1. Introduction

Food constitutes one of the most important aspects of human life. Since almost a millennium, humans have been fascinated by the concept of food and from mere mortal pleasure, it has evolved to be a source of goodwill and happiness. Humans consume food on the belief that the products they are consuming are manufactured, processed, stored, and transported in ways that are following the quality standards. However, in the past couple of years, thousands of humans across the world have been infected by consuming contaminated and adulterated food products. One such category of food is dairy products, which have seen significant contamination and adulteration practices in the past. The history of milk adulteration can be traced to 1850 when in New York about 8000 children were killed by the Swill milk scandal [

1]. Later, it became a serious concern when in China infant milk products were adulterated with melamine [

2]. The adulteration is made for economic reasons; however, it affects public health [

3]. Dairy products are one of the largest consumable categories of food products and are seen as a primary source of nutrition across multiple age groups. However, adulteration and contamination affect the nutritional value and host presence of perilous substances making milk inconsumable and harmful. The common milk adulterants are water, starch, urea, glucose, detergents, Vanaspati, and preservatives. Contamination can be biological (microbes), chemical (pesticides, antibiotics, metal etc.), or physical (dust). The contamination in milk initiates in the mammary glands of livestock by excretion of xenobiotic substances such as antibiotics and other veterinary drugs followed by exposure to environmental pollutants, pesticides, pathogens, etc. Fodder is also a significant source of contamination as it may increase the spore load in raw milk. A bad hygiene practice is primarily responsible for microbial contamination in milk, cheese, butter, and other milk products. A knowledge of udder health status, antibiotics administrated, and common pathogens in the dairy farm is a must to ensure milk safety and dairy product quality. The other microbial contamination is possible during the long storage period, inefficient cooling storage practices, use of non-sterilized storage tanks, etc. Poor pasteurization paves the path for the survival of microbial pathogens and may cause several food-borne diseases.

Adulteration starts from the mere addition of water into milk. The addition of water decreases the nutritional value of milk and can cause several diseases. The food chain of a dairy product must be transparent to its customers and other participants to maintain the prescribed quality and nutritional values of a product. The lack of transparency, traceability, and provenance in the dairy supply chain has led to large-scale food frauds impacting the lives of millions. The dairy supply chain is one of the most complex food supply chains, as it involves the movement of multiple perishable food products across different stakeholders and complex processing operations. Henceforth, making it a challenging process to ensure food safety for the customer. Thankfully we have blockchain, a new-age technology that enables enterprises to create and manage traceable supply chains [

4,

5,

6,

7]. In its initial years, blockchain was limited in its applicability around the cryptocurrency domain. As time followed, researchers began to identify numerous advantages of integrating blockchain technology across different verticals. One of the recent areas of blockchain research involves its applicability in the area of supply chain management. Blockchain allows the creation of a decentralised supply chain with immutable transaction records. It helps in tracking the origin of a product and its raw materials from farm to fork [

8]. The use of a blockchain-enabled dairy supply chain would allow multiple stakeholders such as farmers, consumers, government authorities, and shipping companies to be on one single platform [

9,

10,

11]. Information regarding products and their movements will be shared with these stakeholders transparently and securely. Apart from providing traceability and transparency to the supply chain, blockchain ensures reduced operational costs and helps in automating the decision-making process. Blockchain technology allows a customer to be aware of the nature and quality of a product and its origin. Blockchain technology coupled with the Internet of Things (IoT) and Cloud has the potential to monitor critical parameters of a dairy product along the entire supply chain. The quality parameters of a dairy product can efficiently be monitored and communicated using a distributed ledger technology such as blockchain. Reduced transportation time, faster payment settlements, and prevention of unnecessary food wastage can be ensured by implementing a blockchain-enabled dairy supply chain. Being an emerging area of research, blockchain-enabled food supply chains have their share of impediments at people and process levels. Despite the challenges, we believe blockchain has the potential to transform the dairy supply chain and facilitate the establishment of trust and willingness to purchase among customers. The following are some of the prominent contributions of our work:

Identifying existing problems in the Indian dairy industry

Analysing the benefits of blockchain integration for creating a dairy food traceability system

Creation of an end-to-end supply chain management platform for the dairy industry

Creation of a blockchain-enabled food safety platform for maintaining the quality of dairy products and their nutritional value throughout the supply chain

Creation of a platform that enables its customers to identify levels of adulteration and contamination in dairy products

Predicting sales of dairy products concerning product type, region, retailer, and distributor

Preventing overproduction and minimizing wastage of dairy products by the use of machine learning and blockchain technology

The rest of the paper is organized as follows.

