossRef]

- Yilmaz, E.; Ogutcu, M. The texture, sensory properties and stability of cookies prepared with wax oleogel. Food Funct. 2015, 6, 1194–1204. [Google Scholar] [CrossRef]

- Hwang, H.S.; Singh, M.; Lee, S. Properties of cookies made with natural wax-vegetable oil organogels. J. Food Sci. 2016, 81, 5. [Google Scholar] [CrossRef]

- Jang, A.; Bae, W.; Hwang, H.S.; Lee, H.G.; Lee, S. Evaluation of canola oil oleogels with candelilla wax as an alternative to shortening in baked goods. Food Chem. 2015, 187, 525–529. [Google Scholar] [CrossRef]

- Mert, B.; Demirkesen, I. Evaluation of highly unsaturated oleogels as shortening replacer in a short dough product. LWT Food Sci. Technol. 2016, 68, 477–484. [Google Scholar] [CrossRef]

- Marangoni, F.; Agostoni, C.; Borghi, C.; Catapano, A.L.; Cena, H.; Ghiselli, A.; La Vecchia, C.; Lercker, G.; Manzato, E.; Pirillo, A.; et al. Dietary linoleic acid and human health: Focus on cardiovascular and cardiometabolic effects. Atherosclerosis 2020, 292, 90–98. [Google Scholar] [CrossRef]

- Oh, I.K.; Amoah, C.; Lim, J.; Jeong, S.; Lee, S. Assessing the effectiveness of wax-based sunflower oil oleogels in cakes as a shortening replacer. LWT 2017, 86, 430–437. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lim, J.; Lee, J.; Hwang, H.S.; Lee, S. Utilization of oleogels as a replacement for solid fat in aerated baked goods: Physicochemical, rheological, and tomographic characterization. J. Food Sci. 2017, 82, 445–452. [Google Scholar] [CrossRef]

- Giacomozzi, A.S.; Carrin, M.E.; Palla, C.A. Muffins elaborated with optimized monoglycerides oleogels: From solid fat replacer obtention to product quality evaluation. J. Food Sci. 2018, 83, 1505–1515. [Google Scholar] [CrossRef] [PubMed]

- Oh, I.K.; Lee, S. Utilization of foam structured hydroxypropyl methylcellulose for oleogels and their application as a solid fat replacer in muffins. Food Hydrocoll. 2018, 77, 796–802. [Google Scholar] [CrossRef]

- Qian, M.; Liu, D.; Zhang, X.; Yin, Z.; Ismail, B.B.; Ye, X.; Guo, M. A review of active packaging in bakery products: Applications and future trends. Trends Food Sci. Technol. 2021, 114, 459–471. [Google Scholar] [CrossRef]

- Joshi, A.; Sagar, V.R.; Sharma, S.; Singh, B. Potentiality of potato flour as humectants (Anti-staling agent) in bakery product: Muffin. Potato Res. 2018, 61, 115–131. [Google Scholar] [CrossRef]

- Perk, S.H.; Na, Y.; Kim, J.; Kang, S.D.; Park, K.H. Properties and applications of starch modifying enzymes for use in the baking industry. Food Sci. Technol. 2018, 27, 299–312. [Google Scholar] [CrossRef]

- Cox, S.; Sandall, A.; Smith, L.; Rossi, M.; Whelan, K. Food additive emulsifiers: A review of their role in foods, legislation and classifications, presence in food supply, dietary exposure, and safety assessment. Nutr. Rev. 2021, 79, 726–741. [Google Scholar] [CrossRef]

- Jyotsna, R.; Manohar, S.; Indrani, D.; Venkateswara Rao, G. Effect of Whey Protein Concentrate on the Rheological and Baking Properties of Eggless Cake. Int. J. Food Prop. 2007, 10, 599–606. [Google Scholar] [CrossRef]

- Reschm, J.J.; Daubert, C.R. Rheological and physicochemical properties of derivatized whey protein concentrate powder. Int. J. Food Prop. 2002, 5, 419–434. [Google Scholar] [CrossRef]

