Cutting Techniques in the Fish Industry: A Critical Review

Abstract

:1. Introduction

2. Modern Fish Cutting

2.1. Metal Blade Cutting Machines

2.2. Metal Blade Design and Operation Parameters

2.3. Drawbacks and Limitations

3. Waterjet Cutting

4. Machine Vision and Artificial Intelligence for Fish Cutting

5. Future Perspectives

- (1)

- Some fish species deserve more attention, such as catfish. Catfish was ranked 8th in the top 10 seafood of U.S. per capita consumption in 2019 [138]. Mississippi and Alabama were ranked first and second in catfish farming and production in 2021, respectively [139]. However, compared with 300 million kilograms in 2003, the U.S. catfish industry’s yield decreased to 136.5 million kilograms in 2014 because of international market competition and increasing feed costs [140]. Furthermore, compared with other fish species, catfish have just a few rib bones, so the catfish belly flap portion can be trimmed and sold as fish nuggets [141]. Therefore, developing special cutting machines or trimming and portioning methods for catfish can keep catfish farming and fillet processing industries (with a total impact of more than one billion dollars) as an important agricultural and food industry, which their existence is vital to the success of the US rural economy.

- (2)

- Waterjet cutting should be further developed for other fish-cutting steps. Although the waterjet cutting works well for fish fillet portioning and trimming steps, there is no waterjet cutting application for other fish cutting steps, such as filleting and deheading. Also, the small-scale fish cutting processes are all performed by a metal blade system, and no waterjet cutting machine is designed or modified for small-scale fish. The cutting parameters can be adjusted to reach a critical condition: the water stream will cut along the edge of the fish meat and touch the fish bones but cut the meat only, which means that the water cutting force is adjusted to be just good for cutting meat but not strong enough for cutting bones. Under critical conditions, waterjet cutting can realize the maximum fish fillet yield. Besides, there is no research on abrasive waterjet fish cutting. It can be a better solution for further improving the fish-cutting quality and efficiency in deheading and filleting processing steps. The abrasives, including salt, sugar, ice, and starch particles, can be added to the high-pressure waterjet, which can reduce the surface roughness, favor energy saving, and lower the overall costs of equipment maintenance [33,34,142,143].

- (3)

- Other novel cutting techniques should be developed for the fish-cutting process. Another two common food cutting techniques, ultrasonic cutting and laser cutting, are currently not good for fish processing. Even though some companies have designed ultrasonic cutting for slicing frozen fish [144], regular raw fresh fish is too soft, which cannot promise cutting quality and efficiency. Laser cutting will have heat-affected zones, which reduces the shelf life and quality of the fish meat. As potential directions for future research, ultrasonic cutting and laser cutting techniques can be adapted into fish cutting. Other novel direct-contact and non-contact cutting techniques can also be developed for fish-cutting innovations.

- (4)

- Fully automated cutting production lines and integrated control systems should be designed by advancing singulation, machine vision, and AI technologies. Current automation cutting machines need manual singulation and placement processes for fish supply. Novel singulation methods can help realize fully automated systems to further reduce the total cutting and processing time, labor, and turnover. Considering the uniqueness and characteristic of each fish, the machine vision system in fish cutting lines could still be improved in both hardware and software aspects. As for the hardware system, the machine vision system should be able to capture the depth information. Therefore, the 3D sensing system, such as a laser profilometer or stereo cameras, could provide more comprehensive detail to guide the fish-cutting process. Meanwhile, due to the high computation requirement of 3D information, the data processing efficiency should be improved to satisfy the high-speed requirement of fish cutting lines. As for software development, first, key-point detection is widely used in machine vision applications and has made great progress in the past few years, where it can be applied to detect critical points in fish [145], such as gill [13] and mouth [146,147]. If the key points on the fish can be correctly located, this can facilitate the machine to cut the fish more accurately. Second, training DL models with large parameters is another major trend in machine vision and AI for visual pattern recognition tasks. Many studies have demonstrated that DL models better learn the representations of images. Therefore, visual transformer [148] and self-supervised learning [149,150] are two other techniques that can be used to extract meaning information from fish images. A better image feature extractor helps the system to analyze fish images and optimize fish-cutting operations.

- (5)

- More research and simulation development should be devoted to quantifying and predicting fish cutting quality and efficiency. Especially for waterjet cutting, the scientific reports only define the cutting quality and efficiency for metals, woods, composite materials, and other food species. Except for the cutting grade definition, there is no specified parameter quantifying fish cutting quality and efficiency. Some parameters, such as surface roughness, need to be further investigated and adapted to evaluate the fish-cutting quality. As for simulation development, current simulation models for cutting processes and quality are mainly based on regression analysis, response surface methodology (RSM), computational fluid dynamics (CFD), and finite element method (FEM) [151,152,153,154]. Since the waterjet cutting method has great potential for fish cutting, future fish cutting simulation and theory development should pay more attention to pure and abrasive waterjet cutting processes of whole fish and fish fillets with higher accuracy and robustness.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bjørndal, T.; Brasão, A.; Ramos, J.; Tusvik, A. Fish processing in Portugal: An industry in expansion. Mar. Policy 2016, 72, 94–106. [Google Scholar] [CrossRef] [Green Version]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [Green Version]

- Jeebhay, M.F.; Robins, T.G.; Lopata, A.L. World at work: Fish processing workers. Occup. Environ. Med. 2004, 61, 471–474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- FAO. The State of World Fisheries and Aquaculture 2022; Towards Blue Transformation; FAO: Rome, Italy, 2022. [Google Scholar]

- Adeyeye, S.A.O. Traditional fish processing in Nigeria: A critical review. Nutr. Food Sci. 2016, 46, 321–335. [Google Scholar] [CrossRef]

- Aldás Guerrero, R.F. Diseño de un Negocio Dedicado a la Exportación de Filete de Tilapia en Camas Frías al Mercado Canadiense Período 2014–2018. Bachelor’s Thesis, UIDE, Quito, The Republic of Ecuador, 2013. [Google Scholar]

- Buljo, J.; Gjerstad, T. Robotics and automation in seafood processing. In Robotics and Automation in the Food Industry; Woodhead Publishing: Sawston, UK, 2013; pp. 354–384. [Google Scholar]

- Einarsdóttir, H.; Guðmundsson, B.; Ómarsson, V. Automation in the fish industry. Anim. Front. 2022, 12, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Nagaishi, H.; Inada, T.; Yoshioka, T.; Sato, A. Development of a compact, onboard slurry icemaker to rapidly produce optimal ice for maintaining freshness of marine products. Synth. Engl. Ed. 2017, 10, 1–10. [Google Scholar]

- Thordarson, G.; Karlsdottir, M.; Pedersen, R.; Johannsson, M.; Hognason, A. Sub-Chilling of Salmon; Ísafjordur: Matis, France, 2015. [Google Scholar]

- Tsukagoshi, T.; Uchita, T. Toyo Suisan Kikai Co Ltd, 2019. Method for Removing Guts of Fish Body and Device for Same. U.S. Patent 10,470,472, 12 November.

