Microwave and Roasting Impact on Pumpkin Seed Oil and Its Application in Full-Fat Mayonnaise Formula

Abstract

:1. Introduction

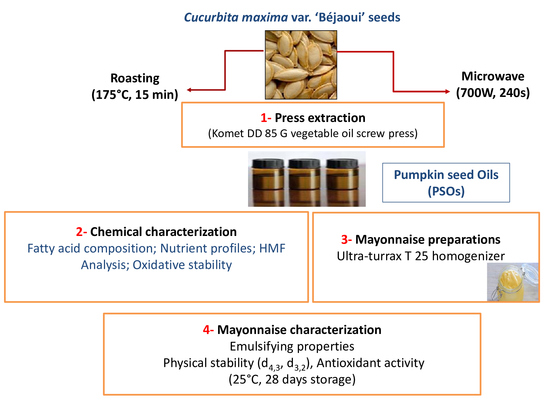

2. Material and Methods

2.1. Sampling

2.2. Microwave and Roasting Pretreatments

2.3. Oil Extraction

2.4. Chemical and Physical Characterization of PSO

2.4.1. Fatty Acid (FA) Profile Analysis

2.4.2. Tocopherol Composition

2.4.3. Sterols Analysis (STs)

2.4.4. 5-Hydroxymethylfurfural (HMF) Analysis

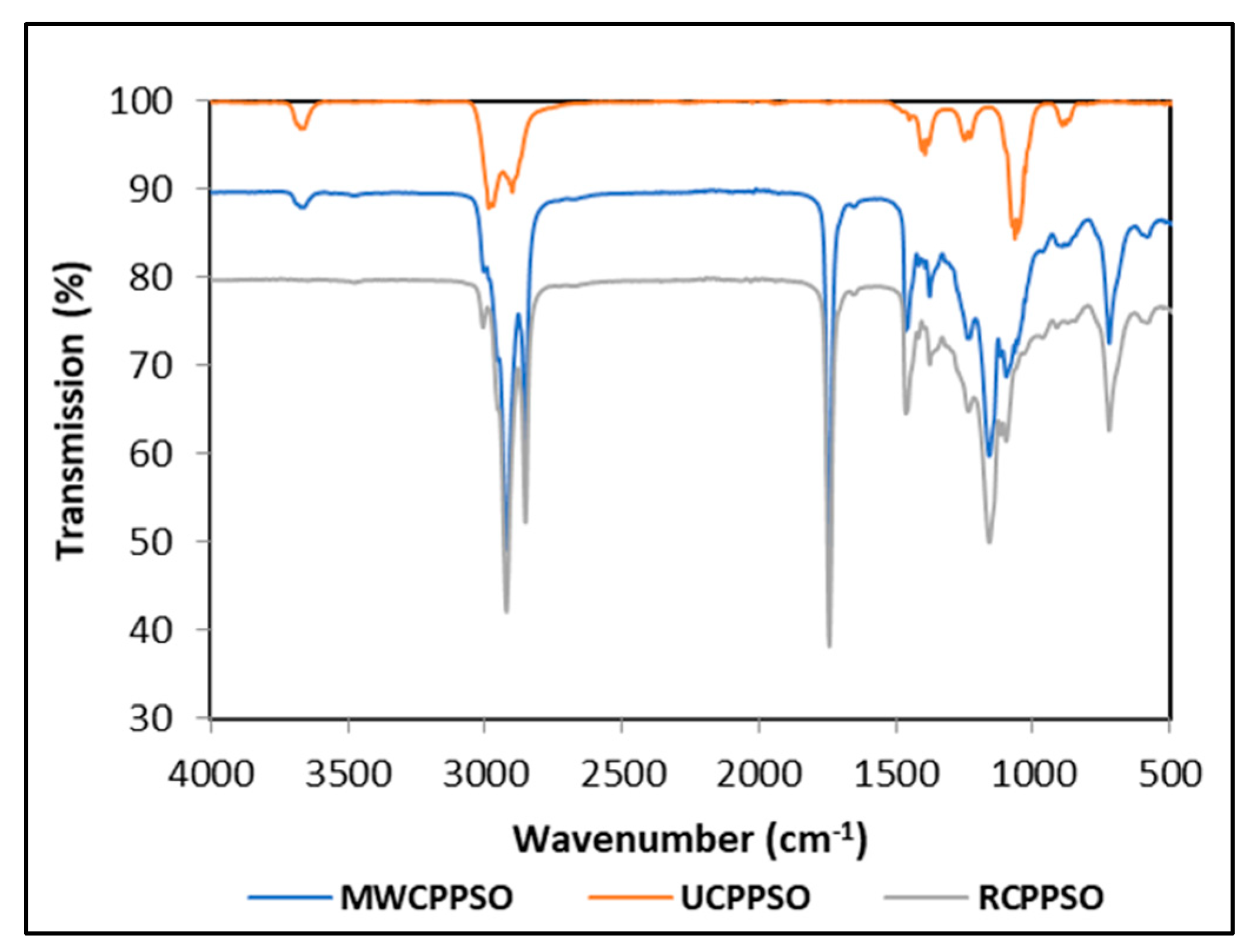

2.4.5. FTIR-Analysis

2.4.6. Oxidative Stability

2.5. Mayonnaise Preparation (O/W Emulsions)

2.6. Emulsifying Properties

2.7. Characterization and Stability of Mayonnaise during Storage

2.7.1. Particle Size Measurement

2.7.2. Creaming Index (CI)

2.7.3. PH Measurement

2.8. Bioactive Properties of Mayonnaise

2.8.1. Evaluation of Antioxidant Activity (AA)

2.8.2. Total Phenolic Content (TPC)

2.9. Oxidation Experiments in Mayonnaise

2.10. Statistical Analyses

3. Results and Discussion

3.1. PSO Characterization

3.1.1. Fatty Acid Composition

3.1.2. Tocopherols

3.1.3. Phytosterols

3.1.4. HMF

3.1.5. Evaluation by FTIR