Section 2 talks about the research questions and impact dimensions addressed by the paper. In

Section 3, we discuss some of the recent works concerning the applicability of blockchain technology in food traceability along with the works describing the impact of adulteration and contamination on food quality and its nutritional values. The extent of the Indian dairy industry and standard practices for processing, storage, and circulation of dairy products by the Indian government are discussed in

Section 4. In

Section 5, we present the success factors for adopting blockchain technology as a game changer for supply chain management.

Section 6 talks about the system architecture for the proposed blockchain platform along with its various actors. In

Section 7, we describe in detail the smart contracts being implemented for the execution of transactions between different stakeholders of the supply chain.

Section 8 presents some of the most prominent blockchain adoption challenges for creating a food traceability platform.

Section 9 explains use cases pertaining to different impact dimensions for easing the practical implementation of the proposed food safety and traceability platform.

Section 10 illustrates the experimental setup of the proposed blockchain platform. Finally,

Section 11 summarizes our findings and concludes the work. The following

Figure 1 depicts the entire structure of the paper.

2. Research Methodology

In line with the aim of the paper, a systematic literature review was conducted. The purpose of the literature review was to identify, analyse, and categorise recent works concerning the applicability of blockchain technology in the food and dairy supply chain. The comprehensive literature review assisted us in understanding the characteristics of blockchain technology in enabling the creation of food traceability systems. Research gaps were identified concerning food traceability and the dairy supply chain. Secondly, it enabled us in creating the following research questions which we address throughout different sections of our work.

- RQ1:

What features of blockchain technology can assist in the creation of a sustainable supply chain for the dairy industry?

- RQ2:

What are the ways in which the use of blockchain-based smart contracts can facilitate the prevention and identification of contamination in dairy products?

- RQ3:

What are the ways in which the use of blockchain-based smart contracts can facilitate the prevention and identification of adulteration in dairy products?

- RQ4:

How can a blockchain-enabled dairy supply chain prevent socio-economic implications of contamination and adulteration of dairy products?

- RQ5:

How can a blockchain-enabled dairy supply chain support the creation of a circular economy for the dairy industry?

The literature review was conducted for the time period of 2017–2022.

Figure 2 describes the process followed during our research. The following are the sets of search terms used during our survey:

Blockchain + Supply Chain;

Blockchain + Food Supply Chain;

Blockchain + Dairy Supply Chain.

The search covered titles, abstracts, and keywords for peer-reviewed publications from the Scopus database [

12]. The distribution of publications over time and classification of publications were presented in the following section.

Table 1 illustrates the comparative analysis between some of the recent works in areas of food and dairy supply chain.

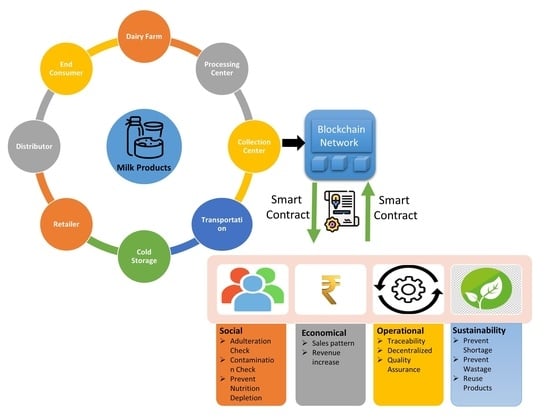

Table 2 and

Table 3 are constructed subsequent to the literature review. Apart from defining research questions, the literature analysis helped us create areas of maximum impact, known as the impact dimensions. There are four impact dimensions which have been identified and each of them represents a specific area of influence. The following are the four impact dimensions:

- Impact Dimension 1:

Social

- Impact Dimension 2:

Economic

- Impact Dimension 3:

Operations

- Impact Dimension 4:

Sustainability

The concept of creating impact dimensions helped us in achieving a multidimensional research approach through our work. Every impact dimension is related to a certain set of research questions. The following

Figure 3 illustrates the relationship between impact dimensions and research questions.

3. Literature Review

The paper aims to explore ways in which blockchain technology can prove beneficial in overcoming food safety issues in the dairy industry of Vietnam [

25]. It examines how the people of Vietnam have been suffering from a crisis in food safety. The authors propose a food traceability framework that combines the use of blockchain technology and the Internet of Things. The paper focuses on milk as the product of choice and details its journey from the farm to the processing plant. All processing steps which the milk undergoes are recorded and uploaded onto the blockchain in an automated manner by the use of sensors. The use of QR codes can be widely seen in the work as it acts as a gateway to all information concerning a particular product. The proposed framework is successful in presenting a traceability system and allowing the customer to have complete authentic information regarding a product being purchased.