- Galvan, D.; Effting, L.; Cremasco, H.; Conte-Junior, C.A. Recent applications of Mixture Designs in beverages, foods and pharmaceutical healt: A systematic review and meta-analysis. Foods 2021, 10, 1941. [Google Scholar] [CrossRef]

- Marra, F. Food Products and Digital Tools: The Unexpected Interconnections. Front. Nutr. 2022, 9, 847038. [Google Scholar] [CrossRef] [PubMed]

- Santos, F.G.; Fratelli, C.; Muniz, D.G.; Capriles, V.D. Mixture design applied to the development of chickpea-based gluten-free bread with attractive technological, sensory, and nutritional quality. J. Food Sci. 2018, 83, 188–197. [Google Scholar] [CrossRef] [PubMed]

- Franklin, M.E.E.; Pushpadass, H.A.; Kamaraj, M.; Muthurayappa, M.; Battula, S.N. Application of D-optimal mixture design and fuzzy logic approach in the preparation of chhana podo (baked milk cake). J. Food Process Eng. 2019, 42, e13121. [Google Scholar] [CrossRef]

- Tormena, M.M.L.; de Medeiros, L.T.; de Lima, P.C.; Possebon, G.; Fuchs, R.H.B.; Bona, E. Application of multi-block analysis and mixture design with process variable for development of chocolate cake containing yacon (Smallanthus sonchifolius) and maca (Lepidium meyenii). J. Sci. Food Agric. 2017, 97, 3559–3567. [Google Scholar] [CrossRef] [PubMed]

- Albanese, D.; Di Matteo, M.; Poiana, M.; Spagnamusso, S. Espresso coffee (EC) by POD: Study of thermal profile during extraction process and influence of water temperature on chemical-physical and sensorial properties. Int. Food Res. J. 2009, 42, 727–732. [Google Scholar] [CrossRef]

- Borhan, F.P.; Gani, S.S.A.; Shamsuddin, R. The use of D-optimal mixture design in optimizing okara soap formulation for stratum corneum application. Sci. World J. 2014, 2014, 173979. [Google Scholar] [CrossRef]

- Khiabani, A.E.; Tabibiazar, M.; Roufegarinejad, L.; Hamishehkar, H.; Alizadeh, A. Preparation and characterization of carnauba wax/adipic acid oleo gel: A review reinforced oleo gel for application in cake and beef burger. Food Chem. 2020, 333, 127446. [Google Scholar] [CrossRef]

- Rathnayake, H.A.; Navaratne, S.B.; Navaratne, C.M. Porous crumb structure of leavened baked products. Int. J. Food Sci. 2018, 2018, 8187318. [Google Scholar] [CrossRef]

- Onyango, C.; Unbehend, G.; Lindhauer, M.G. Effect of cellulose-derivatives and emulsifiers on creep-recovery and crumb properties of gluten-free bread prepared from sorghum and gelatinized cassava starch. Int. Food Res. J. 2009, 8, 949–955. [Google Scholar] [CrossRef]

- De Wit, J.N. Nutritional and Functional characteristics of whey proteins in food products. Int. J. Dairy Sci. 1998, 81, 597–608. [Google Scholar] [CrossRef]

- Kumar, R.; Chauhan, S.K.; Gokul, S.; Vijayalakshm, S.; Shamugam, N. Whey Proteins: A potential ingredient for food industry—A review. J. Dairy Foods Home Sci. 2018, 37, 283–290. [Google Scholar]

- Jeong, S.; Lee, S.; Oh, I. Development of Antioxidant-fortified oleo gel and its application as a solid fat replacer to muffin. Foods 2021, 10, 2059. [Google Scholar] [CrossRef]

- Calligaris, S.; Manzocco, L.; Valloppi, F.; Nicoli, M.C. Effect of palm il replacement with monoglyceride organogel and hydrogel on sweet bread properties. Int. Food Res. J. 2013, 51, 596–602. [Google Scholar] [CrossRef]