3.1.6. Oxidative Stability

3.2. Emulsifying Properties

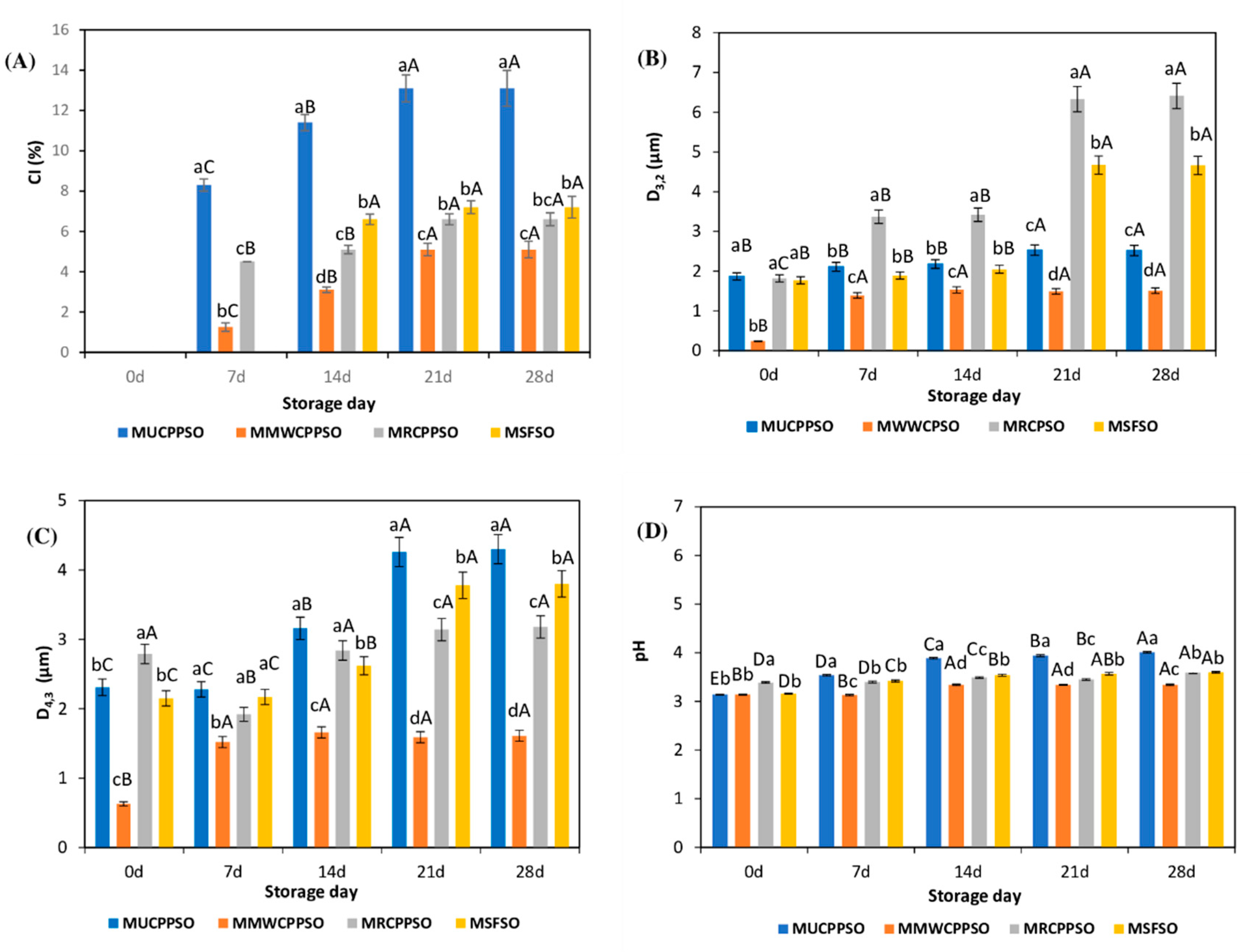

3.3. Physical Stability of Mayonnaise during Storage

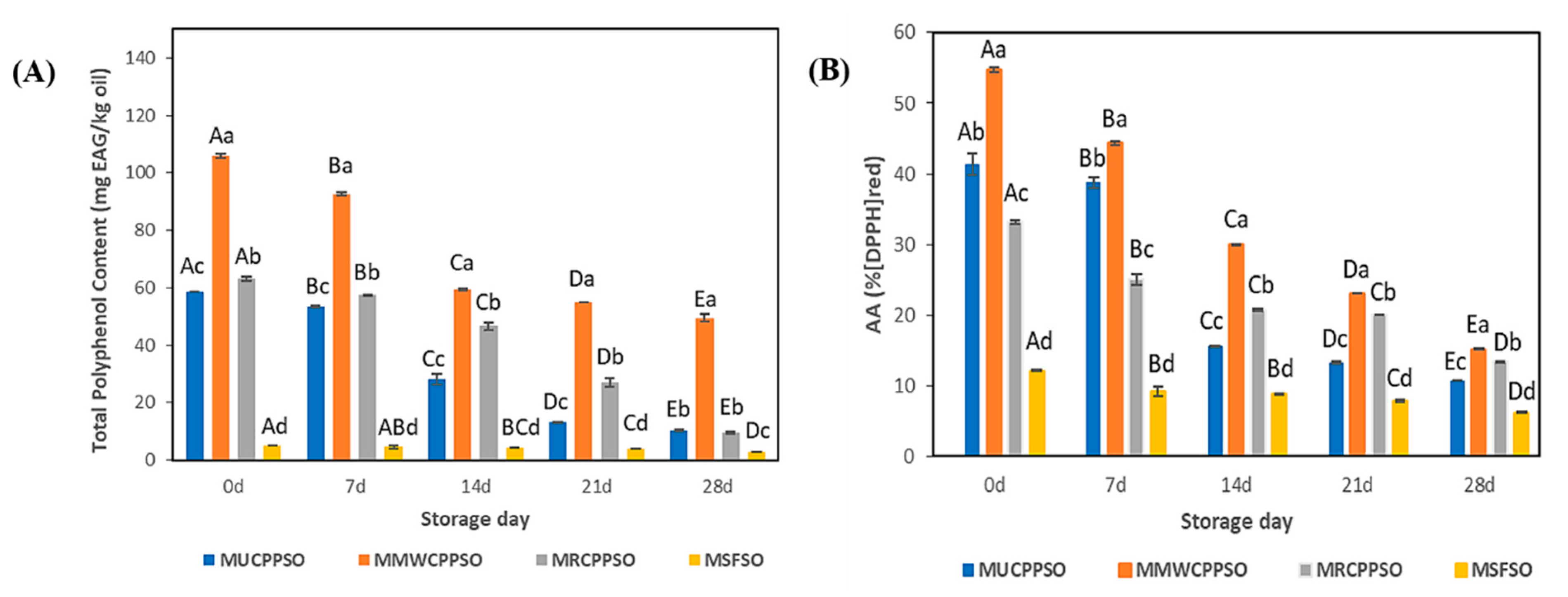

3.4. TPC and Antioxidant Activity

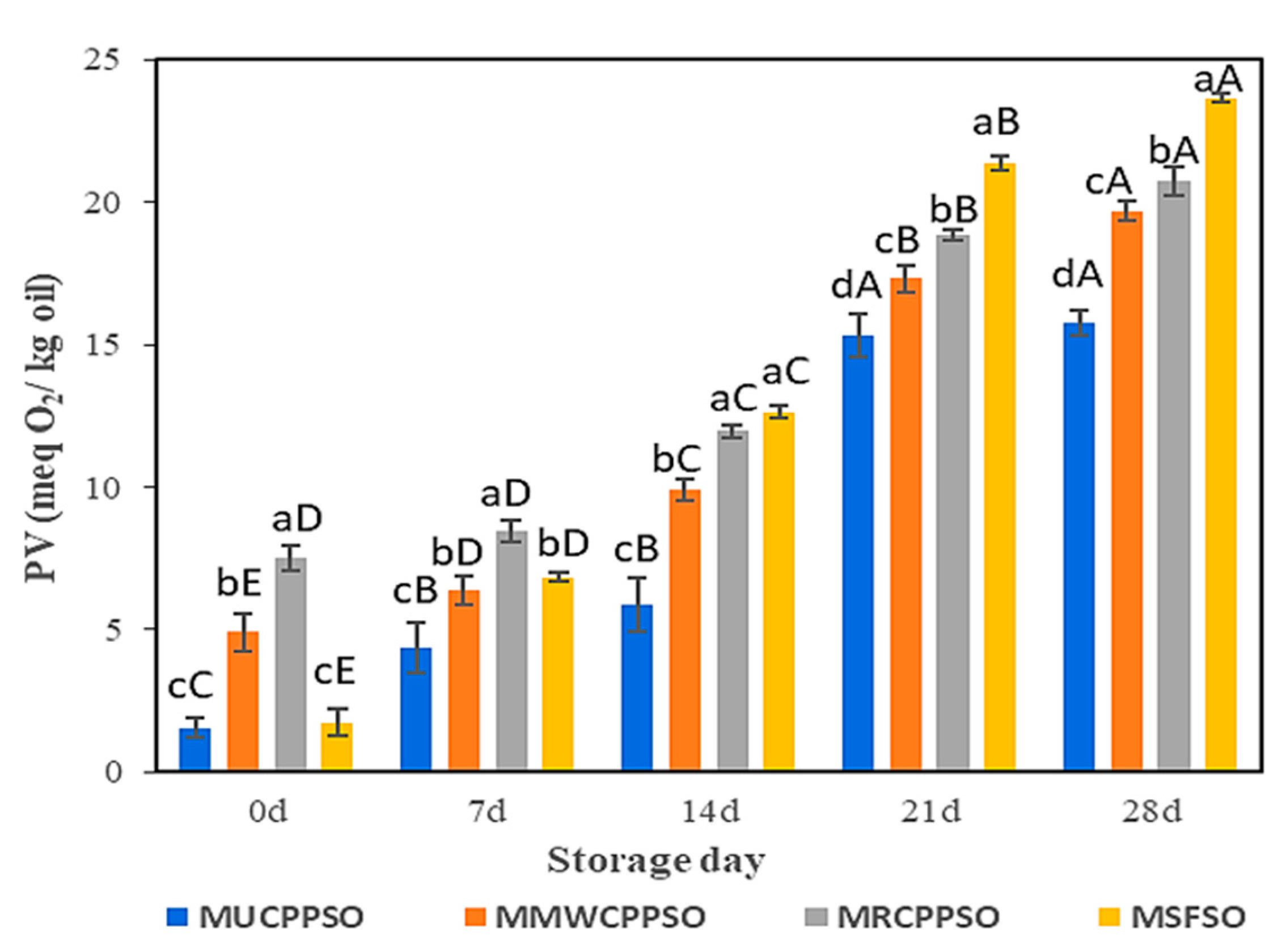

3.5. Changes in the PV

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rezig, L.; Chouaibi, M.; Meddeb, W.; Msaada, K.; Hamdi, S. Chemical composition and bioactive compounds of Cucurbitaceae seeds: Potential sources for new trends of plant oils. Process Saf. Environ. Prot. 2019, 127, 73–81. [Google Scholar] [CrossRef]

- Prommaban, A.; Kuanchoom, R.; Seepuan, N.; Chaiyana, W. Evaluation of Fatty Acid Compositions, Antioxidant, and Pharmacological Activities of Pumpkin (Cucurbita moschata) Seed Oil from Aqueous Enzymatic Extraction. Plants 2021, 10, 1582. [Google Scholar] [CrossRef] [PubMed]

- Nakić, S.N.; Rade, D.; Škevin, D.; Štrucelj, D.; Mokrovcak, Z.; Bartolić, M. Chemical characteristics of oils from naked and husk seeds of Cucurbita pepo L. Eur. J. Lipid Sci. Technol. 2006, 108, 936–943. [Google Scholar] [CrossRef]

