Development of an Abalone 3D Food Printing Ink for the Personalized Senior-Friendly Foods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Abalone Powder

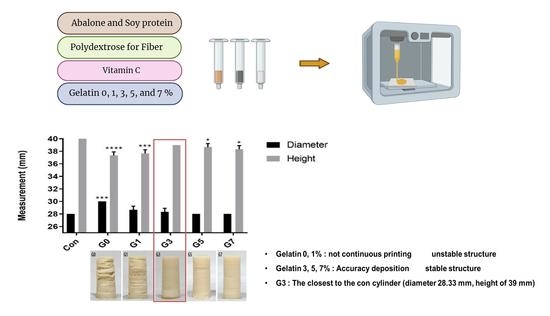

2.3. Preparation of the 3D Print Ink with Abalone (Abalone 3D Print Ink: API)

2.4. Texture Analysis

2.5. Water Holding Capacity (WHC)

2.6. Rheological Properties of API

2.7. 3D Printing Process

2.8. Scanning Electron Microscopy (SEM)

2.9. Statistical Analysis

3. Results

3.1. Texture Analysis

3.2. Water Holding Capacity

3.3. Rheological Properties of API

3.4. 3D Printing Process

3.5. Scanning Electron Microscopy (SEM)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, H.-S.; Nam, Y.-J. Policies and industrial technology trends for senior-friendly foods. Food Sci. Ind. 2020, 53, 435–443. [Google Scholar]

- Kim, D.-H.; Hwang, S.-J. Influence of the food intake ability and the number of remaining teeth on oral health related quality of life in some elderly people. J. Dent. Hyg. Sci. 2016, 16, 53–61. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Lee, Y. Senior-Friendly Food Market and Its Vitalization; Report Research R811; Korea Rural Economic Institute: Naju, Korea, 2018; pp. 1–321. [Google Scholar]

- Liu, Z.; Zhang, M. 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, T.J. Polymers for food applications: News. In Polymers for Food Applications; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–4. [Google Scholar]

- Prakash, S.; Bhandari, B.R. Future outlook of 3D food printing. In Fundamentals of 3D Food Printing and Applications; Academic Press: Cambridge, MA, USA, 2018; pp. 373–381. [Google Scholar]

- Tan, C.; Toh, W.Y. Extrusion-based 3D food printing—Materials and machines. Int. J. Bioprint. 2018, 4, 143. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Gudmundsson, M. Rheological properties of fish gelatins. J. Food Sci. 2002, 67, 2172–2176. [Google Scholar] [CrossRef]

- Burey, P.; Bhandari, B. Confectionery gels: A review on formulation, rheological and structural aspects. Int. J. Food Prop. 2009, 12, 176–210. [Google Scholar] [CrossRef] [Green Version]

- Graulus, G.-J.; Mignon, A. Cross-linkable alginate-graft-gelatin copolymers for tissue engineering applications. Eur. Polym. J. 2015, 72, 494–506. [Google Scholar] [CrossRef]

- Makino, M.; Fukuzawa, D. Simulation of 3D food printing extrusion and deposition. In Nanosensors, Biosensors, Info-Tech Sensors and 3D Systems 2017; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10167, p. 1016717. [Google Scholar]

- Alipal, J.; Pu’ad, N.M.; Lee, T.C.; Nayan, N.H.; Sahari, N.; Basri, H.; Idris, M.I.; Abdullah, H.Z. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today Proc. 2021, 42, 240–250. [Google Scholar] [CrossRef]

- Pang, Z.; Deeth, H. Rheology, texture and microstructure of gelatin gels with and without milk proteins. Food Hydrocoll. 2014, 35, 484–493. [Google Scholar] [CrossRef]

- Doh, H.; Lee, M.H. Effect of different cooking methods on the content and bioaccessibility of iodine components in abalone (Haliotis discus hannai). Food Chem. 2019, 301, 125197. [Google Scholar] [CrossRef] [PubMed]

- Wolfe, R.R.; Miller, S.L. Optimal protein intake in the elderly. Clin. Nutr. 2008, 27, 675–684. [Google Scholar] [CrossRef] [PubMed]

- Peter, A. Cook, Recent Trends in Worldwide Abalone Production. J. Shellfish Res. 2016, 35, 581–583. [Google Scholar]

- Shi, L.; Hao, G. Nutritional evaluation of Japanese abalone (Haliotis discus hannai Ino) muscle: Mineral content, amino acid profile and protein digestibility. Food Res. Int. 2020, 129, 108876. [Google Scholar] [CrossRef]

