Non-Conventional Induction Heat Treatment: Effect of Design and Electrical Parameters on Apple Juice Safety and Quality

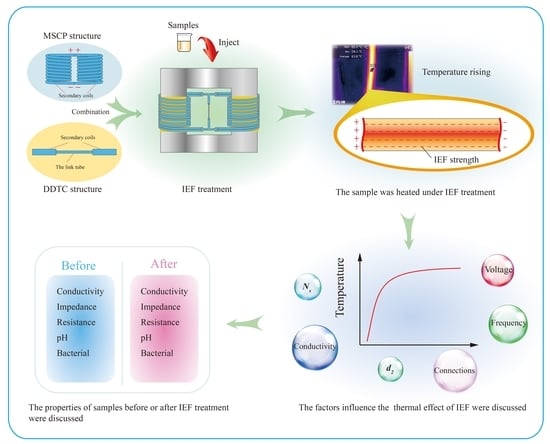

Abstract

:1. Introduction

2. Methods and Materials

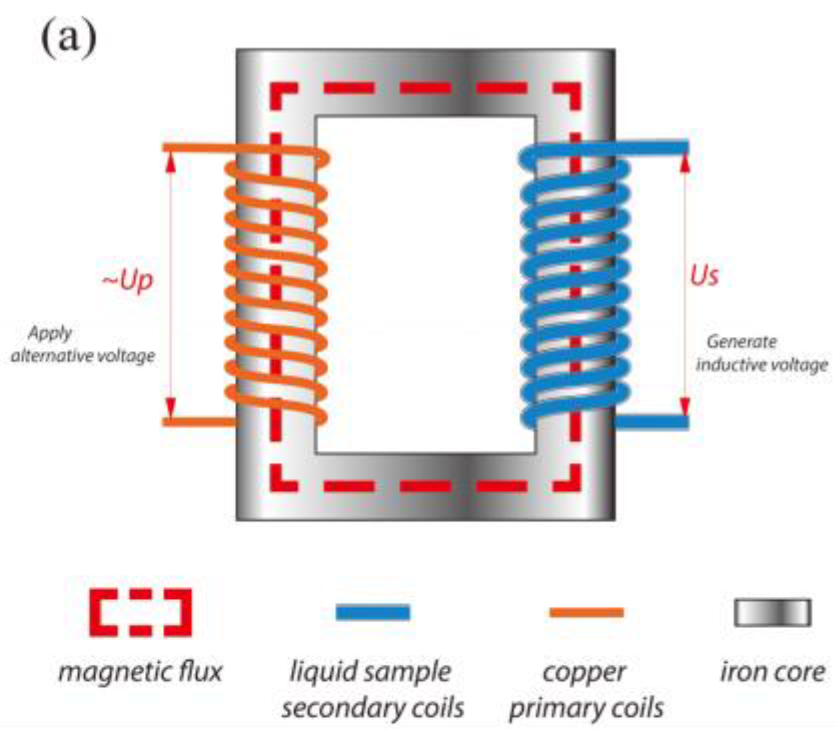

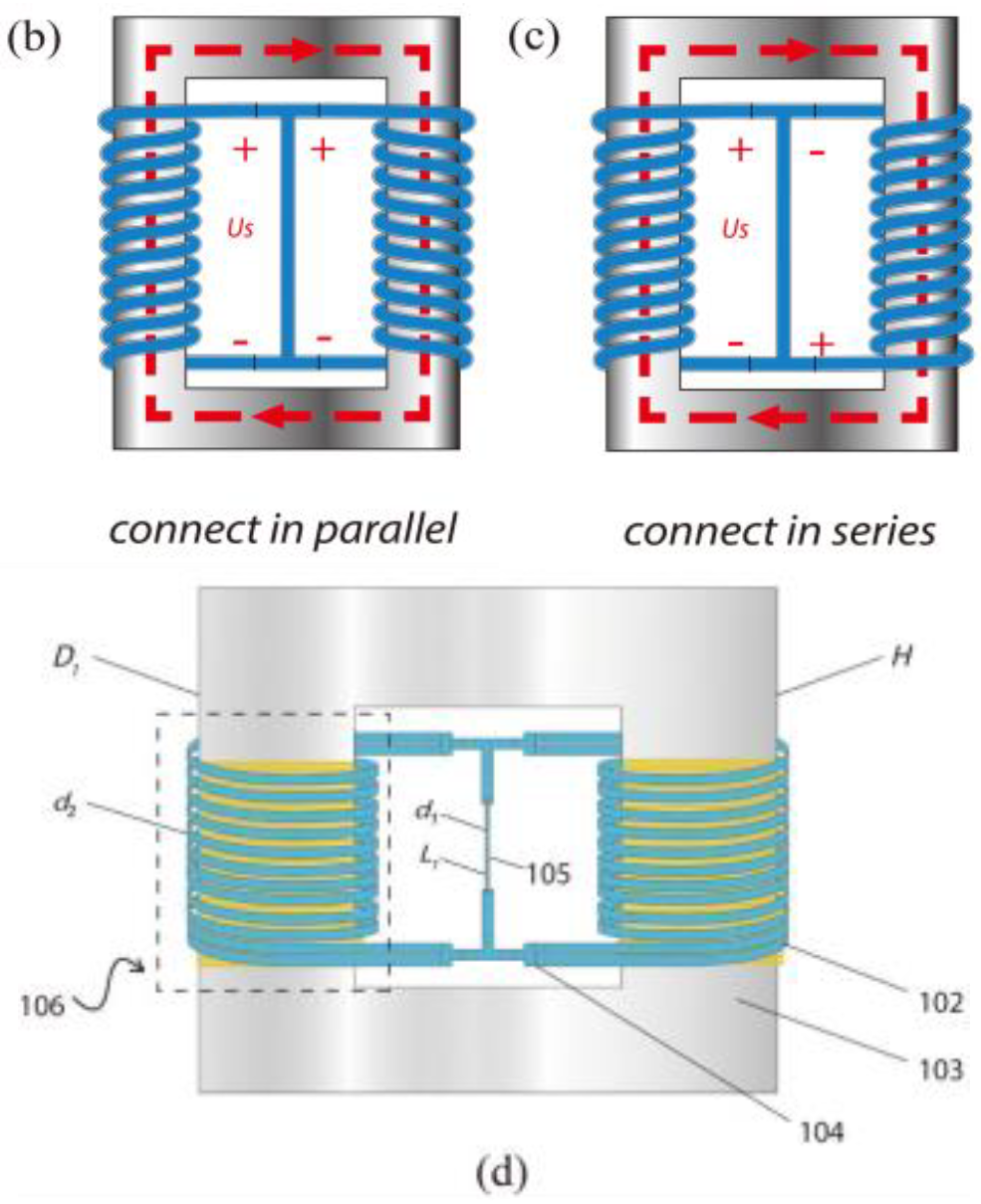

2.1. IEF Generator

2.2. Structures of MSCP and VDC

2.3. Operation Principle

2.4. Sample Preparation

2.5. Temperature Rise

2.6. Conductivity, pH, Brix, Impedance and Resistance

2.7. Microorganisms Counting

2.8. Statistical Analysis

