Processing Technology and Quality Change during Storage of Fish Sausages with Textured Soy Protein

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Materials

2.2. Preparation of Fish Sausage

2.3. Single-Factor Experiment

2.4. Orthogonal Experimental Design

2.5. Gel Strength Measurement

2.6. Sensory Evaluation

2.7. Determination of Quality Changes during Frozen Storage

2.7.1. Water-Holding Capacity

2.7.2. Whiteness

2.7.3. Cooking Loss and Thermal Loss

2.8. Evaluation of Texture Properties

2.9. Evaluation of TBARS Value and TVB-N Value

2.9.1. TBARS Value

2.9.2. TVB-N Value

2.10. Statistical Analysis

3. Results and Discussion

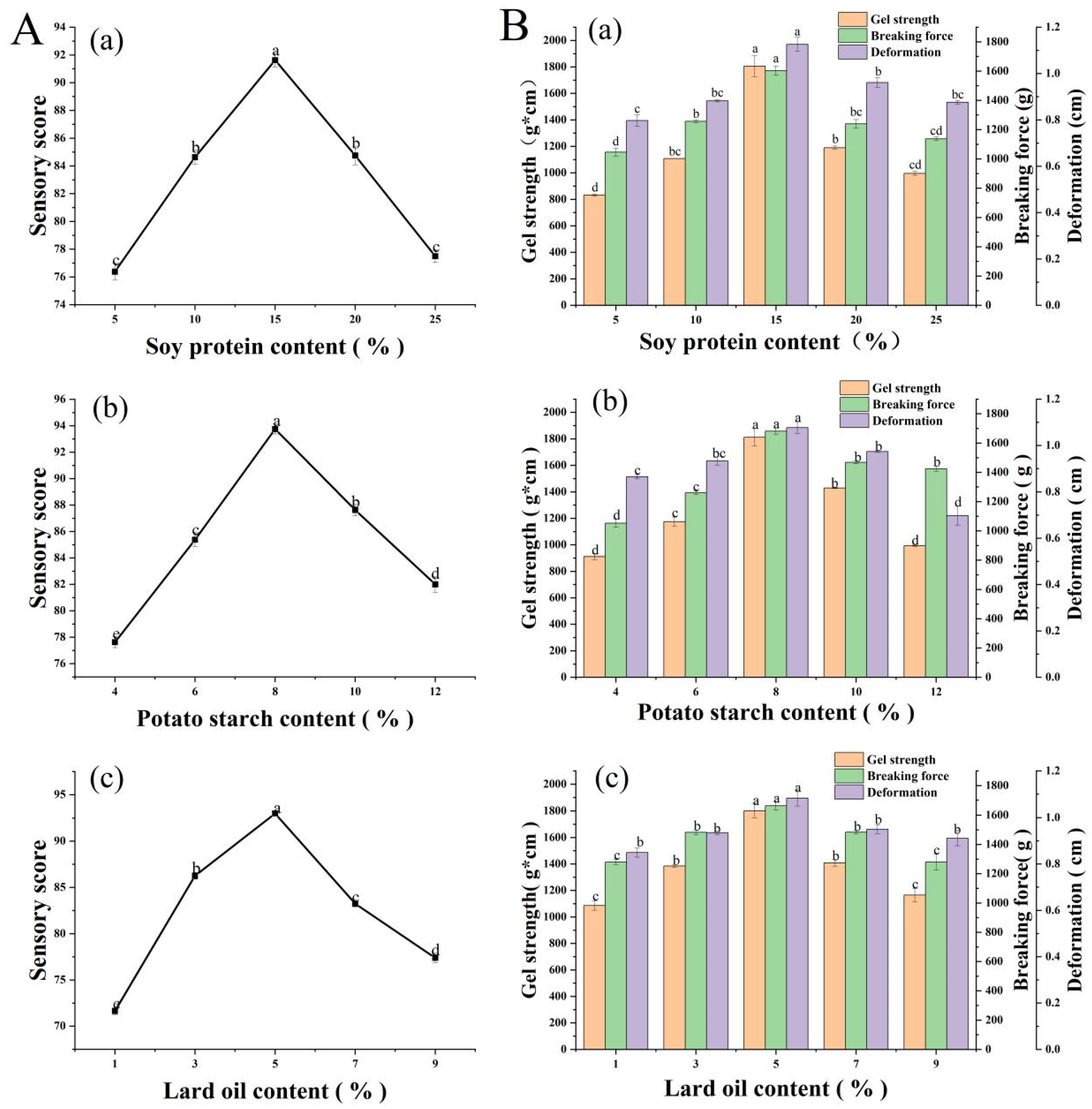

3.1. Results of Single-Factor Experiments

3.1.1. Effect of TSP Mixture Addition on Gel Strength of Fish Sausages

3.1.2. Effect of Potato Starch Addition on Gel Strength of Fish Sausage

3.1.3. Effect of Lard Oil Addition on Gel Strength of Fish Sausages

3.2. Analysis of Orthogonal Experiment Results

3.3. Fish Sausage Quality Changes during Frozen Storage

3.3.1. Water-Holding Capacity

3.3.2. Whiteness

3.3.3. Cooking Loss and Thawing Loss

3.4. Changes in the Texture Properties of Fish Sausage during Frozen Storage

3.5. Changes in Gel Strength during Frozen Storage of Fish Sausage

3.6. Changes in TBARS Values and TVB-N Values of Fish Sausages during Storage

3.6.1. TBARS Value

3.6.2. TVB-N Value

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mittendorfer, B.; Klein, S.; Fontana, L. A word of caution against excessive protein intake. Nat. Rev. Endocrinol. 2020, 16, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Kong, W.J.; Zhang, T.; Feng, D.D.; Xue, Y.; Wang, Y.M.; Li, Z.J.; Yang, W.G.; Xue, C.H. Effects of modified starches on the gel properties of Alaska Pollock surimi subjected to different temperature treatments. Food Hydrocoll. 2016, 56, 20–28. [Google Scholar] [CrossRef]