- Shirai, K.; Ramirez-Ramirez, J.C. Utilization of Fish Processing By-products for Bioactive Compounds. In Fish Processing: Sustainability and New Opportunities; Wiley-Blackwell: Hoboken, NJ, USA, 2010; pp. 236–265. [Google Scholar] [CrossRef]

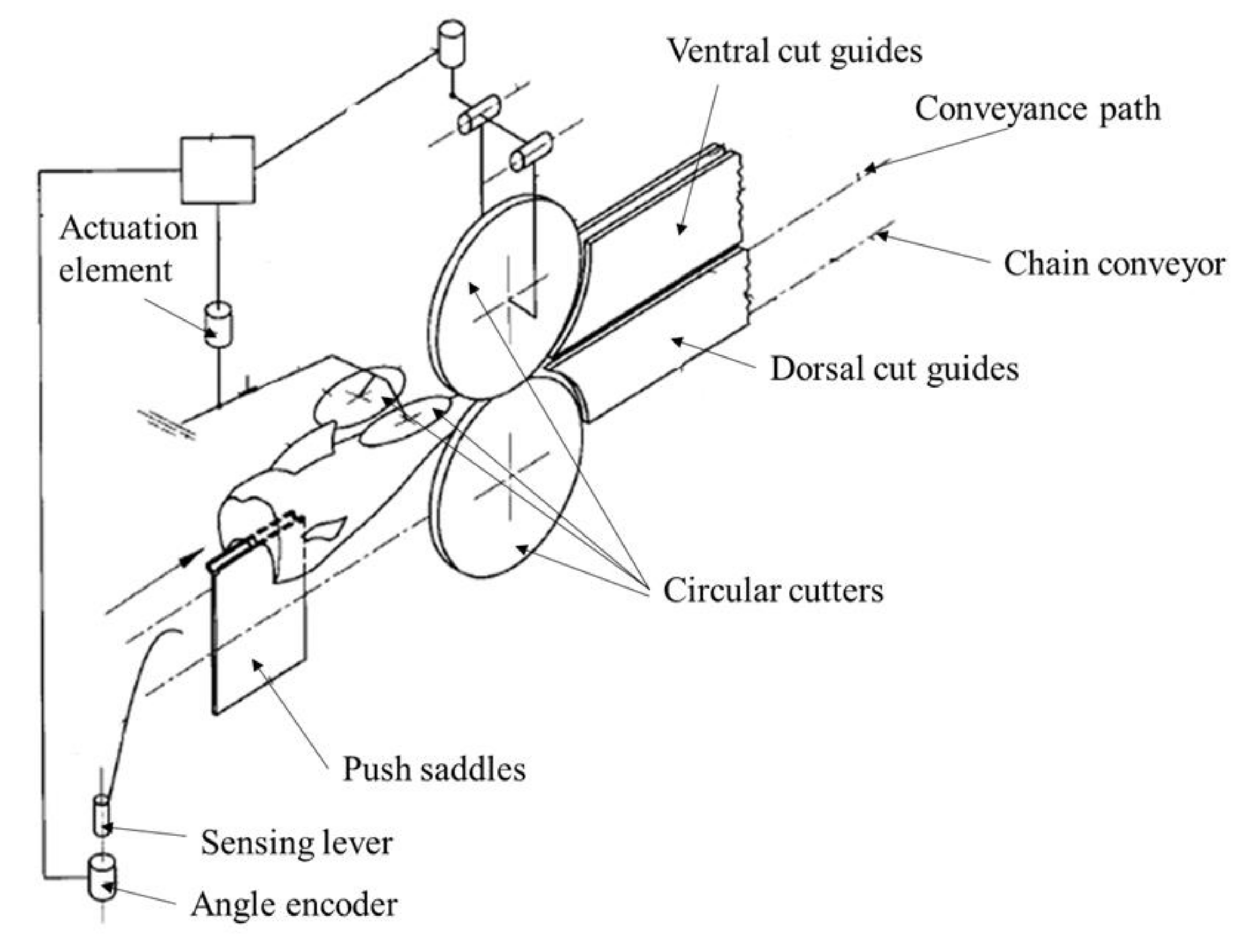

- de Silva, C.; Wickramarachchi, N. An innovative machine for automated cutting of fish. IEEE/ASME Trans. Mechatron. 1997, 2, 86–98. [Google Scholar] [CrossRef]

- Lang, H.; Wang, Y.; de Silva, C.W. An automated industrial fish cutting machine: Control, fault diagnosis and remote monitoring. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2018; IEEE: Piscataway, NJ, USA, 2008; pp. 775–780. [Google Scholar]

- Ageev, O.V.; Dowgiałło, A.; Sterczyńska, M.; Piepiórka-Stepuk, J.; Giurgiulescu, L.; Janowicz, M.; Jakubowski, M. Experimental characterization and theoretical modeling of fracture and friction resistance forces during tuna cutting. J. Food Eng. 2021, 307, 110648. [Google Scholar] [CrossRef]

- Ashwinkumar, N.; Bhuvaneshkumar, S.; Adithya, K. Development and Study of Universal Fish Cutting Apparatus. Int. J. Res. Eng. Sci. Manag. 2021, 4, 306–308. [Google Scholar]

- Kamaruzzaman, K.A.; Mahfurdz, A.; Hashim, M.; Bidin, M.N. Design and Performance Evaluation of Semi-Automatic Fish Cutting Machine for Industry. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 864, p. 012112. [Google Scholar]

- Dowlati, M.; de la Guardia, M.; Mohtasebi, S.S. Application of machine-vision techniques to fish-quality assessment. TrAC Trends Anal. Chem. 2012, 40, 168–179. [Google Scholar] [CrossRef]

- Gamage, L.B.; De Silva, C.W.; Gosine, R.G. Statistical pattern recognition for cutter positioning in automated fish processing. In Proceedings of the IEEE Pacific Rim Conference on Communications Computers and Signal Processing, Victoria, BC, Canada, 19–21 May 1993; IEEE: Piscataway, NJ, USA, 1993; Volume 2, pp. 786–789. [Google Scholar]

- Arvanitoyannis, I.S.; Kassaveti, A. Fish industry waste: Treatments, environmental impacts, current and potential uses. Int. J. Food Sci. Technol. 2008, 43, 726–745. [Google Scholar] [CrossRef]

- Goossens, Y.; Schmidt, T.G.; Kuntscher, M. Evaluation of Food Waste Prevention Measures—The Use of Fish Products in the Food Service Sector. Sustainability 2020, 12, 6613. [Google Scholar] [CrossRef]

- Jain, A.; De Silva, C.W.; Wu, Q.M.J. Intelligent fusion of sensor data for product quality assessment in a fish cutting machine. In Proceedings of the Joint 9th IFSA World Congress and 20th NAFIPS International Conference (Cat. No. 01TH8569), Vancouver, BC, Canada, 5–28 July 2001; IEEE: Piscataway, NJ, USA, 2001; Volume 1, pp. 316–321. [Google Scholar]