- Dagnas, S.; Membre, K.M. Modeling growth of three bakery product spoilage molds as a function of water activity, temperature and pH. Int. J. Food Microbiol. 2014, 186, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Goncalves, C.M.; de Souza, H.B.; Suguimoto, H.H.; Ishii, P.L.; dos Santos, L.F. Addition of whey protein in bread-making textural parameters and antioxidant potential of leavened and unleavened bread. Int. J. Food Eng. 2017, 3, 20160218. [Google Scholar] [CrossRef]

| Formulation | Coded Ingredients | Original Ingredients (g/100 gdough) | ||||

|---|---|---|---|---|---|---|

| x1 | x2 | x3 | Olive Oil Oleogel | Emulsifier E471 | Whey Proteins | |

| P1 | 0.85 | 0.04 | 0.11 | 17.00 | 0.80 | 2.20 |

| P2 | 0.78 | 0.10 | 0.12 | 15.60 | 2.00 | 2.40 |

| P3 | 0.75 | 0.00 | 0.25 | 15.00 | 0.00 | 5.00 |

| P4 | 0.65 | 0.10 | 0.25 | 13.00 | 2.00 | 5.00 |

| P5 | 1.00 | 0.00 | 0.00 | 20.00 | 0.00 | 0.00 |

| P6 | 0.83 | 0.05 | 0.12 | 16.60 | 1.00 | 2.40 |

| P7 | 0.90 | 0.10 | 0.00 | 18.00 | 2.00 | 0.00 |

| P8 | 0.87 | 0.00 | 0.13 | 17.40 | 0.00 | 2.60 |

| P9 | 0.95 | 0.05 | 0.00 | 19.00 | 1.00 | 0.00 |

| P10 | 0.72 | 0.03 | 0.25 | 14.40 | 0.60 | 5.00 |

| Formulation | Ingredients’ Composition | Hardness [N] | Water Activity | Porosity [%] | Moistness | ||

|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | y1 | y2 | y3 | y4 | |

| P1 | 0.85 | 0.04 | 0.11 | 2.00 ± 0.01 a | 0.82 ± 0.01 a | 80.60 ± 0.20 a | 3.00 ± 0.01 a |

| P2 | 0.78 | 0.10 | 0.12 | 2.00 ± 0.01 a | 0.81 ± 0.01 a | 83.68 ± 0.40 b | 2.45 ± 0.02 b |

| P3 | 0.75 | 0.00 | 0.25 | 2.64 ± 0.02 b | 0.81 ± 0.01 a | 74.87 ± 0.30 c | 2.78 ± 0.01 c |

| P4 | 0.65 | 0.10 | 0.25 | 3.80 ± 0.01 c | 0.81 ± 0.01 a | 82.78 ± 0.10 d | 2.12 ± 0.02 d |

| P5 | 1.00 | 0.00 | 0.00 | 2.04 ± 0.02 a | 0.84 ± 0.01 a | 75.17 ± 0.20 c | 3.30 ± 0.01 e |

| P6 | 0.83 | 0.05 | 0.12 | 2.12 ± 0.01 d | 0.84 ± 0.01 a | 73.32 ± 0.20 e | 3.50 ± 0.03 f |

| P7 | 0.90 | 0.10 | 0.00 | 1.73 ± 0.01 e | 0.84 ± 0.01 a | 79.46 ± 0.30 f | 3.20 ± 0.01 g |

| P8 | 0.87 | 0.00 | 0.13 | 2.81 ± 0.01 f | 0.81 ± 0.02 a | 82.34 ± 0.30 g | 3.00 ± 0.01 a |

| P9 | 0.95 | 0.05 | 0.00 | 2.45 ± 0.02 g | 0.84 ± 0.02 a | 85.62 ± 0.10 h | 3.10 ± 0.01 h |