- Muriel-Galet, V.; Lopez-Carballo, G.; Gavara, R.; Hernandez-Munoz, P. Antimicrobial effectiveness of lauroyl arginate incorporated into ethylene vinyl alcohol copolymers to extend the shelf-life of chicken stock and surimi sticks. Food Bioprocess Technol. 2015, 8, 208–217. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.N.; Leung, P. Unlocking the potential of aquatic foods in global food security and nutrition: A missing piece under the lens of seafood liking index. Glob. Food Secur. Agric. Policy Econ. Environ. 2022, 33, 100641. [Google Scholar] [CrossRef]

- Lin, D.Q.; Zhang, L.T.; Li, R.J.; Zheng, B.D.; Rea, M.C.; Miao, S. Effect of plant protein mixtures on the microstructure and rheological properties of myofibrillar protein gel derived from red sea bream (Pagrosomus major). Food Hydrocoll. 2019, 96, 537–545. [Google Scholar] [CrossRef]

- Bohrer, B.M. An investigation of the formulation and nutritional composition of modern meat analogue products. Food Sci. Hum. Wellness 2019, 8, 320–329. [Google Scholar] [CrossRef]

- Jovanovic, I.; Novic, G.; Jovanovi, M.; Vujacic, L. Characteristics of textured soy protein products as raw materials in the meat industry. IOP Conf. Ser. Earth Environ. Sci. 2019, 333, 012068. [Google Scholar] [CrossRef] [Green Version]

- Zheng, M.J.; Liu, X.; Chuai, P.J.; Jiang, Z.D.; Zhu, Y.B.; Zhang, B.; Ni, H.; Li, Q.B. Effects of crude fucoidan on physicochemical properties, antioxidation and bacteriostasis of surimi products. Food Control. 2021, 122, 107806. [Google Scholar] [CrossRef]

- Maningat, C.C.; Jeradechachai, T.; Buttshaw, M.R. Textured wheat and pea proteins for meat alternative applications. Cereal Chem. 2022, 99, 37–66. [Google Scholar] [CrossRef]