- Atkins, A.; Xu, X. Slicing of soft flexible solids with industrial applications. Int. J. Mech. Sci. 2005, 47, 479–492. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Cai, Y. Research on Fish Slicing Method Based on Simulated Annealing Algorithm. Appl. Sci. 2021, 11, 6503. [Google Scholar] [CrossRef]

- A Saltykov, M.; I Tkachenko, T. Multidimensional Classification for Systematization of Fish Processing Equipment. IOP Conf. Series Earth Environ. Sci. 2021, 666, 022087. [Google Scholar] [CrossRef]

- Tomaszewska-Gras, J. Rapid quantitative determination of butter adulteration with palm oil using the DSC technique. Food Control 2016, 60, 629–635. [Google Scholar] [CrossRef]

- Franklínsdóttir, H. Application of Water Jet Cutting in Processing of Cod and Salmon Fillets. Master’s Thesis, University of Iceland, Reykjavik, Iceland, 2014. [Google Scholar]

- Schreuders, F.K.G.; Sagis, L.M.C.; Bodnár, I.; Boom, R.M.; van der Goot, A.J. Non-linear rheology reveals the importance of elasticity in meat and meat analogues. Sci. Rep. 2022, 12, 1334. [Google Scholar] [CrossRef]

- Bogue, R. Cutting robots: A review of technologies and applications. Ind. Robot. Int. J. Robot. Res. Appl. 2008, 35, 390–396. [Google Scholar] [CrossRef]

- Khodabandehloo, K. Achieving robotic meat cutting. Anim. Front. 2022, 12, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Carreño-Olejua, R.; Hofacker, W.C.; Hensel, O. High-Pressure Water-Jet Technology as a Method of Improving the Quality of Post-Harvest Processing. Food Bioprocess Technol. 2010, 3, 853–860. [Google Scholar] [CrossRef]

- Kasperowicz, M.B.; Chomka, G.P.; Bil, T. Determination of Supply Pressure during Cutting Fish Using High-Pressure Water Stream Taking into Account the Cutting Place and Diameter of the Water Nozzle. Int. J. Food Eng. 2019, 16. [Google Scholar] [CrossRef]

- McGeough, J. Cutting of Food Products by Ice-particles in a Water-jet. Procedia CIRP 2016, 42, 863–865. [Google Scholar] [CrossRef]

- Wang, J.; Shanmugam, D. Cutting meat with bone using an ultrahigh pressure abrasive waterjet. Meat Sci. 2009, 81, 671–677. [Google Scholar] [CrossRef] [PubMed]

- Pogrebnyak, A.; Pogrebnyak, V. Mechanism of the High Efficiency of the Cutting Frozen Food Products Using Water-Jet with Polymer Additions. Food Sci. Technol. 1567, 11, 73–78. [Google Scholar] [CrossRef]

- Hao, M.; Yu, H.; Li, D. The measurement of fish size by machine vision—A review. In Proceedings of the International Conference on Computer and Computing Technologies in Agriculture, Beijing, China, 27–30 September 2015; Springer: Cham, Switzerland, 2015; pp. 15–32. [Google Scholar]

- Diamond, K.M.; Avants, B.B.; Maga, A.M. Machine learning-based segmentation and landmarking of 2D fish images. In Integrative and Comparative Biology; Oxford University Press Inc.: Cary, NC, USA, 2021; Volume 61, pp. E1100–E1101. [Google Scholar]

- Xu, W.; Wang, J.; Deng, Y.; Li, J.; Yan, T.; Zhao, S.; Yang, X.; Xu, E.; Wang, W.; Liu, D. Advanced cutting techniques for solid food: Mechanisms, applications, modeling approaches, and future perspectives. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1568–1597. [Google Scholar] [CrossRef]

- Bland, J.M.; Bett-Garber, K.L.; Li, C.H.; Brashear, S.S.; Lea, J.M.; Bechtel, P.J. Comparison of sensory and instrumental methods for the analysis of texture of cooked individually quick frozen and fresh-frozen catfish fillets. Food Sci. Nutr. 2018, 6, 1692–1705. [Google Scholar] [CrossRef]

- Buckingham, R.; Graham, A.; Arnarson, H.; Snaeland, P.; Davey, P. Robotics for de-heading fish—A case study. Ind. Robot. Int. J. 2001, 28, 302–309. [Google Scholar] [CrossRef]

- Ketels, D. Apparatus for Positioning Fish for Heading. U.S. Patent 7,467,995, 23 December 2008. [Google Scholar]

- Sampels, S. The effects of processing technologies and preparation on the final quality of fish products. Trends Food Sci. Technol. 2015, 44, 131–146. [Google Scholar] [CrossRef]

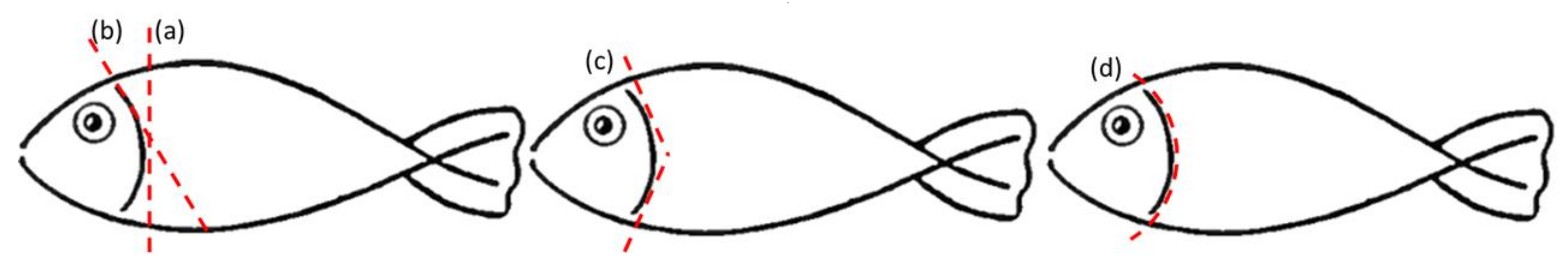

- Dowgiallo, A. The effect of cutting and fish-orientation systems on the deheading yield of carp. Int. J. Food Sci. Technol. 2008, 43, 1688–1692. [Google Scholar] [CrossRef]

- Tomczak-Wandzel, R.; Vik, E.A.; Wandzel, T. BAT in Fish Processing Industry: Nordic Perspective; Nordic Council of Ministers: Copenhagen, Denmark, 2015. [Google Scholar]

- Martín Rodríguez, F.; Barral Martínez, M. Automatic turbot fish cutting using machine vision. Instrum. Viewp. 2015, 18, 24–25. [Google Scholar]

- Sharapov, S. Compact Design of Fish Processing Equipment and Implementation of Lean Tools. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2013. [Google Scholar]

- Kaufman, D.; Fisher, R.A.; Wanchese Fish Company. Feasibility Study for Machine Processing Croakers into Fillets and for Forming the Fillets into Larger Portions. Fishery Resource Grant FRG 1999 - 24. Virginia Institute of Marine Science, William & Mary. Available online: https://scholarworks.wm.edu/reports/2216 (accessed on 7 September 2022).