The authors propose a blockchain-enabled smart contract-based system for payment settlements in the supply chain [

27]. The work explores the risks associated with organizations failing to withhold their financial commitments in an agreed period. The primary objective of the paper is to uphold payment options such as cash, credit, and advance without any hidden or intermediatory cost being associated. The proposed smart contract provides traceability of a product all along the supply chain. Being a blockchain-enabled solution, any transaction performed in the supply chain is prevented from any form of data tampering and misinterpretation. The prosed system aims to establish trust during processes relating to payments, inventory audits, and asset traceability.

The work proposes a traceability system that is low on energy consumption, and cost-saving with minimum impact on the environment [

24]. Algorand is the blockchain network that is used by the authors for creating the blockchain. The authors use the Pure Proof-of-Stake as a consensus algorithm to build a traceability platform on the principles of green blockchain which requires minimum computational power and is scannable in nature. The case study discussed by the authors is of the dairy industry with “Fontina PDO” which is a semi-cooked cheese as the target product.

The work presents a dairy logistic ecosystem that is built using blockchain technology [

23]. The authors use a combination of blockchain technology and IoT to track the temperature of dairy products across the supply chain. The proposed decentralized supply chain collects and stores real-time data collected by various sensors relating to milk as it is the target product. This research aims to ensure the safety of dairy products and reduce any operational errors during the process of milking, transportation, processing, and distribution. The system allowed stakeholders to store and share regulatory certifications in a tamper-proof manner over the blockchain.

The proposed work discusses a blockchain-enabled decentralized supply chain “NUTRIA” for the dairy industry of Switzerland [

22]. A series of interviews were conducted by the authors to collect data concerning the expectations of people and different stakeholders in a dairy supply chain. The purpose of this research is to develop an application that allows traceability of milk from farm to shelf. Each product is associated with a QR code that stores information regarding the physical flow of the product across the supply chain. Ethereum is the blockchain platform used for creating the application and every transaction that occurs in the supply chain is recorded on two supply chains.

The authors propose a blockchain-enabled supply chain architecture that supports tamper-proof data sharing on a real-time basis [

17]. Using the proposed architecture, the authors ensure creating an audit trail throughout the food supply chain. The paper is written in the backdrop of COVID-19 and ensures that the proposed architecture can trace all practices along the food supply chain and minimize the risks associated with bacteria, fungi, and parasites. Information such as animal breed, age, and temperature of employees working in processing plants are stored on the blockchain. The proposed work facilitates streamlining documentation and reducing unnecessary paper trails required by government authorities for importing food products. Tamper-proof quality certificates relating to food products are stored and circulated using blockchain transparently and authentically.

The work discusses the creation of a supply chain traceability system based on blockchain and RFID technology [

19]. The proposed platform allows storage and management of data collected from RFID readers onto the blockchain. Hyperledger Fabric 2.0 was used as the development platform to create a consortium blockchain. The proposed architecture aims to track products across stages of shipment, stocking, and storage in the supply chain. The architecture comprises three parts, namely RFID tags, RFID reader, and blockchain platform. The RFID tag contains information related to the product and the hash value of the previous block. Every time an RDIF tag passes through an RFID reader, a new block is generated. The RFID reader is connected to the backend blockchain platform and shares with it all information scanned from the RFID tags. The end user is connected to the blockchain platform through a user interface for accessing information about a particular food product in the supply chain.

The authors propose a blockchain-enabled traceability system for extra virgin olive oil (EVOO) production on an Italian farm [

18]. The authors believe that the quality of EVOO is directly linked to the cultivators being used and the environmental conditions of their growing area. The traceability system comprises thirty-three olive trees from three different cultivators. The purpose of the traceability system is to trace the origin of an EVOO product back to its olive tree. The prototype of the proposed system was implemented in the orchards of Italy. The information gathered by the traceability system assisted the farmers and manufacturers at an economic level.

Authors [

28] reviewed milk adulteration, its reason, and its effects on human health. They reported that along with economic benefits the reason for milk adulteration is a high ratio of demand to supply. In many parts of the country, the milk delivered is not as per the FSSAI standards. There is a need for an effective and consistent quality check for monitoring the quality of milk and milk products. Keeping in mind the statement issued by WHO that to avoid serious diseases in the major population of India a legitimate checking of milk adulteration is required, the authors proposed that a human and technology interface, cognizance, and traceability are the need of the hour for adulterant-free milk for consumption.

Authors defined contamination issues in dairy products as a global problem [

10]. They reviewed several scientific literature and other databases from 2015 to 2019 and found that not only biological contamination but physical and chemical contamination are serious concerns for human health. The authors extracted safety and fraud data of milk and milk products from online resources such as HorizonSCan and the EU Rapid Alert System for Food and Feed (RASFF). The data reflected that most cited microbial contamination or malpractices in production were for cheese. The work also mentioned that there are many reports of contamination and adulteration as grey literature. It is vital to be aware of the safety, legitimacy, and quality of milk and products by all the stakeholders.