- Revilla, I.; Santos, S.; Hernandez-Jimenez, M.; Vivar-Quintana, A.M. The effects of the progressive replacement of meat with texturized pea protein in low-fat frankfurters made with olive oil. Foods 2022, 11, 923. [Google Scholar] [CrossRef]

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; de Graaf, C. Replacement of meat by meat substitutes. A survey on person- and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef] [PubMed]

- Lago, A.M.T.; Teixeira, J.T.; Olimpio, B.J.G.; Schiassi, M.; Pimenta, C.J.; Gomes, M.E.D. Shelf life determination of frozen fish sausage produced with fillet and minced fish derived from the Nile tilapia processing. J. Food Process. Preserv. 2019, 43, e13984. [Google Scholar] [CrossRef]

- Shuqi, Y. Effect of Drawing Soy Protein on the Quality Characteristic of Surimi. Master Thesis, Fujian Agriculture and Forestry University, Fujian, China, 2022. [Google Scholar]

- Siripatrawan, U.; Noipha, S. Active film from chitosan incorporating green tea extract for shelf life extension of pork sausages. Food Hydrocoll. 2012, 27, 102–108. [Google Scholar] [CrossRef]

- Jia, R.; Jiang, Q.Q.; Kanda, M.; Tokiwa, J.; Nakazawa, N.; Osako, K.; Okazaki, E. Effects of heating processes on changes in ice crystal formation, water holding capacity, and physical properties of surimi gels during frozen storage. Food Hydrocoll. 2019, 90, 254–265. [Google Scholar] [CrossRef]

- Liu, H.M.; Nie, Y.N.; Chen, H.X. Effect of different starches on colors and textural properties of surimi-starch gels. Int. J. Food Prop. 2014, 17, 1439–1448. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, W.; Wang, H.; Ye, Q. Effects of a highly resistant rice starch and pre-incubation temperatures on the physicochemical properties of surimi gel from grass carp (Ctenopharyn odon idellus). Food Chem. 2014, 145, 212–219. [Google Scholar] [CrossRef]

- Bagarinao, N.C.; Kaur, L.; Boland, M. Effects of ultrasound treatments on tenderness andin vitro protein digestibility of New Zealand abalone, Haliotis iris. Foods 2020, 9, 1122. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Sun, Q.X.; Pan, Y.M.; Wei, S.; Xia, Q.Y.; Liu, S.C.; Ji, H.W.; Deng, C.J.; Hao, J.M. Investigation on the correlation between changes in water and texture properties during the processing of surimi from golden pompano (Trachinotus ovatus). J. Food Sci. 2021, 86, 376–384. [Google Scholar] [CrossRef]

- Fan, W.J.; Chi, Y.L.; Zhang, S. The use of a tea polyphenol dip to extend the shelf life of silver carp (Hypophthalmicthys molitrix) during storage in ice. Food Chem. 2008, 108, 148–153. [Google Scholar] [CrossRef]

- Yi, S.M.; Huo, Y.; Qiao, C.P.; Wang, W.; Li, X.P. Synergistic gelation effects in surimi mixtures composed of Nemipterus virgatus and hypophthalmichtys molitrix. J. Food Sci. 2019, 84, 3634–3641. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhang, F.X.; Wang, X. Effects of hydrolyzed wheat gluten on the properties of high-temperature (≥100 °C) treated surimi gels. Food Hydrocoll. 2015, 45, 196–202. [Google Scholar] [CrossRef]

- Niu, H.; Xia, X.; Wang, C.; Kong, B.; Liu, Q. Thermal stability and gel quality of myofibrillar protein as affected by soy protein isolates subjected to an acidic pH and mild heating. Food Chem. 2018, 242, 188–195. [Google Scholar] [CrossRef] [PubMed]

- Pardi, M.C.; Santos, I.F.; Souza, E.R.; Pardi, H.S. Ciência, Higiene e Tecnologia da Carne; GEGRAF-Universidade Federal de Goiás: Goiânia, Brazil, 2001. [Google Scholar]