| P10 | 0.72 | 0.03 | 0.25 | 3.47 ± 0.01 h | 0.79 ± 0.01 b | 89.05 ± 0.30 i | 2.34 ± 0.01 i |

| Hardness | Water Activity | Porosity | Moistness | |||||

|---|---|---|---|---|---|---|---|---|

| Model | Significant | Significant | Significant | Significant | ||||

| R2 | 0.9274 | 0.9581 | 0.7956 | 0.9639 | ||||

| Adjusted R2 | 0.8404 | 0.9078 | 0.7623 | 0.9206 | ||||

| p value | 0.0100 | 0.0027 | 0.0109 | 0.0019 | ||||

| F value | 10.6547 | 19.0481 | 1.2274 | 22.2434 | ||||

| Lack of fit | Not significant | Not significant | Not significant | Not significant | ||||

| Standard deviation | 0.2970 | 0.0051 | 4.5004 | 0.1359 | ||||

| Estimated parameter () | p-value | Estimated parameter () | p-value | Estimated parameter () | p-value | Estimated parameter () | p-value | |

| Oleogel | 2.1141 | 0.0002 | 0.8396 | <0.0001 | 74.6728 | <0.0001 | 3.3794 | <0.0001 |

| E471 | −11.2812 | 0.2124 | 0.7520 | 0.0026 | −132.5664 | 0.3183 | 4.6596 | 0.2537 |

| Whey proteins | 3.1417 | 0.0106 | 0.8099 | <0.0001 | 75.7432 | 0.0015 | 2.3239 | 0.0014 |

| Oleogel*E471 | 17.1307 | 0.1762 | 0.1216 | 0.5435 | 316.2800 | 0.1133 | −2.9226 | 0.5829 |

| Oleogel*whey proteins | 0.1614 | 0.9460 | −0.1062 | 0.0411 | 14.5741 | 0.6889 | 0.4761 | 0.6654 |

| E471*whey proteins | 23.6151 | 0.1087 | 0.07898 | 0.7195 | 315.6269 | 0.1462 | −4.5795 | 0.4464 |

| Oleogel*E471*whey proteins | −23.6073 | 0.0813 | 0.1212 | 0.5030 | 17.4821 | 0.9194 | −4.7721 | 0.3803 |

| Predicted Value | Detected Value | ||

|---|---|---|---|

| t = 0 | t = 0 | t = 3 Months | |

| Hardness [N] | 2.49 | 2.51 ± 0.02 a | 4.52 ± 0.02 b |

| Porosity [%] | 86.89 | 87.56 ± 0.03 a | 87.22 ± 0.02 b |

| aw | 0.81 | 0.81 ± 0.01 a | 0.78 ± 0.01 b |

| Moistness | 2.45 | 2.50 ± 0.02 a | 1.13 ± 0.01 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malvano, F.; Laudisio, M.; Albanese, D.; d’Amore, M.; Marra, F. Olive Oil-Based Oleogel as Fat Replacer in a Sponge Cake: A Comparative Study and Optimization. Foods 2022, 11, 2643. https://doi.org/10.3390/foods11172643

Malvano F, Laudisio M, Albanese D, d’Amore M, Marra F. Olive Oil-Based Oleogel as Fat Replacer in a Sponge Cake: A Comparative Study and Optimization. Foods. 2022; 11(17):2643. https://doi.org/10.3390/foods11172643

Chicago/Turabian StyleMalvano, Francesca, Mariachiara Laudisio, Donatella Albanese, Matteo d’Amore, and Francesco Marra. 2022. "Olive Oil-Based Oleogel as Fat Replacer in a Sponge Cake: A Comparative Study and Optimization" Foods 11, no. 17: 2643. https://doi.org/10.3390/foods11172643

APA StyleMalvano, F., Laudisio, M., Albanese, D., d’Amore, M., & Marra, F. (2022). Olive Oil-Based Oleogel as Fat Replacer in a Sponge Cake: A Comparative Study and Optimization. Foods, 11(17), 2643. https://doi.org/10.3390/foods11172643