- Schilcher, H.; Dunzendorfer, U.; Ascali, F. Delta-7-sterole, das prostatotrope Wirkprinzip in Kürbissamen? Urol. B 1987, 27, 316–319. [Google Scholar]

- Yadav, M.; Jain, S.; Tomar, R.; Prasad, G.B.K.S.; Yadav, H. Medicinal and biological potential of pumpkin: An updated review. Nutr. Res. Rev. 2010, 23, 184–190. [Google Scholar] [CrossRef]

- Martha, R.; Gutierrez, P. Review of Cucurbita pepo (pumpkin) its phytochemistry and pharmacology. Med. Chem. 2016, 6, 12–21. [Google Scholar] [CrossRef]

- Rezig, L.; Chouaibi, M.; Msaada, K.; Hamdi, S. Chemical composition and profile characterization of pumpkin (Cucurbita maxima) seed oil. Ind. Crops Prod. 2012, 37, 82–87. [Google Scholar] [CrossRef]

- Bardaa, S.; Ben Halima, N.; Aloui, F.; Ben Mansour, R.; Jabeur, H.; Bouaziz, M.; Sahnoun, Z. Oil from pumpkin (Cucurbita pepo L.) seeds: Evaluation of its functional properties on wound healing in rats. Lipids Health Dis. 2016, 15, 73. [Google Scholar] [CrossRef]

- Medjakovic, S.; Hobiger, S.; Ardjomand-Woelkart, K.; Bucar, F.; Jungbauer, A. Pumpkin seed extract: Cell growth inhibition of hyperplastic and cancer cells, independent of steroid hormone receptors. Fitoterapia 2016, 110, 150–156. [Google Scholar] [CrossRef]