3. Results and Discussions

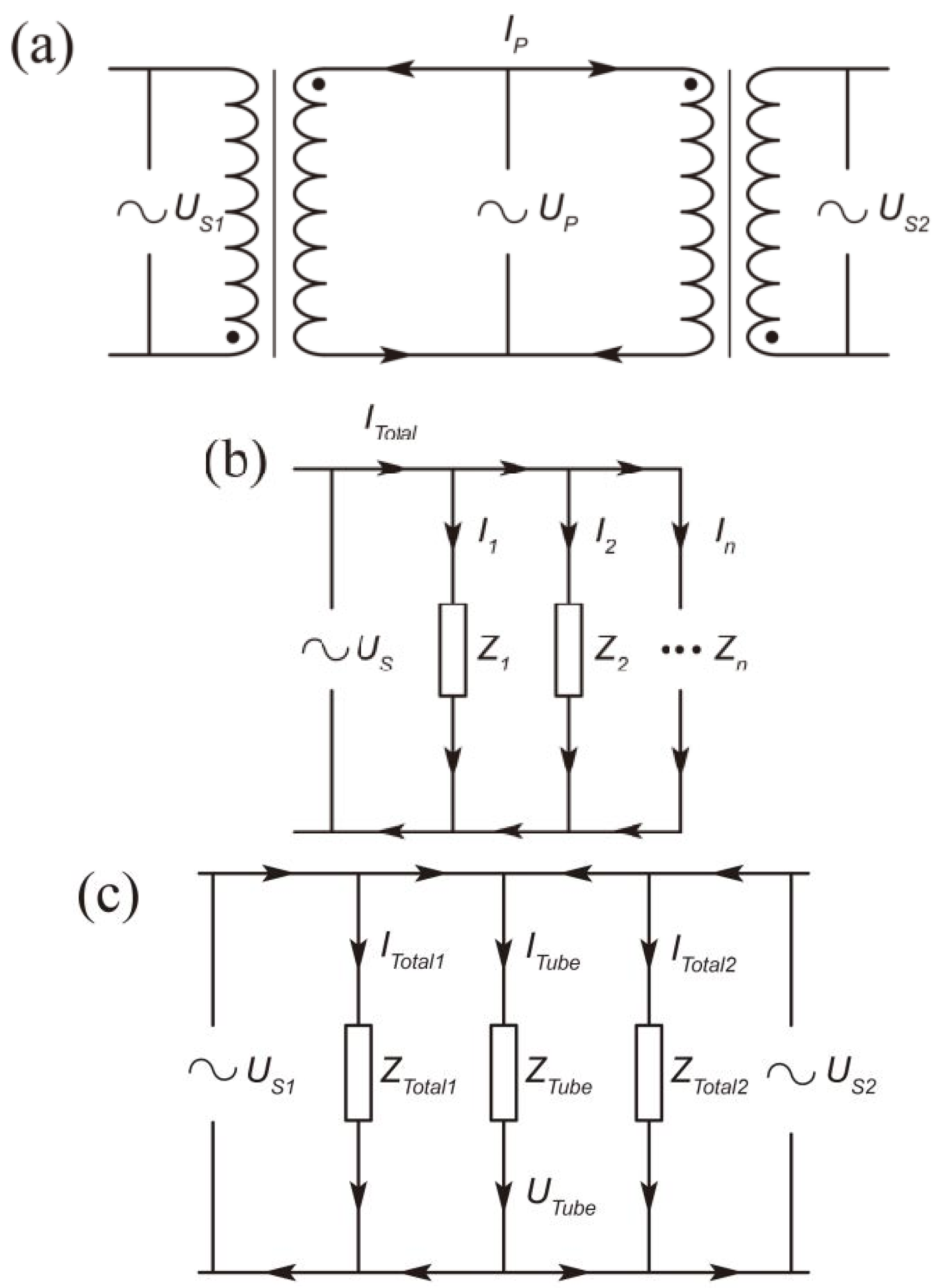

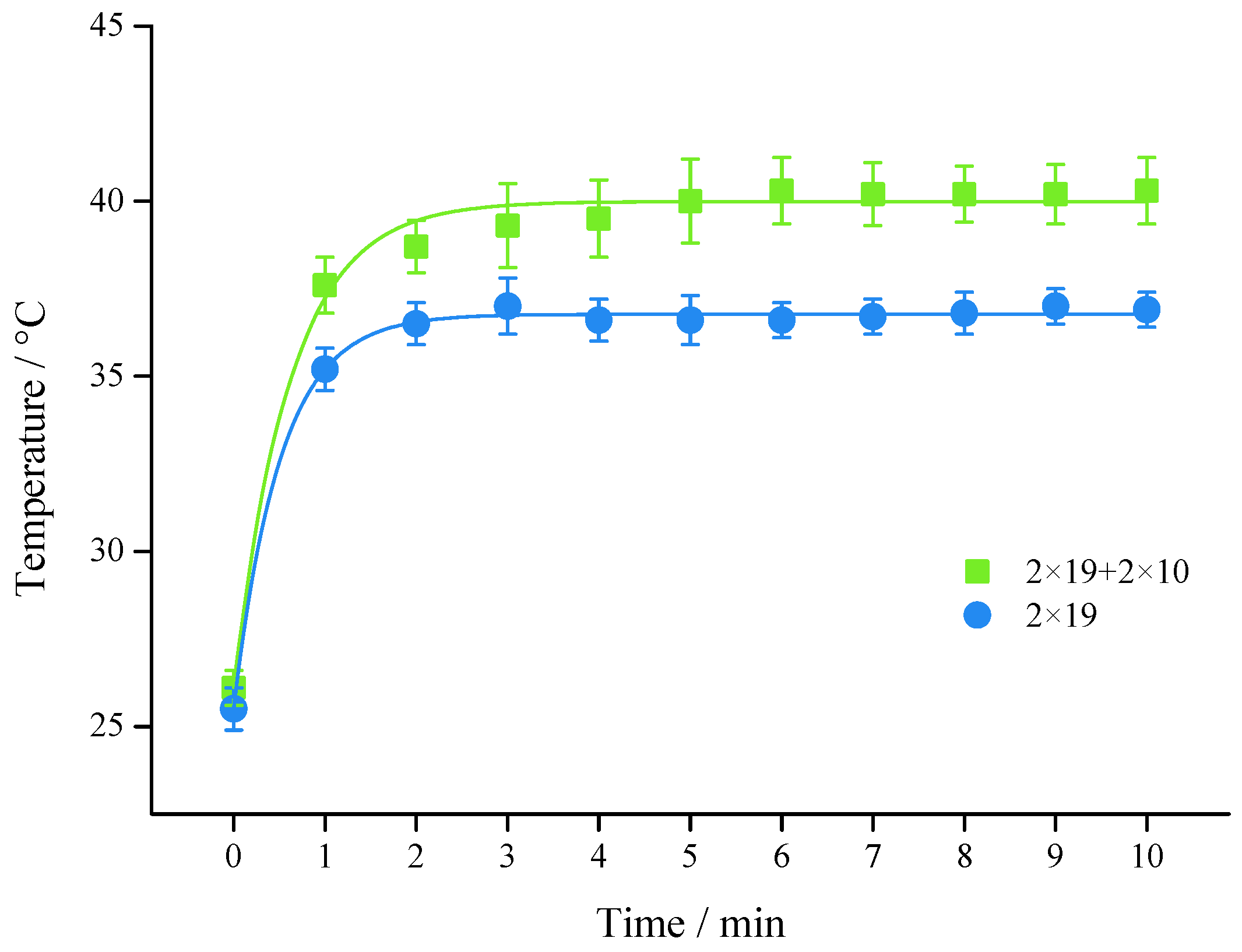

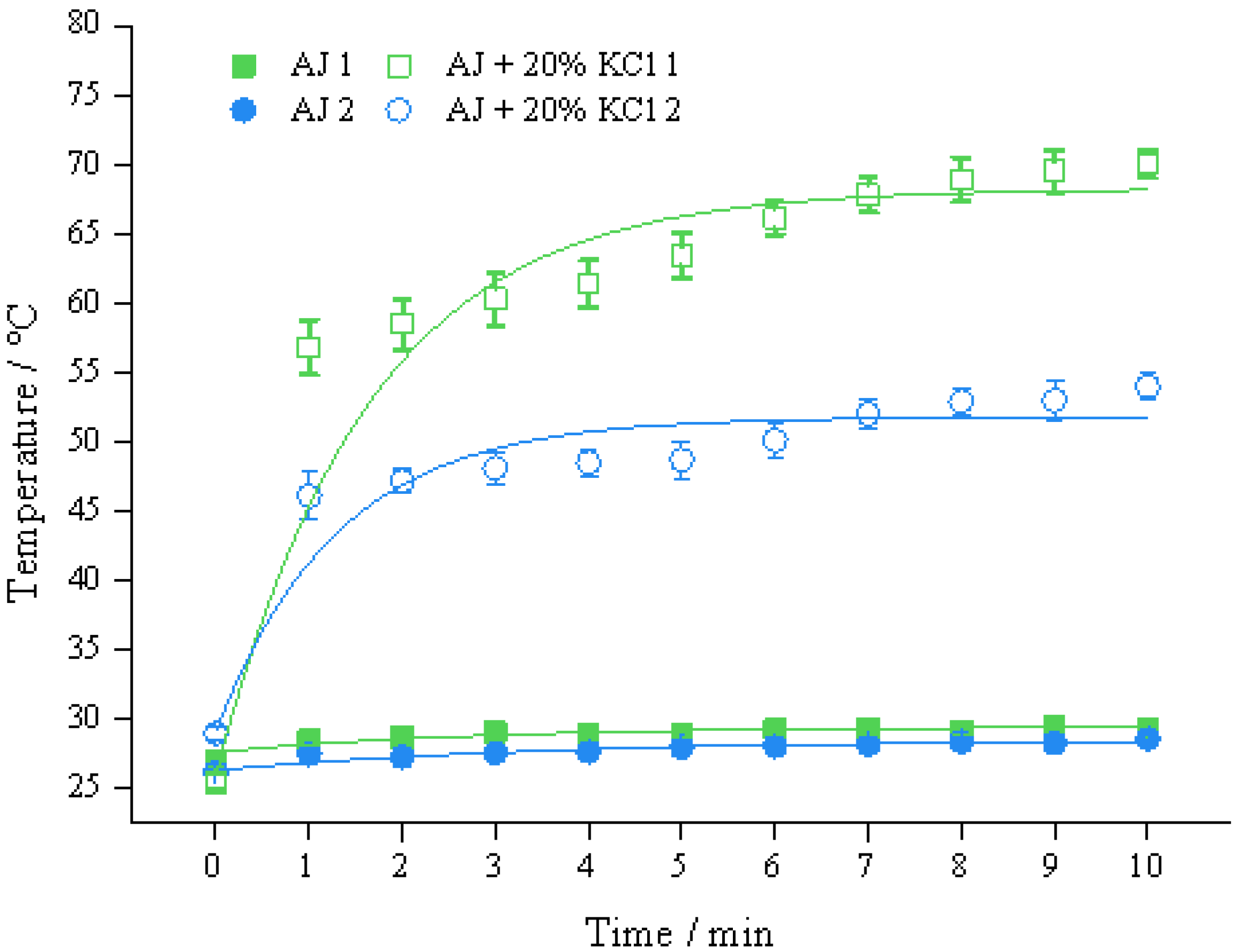

3.1. Different Connections and the Diameter of the Link Tube

3.2. Primary Voltage and Conductivity

3.3. Number of Parallel Secondary Coils (NS)

3.4. Number of Parallel Link Tubes (NTube)

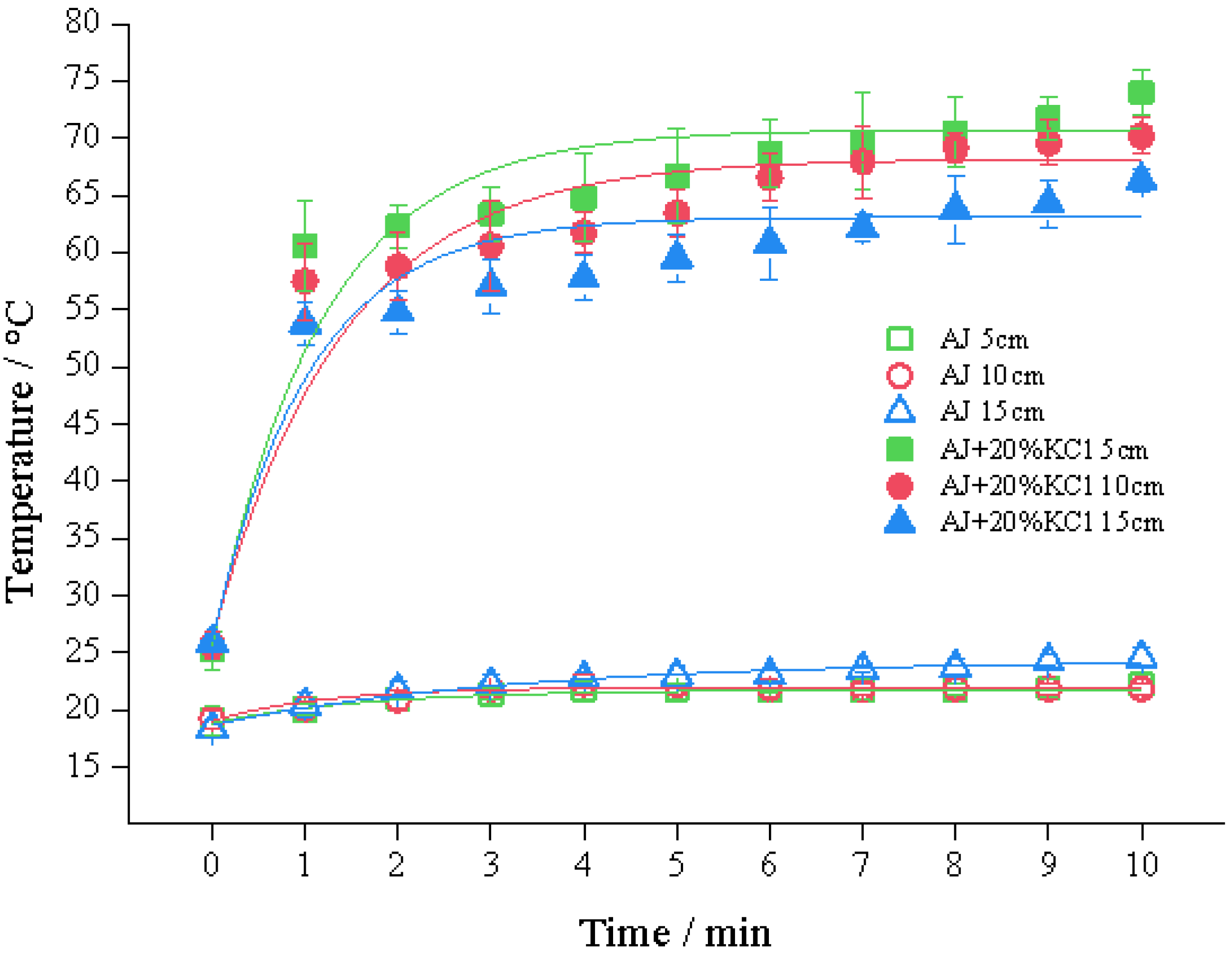

3.5. The Length of the Link Tube (L1)

3.6. Frequency

3.7. Physical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soni, A.; Smith, J.; Thompson, A.; Brightwell, G. Microwave-induced