- Lempek, T.S.; Martins, V.G.; Prentice, C. Rheology of surimi-based products from fatty fish underutilized by the industry: Argentine Croaker (Umbrina canosai). J. Aquat. Food Prod. Technol. 2007, 16, 27–44. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Waili, H.; Guizani, N.; Kasapis, S. Instrumental-sensory evaluation of texture for fish sausage and its storage stability. Fish. Sci. 2007, 73, 1166–1176. [Google Scholar] [CrossRef]

- Guo, J.; Hu, L.; Yang, X.Q.; Yu, S.J.; Liu, Y.C.; Jin, Y.C. Influence of soy protein isolate prepared by phosphate-assisted Hydrothermal cooking on the gelation of myofibrillar protein. J. Am. Oil Chem. Soc. 2015, 92, 523–531. [Google Scholar] [CrossRef]

- Jia, R.; Hiraoka, Y.; Tung, Y.; Nakazawa, N.; Osako, K.; Okazaki, E. “Setting-Freezing-Reheating” procedure improves the gel properties of frozen starch-surimi gel. Food Sci. Technol. Res. 2018, 24, 999–1006. [Google Scholar] [CrossRef]

- Taskaya, L.; Chen, Y.C.; Jaczynski, J. Color improvement by titanium dioxide and its effect on gelation and texture of proteins recovered from whole fish using isoelectric solubilization/precipitation. LWT-Food Sci. Technol. 2010, 43, 401–408. [Google Scholar] [CrossRef]

- Luo, H.; Guo, C.; Lin, L.; Si, Y.; Gao, X.; Xu, D.; Jia, R.; Yang, W. Combined use of rheology, LF-NMR, and MRI for characterizing the gel properties of Hairtail surimi with potato starch. Food Bioprocess Technol. 2020, 13, 637–647. [Google Scholar] [CrossRef]

- Mao, L.C.; Wu, T. Gelling properties and lipid oxidation of kamaboko gels from grass carp (Ctenopharyngodon idellus) influenced by chitosan. J. Food Eng. 2007, 82, 128–134. [Google Scholar] [CrossRef]

- Gujral, H.S.; Kaur, A.; Singh, N.; Sodhi, N.S. Effect of liquid whole egg, fat and textured soy protein on the textural and cooking properties of raw and baked patties from goat meat. J. Food Eng. 2002, 53, 377–385. [Google Scholar] [CrossRef]

- Vieira, C.; Diaz, M.T.; Martinez, B.; Garcia-Cachan, M.D. Effect of frozen storage conditions (temperature and length of storage) on microbiological and sensory quality of rustic crossbred beef at different states of ageing. Meat Sci. 2009, 83, 398–404. [Google Scholar] [CrossRef] [PubMed]

- Walayat, N.; Xiong, H.G.; Xiong, Z.Y.; Moreno, H.M.; Nawaz, A.; Niaz, N.; Randhawa, M.A. Role of cryoprotectants in surimi and factors affecting surimi gel properties: A review. Food Rev. Int. 2022, 38, 1103–1122. [Google Scholar] [CrossRef]

- Surasani, V.K.R.; Varadaraju, R.C.; Singh, A. Biochemical, microbial, and textural quality changes in rohu protein isolates supplemented pangas mince sausages packed in LDPE and cellulose casing during frozen storage. J. Food Process. Preserv. 2021, 45, e15767. [Google Scholar] [CrossRef]

- Cao, H.J.; Zhong, S.Y.; Zhang, B.; Wei, W.Y.; Shen, C.L.; Ying, X.G. Sodium erythorbate, stable chlorine dioxide, and gellan gum glazing for shelf life extension of commercial peeled shrimp (Litopenaeus vannamei) during frozen storage. J. Food Process. Preserv. 2019, 43, e14108. [Google Scholar] [CrossRef]

- Cai, L.Y.; Li, X.P.; Wu, X.S.; Lv, Y.F.; Liu, X.F.; Li, J.R. Effect of chitosan coating enriched with ergothioneine on quality changes of Japanese sea bass (Lateolabrax japonicas). Food Bioprocess Technol. 2014, 7, 2281–2290. [Google Scholar] [CrossRef]