- Murkovic, M.; Hillebrand, A.; Winkler, H.; Pfannhauser, W. Variability of vitamin E content in pumpkin seeds (Cucurbita pepo L.). Z Leben. Unters. For. 1996, 202, 275–278. [Google Scholar] [CrossRef]

- El-Adawy, T.A.; Taha, K.M. Characteristics and composition of different seed oils and flours. Food Chem. 2001, 74, 47–54. [Google Scholar] [CrossRef]

- Stevenson, D.G.; Eller, F.J.; Wang, L.; Jane, J.-L.; Wang, T.; Inglett, G.E. Oil and tocopherol content and composition of pumpkin seed oil in 12 cultivars. J. Agric. Food Chem. 2007, 55, 4005–4013. [Google Scholar] [CrossRef]

- Jiao, J.; Li, Z.G.; Gai, Q.Y.; Li, X.J.; Wei, F.Y.; Fu, Y.J.; Ma, W. Microwave-assisted aqueous enzymatic extraction of oil from pumpkin seeds and evaluation of its physicochemical properties, fatty acid compositions and antioxidant activities. Food Chem. 2014, 147, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Procida, G.; Stancher, B.; Cateni, F.; Zacchigna, M. Chemical composition and functional characterisation of commercial pumpkin seed oil. J. Sci. Food Agric. 2013, 93, 1035–1041. [Google Scholar] [CrossRef] [PubMed]