thermal sterilization—A review on history, technical progress, advantages and challenges as compared to the conventional methods. Trends Food Sci. Technol. 2020, 97, 433–442. [Google Scholar] [CrossRef]

- You, Y.; Li, N.; Han, X.; Guo, J.; Zhao, Y.; Liu, G.; Huang, W.; Zhan, J. Influence of different sterilization treatments on the color and anthocyanin contents of mulberry juice during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2018, 48, 1–10. [Google Scholar] [CrossRef]

- Al-Ghamdi, S.; Sonar, C.R.; Patel, J.; Albahr, Z.; Sablani, S.S. High pressure-assisted thermal sterilization of low-acid fruit and vegetable purees: Microbial safety, nutrient, quality, and packaging evaluation. Food Control. 2020, 114, 107233. [Google Scholar] [CrossRef]

- Wang, J.; Tang, J.; Park, J.W.; Rasco, B.; Tang, Z.; Qu, Z. Thermal gelation of Pacific whiting surimi in microwave assisted pasteurization. J. Food Eng. 2019, 258, 18–26. [Google Scholar] [CrossRef]

- Mendes-Oliveira, G.; Jin, T.Z.; Campanella, O.H. Modeling the inactivation of Escherichia coli O157:H7 and Salmonella Typhimurium in juices by pulsed electric fields: The role of the energy density. J. Food Eng. 2020, 282, 110001. [Google Scholar] [CrossRef]

- Buitimea-Cantúa, G.V.; Rico-Alderete, I.A.; Rostro-Alanís, J.; Welti-Chanes, J.; Escobedo-Avellaneda, Z.J.; Soto-Caballero, M.C. Effect of High Hydrostatic Pressure and Pulsed Electric Fields Processes on Microbial Safety and Quality of Black/Red Raspberry Juice. Foods 2022, 11, 2342. [Google Scholar] [CrossRef] [PubMed]