Authors [

29] said that the adulterants are added to milk for financial gain but the contaminations are due to a lack of knowledge of the processing of milk, hygiene consciousness, and insensitivity to human health risks. Water, synthetic milk, sugar, and benzoic acid are the most common adulterants used in milk. Benzoic acid is added to increase milk’s shelf life, and its addition can cause adverse effects on consumers.

Adulteration in milk and products is causing serious impacts on human beings including gastrointestinal and cardiac issues, endocrinal imbalances, neural disorders, etc. [

30]. For instance, starch, a common adulterant, induces diarrhoea as its intestinal absorption is difficult. Starch can also shoot up sugar levels and can be lethal for diabetic patients. The evaluation of milk properties, qualitative as well as quantitative, is a must and proper traceability is desirable to avoid all harmful impacts on human health and the nutritional value of milk and products. The authors described different methods for the detection of contaminants and adulterants in milk products such as pulverized soap, benzoic acid, skim milk powder, sugar, Vanaspati, salicylic acid, starch, etc.

4. Overview of the Indian Dairy Industry

India has been one of the largest producers and consumers of dairy products across the world since the late 1990s. The dairy industry is an essential part of the Indian economy and has a significant role in generating rural employment [

31,

32,

33,

34]. As of 2021, the Indian dairy market reached a valuation of INR 13,174 billion with a growth trajectory of reaching INR 30,840 billion by the year 2027. Most of the dairy products in India are consumed domestically, with milk having the largest consumption value. In terms of milk production, India produced more than 198 million tonnes of milk in the year 2019–2020. As per a study conducted by the National Dairy Development Board (NDDB), India will be producing 266.5 million metric tonnes of milk by 2023. States such as Uttar Pradesh, Rajasthan, Madhya Pradesh, Gujarat, and Andhra Pradesh are considered to be the highest producers of milk. In India, the dairy sector holds significant importance as it has huge implications for the socio-economic aspects of its people. Keeping this in mind, the Government of India has launched the National Dairy Programme to boost cattle productivity, enhance milk production, and therefore improve the livelihoods of the farmers. Strategic investments are being made by the governments to improve milk procurement infrastructure in rural parts of India. In recent years, the Indian dairy sector has seen a significant rise in the production and consumption of milk-related value-added products (VAP). Products such as cheese, butter, and yoghurt are witnessing a rise in per-capita consumption. Despite numerous government schemes and the largest bovine population, the milk production per animal in India is less than its contemporaries such as the US and UK. The use of non-scientific methods, inefficient cattle breeding, poor management strategies, and above all the lack of technology intervention are some of the reasons that have led to the diminished growth of the Indian dairy sector. Moreover, a majority of the Indian dairy sector is unorganized in nature and therefore unable to adapt to new technologies and reach competitive markets [

35,

36,

37,

38,

39]. With 3/4th of the sector being unorganised, the Indian dairy sector has emerged as a breeding ground for numerous malpractices. The absence of strict audit mechanisms and lack of quality certifications from the governments have led to the surplus use of contaminated and adulterated dairy products. Circulation of adulterated dairy products has become the new normal for the Indian dairy sector causing severe health implications for its people. It is believed that 79% of milk available in the Indian market is adulterated to a report presented by the Consumer Guidance Society of India (CGSI) in the year 2020. The food supply chains in India are significantly unorganised and perform worse when dealing with perishable food items such as dairy products. The Indian dairy supply chain is highly fragmented and even dysfunctional at certain levels. Poor linkages between different stakeholders within the supply chain have led to a shortage of dairy products and even caused price inflation. The Indian dairy supply chain is highly dependent on manual handling thus resulting in hygiene issues and human errors. The supply chains lack the presence of regulatory authorities at small and medium scales thereby allowing the entry of adulterated dairy products into the supply chain. The Indian dairy supply chains are mostly devoid of technologies and therefore are unable to address the changing consumer behaviours and global export initiatives.

A food product must be safe to consume and all the stakeholders (farmers, consumers, cooperatives, processors, and government agencies) share a responsibility to ensure the suitability of a food item. In the dairy industry, regulatory laws are in existence since 1899 for the safety and quality of milk and its products. There have been substantial amendments and increments in the legislation and quality standards of milk and products. The Food Safety and Standards Act received a nod in the year 2006.