- Francesco, S.; Maria, C.S.; Marina, P.; Gabriella, F.; Floriana, B.; Maria, G.V. Physico-chemical properties and fatty acid composition of pomegranate, cherry and pumpkin seed oils. J. Sci. Food Agric. 2016, 96, 1730–1735. [Google Scholar] [CrossRef]

- Azadmard-Damirchi, S.; Alirezalu, K.; Fathi Achachlouei, B. Microwave pretreatment of seeds to extract high quality vegetable oil. World Acad. Sci. Eng. Technol. 2011, 57, 72–75. [Google Scholar]

- Tang, J. Unlocking potentials of microwaves for food safety and quality. J. Food Sci. 2015, 80, E1776–E1793. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, S. Recent developments in radio frequency drying of food and agricultural products: A review. Dry. Technol. 2019, 37, 271–286. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, S.; Tang, Z.; Tang, J.; Takhar, P.S. Microwave frying and post-frying of French fries. Food Res. Int. 2022, 159, 111663. [Google Scholar] [CrossRef]

- Ali, M.A.; Nargis, A.; Othman, N.H.; Noor, A.F.; Sadik, G.; Hossen, J. Oxidation Stability and Compositional Characteristics of Oils from Microwave Roasted Pumpkin Seeds during Thermal Oxidation. Int. J. Food Prop. 2017, 20, 2569–2580. [Google Scholar] [CrossRef]

- Aktaş, N.; Gerçekaslan, K.E.; Uzlaşır, T. The effect of some pre-roasting treatments on quality characteristics of pumpkin seed oil. OCL 2018, 25, A301. [Google Scholar] [CrossRef]

- Potočnik, T.; Cizej, M.R.; Košir, I.J. Influence of Seed Roasting on Pumpkin Seed Oil Tocopherols, Phenolics and Antiradical Activity. J. Food Compos. Anal. 2018, 69, 7–12. [Google Scholar] [CrossRef]

- Delfan-Hosseini, S.; Nayebzadeh, K.; Mirmoghtadaie, L.; Kavosi, M.; Marzieh Hosseini, S. Effect of extraction process on composition, oxidative stability and rheological properties of purslane seed oil. Food Chem. 2017, 222, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Uquiche, E.; Jérez, M.; Ortíz, J. Effect of pretreatment with microwaves on mechanical extraction yield and quality of vegetable oil from Chilean hazelnuts (Gevuina avellana Mol). Innov. Food Sci. Emerg. Technol. 2008, 9, 495–500. [Google Scholar] [CrossRef]

- Yoshida, H.; Hirakawa, Y.; Tomiyama, Y.; Nagamizua, T.; Mizushina, Y. Fatty acid distributions of triacylglycerols and phospholipids in peanut seeds (Arachis hypogaea L.) following microwave treatment. J. Food Compos. Anal. 2005, 18, 3–14. [Google Scholar] [CrossRef]

- Yoshida, H.; Tomiyama, Y.; Hirakawa, Y.; Mizushina, Y. Microwave roasting effects on the oxidative stability of oils and molecular species of triacylglycerols in the kernels of pumpkin (Cucurbita spp.) seeds. J. Food Compos. Anal. 2006, 19, 330–339. [Google Scholar] [CrossRef]

- Moslavac, T.; Pazman, A.; Vukina, T.; Jakobović, M. Reološka svojstva salatne majoneze s dodatkom pulpe kivija. MESO 2018, 20, 131–137. [Google Scholar] [CrossRef]

- Moslavac, T.; Babić, J.; Marković, T.; Mrgan, A.; Konjarević, A. Effect of ingredients and homogenisation on rheological properties of salad mayonnaise with banana purée. MESO Prvi Hrvat. Časopis O Mesu 2019, 21, 170–179. [Google Scholar] [CrossRef]

- Rojas, V.M.; Marconi, L.F.D.C.B.; Guimarães-Inácio, A.; Leimann, F.V.; Tanamati, A.; Gozzo, Â.M.; Fuchs, R.H.B.; Barreiro, M.F.; Barros, L.; Ferreira, I.C.F.R.; et al. Formulation of mayonnaises containing PUFAs by the addition of microencapsulated chia seeds, pumpkin seeds and baru oils. Food Chem. 2019, 274, 220–227. [Google Scholar] [CrossRef]

- Tekin-Cakmak, Z.H.; Atik, I.; Karasu, S. The Potential Use of Cold-Pressed Pumpkin Seed Oil By-Products in a Low-Fat Salad Dressing: The Effect on Rheological, Microstructural, Recoverable Properties, and Emulsion and Oxidative Stability. Foods 2021, 10, 2759. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of the Official Analytical Chemists; Firestone, D., Ed.; Association of the Official Analytical Chemists, Inc.: Arlington, VA, USA, 1990. [Google Scholar]

- European Economic Community. Characteristics of Olive and Olive Pomace Oils and Their Analytical Methods, Regulation EEC/2568/1991; European Economic Community: Brussels, Belgium, 1991; pp. 1–82. [Google Scholar]

- NF EN ISO 9936; Association Française de Normalisation, European Norm, NF EN ISO 9936 Octobre 2006; French Norm T60-239: Animal and Vegetable Fats and Oils-Determination of Tocopherols and Tocotrienols Contents-Method Using High-Performance Liquid Chromatography. ISO: Genève, Switzerland, 2006; 17p.