- Rocha, R.S.; Silva, R.; Guimarães, J.T.; Balhtazar, C.F.; Silveira, M.R.; Martins, A.A.; Rojas, V.P.; Graça, J.S.; Pimentel, T.C.; Esmerino, E.A.; et al. Ohmic heating does not influence the biochemical properties of Minas Frescal cheese but decreases uric acid levels in healthy Wistar rats. J. Dairy Sci. 2020, 103, 4929–4934. [Google Scholar] [CrossRef]

- Lindgren, M.; Aronsson, K.; Galt, S.; Ohlsson, T. Simulation of the temperature increase in pulsed electric field (PEF) continuous flow treatment chambers. Innov. Food Sci. Emerg. Technol. 2002, 3, 233–245. [Google Scholar] [CrossRef]

- Wu, S.L.; Yang, N.; Jin, Y.M.; Li, D.D.; Xu, Y.; Xu, X.M.; Jin, Z.Y. Development of an innovative induction heating technique for the treatment of liquid food: Principle, experimental validation and application. J. Food Eng. 2020, 271, 109780. [Google Scholar] [CrossRef]

- Lu, Q.; Peng, Y.; Zhu, C.; Pan, S. Effect of thermal treatment on carotenoids, flavonoids and ascorbic acid in juice of orange cv. Cara Cara. Food Chem. 2018, 265, 39–48. [Google Scholar] [CrossRef]

- Pires, R.P.S.; Cappato, L.P.; Guimarães, J.T.; Rocha, R.S.; Silva, R.; Balthazar, C.F.; Freitas, M.Q.; Silva, P.H.F.; Neto, R.P.C.; Tavares, M.I.B.; et al. Ohmic heating for infant formula processing: Evaluating the effect of different voltage gradient. J. Food Eng. 2020, 280, 109989. [Google Scholar] [CrossRef]

- Rocha, R.S.; Silva, R.; Guimarães, J.T.; Balthazar, C.F.; Pimentel, T.C.; Neto, R.P.C.; Tavares, M.I.B.; Esmerino, E.A.; Freitas, M.Q.; Cappato, L.P.; et al. Possibilities for using ohmic heating in Minas Frescal cheese production. Food Res. Int. 2020, 131, 109027. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Reynosa, A.; Romaní, A.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Comparison of microwave and conduction-convection heating autohydrolysis pretreatment for bioethanol production. Bioresour. Technol. 2017, 243, 273–283. [Google Scholar] [CrossRef]

- García-Valladares, O.; Ortiz, N.M.; Pilatowsky, I.; Menchaca, A.C. Solar thermal drying plant for agricultural products. Part 1: Direct air heating system. Renew. Energy 2020, 148, 1302–1320. [Google Scholar] [CrossRef]

- Jiao, X.; Cao, H.; Fan, D.; Huang, J.; Zhao, J.; Yan, B.; Zhou, W.; Zhang, W.; Ye, W.; Zhang, H. Effects of fish oil incorporation on the gelling properties of silver carp surimi gel subjected to microwave heating combined with conduction heating treatment. Food Hydrocoll. 2019, 94, 164–173. [Google Scholar] [CrossRef]

- Karayannakidis, P.D.; Apostolidis, E.; Lee, C.M. Comparison of direct steam injection and steam-jacketed heating in squid protein hydrolysis for energy consumption and hydrolysis performance. LWT Food Sci. Technol. 2014, 57, 134–140. [Google Scholar] [CrossRef]

- Cappato, L.P.; Ferreira, M.V.S.; Guimaraes, J.T.; Portela, J.B.; Costa, A.L.R.; Freitas, M.Q.; Cunha, R.L.; Oliveira, C.A.F.; Mercali, G.D.; Marzack, L.D.F.; et al. Ohmic heating in dairy processing: Relevant aspects for safety and quality. Trends Food Sci. Technol. 2017, 62, 104–112. [Google Scholar] [CrossRef]

- Resurreccion, F.P.; Luan, D.; Tang, J.; Liu, F.; Tang, Z.; Pedrow, P.D.; Cavalieri, R. Effect of changes in microwave frequency on heating patterns of foods in a microwave assisted thermal sterilization system. J. Food Eng. 2015, 150, 99–105. [Google Scholar] [CrossRef]

- Wu, S.L.; Yang, N.; Jin, Y.M.; Xu, X.M.; Jin, Z.Y.; Xie, Z.J. Effects of induced electric field (IEF) on the reduction of Saccharomyces cerevisiae and quality of fresh apple juice. Food Chem. 2020, 325, 126943. [Google Scholar] [CrossRef]

- Atwa, O.S.E. Chapter 11—Voltage Transformers, In Practical Power System and Protective Relays Commissioning; Atwa, O.S.E., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 123–132. [Google Scholar]