- Mahoney, E.; Holt, A.; Swain, M.; Kilpatrick, N. The hardness and modulus of elasticity of primary molar teeth: An ultra-micro-indentation study. J. Dent. 2000, 28, 589–594. [Google Scholar] [CrossRef]

- Te Nijenhuis, K. Investigation into the ageing process in gels of gelatin/water systems by the measurement of their dynamic moduli. Colloid Polym. Sci. 1981, 259, 522–535. [Google Scholar] [CrossRef]

- Normand, V.; Muller, S. Gelation kinetics of gelatin: A master curve and network modeling. Macromolecules 2000, 33, 1063–1071. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Lim, S.-T. Dynamic rheological properties of gelatin. Korean J. Food Sci. Technol. 2002, 34, 830–834. [Google Scholar]

- Almeida, P.F.; Lannes, S.C.D.S. Extraction and physicochemical characterization of gelatin from chicken by-product. J. Food Process Eng. 2013, 36, 824–833. [Google Scholar] [CrossRef]

- Supavititpatana, P.; Wirjantoro, T.I. Addition of gelatin enhanced gelation of corn–milk yogurt. Food Chem. 2008, 106, 211–216. [Google Scholar] [CrossRef]

- Le, H.; Ting, L. Gelling properties of myofibrillar protein from abalone (Haliotis Discus Hannai Ino) muscle. Int. J. Food Prop. 2018, 21, 277–288. [Google Scholar] [CrossRef] [Green Version]

- Mao, R.; Tang, J. Water holding capacity and microstructure of gellan gels. Carbohydr. Polym. 2001, 46, 365–371. [Google Scholar] [CrossRef]

- Jridi, M.; Abdelhedi, O. Improvement of the physicochemical, textural and sensory properties of meat sausage by edible cuttlefish gelatin addition. Food Biosci. 2015, 12, 67–72. [Google Scholar] [CrossRef]

- Carmona, J.; Ramírez, P. Large amplitude oscillatory shear of xanthan gum solutions. Effect of sodium chloride (NaCl) concentration. J. Food Eng. 2014, 126, 165–172. [Google Scholar] [CrossRef]

- Chen, H.; Xie, F. Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. J. Food Eng. 2019, 244, 150–158. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Zhang, M. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT 2018, 87, 67–76. [Google Scholar] [CrossRef] [Green Version]

- Aguilera, J.M. Why food microstructure? J. Food Eng. 2005, 67, 3–11. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Qin, H. An integrated manufacturing strategy to fabricate delivery system using gelatin/alginate hybrid hydrogels: 3D printing and freeze-drying. Food Hydrocoll. 2021, 111, 106262. [Google Scholar] [CrossRef]

- Skopinska-Wisniewska, J.; Tuszynska, M.; Olewnik-Kruszkowska, E. Comparative study of gelatin hydrogels modified by various cross-linking agents. Materials 2021, 14, 396. [Google Scholar] [CrossRef] [PubMed]

| Sample | Gelatin | Abalone | Isolated Soy Protein | Polydextrose | Vitamin C | Gellan Gum | Water |

|---|---|---|---|---|---|---|---|

| G0 | 0 | 10 | 4.5 | 2.5 | 0.01 | 1 | 82 |

| G1 | 1 | 81 | |||||

| G3 | 3 | 79 | |||||

| G5 | 5 | 77 | |||||

| G7 | 7 | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, H.-J.; Han, N.-R.; An, H.-W.; Jung, W.-K.; Kim, H.-W.; Lee, S.-G. Development of an Abalone 3D Food Printing Ink for the Personalized Senior-Friendly Foods. Foods 2022, 11, 3262. https://doi.org/10.3390/foods11203262

Yun H-J, Han N-R, An H-W, Jung W-K, Kim H-W, Lee S-G. Development of an Abalone 3D Food Printing Ink for the Personalized Senior-Friendly Foods. Foods. 2022; 11(20):3262. https://doi.org/10.3390/foods11203262

Chicago/Turabian StyleYun, Hyun-Jung, Na-Ra Han, Hyun-Woo An, Won-Kyo Jung, Hyun-Woo Kim, and Sang-Gil Lee. 2022. "Development of an Abalone 3D Food Printing Ink for the Personalized Senior-Friendly Foods" Foods 11, no. 20: 3262. https://doi.org/10.3390/foods11203262

APA StyleYun, H.-J., Han, N.-R., An, H.-W., Jung, W.-K., Kim, H.-W., & Lee, S.-G. (2022). Development of an Abalone 3D Food Printing Ink for the Personalized Senior-Friendly Foods. Foods, 11(20), 3262. https://doi.org/10.3390/foods11203262