- NF EN ISO 12228; Association Française de Normalisation, European Norm, NF EN ISO 12228 May 1999; French Norm T60-258: Animal and Vegetable Fats and Oils- Determination of Individual and Total Sterols Contents-Gas Chromatographic Method. AFNOR: Paris, France, 1999; 18p.

- Durmaz, G.; Gökmen, V. Determination of 5-hydroxymethyl-2-furfural and 2-furfural in oils as indicators of heat pre-treatment. Food Chem. 2010, 123, 912–916. [Google Scholar] [CrossRef]

- Suri, K.; Singh, B.; Kaur, A.; Singh, N. Impact of roasting and extraction methods on chemical properties, oxidative stability and Maillard reaction products of peanut oils. J. Food Sci. Technol. 2019, 56, 2436–2445. [Google Scholar] [CrossRef] [PubMed]

- Flamminii, F.; Di Mattia, C.D.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and sensory properties of mayonnaise enriched with encapsulated olive leaf phenolic extracts. Foods 2020, 9, 997. [Google Scholar] [CrossRef] [PubMed]

- Alpizar-Reyes, E.; Carrillo-Navas, H.; Gallardo-Rivera, R.; Varela-Guerrero, V.; Alvarez-Ramirez, J.; Pérez-Alonso, C. Functional properties and physicochemical characteristics of tamarind (Tamarindus indica L.) seed mucilage powder as a novel hydrocolloid. J. Food Eng. 2017, 209, 68–75. [Google Scholar] [CrossRef]

- Alpizar-Reyes, E.; Varela-Guerrero, V.; Cruz-Olivares, J.; Carrillo-Navas, H.; Alvarez-Ramirez, J.; Pérez-Alonso, C. Microencapsulation of sesame seed oil by tamarind seed mucilage. Int. J. Biol. Macromol. 2020, 145, 207–215. [Google Scholar] [CrossRef]

- Romeo, R.; De Bruno, A.; Piscopo, A.; Brenes, M.; Poiana, M. Effects of Phenolic Enrichment on Antioxidant Activity of Mayonnaise. Chem. Eng. Trans. 2021, 87, 127–132. [Google Scholar] [CrossRef]

- Ozdemir, N.; Kantekin-Erdogan, M.N.; Tat, T.; Tekin, A. Effect of black cumin oil on the oxidative stability and sensory characteristics of mayonnaise. J. Food Sci. Technol. 2018, 55, 1562–1568. [Google Scholar] [CrossRef]

- Tsimidou, M. Polyphenols and quality of virgin oil in retrospect. Ital. J. Food Sci. 1998, 10, 99–116. [Google Scholar]

- Altunkaya, A.; Hedegaard, R.V.; Harholt, J.; Brimer, L.; Gökmen, V.; Skibsted, L.H. Oxidative stability and chemical safety of mayonnaise enriched with grape seed extract. Food Funct. 2013, 4, 1647–1653. [Google Scholar] [CrossRef] [PubMed]

- AOCS. Official methods P-anisidine value. In Official Methods and Recommended Practices of the American Oil Chemists Society, 15th ed.; Firestone, D., Ed.; American Oil Chemists Society: Urbana, IL, USA, 1998; pp. 18–90. [Google Scholar]

- STATISTICA Software; Statsoft, Inc.: Tulsa, OK, USA, 1998.

- Neđeral, S.; Škevin, D.; Kraljić, K.; Obranović, M.; Papeša, S.; Bataljaku, A. Chemical composition and oxidative stability of roasted and cold pressed pumpkin seed oils. J. Am. Oil Chem. Soc. 2012, 89, 1763–1770. [Google Scholar] [CrossRef]

- Murkovic, M.; Piironen, V.; Lampi, A.M.; Kraushofer, T.; Sontag, G. Changes in chemical composition of pumpkin seeds during the roasting process for production of pumpkin seed oil (Part 1: Non-volatile compounds). Food Chem. 2004, 84, 359–365. [Google Scholar] [CrossRef]

- Azadmard-Damirchi, S.; Habibi-Nodeh, F.; Hesari, J.; Nemati, M.; Achachlouei, B.F. Effect of pretreatment with microwaves on oxidative stability and nutraceuticals content of oil from rapeseed. Food Chem. 2010, 121, 1211–1215. [Google Scholar] [CrossRef]

- Suri, K.; Singh, B.; Kaur, A. Impact of microwave roasting on physicochemical properties, maillard reaction products, antioxidant activity and oxidative stability of nigella seed (Nigella sativa L.) oil. Food Chem. 2022, 368, 130777. [Google Scholar] [CrossRef] [PubMed]

- Suri, K.; Singh, B.; Kaur, A.; Yadav, M.P.; Singh, N. Impact of infrared and dry air roasting on the oxidative stability, fatty acid composition, Maillard reaction products and other chemical properties of black cumin (Nigella sativa L.) seed oil. Food chem. 2019, 295, 537–547. [Google Scholar] [CrossRef]

- Pușcaș, A.; Mureșan, A.; Ranga, F.; Fetea, F.; Muste, S.; Socaciu, C.; Mureșan, V. Phenolics Dynamics and Infrared Fingerprints during the Storage of Pumpkin Seed Oil and Thereof Oleogel. Processes 2020, 8, 1412. [Google Scholar] [CrossRef]