- Char, C.D.; Mitilinaki, E.; Guerrero, S.N.; Alzamora, S.M. Use of High-Intensity Ultrasound and UV-C Light to Inactivate Some Microorganisms in Fruit Juices. Food Bioprocess. Technol. 2010, 3, 797–803. [Google Scholar] [CrossRef]

- Li, D.D.; Zhang, Y.; Yang, N.; Jin, Z.Y.; Xu, X.M. Impact of electrical conductivity on acid hydrolysis of guar gum under induced electric field. Food Chem. 2018, 259, 157–165. [Google Scholar] [CrossRef]

- Sarkis, J.R.; Mercali, G.D.; Tessaro, I.C.; Marczak, L.D.F. Evaluation of key parameters during construction and operation of an ohmic heating apparatus. Innov. Food Sci. Emerg. Technol. 2013, 18, 145–154. [Google Scholar]

- Fryer, P.J.; De Alwis, A.A.P.; Koury, E.; Stapley, A.G.F.; Zhang, L. Ohmic processing of solid-liquid mixtures: Heat generation and convection effects. J. Food Eng. 1993, 18, 101–125. [Google Scholar] [CrossRef]

- Timmermans, R.A.H.; Mastwijk, H.C.; Berendsen, L.B.J.M.; Nederhoff, A.L.; Matser, A.M.; Van Boekel, M.A.J.S.; Nierop Groot, M.N. Moderate intensity Pulsed Electric Fields (PEF) as alternative mild preservation technology for fruit juice. Int. J. Food Microbiol. 2019, 298, 63–73. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, C.; Saxena, V.K.; Dutta, S. Novel thermal and non-thermal processing of watermelon juice. Trends Food Sci. Technol. 2019, 93, 234–243. [Google Scholar]

- Rivas, A.; Rodrigo, D.; Martínez, A.; Barbosa-Cánovas, G.V.; Rodrigo, M. Effect of PEF and heat pasteurization on the physical–chemical characteristics of blended orange and carrot juice. LWT Food Sci. Technol. 2006, 39, 1163–1170. [Google Scholar] [CrossRef]

- Assiry, A.M.; Gaily, M.H.; Alsamee, M.; Sarifudin, A. Electrical conductivity of seawater during ohmic heating. Desalination 2010, 260, 9–17. [Google Scholar]

- Sastry, S.K.; Li, Q. Modeling the Ohmic heating of foods. Food Technol. 1996, 50, 246–248. [Google Scholar]

- Pataro, G.; Barca, G.M.J.; Donsì, G.; Ferrari, G. On the modelling of the electrochemical phenomena at the electrode-solution interface of a PEF treatment chamber: Effect of electrical parameters and chemical composition of model liquid food. J. Food Eng. 2015, 165, 45–51. [Google Scholar] [CrossRef]

- Shao, L.; Liu, Y.; Tian, X.; Wang, H.; Yu, Q.; Li, X.; Dai, R. Inactivation of Staphylococcus aureus in phosphate buffered saline and physiological saline using ohmic heating with different voltage gradient and frequency. J. Food Eng. 2020, 274, 109834. [Google Scholar] [CrossRef]

- Li, Z.; Sun, Q.; Zheng, Y.; Wang, J.; Tian, Y.; Zheng, B.; Guo, Z. Effect of two-step microwave heating on the gelation properties of golden threadfin bream (Nemipterus virgatus) myosin. Food Chem. 2020, 328, 127104. [Google Scholar] [CrossRef] [PubMed]

- Donsì, F.; Ferrari, G.; Fruilo, M.; Pataro, G. Pulsed Electric Field-Assisted Vinification of Aglianico and Piedirosso Grapes. J. Agric. Food Chem. 2010, 58, 11606–11615. [Google Scholar] [CrossRef] [PubMed]

- Knorr, D.; Angersbach, A. Impact of high-intensity electric field pulses on plant membrane permeabilization. Trends Food Sci. Technol. 1998, 9, 185–191. [Google Scholar] [CrossRef]

- Peña-Gómez, N.; Ruiz-Rico, M.; Fernández-Segovia, I.; Barat, J.M. Study of apple juice preservation by filtration through silica microparticles functionalised with essential oil components. Food Control. 2019, 106, 106749. [Google Scholar] [CrossRef]

| d1/mm | T0/°C | T2/°C | T10/°C | Tmean/°C | Vmean/°C·min−1 | |

|---|---|---|---|---|---|---|

| AJ | 1 | 25.5 ± 0.6 ab | 36.5 ± 0.6 b | 36.9 ± 0.5 b | 36.7 ± 0.4 b | 3.8 ± 0.3 b |

| 2 | 25.6 ± 0.5 ab | 28.7 ± 0.4 c | 29.3 ± 0.3 a | 29.2 ± 0.1 a | 1.1 ± 0.02 a | |

| 3 | 25.3 ± 0.4 ab | 26.6 ± 0.7 a | 28.6 ± 0.5 a | 28.2 ± 0.1 a | 0.6 ± 0.01 a | |