- Wastell, T.T. Pisces Fish Machinery Inc. Fish Filleting Machine. U.S. Patent 11,140,907, 12 October 2021. [Google Scholar]

- Rora, A.M.B.; Mørkøre, T.; Einen, O. Primary processing (evisceration and filleting). In Farmed Fish Quality; Kestin, S.C., Warriss, P.D., Eds.; Blackwell Science: Oxford, UK, 2001; pp. 249–260. [Google Scholar]

- Braeger, H.; Scherch, R.P. Baader North America Corp. Process for Fileting Fish and Machine for Performing This Process. U.S. Patent 6,200,211, 13 March 2001. [Google Scholar]

- Jacobsen, P.H.; Jakobsen, B.K. Marel Salmon, A.S. Fish filleting machine. U.S. Patent 8,715,045, 6 May 2014. [Google Scholar]

- Jakobsen, B.; Jacobsen, P.H. Carnitech, A.S. Fish Filleting Machine. U.S. Patent 6,994,617, 7 February 2006. [Google Scholar]

- Kowalski, W. Nordischer Maschinenbau Rud Baader GmbH; Co, K.G. Method for Removing Blood Released during Filleting from the Backbone of Fish, and Device for Removing Such Blood. U.S. Patent 8,956,205, 17 February 2015. [Google Scholar]

- Kowalski, W. Nordischer Maschinenbau Rud Baader GmbH; Co, K.G. Method for Mechanically Removing Pin Bones from Fillet Parts of Conveyed Fish and Device for Performing Said Method. U.S. Patent 9,357,789, 7 June 2016. [Google Scholar]

- Jürs, M.; Schroeder, M. Nordischer Maschinenbau Rud Baader GmbH; Co, K.G. Apparatus and Method for Filleting Beheaded and Eviscerated Fish. U.S. Patent 8,814,637, 26 August 2014. [Google Scholar]

- Ryan, R.M. RYCO EQUIPMENT Inc. Fish Processing System and Method. U.S. Patent 8,512,106, 20 August 2013. [Google Scholar]

- Ryan, R.M. RYCO EQUIPMENT Inc. Fish Processing System and Method. U.S. Patent 8,834,238, 16 September 2014. [Google Scholar]

- Ryan, R.M. RYCO EQUIPMENT Inc. Fish Processing Systems and Methods. U.S. Patent 9,839,223, 12 December 2017. [Google Scholar]

- Sone, I.; Sveinsdóttir, H.I.; Stefánsson, G.; Larsson, K.; Undeland, I.; Skåra, T.; Romotowska, P.E.; Karlsdóttir, M.G. Investigating commercially relevant packaging solutions to improve storage stability of mechanically filleted Atlantic mackerel (Scomber scombrus) produced under industrial conditions. Eur. Food Res. Technol. 2020, 246, 693–701. [Google Scholar] [CrossRef] [Green Version]

- Sveinsdóttir, H.I.; Karlsdóttir, M.G.; Arason, S.; Stefánsson, G.; Sone, I.; Skåra, T.; Rustad, T.; Larsson, K.; Undeland, I.; Gudjónsdóttir, M. Effect of antioxidants on the sensory quality and physicochemical stability of Atlantic mackerel (Scomber scombrus) fillets during frozen storage. Food Chem. 2020, 321, 126744. [Google Scholar] [CrossRef] [PubMed]

- Da Mota, A.M. Optimização da Estratégia de Serviço Pós-Venda da Peruza. Ph.D. Thesis, Instituto Politecnico do Porto, Porto, Portugal, 2019. [Google Scholar]

- Thrane, M.; Nielsen, E.H.; Christensen, P. Cleaner production in Danish fish processing–experiences, status and possible future strategies. J. Clean. Prod. 2009, 17, 380–390. [Google Scholar] [CrossRef]

- Zieliński, B.; Kapłonek, W.; Nadolny, K. Regeneration of industrial cutting blades made from X39Cr13 steel used in skinning process of Pleuronectidae-family flatfishes. J. Mech. Energy Eng. 2018, 2, 277–284. [Google Scholar] [CrossRef] [Green Version]

- Schwarz, O. Nordischer Maschinenbau Rud Baader GmbH; Co, K.G. Conveying Apparatus Comprising a Conveying Path and Designed to Supply a Plurality of Products for Consumption Having Soft Parts to a Processing Device, and Processing Machine Comprising a Conveying Apparatus and a Processing Device. U.S. Patent 9,039,498, 26 May 2015. [Google Scholar]

- Schwarz, O. Nordischer Maschinenbau Rud Baader GmbH; Co, K.G. Device and Method for Removing a Surface Layer Including the Skin from Fish Fillets. U.S. Patent 9,872,507, 23 January 2018. [Google Scholar]

- Arnesen, J.A.; Gildberg, A. Extraction and characterisation of gelatine from Atlantic salmon (Salmo salar) skin. Bioresour. Technol. 2007, 98, 53–57. [Google Scholar] [CrossRef]

- Bland, J.M.; Grimm, C.C.; Bechtel, P.J.; Deb, U.; Dey, M.M. Proximate Composition and Nutritional Attributes of Ready-to-Cook Catfish Products. Foods 2021, 10, 2716. [Google Scholar] [CrossRef] [PubMed]

- Zieliński, B.; Kapłonek, W.; Sutowska, M.; Nadolny, K. Analysis of a Feasibility Study of a Precision Grinding Process for Industrial Blades Used in the Cutting of Soft Tissues by a Prototype 5-Axis CNC Grinding Machine. Appl. Sci. 2019, 9, 3883. [Google Scholar] [CrossRef] [Green Version]

- Joensen, S.; Olsen, J.V. Bløt Hyse. In Spalting av Hysefilet Etter Skinning; Fiskeriforskning: Tromsø, Norway, 27 August 2003. [Google Scholar]

- Arnþórsdóttir, M.G.; Arason, S.; Margeirsson, B. Combined Blast and Contact; Skýrsla Matís: Reykjavík, Iceland, 2008. [Google Scholar]

- Waterston, S.W.; Holmes, J.D. The Fish-Skinning Machine: An Unusual Source Of Hand Trauma. Plast. Reconstr. Surg. 2005, 116, 1831–1832. [Google Scholar] [CrossRef] [PubMed]

- Ørnholt-Johansson, G.; Gudjónsdóttir, M.; Nielsen, M.E.; Skytte, J.L.; Frosch, S. Analysis of the production of salmon fillet—Prediction of production yield. J. Food Eng. 2017, 204, 80–87. [Google Scholar] [CrossRef] [Green Version]

- Mathiassen, J.R.; Misimi, E.; Bondø, M.; Veliyulin, E.; Østvik, S.O. Trends in application of imaging technologies to inspection of fish and fish products. Trends Food Sci. Technol. 2011, 22, 257–275. [Google Scholar] [CrossRef]

- Grasselli, G. Industrial Slicer. U.S. Patent Application 14/283,670, 4 December 2014. [Google Scholar]