- Niu, B.; Yan, Z.; Shao, P.; Kang, J.; Chen, H. Encapsulation of cinnamon essential oil for active food packaging film with synergistic antimicrobial activity. Nanomaterials 2018, 8, 598. [Google Scholar] [CrossRef]

- Vujasinovic, V.; Djilas, S.; Dimic, E.; Basic, Z.; Radocaj, O. The effect of roasting on the chemical composition and oxidative stability of pumpkin oil. Eur. J. Lipid Sci. Technol. 2012, 114, 568–574. [Google Scholar] [CrossRef]

- Amarowicz, R. Antioxidant activity of Maillard reaction products. Eur. J. Lipid Sci. Technol. 2009, 111, 109–111. [Google Scholar] [CrossRef]

- Sakai, S.; Ikeda, N. A numerical analysis to evaluate the emulsifying activity of pasteurized egg yolk. Food Hydrocoll. 2022, 123, 107087. [Google Scholar] [CrossRef]

- Gmach, O.; Bertsch, A.; Bilke-Krause, C.; Kulozik, U. Impact of oil type and pH value on oil-in-water emulsions stabilized by egg yolk granules. Colloids Surf. A 2019, 581, 123788. [Google Scholar] [CrossRef]

- Nikolovski, B.G.; Ilić, J.D.; Sovilj, M.N.; Nikolić, M.P.; Milanović, J.L. Influence of pumpkin seed oil in continuous phase on droplet size and stability of water-in-oil emulsions. Acta Period. Technol. 2011, 42, 175–183. [Google Scholar] [CrossRef]

- Anicescu, M.C.; Dinu-Pîrvu, C.E.; Ghica, M.V.; Anuţa, V.; Prisada, R.M.; Talianu, M.T.; Popa, L. Preliminary analysis of emulsion-based formulations containing pumpkin seed oil and hemp seed oil for internal use. In Proceedings of the 8th International Conference of Advanced Materials and Systems; Certex Publishing: Bucharest, Romania, 2020; pp. 115–120. [Google Scholar] [CrossRef]

- McClements, D.J. Critical review of techniques and methodologies for characterization of emulsion stability. Crit. Rev. Food Sci. Nutr. 2007, 47, 611–649. [Google Scholar] [CrossRef] [PubMed]

- Worrasinchai, S.; Suphantharika, M.; Pinjai, S.; Jamnong, P. β-Glucan prepared from spent brewer’s yeast as a fat replacer in mayonnaise. Food Hydrocoll. 2006, 20, 68–78. [Google Scholar] [CrossRef]

- Laca, A.; Sáenz, M.C.; Paredes, B.; Dίaz, M. Rheological properties, stability and sensory evaluation of low-cholesterol mayonnaises prepared using egg yolk granules as emulsifying agent. J. Food Eng. 2010, 97, 243–252. [Google Scholar] [CrossRef]

- Liu, H.; Xu, X.M.; Guo, S.D. Rheological texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT-Food Sci. Technol. 2007, 40, 946–954. [Google Scholar] [CrossRef]

- Wang, A.; Xiao, Z.; Wang, J.; Li, G.; Wang, L. Fabrication and characterization of emulsion stabilized by table egg-yolk granules at different pH levels. J. Sci. Food Agric. 2020, 100, 1470–1478. [Google Scholar] [CrossRef]

- Sørensen, A.D.M.; Nielsen, N.S.; Hyldig, G.; Jacobsen, C. Influence of emulsifier type on lipid oxidation in fish oil enriched light mayonnaise. Eur. J. Lipid Sci. Technol. 2010, 112, 1012–1023. [Google Scholar] [CrossRef]

- Honold, P.J.; Jacobsen, C.; Jónsdóttir, R.; Kristinsson, H.G.; Hermund, D.B. Potential seaweed-based food ingredients to inhibit lipid oxidation in fish-oil-enriched mayonnaise. Eur. Food Res. Technol. 2016, 242, 571–584. [Google Scholar] [CrossRef]

- Li, C.Y.; Kim, H.W.; Li, H.; Lee, D.C.; Rhee, H.I. Antioxidative effect of purple corn extracts during storage of mayonnaise. Food Chem. 2014, 152, 592–596. [Google Scholar] [CrossRef]

- Raikos, V.; Neacsu, M.; Morrice, P.; Duthie, G. Anti-and pro-oxidative effect of fresh and freeze-dried vegetables during storage of mayonnaise. J. Food Sci. Technol. 2015, 52, 7914–7923. [Google Scholar] [CrossRef] [Green Version]

| Untreated Cold Press PSO (UCPPSO) | Microwave Cold Press PSO (MWCPPSO) | Roasted Cold Press PSO (RCPPSO) | |