| 5 | 24.9 ± 0.3 a | 26.0 ± 0.3 a | 28.4 ± 0.3 a | 29.2 ± 0.5 a | 1.1 ± 0.02 a | |

| AJ + 20% KCl | 1 | 26.3 ± 0.3 b | – | – | – | – |

| 2 | 25.5 ± 0.2 ab | 58.5 ± 1.8 d | 70.0 ± 1.2 c | 66.7 ± 0.3 c | 11.6 ± 1.1 c | |

| 3 | 26.2 ± 0.4 b | 54.3 ± 0.9 e | 62.9 ± 1.1 d | 60.2 ± 0.9 d | 9.7 ± 0.9 d | |

| 5 | 25.0 ± 0.2 a | 43.0 ± 0.6 f | 54.0 ± 0.9 e | 52.4 ± 0.7 e | 7.3 ± 0.6 e |

| UP/V | T0/°C | T2/°C | T10/°C | Tmean/°C | Vmean/°C·min−1 | |

|---|---|---|---|---|---|---|

| AJ | 200 | 25.1 ± 0.4 a | 26.2 ± 0.6 ab | 26.7 ± 0.4 a | 26.7 ± 0.1 bc | 0.3 ± 0.01 a |

| 500 | 25.0 ± 0.4 a | 27.1 ± 0.9 abc | 28.8 ± 0.6 b | 28.3 ± 0.2 d | 0.8 ± 0.1 ab | |

| 800 | 25.1 ± 0.3 a | 28.7 ± 0.5 cd | 29.3 ± 0.2 b | 29.2 ± 0.3 a | 1.3 ± 0.2 ab | |

| AJ + 20% KCl | 200 | 25.2 ± 0.5 a | 29.9 ± 0.4 d | 31.7 ± 0.7 c | 31.1 ± 0.3 a | 1.6 ± 0.1 b |

| 500 | 25.2 ± 0.4 a | 37.7 ± 1.4 e | 48.8 ± 1.5 d | 45.7 ± 0.8 e | 5.5 ± 0.3 c | |

| 800 | 25.5 ± 0.3 a | 58.5 ± 1.6 f | 70.0 ± 1.3 e | 66.7 ± 0.9 f | 11.6 ± 0.5 d |

| pH | Brix/% | Conductivity/ms·cm−1 | Impedance/Ω | Resistance/Ω | |

|---|---|---|---|---|---|

| Control | 3.87 ± 0.02 a | 12.40 ± 0.12 a | 2.72 ± 0.01 a | 39.91 ± 1.32 a | 37.47 ± 1.21 a |

| Treated AJ | 3.84 ± 0.03 a | 12.10 ± 0.20 a | 2.71 ± 0.01 a | 58.96 ± 1.54 b | 52.87 ± 1.06 b |

| AJ + 20%KCl | 3.56 ± 0.05 b | 27.10 ± 0.26 b | 224.50 ± 1.2 b | 8.37 ± 0.34 c | 4.77 ± 0.21 c |

| Treated AJ + 20%KCl | 3.58 ± 0.04 b | 26.70 ± 0.34 b | 212.90 ± 2.3 c | 8.59 ± 0.56 c | 4.48 ± 0.42 c |

| Treated AJ 40 kHz | 3.45 ± 0.01 c | 12.23 ± 0.32 a | 2.84 ± 0.01 d | 30.42 ± 1.2 d | 28.43 ± 0.8 d |

| C/CFU·mL−1 | NIEF/% | Tmax/°C | |

|---|---|---|---|

| AJ | 2.40 × 105 | – | 25.0 |

| Treated AJ | 2.38 × 105 | 0.83 | 29.3 |

| Treated AJ 40 kHz | UD | 100 | 62.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Xu, X.; Yang, N.; Jin, Y.; Jin, Z.; Xie, Z. Non-Conventional Induction Heat Treatment: Effect of Design and Electrical Parameters on Apple Juice Safety and Quality. Foods 2022, 11, 3937. https://doi.org/10.3390/foods11233937

Wu S, Xu X, Yang N, Jin Y, Jin Z, Xie Z. Non-Conventional Induction Heat Treatment: Effect of Design and Electrical Parameters on Apple Juice Safety and Quality. Foods. 2022; 11(23):3937. https://doi.org/10.3390/foods11233937

Chicago/Turabian StyleWu, Shilin, Xueming Xu, Na Yang, Yamei Jin, Zhengyu Jin, and Zhengjun Xie. 2022. "Non-Conventional Induction Heat Treatment: Effect of Design and Electrical Parameters on Apple Juice Safety and Quality" Foods 11, no. 23: 3937. https://doi.org/10.3390/foods11233937

APA StyleWu, S., Xu, X., Yang, N., Jin, Y., Jin, Z., & Xie, Z. (2022). Non-Conventional Induction Heat Treatment: Effect of Design and Electrical Parameters on Apple Juice Safety and Quality. Foods, 11(23), 3937. https://doi.org/10.3390/foods11233937