- Grasselli, G. Industrial Slicer. U.S. Patent 9,751,233, 5 September 2017. [Google Scholar]

- Ross, K.; Edwards, J. Spatial Variation in the Mercury Concentration of Muscle Myomeres in Steaks of Farmed Southern Bluefin Tuna. Foods 2015, 4, 254–262. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Surasani, V.K.R. Fish processing: An entrepreneurial opportunity for livelihood and income generation. J. Krishi Vigyan 2020, 9, 144–149. [Google Scholar] [CrossRef]

- Lorentzen, G.; Ageeva, T.N.; Heia, K. Desalting of dried salt-cured cod (Gadus morhua L.) without water renewal-3D imaging of volume change. Food Control 2021, 121, 107613. [Google Scholar] [CrossRef]

- Sture, Ø.; Øye, E.R.; Skavhaug, A.; Mathiassen, J.R. A 3D machine vision system for quality grading of Atlantic salmon. Comput. Electron. Agric. 2016, 123, 142–148. [Google Scholar] [CrossRef]

- Bro, T. Marel Salmon, A.S. D-Cut Slicer. U.S. Patent 9,180,601, 10 November 2015. [Google Scholar]

- Manchay Aparco, L.D. Evaluación de Conservas en Base a Productos Hidrobiológicos. Bachelor’s Thesis, César Vallejo University, Trujillo, Peru, 2020. [Google Scholar]

- Kapłonek, W.; Nadolny, K.; Zieliński, B.; Plichta, J.; Pimenov, D.Y.; Sharma, S. The Role of Observation–Measurement Methods in the Surface Characterization of X39Cr13 Stainless-Steel Cutting Blades Used in the Fish Processing Industry. Materials 2020, 13, 5796. [Google Scholar] [CrossRef]

- Faostat: Statistical Databases. Available online: http://faostat.fao.org/ (accessed on 23 December 2021).

- Karltun, J.; Vogel, K.; Bergstrand, M.; Eklund, J. Maintaining knife sharpness in industrial meat cutting: A matter of knife or meat cutter ability. Appl. Ergon. 2016, 56, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Viatcheslavovich, A.O.; Arkadievich, N.V.; Adgamovich, F.Y. Mathematical simulation of knife profile resistance force during fish cutting. Вестник Астраханскoгo Гoсударственнoгo Техническoгo Университета. Серия: Рыбнoе Хoзяйствo 2019, 3, 150–158. [Google Scholar]

- Ageev, O.V.; Fatykhov, Y.; Ivanova, E.E. Optimization of the knife profile for resource-saving primary fish processing. News of institutes of higher education. Food Technol. 2020, 1, 77–80. [Google Scholar]

- Ageev, O.; Naumov, V.A.; Fatykhov, J.A. Mathematical Modeling of the Resistance Force of the Profile of a Flat-Back Knife. J. Frict. Wear 2019, 40, 580–587. [Google Scholar] [CrossRef]

- Chu, J.P.; Diyatmika, W.; Tseng, Y.-J.; Liu, Y.-K.; Liao, W.-C.; Chang, S.-H.; Chen, M.-J.; Lee, J.-W.; Jang, J.S.C. Coating Cutting Blades with Thin-Film Metallic Glass to Enhance Sharpness. Sci. Rep. 2019, 9, 15558. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dowgiallo, A. Cutting force of fibrous materials. J. Food Eng. 2005, 66, 57–61. [Google Scholar] [CrossRef]

- Jayraj, P.; Machavaram, R.; Sahu, G.; Paradkar, V. Measurement of Morphometric Dimensions and Mechanical Properties of Rohu Fish for Design of Processing Machines. J. Aquat. Food Prod. Technol. 2019, 28, 150–164. [Google Scholar] [CrossRef]

- Jain, D.; Pathare, P.B.; Manikantan, M. Evaluation of texture parameters of Rohu fish (Labeo rohita) during iced storage. J. Food Eng. 2007, 81, 336–340. [Google Scholar] [CrossRef]

- Yamase, S.; Tsukagoshi, T.; Morita, K.; Takeuchi, K.; Obara, T.; Maloney, P.J. Toyo Suisan Kikai Co Ltd; Nippon Suisan, K.K.; UniSea Inc. Method of Separation of Backbone Part of Fish and Device Therefor. U.S. Patent 7,988,542, 2 August 2011. [Google Scholar]

- Vallamkondu, V.; Carlile, S.; Shakeel, M.; Ah-See, K.W. Neck abscess and vocal cord paresis: Delayed complications of a self-extruded long fishbone stuck in throat. BMJ Case Rep. 2013, 2013, bcr2013201832. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liang, Z.; Wen, G.; Yuan, X. Waterjet machining and research developments: A review. Int. J. Adv. Manuf. Technol. 2019, 102, 1257–1335. [Google Scholar] [CrossRef]

- Krajcarz, D. Comparison Metal Water Jet Cutting with Laser and Plasma Cutting. Procedia Eng. 2014, 69, 838–843. [Google Scholar] [CrossRef] [Green Version]

- Wulfkuehler, S.; Stark, S.; Dietz, J.; Schmidt, H.; Weiss, A.; Carle, R. Effect of Water Jet Cutting and Moderate Heat Treatment on Quality of Fresh-Cut Red Oak Leaf Lettuce (Lactuca sativa L. var. crispa). Food Bioprocess Technol. 2014, 7, 3478–3492. [Google Scholar] [CrossRef]

- Muthukumaran, S.; Baskaran, K. Organic and nutrient reduction in a fish processing facility—A case study. Int. Biodeterior. Biodegrad. 2013, 85, 563–570. [Google Scholar] [CrossRef]

- Hace, A.; Jezernik, K. Control system for the waterjet cutting Machine. IEEE/ASME Trans. Mechatron. 2004, 9, 627–635. [Google Scholar] [CrossRef]

- Huang, S.-W.; Chou, J.-H.; Tsai, J.-T. Uniform Design and Regression Analysis Methods for Optimal Operational Parameter Design of High-pressure Waterjet Machine. Int. J. Autom. Smart Technol. 2018, 8, 85–88. [Google Scholar] [CrossRef] [Green Version]

- Omar, F.K.; de Silva, C.W. Optimal portion control of natural objects with application in automated cannery processing of fish. J. Food Eng. 2000, 46, 31–41. [Google Scholar] [CrossRef]

- Thorarinsdottir, K.A. APRICOT-Automated Pinbone Removal in Cod and Whitefish; Nordic Innovation: Oslo, Norway, 2015. [Google Scholar]

- Barbut, S. Meat industry 4.0: A distant future? Anim. Front. 2020, 10, 38–47. [Google Scholar] [CrossRef] [PubMed]

- Barbut, S. Review: Automation and meat quality-global challenges. Meat Sci. 2014, 96, 335–345. [Google Scholar] [CrossRef]

- Folkes, J. Waterjet—An innovative tool for manufacturing. J. Mater. Process. Technol. 2009, 209, 6181–6189. [Google Scholar] [CrossRef]