|---|---|---|---|

| Fatty acids | Composition | ||

| Myristic (C14:0) | tr. | tr. | tr. |

| Palmitic (C16:0) | 13.59 ± 0.64 a | 14.05 ± 0.7 a | 14.33 ± 0.65 a |

| Palmitoleic (C16:1) | tr. | tr. | tr. |

| Stearic (C18:0) | 6.35 ± 0.34 a | 6.54 ± 0.36 a | 6.85 ± 0.34 a |

| Oleic (C18:1) | 34.45 ± 1.75 a | 34.37 ± 1.73 a | 33.95 ± 1.48 a |

| Linoleic (C18:2) | 45.20 ± 2.38 a | 44.44 ± 2.22 a | 44.29 ±2.19 a |

| Linolenic (C18:3) | tr. | tr. | tr. |

| Arachidic (C20:0) | 0.38 ± 0.13 a | 0.46 ± 0.09 a | 0.35 ± 0.12 a |

| Eicosenoic (C20:1) | tr. | tr. | tr. |

| Behenic (C22:0) | tr. | tr. | tr. |

| Lignoceric (C24:0) | tr. | tr. | tr. |

| SAFA | 20.33 ± 1.04 a | 21.06 ± 1.01 a | 21.54 ± 1.02 a |

| MUFA | 34.46 ± 1.77 a | 34.38 ± 1.68 a | 33.96 ± 1.45 a |

| PUFA | 45.21 ± 2.28 a | 44.45 ± 2.12 a | 44.30 ± 2.11 a |

| Sterol | Composition | ||

| Cholesterol | 9.47 ± 0.47 b | 11.97 ± 0.60 a | 12.16 ± 0.71 a |

| 24-methylenecholesterol | 26.51 ± 1.42 b | 28.74 ± 1.19 b | 32.20 ± 1.43 a |

| Campesterol | 53.03 ± 2.36 b | 44.31 ± 2.39 c | 62.25 ± 2.86 a |

| Campestanol | 20.83 ± 0.94 a | 17.96 ± 5.39 a | 25.04 ± 1.43 a |

| Stigmasterol | 115.53 ± 5.68 a | 107.80 ± 80 a | 127.37 ± 6.44 a |

| Δ5-Avenasterol | 37.88 ± 1.89 b | 38.32 ± 1.79 b | 46.51 ± 2.14 a |

| Δ5,24-Stigmastadienol | 1395.87 ± 69.60 c | 1801 ± 89.83 b | 2090.98 ± 104.47 a |

| Δ7-Campesterol | 148.20 ± 7.10 c | 234.76 ± 11.38 b | 269.78 ± 13.59 a |

| Δ7-Avenasterol | 713.56 ± 35.51 c | 992.97 ± 49.70 b | 1162.13 ± 57.96 a |

| Δ7-Stigmastenol | 425.67 ± 21.30 c | 561.16 ± 28.14 b | 646.18 ± 32.20 a |

| Clerosterol | 60.13 ± 2.84 b | 67.67 ± 3.00 a,b | 71.56 ± 3.57 a |

| Sitosterol + Δ5,23-Stigmastadienol | 1629.84 ± 81.44 c | 1905.07 ± 95.22 b | 2400.89 ± 119.50 a |

| Sitostanol | 98.48 ± 4.73 c | 177.27 ± 8.98 b | 208.95 ± 10.73 a |

| Total | 4735 ± 236.75 c | 5989 ± 299.45 b | 7156 ± 357.8 a |

| Tocopherol | Composition | ||

| α-Tocopherol | 6.71 ± 0.8 a | 5.87 ± 0.7 a | 4.03 ± 0.16 b |

| γ-Tocopherol | 380.49 ± 38.63 a | 383.08 ± 8.98 a | 349.54 ± 8.18 a |

| Total | 387.2 ± 39.43 a | 388.95 ± 9.69 a | 353.57 ± 8.34 a |

| Oxidative Stability (h) | 3 h 46 min ± 10 min b | 4 h 32 min ± 14 min a | 3 h 50 min ± 20 min a,b |

| Samples (b) | MUCPPSO | MMWCPPSP | MRCPPSO | MSFSO |

|---|---|---|---|---|

| Emulsifying ability (%) | 100 ± 0.00 | 100 ± 0.00 | 100 ± 0.00 | 100 ± 0.00 |

| Emulsifying stability (%) | 98.18 ± 0.1 a | 87.27 ± 0.13 d | 96.36± 0.12 b | 89.66 ± 0.1 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezig, L.; Harzalli, Z.; Gharsallah, K.; Mahfoudhi, N.; Chouaibi, M.; Majdoub, H.; Oueslati, I. Microwave and Roasting Impact on Pumpkin Seed Oil and Its Application in Full-Fat Mayonnaise Formula. Foods 2022, 11, 2732. https://doi.org/10.3390/foods11182732

Rezig L, Harzalli Z, Gharsallah K, Mahfoudhi N, Chouaibi M, Majdoub H, Oueslati I. Microwave and Roasting Impact on Pumpkin Seed Oil and Its Application in Full-Fat Mayonnaise Formula. Foods. 2022; 11(18):2732. https://doi.org/10.3390/foods11182732

Chicago/Turabian StyleRezig, Leila, Zina Harzalli, Karima Gharsallah, Nesrine Mahfoudhi, Moncef Chouaibi, Hatem Majdoub, and Imen Oueslati. 2022. "Microwave and Roasting Impact on Pumpkin Seed Oil and Its Application in Full-Fat Mayonnaise Formula" Foods 11, no. 18: 2732. https://doi.org/10.3390/foods11182732

APA StyleRezig, L., Harzalli, Z., Gharsallah, K., Mahfoudhi, N., Chouaibi, M., Majdoub, H., & Oueslati, I. (2022). Microwave and Roasting Impact on Pumpkin Seed Oil and Its Application in Full-Fat Mayonnaise Formula. Foods, 11(18), 2732. https://doi.org/10.3390/foods11182732