- Maheshwara, K.J.; Naik, J.; Balamatti, A.; Jagadish, T.D. Biochemical and shelf life study of quality of fish sausage in ambinet and refrigerated storage. Biochem. Cell Arch. 2017, 17, 265–270. [Google Scholar]

| Test Items | Score Standards | Sensory Score |

|---|---|---|

| Taste (25) | Gritty, foreign body sensation in chewing, poor taste, too salty or too bland. | 0~8 |

| Slightly gritty chewing, no foreign body sensation, moderate saltiness. | 9~17 | |

| Chewing without sandy feeling, no foreign body feeling, just right saltiness. | 18~25 | |

| Smell (25) | Bad smell. | 0~8 |

| Slight beany and fishy smell. | 9~17 | |

| Mixed fragrance. | 18~25 | |

| Color and lustre (25) | Dark color, yellow-gray, matt. | 0~8 |

| Medium bright color, yellow–white, slightly glossy. | 9~17 | |

| Brighter color, yellow–white, shiny. | 18~25 | |

| Texture (25) | The surface is normal smooth, the structure is loose with many holes, the TSP is not evenly mixed, and no elasticity. | 0~8 |

| The surface is smooth, the structure is loose with individual holes, the blending of the TSP is unevenly mixed, and the elasticity is poor. | 9~17 | |

| The surface is smooth, the structure is dense with no pores, the TSP is evenly mixed, and the elasticity is good. | 18~25 |

| Level | Factor | ||

|---|---|---|---|

| A (Textured Soy Protein Mixture)/% | B (Potato Starch)/% | C (Lard Oil)/% | |

| 1 | 10 | 6 | 3 |

| 2 | 15 | 8 | 5 |

| 3 | 20 | 10 | 7 |

| Number | A (Textured Soy Protein Mixture)/% | B (Potato Starch)/% | C (Lard Oil)/% | Null Columns | Gel Strength (g*cm) |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1789.86 |

| 2 | 1 | 2 | 2 | 2 | 1860.99 |

| 3 | 1 | 3 | 3 | 3 | 1811.49 |

| 4 | 2 | 1 | 2 | 3 | 1848.29 |

| 5 | 2 | 2 | 3 | 1 | 1892.37 |

| 6 | 2 | 3 | 1 | 2 | 1817.55 |

| 7 | 3 | 1 | 3 | 2 | 1691.65 |

| 8 | 3 | 2 | 1 | 3 | 1824.22 |

| 9 | 3 | 3 | 2 | 1 | 1741.92 |

| K1 | 5462.34 | 5329.80 | 5431.63 | ||

| K2 | 5558.21 | 5577.58 | 5451.20 | ||

| K3 | 5257.79 | 5370.96 | 5395.51 | ||

| The optimal level | A2 | B2 | C2 | ||

| R | 300.42 | 247.78 | 55.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, S.; Yang, S.; Li, L.; Zheng, B.; Zhang, Y.; Zeng, H. Processing Technology and Quality Change during Storage of Fish Sausages with Textured Soy Protein. Foods 2022, 11, 3546. https://doi.org/10.3390/foods11223546

You S, Yang S, Li L, Zheng B, Zhang Y, Zeng H. Processing Technology and Quality Change during Storage of Fish Sausages with Textured Soy Protein. Foods. 2022; 11(22):3546. https://doi.org/10.3390/foods11223546

Chicago/Turabian StyleYou, Shuyi, Shuqi Yang, Lanxin Li, Baodong Zheng, Yi Zhang, and Hongliang Zeng. 2022. "Processing Technology and Quality Change during Storage of Fish Sausages with Textured Soy Protein" Foods 11, no. 22: 3546. https://doi.org/10.3390/foods11223546

APA StyleYou, S., Yang, S., Li, L., Zheng, B., Zhang, Y., & Zeng, H. (2022). Processing Technology and Quality Change during Storage of Fish Sausages with Textured Soy Protein. Foods, 11(22), 3546. https://doi.org/10.3390/foods11223546