- Irwansyah, I.; Ibrahim, M.; Ferdiansyah, H. Influence of water-jet nozzle geometry on cutting ability of soft material. J. Rekayasa Kim. Lingkung. 2012, 9, 6–11. [Google Scholar]

- Kasperowicz, M.; Chudy, J.; Chomka, G. Determining the supply pressure depending on the feed speed and the diameter of the nozzle. Carpathian J. Food Sci. Technol. 2018, 10, 17–23. [Google Scholar]

- Pogrebnyak, A.; Pogrebnyak, V.; Perkun, I.; Vasyliv, N. Influence of geometric and dynamic parameters of a water-polymer jet on characteristics of food products hydro-cutting process. Ukr. Food J. 2020, 9, 197–208. [Google Scholar] [CrossRef]

- Sandor, Z.; Papp, Z.G.; Csengeri, I.; Jeney, Z. Fish meat quality and safety. Sci. J. Meat Technol. 2011, 52, 97–105. [Google Scholar]

- Hyldig, G.; Nielsen, D. A review of sensory and instrumental methods used to evaluate the texture of fish muscle. J. Texture Stud. 2001, 32, 219–242. [Google Scholar] [CrossRef]

- Komlatsky, V.I.; Podoinitsyna, T.A.; Verkhoturov, V.V.; Kozub, Y.A. Automation technologies for fish processing and production of fish products. J. Phys. Conf. Ser. 2019, 1399, 044050. [Google Scholar] [CrossRef]

- Kong, F.; Tang, J.; Rasco, B.; Crapo, C.; Smiley, S. Quality Changes of Salmon (Oncorhynchus gorbuscha) Muscle during Thermal Processing. J. Food Sci. 2007, 72, S103–S111. [Google Scholar] [CrossRef]

- Mohd, R.M.S.; Amjad, R.; Rosely, K.; Norhaida, A.; Tanzila, S. FiLeDI framework for measuring fish length from digital images. Int. J. Phys. Sci. 2012, 7, 607–618. [Google Scholar]

- Sharmin, I.; Islam, N.F.; Jahan, I.; Joye, T.A.; Rahman, R.; Habib, T. Machine vision based local fish recognition. SN Appl. Sci. 2019, 1, 1529. [Google Scholar] [CrossRef] [Green Version]

- Storbeck, F.; Daan, B. Fish species recognition using computer vision and a neural network. Fish. Res. 2001, 51, 11–15. [Google Scholar] [CrossRef]

- Tveit, G.M.; Sistiaga, M.B.; Øye, E.R.; Schei, M. Kvalitetsvurdering av Fisk Fanget Med to-og Fire-Panels Seleksjonsinnretninger: Bidrar 4-Panelkonstruksjoner og Knuteløst lin til Økt Kvalitet? Tokt Ombord F/Tr Havtind 28.06. 16–11.07. 16; SINTEF: Trondheim, Norway, 2017. [Google Scholar]

- Azarmdel, H.; Mohtasebi, S.S.; Jafari, A.; Muñoz, A.R. Developing an orientation and cutting point determination algorithm for a trout fish processing system using machine vision. Comput. Electron. Agric. 2019, 162, 613–629. [Google Scholar] [CrossRef]

- Misimi, E.; Erikson, U.; Skavhaug, A. Quality Grading of Atlantic Salmon (Salmo salar) by Computer Vision. J. Food Sci. 2008, 73, E211–E217. [Google Scholar] [CrossRef]

- Sivertsen, A.H.; Chu, C.-K.; Wang, L.-C.; Godtliebsen, F.; Heia, K.; Nilsen, H. Ridge detection with application to automatic fish fillet inspection. J. Food Eng. 2009, 90, 317–324. [Google Scholar] [CrossRef] [Green Version]

- Andersen, K. Processing Quality Seafood. In International Seafood Trade: Challenges and Opportunities; FAO: Rome, Italy, 2009; pp. 93–96. [Google Scholar]

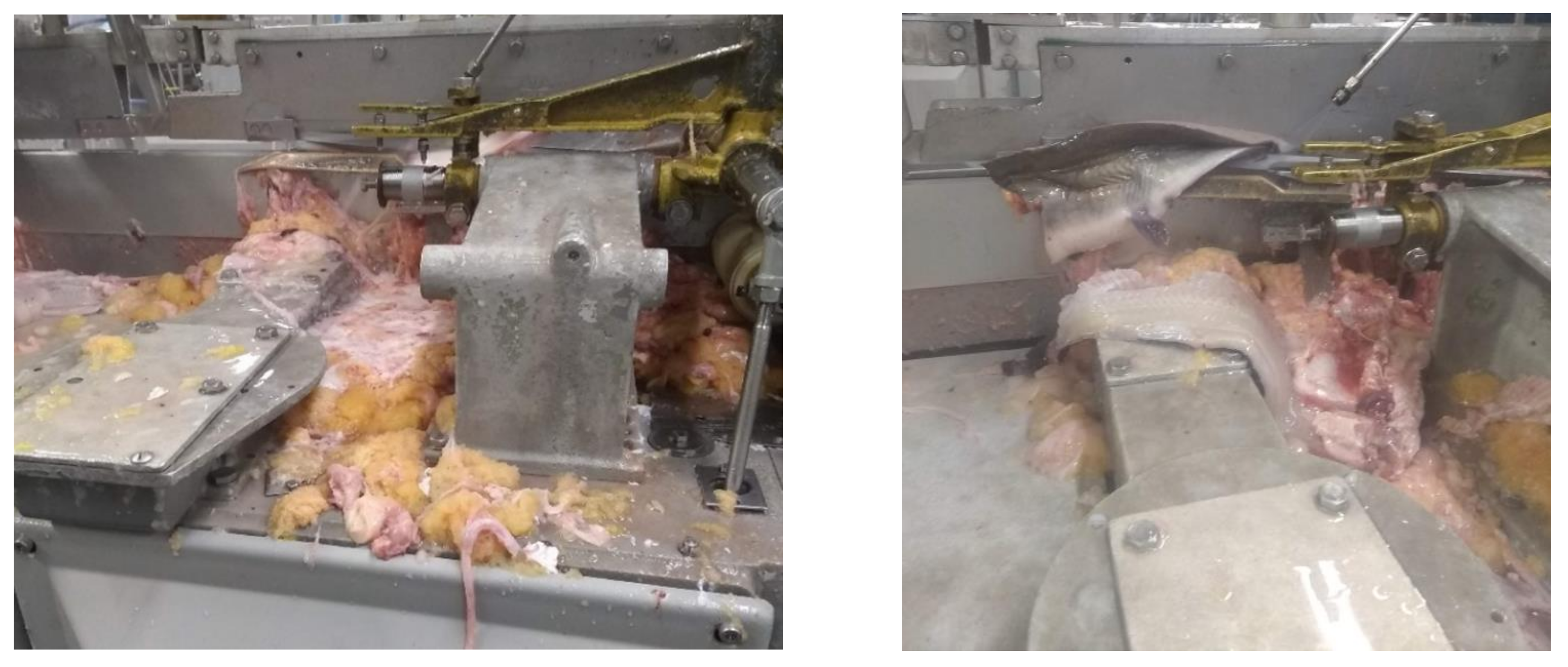

- Bar, E.; Mathiassen, J.R.; Eilertsen, A.; Mugaas, T.; Misimi, E.; Linnerud, S.; Salomonsen, C.; Westavik, H. Towards robotic post-trimming of salmon fillets. Ind. Robot. Int. J. Robot. Res. Appl. 2016, 43, 421–428. [Google Scholar] [CrossRef]