In 2008, the Food Safety and Standards Authority of India (FSSAI) was established under the same act. The FSSAI enforced a regulation to control adulteration and contrived milk products known as Food Safety and Standard Regulations 2011. Under the regulation,

Section 2 mentions the permissible limits of contaminants, toxins, and residues in milk and milk products. The Milk and Milk Products Order (MMPO) 1992 is regulatory order of the Government of India, under the Essential Commodities Act 1955, for rheostat of production, supply, and distribution of milk and milk products to uphold or enhance the supply of milk and products from producer to consumer. The MMPO is to rationalize legal registration, define the terms used for milk, e.g., boiled milk, pasteurized milk, etc., and control restrictions on irrational procurement and supply of milk, stringent rates of production, sincere hygiene environment, proper packaging, labelling, penalization, etc. Thus, MMPO warrants the safety and progress of the Indian dairy industry. The Indian dairy supply chain can benefit significantly from the implementation of blockchain technology. Functionalities such as stakeholder management, inventory management, product movements, and returns management can easily be achieved through the use of blockchain technology. Blockchain-enabled dairy supply chains would ensure last-mile product delivery, quality control mechanisms, inventory optimizations, fault analysis, and pricing optimizations [

40]. Blockchain technology presents itself as a solution to the numerous limitations of the Indian dairy supply chain [

41,

42,

43,

44]. A detailed description of some of the key factors enabling blockchain technology to be a perfect match for the dairy supply chain is presented in the following section.

6. System Architecture

The significance of blockchain technology in the dairy supply chain has been discussed in the previous sections. We are aware of the problems being faced by the Indian dairy sector and how revolutionizing the supply chain holds the key to its transformation. In this section, we discuss the system architecture for our proposed supply chain model. The system architecture comprises four layers, namely the phases layer, traceability layer, blockchain layer, and application layer. All operations within the supply chain are performed using these four layers. The following sub-sections define each layer, their functionalities, and the ways in which they interact with one another to create a comprehensive sustainable dairy supply chain.

Figure 4 presents a detailed overview of the system architecture.

6.1. Phases Layer

The phases layer talks about the various touch points a product passes through in an entire supply chain. It can also be represented as a collection of different stages of the supply chain. The first phase is the dairy farm where cows are milked every day and raw milk is collected by the farmers to be subsequently sold to the dairy company. The term “farmer” here refers to an individual farmer or a collection of farmers in the form of a cooperative society. Traceability starts at this very stage onwards as QR codes are used to store information pertaining to farmer details, breed of the cow, and timestamp of the milking process. All this data is updated onto the blockchain and thus cannot be tampered with by any individual. The next phase we have is the collection centre wherein milk from different dairy farms is collected and tested. It is the first phase where testing takes place for checking contamination and adulterations in milk collected. A smart contract is executed between the farmer and dairy company allowing the purchase of raw milk. Raw milk which fails to meet the required quality standards is deemed unfit for purchase and returned to the farmer. Post-purchase completion, milk is packed in batches and assigned respective QR codes. After the collection centre, the milk is further transported to the processing centre. The QR codes mentioned on the milk batches comprise information regarding the transportation vehicle, source, destination, and timestamp. The transportation phase is responsible for the movement of milk and its related products, in our case cheese and butter, across different stakeholders in the supply chain. The transportation phases update information on the respective QR codes for individual products and different product batches. Various shipments moving across different locations through different modes of transportation are tracked and verified using these QR codes. It is to be noted that the system facilitates minimum paper trail and ensures a single document per shipment across various modes of transportation. A smart contract is executed between the dairy company and the transportation firm for automated settlement of payments. Milk from various collection centres is brought to processing and packaging centres for processing raw milk and converting them into different products such as cheese and butter. Multiple quality tests pertaining to contamination and adulterations are performed at the processing and packaging centre. Any adulterated or contaminated batch is strictly discarded and removed from the supply chain. New QR codes are generated for the packed products having updated information regarding the nature and quality of the product. Processed milk products are then further sent to either cold storage centres or different distributors and retailers. Random quality checks are performed at the distributor and retailer level to prevent the selling of any contaminated or adulterated dairy product. All transactions performed between the different phases of the supply chain are recorded, validated, and stored on the blockchain.

Figure 5 explains the various levels of interaction between different stakeholders in the phases layer.