- Bondø, M.S.; Mathiassen, J.R.; Vebenstad, P.A.; Misimi, E.; Bar, E.M.S.; Toldnes, B.; Østvik, S.O. An automated salmonid slaughter line using machine vision. Ind. Robot. Int. J. Robot. Res. Appl. 2011, 38, 399–405. [Google Scholar] [CrossRef]

- Mathiassen, J.R.; Misimi, E.; Østvik, S.O.; Aursand, I.G. Computer vision in the fish industry. In Computer Vision Technology in the Food and Beverage Industries; Woodhead Publishing: Sawston, UK, 2012; pp. 352–378. [Google Scholar]

- Sun, M.; Yang, X.; Xie, Y. Deep learning in aquaculture: A review. J. Comput. 2020, 31, 294–319. [Google Scholar]

- Xu, J.-L.; Sun, D.-W. Identification of freezer burn on frozen salmon surface using hyperspectral imaging and computer vision combined with machine learning algorithm. Int. J. Refrig. 2017, 74, 151–164. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, S.; Liu, J.; Wang, H.; Zhu, J.; Li, D.; Zhao, R. Application of machine learning in intelligent fish aquaculture: A review. Aquaculture 2021, 540, 736724. [Google Scholar] [CrossRef]

- Odone, F.; Trucco, E.; Verri, A. A trainable system for grading fish from images. Appl. Artif. Intell. 2001, 15, 735–745. [Google Scholar] [CrossRef]

- Xu, J.; Sun, D.-W. Computer Vision Detection of Salmon Muscle Gaping Using Convolutional Neural Network Features. Food Anal. Methods 2017, 11, 34–47. [Google Scholar] [CrossRef]

- Taheri-Garavand, A.; Nasiri, A.; Banan, A.; Zhang, Y.-D. Smart deep learning-based approach for non-destructive freshness diagnosis of common carp fish. J. Food Eng. 2020, 278, 109930. [Google Scholar] [CrossRef]

- Laradji, I.; Saleh, A.; Rodriguez, P.; Nowrouzezahrai, D.; Azghadi, M.R.; Vazquez, D. Affinity lcfcn: Learning to segment fish with weak supervision. arXiv 2020, arXiv:2011.03149. [Google Scholar]

- Savkovic, B.; Kovac, P.; Rodic, D.; Strbac, B.; Klancnik, S. Comparison of artificial neural network, fuzzy logic and genetic algorithm for cutting temperature and surface roughness prediction during the face milling process. Adv. Prod. Eng. Manag. 2020, 15, 137–150. [Google Scholar] [CrossRef]

- Tanikić, D. Computationally intelligent optimization of metal cutting regimes. Measurement 2020, 152, 107358. [Google Scholar] [CrossRef]

- Choudhary, A.; Mian, T.; Fatima, S. Convolutional neural network based bearing fault diagnosis of rotating machine using thermal images. Measurement 2021, 176, 109196. [Google Scholar] [CrossRef]

- He, M.; He, D. Deep Learning Based Approach for Bearing Fault Diagnosis. IEEE Trans. Ind. Appl. 2017, 53, 3057–3065. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Guo, L.; Lin, J.; Xing, S. A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines. Neurocomputing 2018, 272, 619–628. [Google Scholar] [CrossRef]

- Abioye, A.O.; Prior, S.D.; Thomas, G.T.; Saddington, P.; Ramchurn, S.D. The multimodal speech and visual gesture (mSVG) control model for a practical patrol, search, and rescue aerobot. In Annual Conference Towards Autonomous Robotic Systems; Springer: Cham, Switzerland, 2018; pp. 423–437. [Google Scholar]

- Lin, J.; Holmes, M.; Vinson, R.; Ge, C.; Pogoda, F.C.; Mahon, L.; Gentry, R.; Seibel, G.E.; Chen, X.; Tao, Y. Design and testing of an automated high-throughput computer vision guided waterjet knife strawberry calyx removal machine. J. Food Eng. 2017, 211, 30–38. [Google Scholar] [CrossRef]

- Marani, M.; Zeinali, M.; Kouam, J.; Songmene, V.; Mechefske, C.K. Prediction of cutting tool wear during a turning process using artificial intelligence techniques. Int. J. Adv. Manuf. Technol. 2020, 111, 505–515. [Google Scholar] [CrossRef]

- National Marine Fisheries Service (2021) Fisheries of the United States, 2019. U.S. Department of Commerce, NOAA Current Fishery Statistics No. 2019. Available online: https://www.fisheries.noaa.gov/national/sustainable-fisheries/fisheries-united-states (accessed on 7 September 2022).

- USDA United States Department of Agriculture. Catfish Production Reports from National Agricultural Statistics Service (NASS); USDA: Washington, DC, USA, 2022. [Google Scholar]

- Tan, Y.; Gao, H.; Chang, S.K.; Bechtel, P.J.; Mahmoud, B.S. Comparative studies on the yield and characteristics of myofibrillar proteins from catfish heads and frames extracted by two methods for making surimi-like protein gel products. Food Chem. 2018, 272, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Hill, J.I.; Nelson, R.G.; Woods, K.L.; Weese, J.O.; Whitis, G.N. Consumer preferences for attributes of catfish nuggets: Price, breading color, cooking method, and country of origin. Aquac. Econ. Manag. 2013, 17, 123–147. [Google Scholar] [CrossRef]

- Ashrafi, N. Viscoelastic abrasive waterjet. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011; Volume 54891, pp. 677–681. [Google Scholar]

- Shakouri, E.; Abbasi, M. Investigation of cutting quality and surface roughness in abrasive water jet machining of bone. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2018, 232, 850–861. [Google Scholar] [CrossRef] [PubMed]

- Sonikel Ultrasonics. Frozen Fish Slicing with Ultrasonic. Available online: https://www.youtube.com/watch?v=nAe071BoMFY (accessed on 1 August 2022).

- Wang, N.; Gao, X.; Tao, D.; Yang, H.; Li, X. Facial feature point detection: A comprehensive survey. Neurocomputing 2018, 275, 50–65. [Google Scholar] [CrossRef] [Green Version]

- Kristensen, I.; Jorgensen, D.B.; Kroma, A.S. Fish Processing Machine and a Method for Processing Fish. U.S. Patent Application 15/030,078, 8 September 2016. [Google Scholar]

- Kristensen, I.; Jorgensen, D.B.; Kroma, A.S. Fish Processing Machine and a Method Enabling That Fish Can Be Processed through the Mouth. U.S. Patent 9,622,493, 18 April 2017. [Google Scholar]

- Dosovitskiy, A.; Beyer, L.; Kolesnikov, A.; Weissenborn, D.; Zhai, X.; Unterthiner, T.; Dehghani, M.; Minderer, M.; Heigold, G.; Gelly, S.; et al. An image is worth 16x16 words: Transformers for image recognition at scale. arXiv arXiv:2010.11929, 2020.

- Chen, T.; Kornblith, S.; Norouzi, M.; Hinton, G. A simple framework for contrastive learning of visual representations. In International Conference on Machine Learning. In Proceedings of the International Conference on Machine Learning, Vienna, Austria, 21 November 2020. [Google Scholar]

- He, K.; Fan, H.; Wu, Y.; Xie, S.; Girshick, R. Momentum contrast for unsupervised visual representation learning. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 13–19 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 9729–9738. [Google Scholar]

- Annoni, M.; Arleo, F.; Malmassari, C. CFD aided design and experimental validation of an innovative Air Assisted Pure Water Jet cutting system. J. Mater. Process. Technol. 2014, 214, 1647–1657. [Google Scholar] [CrossRef] [Green Version]

- Gzaiel, M.; Triki, E.; Barkaoui, A. Finite element modeling of the puncture-cutting response of soft material by a pointed blade. Mech. Mater. 2019, 136, 103082. [Google Scholar] [CrossRef]

- Hu, H.; Li, H.; Wang, Q.; He, J.; Lu, C.; Wang, Y.; Liu, P. Anti-blocking performance of ultrahigh-pressure waterjet assisted furrow opener for no-till seeder. Int. J. Agric. Biol. Eng. 2020, 13, 64–70. [Google Scholar] [CrossRef]

- Polyakov, A.; Zhabin, A.; Averin, E.; Polyakov, A. Generalized equation for calculating rock cutting efficiency by pulsed water jets. J. Rock Mech. Geotech. Eng. 2019, 11, 867–873. [Google Scholar] [CrossRef]

| Manufacturers | Cutting Operations | Fish Species | Product Advantages | Country | Reference |

|---|---|---|---|---|---|

| Arenco | Deheading, Filleting, Skinning | Pelagics |

| Sweden | [59,60] |

| BAADER | Deheading, Filleting, Portioning, Skinning, Trimming | Salmonids, Tuna, White fish, Pelagics, Aquaculture |

| Germany | [50,53,54,55,69,70] |

| Cabinplant | Skinning | Pelagics |

| Denmark | [7] |

| Cretel | Skinning | White fish, Pelagics, Aquaculture | Easy thickness control for silver, regular and deep skin. | Belgium | [71] |

| JBT | Portioning, Trimming | Salmonids, Tuna, White fish, Aquaculture | Computerized scanning of every piece coming into the machine, and sophisticated programming that controls waterjet portioners, horizontal slicers, 3D portioners, X-ray guided solutions, and systems with multiple cutting heads for portioning, slicing, stripping, and dicing. | USA | [73,122] |

| Kaj Olesen | Portioning, Skinning | Salmonids, White fish, Aquaculture |

| Denmark | [10] |

| Kroma | Deheading, Filleting | Salmonids, Pelagics, Aquaculture |

| Denmark | [146,147] |

| Marel | Deheading, Filleting, Portioning, Skinning, Trimming | Salmonids, Tuna, White fish, Aquaculture |

| Iceland | [27,51,80,101] |

| MARELEC Food Technologies | Portioning, Trimming | Salmonids, White fish |

| Belgium | [73,78,79] |

| Nikko | Deheading, Filleting, Portioning | Salmonids, White fish, Pelagics, Aquaculture |

| Japan | [9] |

| NOCK Maschinenbau | Skinning | Salmonids, White fish, Aquaculture | CBF and SB machine models are suitable for thin, pulling-off the skin, and deep skinning conditions. | Germany | [64,65] |

| PERUZA | Deheading, Filleting | Pelagics | Laser fish measurement system to realize the maximum yield. | Latvia | [46,61] |

| Pisces Fish Machinery | Deheading, Filleting | Salmonids, White fish, Pelagics, Aquaculture |

| USA | [47,48] |

| ROSOMA | Deheading, Portioning | Salmonids, White fish, Pelagics, Aquaculture |

| Germany | [25] |

| Ryco Equipment | Deheading, Filleting, Portioning | Salmonids, White fish, Aquaculture | Collar-on head cutting with maximum recovery to process fish from 1 to 50 pounds. | USA | [56,57,58] |

| Salmco | Portioning | Salmonids | The product range offers everything from simple hand slicers to semi- and fully automatic cold slicers and various fresh slicers with a variable 0° to 90° cutting angle. | Germany | [81] |

| SEAC AB | Deheading, Filleting | Pelagics |

| Sweden | [46] |

| Skaginn 3X | Skinning | White fish, Pelagics, Aquaculture | Skinning after SUB-CHILLING™ preserves the texture of the fillets for better quality and texture and lower yield loss. | Iceland | [70] |

| STEEN | Deheading, Skinning, Trimming | Salmonids, Tuna, White fish, Pelagics, Aquaculture | Skinning and de-frilling in two perfectly synchronized units. | Belgium | [82] |

| Tecnotrans UG | Portioning, Skinning | Salmonids, Tuna, White fish, Aquaculture | Both fresh and frozen goods can be processed to cut weight-accurate and uniform slices & cubes. | Germany | [6] |

| TOYO SUISAN KIKAI | Deheading, Filleting, Portioning, Skinning, Trimming | Salmonids, Tuna, White fish, Pelagics | Cover all the cutting steps and a wide range of fish species. | Japan | [11,92] |

| Uni-Food Technic | Deheading, Filleting, Portioning, Skinning | Salmonids, White fish, Pelagics |

| Denmark | N/A |

| VARLET | Portioning, Skinning | Salmonids, White fish |

| France | N/A |

| Velfag | Deheading, Filleting, Skinning | White fish |

| Iceland | [115] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Lyu, J.; Wu, D.; Cao, Y.; Ma, Q.; Lu, Y.; Zhang, X. Cutting Techniques in the Fish Industry: A Critical Review. Foods 2022, 11, 3206. https://doi.org/10.3390/foods11203206

Liu W, Lyu J, Wu D, Cao Y, Ma Q, Lu Y, Zhang X. Cutting Techniques in the Fish Industry: A Critical Review. Foods. 2022; 11(20):3206. https://doi.org/10.3390/foods11203206

Chicago/Turabian StyleLiu, Wenbo, Jiaqi Lyu, Di Wu, Yupeng Cao, Qingquan Ma, Yuzhen Lu, and Xin Zhang. 2022. "Cutting Techniques in the Fish Industry: A Critical Review" Foods 11, no. 20: 3206. https://doi.org/10.3390/foods11203206

APA StyleLiu, W., Lyu, J., Wu, D., Cao, Y., Ma, Q., Lu, Y., & Zhang, X. (2022). Cutting Techniques in the Fish Industry: A Critical Review. Foods, 11(20), 3206. https://doi.org/10.3390/foods11203206