6.2. Traceability Layer

Traceability is one of the key aspects of any modern-day supply chain. The traceability layer of the system architecture tracks the movement of every raw material and dairy product throughout the supply chain. The movement of a product from one stakeholder to another is marked as a transaction and recorded on the blockchain. Being a blockchain-enabled solution, the traceability information is tamper-proof and shared among all stakeholders. Information relating to a particular product, process, stakeholder, and transportation is collected and managed using the traceability layer. Information pertaining to any form of contamination or adulteration that has occurred in a particular product or group of products at any stage of the supply chain is identified and shared using the traceability layer. From an organization’s point of view, sales information holds significant importance as it is directly related to its revenue streams. The traceability layer tracks and manages information regarding sales of individual products or a type of product. The layer also supports accountability as it only allows authorized entities to perform a transaction, i.e., recognized stakeholders are only permitted to transact a dairy product and update the information regarding its nature and movement. Information concerning any fake product cannot be entered into the system thereby preventing entry of any counterfeit product into the supply chain. It is through the execution of smart contracts which allows all the above information to be exchanged between stakeholders.

6.3. Blockchain Layer

The foundational layer of the entire system is the blockchain layer. It is the layer which provides all channels of communication between different stakeholders of the supply chain. Multiple stakeholders first need to register themselves on the blockchain to conduct transactions and subsequently verify them. Ethereum is the blockchain network that has been used for creating the supply chain model. Solidity-based smart contracts are used to ensure secure and automated transactions between different stakeholders. A collection of transactions is called a block. Each block in the blockchain has a link to its predecessor block. Being a distributed ledger technology, blockchain allows sharing of information transparently and securely. The presence of blockchain technology enables the supply chain to be completely decentralized and prevents any single point of failure. Transactions such as shipping, billing, quality check, and adding products are executed on the blockchain using smart contracts. The blockchain layer ensures immutability in the supply chain thus once a transaction has been validated and stored it cannot be reverted. The blockchain layer establishes connectivity between other layers of the system architecture. All information including information collected from the transactions performed by the phases layer to information relating to the traceability layer is stored and shared using the blockchain layer.

6.4. Application Layer

The application layer is the one which directly relates to the retail customers. The utility of the system is experienced by the end user through its interaction with the application layer. The overall supply chain management system is presented to the end customer employing the application layer. The application layer comprises functionalities that have their roots present in the above three layers. All functionalities being rendered by the application layer are derived from individual traits of the previous three layers. Quality management is one of the most important aspects of the application layer. It allows the customer to be aware of the nature and extent of contamination or adulteration that a particular food product has encountered during its movement in the supply chain. Quality management assures the prevention of any contaminated or adulterated product to reach the customer. It also prevents the entry of fake products within the supply chain. The quality management aspect is also helpful for the dairy company as it allows the company officials to identify the source of contamination or adulteration. It enables the officials to identify the entry of a counterfeit product and trace it back to its origin, i.e., the distributor or retailer through which it was introduced into the supply chain. Contamination and adulteration checks are performed at every level of the supply chain at both product and batch levels. Besides assessing the impact of contamination or adulteration on a product, assessing its nutritional value also holds significant importance. Dairy products such as milk, cheese, and butter are seen as primary sources of nutrition and are consumed across different age groups. Henceforth, it becomes even more essential to maintain the nutritional value of a product throughout the supply chain. The quality management aspect ensures nutritional values of a product are checked and updated at every stage of the supply chain. The QR code associated with a product holds this updated information concerning its nutritional values. Customers will be able to access these values by a simple scan of the QR code. Tracking changes in the nutritional values of a product can be a valuable insight for the dairy company as it will facilitate them to make changes in their processing mechanisms and supply chain routes. All these efforts will be allied to ensure the nutritional values of a product remain intact throughout the supply chain.

Sales management is another important aspect of the application layer. It allows the dairy company to keep track of the type and quantity of the products being sold to a particular distributor and retailer over a specific time. Sales management provides valuable insights concerning the sales patterns of different products across different regions at different time intervals. Companies can launch new products, withdraw existing ones, and make changes to their sales and marketing strategies all based on these sales patterns. Moreover, the companies can vary their production rates for different products seeing to their sales patterns and acceptability among customers. A similar fate can be achieved for products showing signs of depleting nutritional values and high perishability. Being a blockchain-enabled solution, the application layer comprises an aspect concerning the management of payments and settlements. The problems of delayed payments, irregularities in payments, and missing payments are completely prevented by the application layer. Financial settlements happen automatically between stakeholders by the execution of smart contracts.

9. Use Cases for the Dairy Supply Chain

In this section, we will be illustrating the implementation benefits of the proposed blockchain-enabled food safety and traceability platform by means of use cases. Each use case is a replica of a real-world scenario that a dairy company or an end customer may encounter during the production, storage, sales, and purchase of dairy products. The use cases aim to enable the readers in having a better understanding of the proposed platform and enhancing their sense of correlation between different processes of food safety and traceability and stakeholders of the supply chain. The use cases are aligned with the impact dimensions and comprise individual objectives. In total, there are five use cases, one each for economic, operations, and sustainability impact dimensions and two use cases concerning the social impact dimension.

Appendix A lists

Table A1,

Table A2,

Table A3,

Table A4,

Table A5 and

Table A6 which represent the impact of contamination and adulteration on all three dairy products.

9.1. Social

Description: A dairy company named Parag Enterprises is operating in the states of Uttar Pradesh and Uttarakhand, India. Milk is its primary selling product apart from cheese and butter. The company has more than 200 points of sales across the two states. It currently has 10 distributors and each distributor is associated with 20 retailers. Since the past couple of weeks, reports of diarrhoea have been reported by customers consuming its milk products across the regions of Dehradun and Haridwar. Multiple complaints were being reported to its distributors concerning stomach infections and diarrhoea thus resulting in bad publicity. Implementing the proposed blockchain-enabled supply chain platform assisted the company to identify the entry of fake milk products into the supply chain. The platform supports adulteration checks at different stages of the supply chain and identified fake milk packets comprising starch and urea leading to customers suffering from gastro disorders and diarrhoea. Using the platform, the company was even able to identify the particular retailer responsible for selling fake milk packets using the company’s logo. In months to follow, customers in the region of Srinagar, Uttarakhand raised complaints regarding certain cheese products of the company. Similar complaints were being registered by customers from Dehradun regarding the consumption of cheese products. Using the food traceability platform, a set of retailers, distributors, and processing centres were identified for the adulterated products. Quality tests were reconducted at all three levels leading to the identification of a processing centre responsible for adding palm oil during the process of cheese production. Henceforth, causing all operations to be suspended at the processing centre and dairy products produced to be recalled. The proposed platform proved to be an excellent aid in tracking all contaminated cheese products spread across different cities and removing them from the supply chain all at once. Thereby, ensuring the safety of customers from serious cardiac problems.

Description: A dairy company named Gopal Enterprises is operating in the states of Uttar Pradesh and Uttarakhand, India. Milk is its primary selling product apart from cheese and butter. The company has more than 200 points of sales across the two states. Recently, the company’s processing centre has detected batches of raw milk being unfit for consumption and further processing. After performing a series of quality tests, mycotoxins were found in different batches of milk. Implementing our proposed blockchain-enabled supply chain platform assisted the company to update information regarding contaminated batches of milk and remove them from further entering the supply chain. Moreover, the platform helped them in tracing back to the collection centres and dairy farms associated with the contaminated batches of milk. Subsequently, the dairy farms were removed as stakeholders from the supply chain. A similar case of milk contamination was detected with the help of the blockchain-enabled supply chain platform at a Kanpur-based distributor of the company. Cases of decreased shelf life for milk packets were being reported by retailers in parts of Kanpur and Uttar Pradesh. As a result of phase-wise testing supported by the platform, company authorities were able to trace and detect microbial presence in packets of milk at the distributor level. All contaminated milk packets were subsequently removed from the supply chain. In months to come, complaints started surfacing regarding products such as cheese and butter. The distributors of Dehradun, Uttarakhand reported cases of reduced shelf life for certain batches of cheese and butter. Within no time of implementing the proposed blockchain-enabled platform, company authorities were able to find traces of organic pollutants such as dioxins in certain samples of cheese and butter. The traceability platform enabled the authorities to trace the provenance of these products along with identifying the other intermediatory stakeholders. Soon it was noticed that certain cold storage centres in Saharanpur, Uttar Pradesh were responsible for such levels of contamination. The authorities quickly reacted and removed all batches of cheese and butter that were shipped from the concerned cold storage centres. The proposed food safety and traceability platform facilitated the speedy removal of contaminated products and prevented occurrences of diseases such as diarrhoea and cancer among customers with frequent consumption of the contaminated products.

9.2. Economic

Description: A dairy company named Mohan Enterprises is operating in the states of Uttar Pradesh, Uttarakhand, and Madhya Pradesh, India. The company is a renowned cheese producer in the northern region of India. Apart from cheese being its primary selling product, the company also has production lines for milk and butter. The company has more than 500 points of sales spread across the three states. The state of Uttar Pradesh has a maximum of 20 distributors with each distributor being associated with 15 retailers. The state of Rajasthan has 15 distributors with each distributor being associated with 10 retailers. Uttarakhand has 5 distributors with each distributor being associated with 10 retailers. The company plans to come up with a growth strategy that allows it to launch new products and target new customers. In view of its expansion plans, the company incorporated the proposed blockchain-enabled supply chain platform. The platform enabled the company to acquire sales data for every individual product at a distributor and retailer level. The platform allowed the company to possess geo-specific sales data for individual products. Moreso, the company was able to perform data analytics on the mentioned data using machine learning algorithms. The algorithms created trend lines for sales concerning products, locations, distributors, and retailers. Using the platform, the company was able to identify purchasing patterns among customer groups and establish a correlation between sales of different dairy products. Specific product sales patterns were generated with respect to different months of the year. Collective knowledge acquired from the above data analytics enabled the company to increase the sales of its current products and formulate a sales strategy for its future products. Apart from direct benefits to the company’s revenue, the blockchain platform proves its utility by preventing the wastage of food. Dairy products being highly perishable in nature have a limited shelf life thereby making it necessary for the company to produce them in an optimised manner. The blockchain platform allows the company to establish a trade-off between product sales and its shelf life. The platform enables the company to maintain optimised production levels of its dairy products while adhering to sales patterns and perishability, henceforth, preventing food wastage.

9.3. Operational

Description: A dairy company named Krishna Enterprises is operating in the states of Gujrat and Rajasthan, India. Milk is its primary selling product apart from cheese and butter. The company has more than 400 points of sales across the two states. The state of Gujrat has 10 distributors with each distributor being associated with 30 retailers. The state of Rajasthan has 10 distributors with each distributor being associated with 10 retailers. A majority of its collection and processing centres are located in the state of Gujrat, whereas the cold storage centres are predominantly present in the state of Rajasthan. Recently, the company has been experiencing significant extents of bad publicity from its local competitors. In response to the situation, the company adopted the proposed blockchain-enabled food safety and traceability platform. The platform assisted the company to release quality certificates for its products by government standards. The quality certificates were accessible to end customers by scanning the QR code present on the product. In months to come, the company started to face issues regarding payment settlements from a few of its retailers. Few distributors from Rajasthan had rendered credit more than the acceptable limits to their retailers thereby resulting in a financial irregularity. The company management was unaware of such illicit practices as they only surfaced after an internal audit. The practices were going on for months resulting in an imbalance in the accounting books. With the implementation of the proposed blockchain-enabled supply chain platform, the company was able to ensure a culture of real-time payment settlements as soon as the products were delivered to the retailers. The platform allowed the company to monitor payments at a stakeholder level. A single document was generated for every order by a distributor or retailer comprising all shipment and product details. The document was timestamped every time a product passes through a stakeholder in the supply chain. Being a decentralized platform, no single authority possesses governance rights over the document thus proving it to be tamper-proof and ensuring its authenticity. Moreover, the company was able to identify the set of distributors and retailers who were responsible for multiple financial irregularities at different time intervals. The platform ensured accountability of products being sold by every distributor and retailer. Any instance of a counterfeit product was timely identified and subsequently removed from the supply chain.

9.4. Sustainability

Description: A dairy company named Sohan Enterprises is operating in the states of Uttar Pradesh and Bihar, India. The company is a renowned butter producer in the northern region of India. Apart from butter being its primary selling product, the company also has production lines for milk and cheese. The company has more than 250 points of sales spread across the two states. The state of Uttar Pradesh has a maximum of 15 distributors with each distributor being associated with 10 retailers. The state of Bihar has 10 distributors with each distributor being associated with 15 retailers. Recently, a quality check in one of the processing centres of Lucknow district traced contaminated milk. The contamination made milk unfit for direct consumption. Implementing our proposed blockchain-enabled supply chain platform the company gets updated regarding contaminated batches of milk. As a result of phase-wise testing supported by the platform, company authorities were able to trace and detect contamination in packets of milk at the distributor level. All contaminated milk packets were subsequently collected at the retailer, distributor, and processing centre level. The timely detection ensured more release of milk products from the company, preventing a shortage of milk in the market. The milk was tested for kind of contamination and it was found to be microbial. The batch number and order number helped to predict the shelf life of pasteurized milk. It was found that 25% of the milk can be converted to some other milk products as the extent of spoilage is not too severe and milk can be reused after processing. The dairy company converted the fluid milk into other dairy products such as cheese. However, it was found that the rest of the milk can only be thrown away as the impact of contamination was severe, making fluid milk not suitable for reuse. Our experiment has ensured whether to use spoiled milk or discard it. Our platform helped in the proper handling and sustainable disposal of spoiled milk. The company made proper arrangements to discard the milk and prevented the accumulation in landfills that may produce methane gas, pollution in water, and increased chemical oxygen demand. In another incidence of a random quality check of a sample of butter at one of the distributors of Patna, it was found that the sample was not up to the mark. The final analysis showed that it was adulterated with starch. The blockchain-enabled supply chain helped to trace all the batches adulterated with starch. Being the leading distributor of butter, the supplier ensures the makeup of the shortage of butter in the market. It also helped to collect all the samples of adulterated butter for proper disposal as per the government norms and sustainability parameters.