Physico-Chemical Properties and Storage Stability of an Emulsion as a Fat Replacer in Meat Analogs during the Freezing Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Fat Replacer

2.3. Preparation of Meat Analogs

2.4. Visible Appearance

2.5. Color Measurements

2.6. Drip Loss

2.7. Water Holding Capacity

2.8. Moisture Content

2.9. Texture Profile Analysis

2.10. Scanning Electron Microscopy

2.11. Volatile Basic Nitrogen

2.12. Thiobarbituric Acid Reactive Substances

2.13. Microbial Analysis

2.14. Sensory Evaluation

2.15. Statistical Analysis

3. Results and Discussion

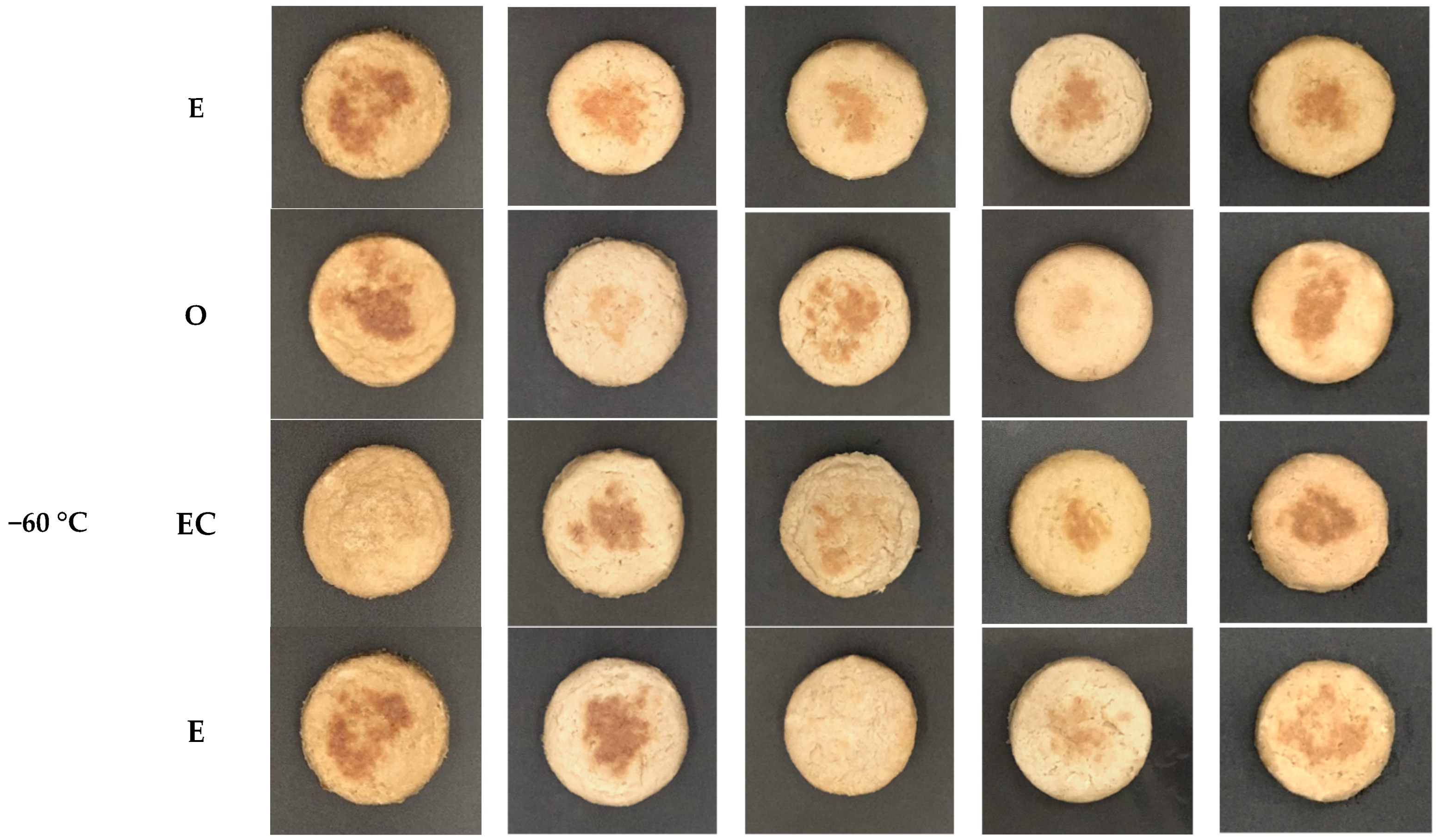

3.1. Visible Appearance and Color Measurements

3.2. Drip Loss

3.3. Liquid Holding Capacity

3.4. Moisture Contents

3.5. Texture Profile Analysis

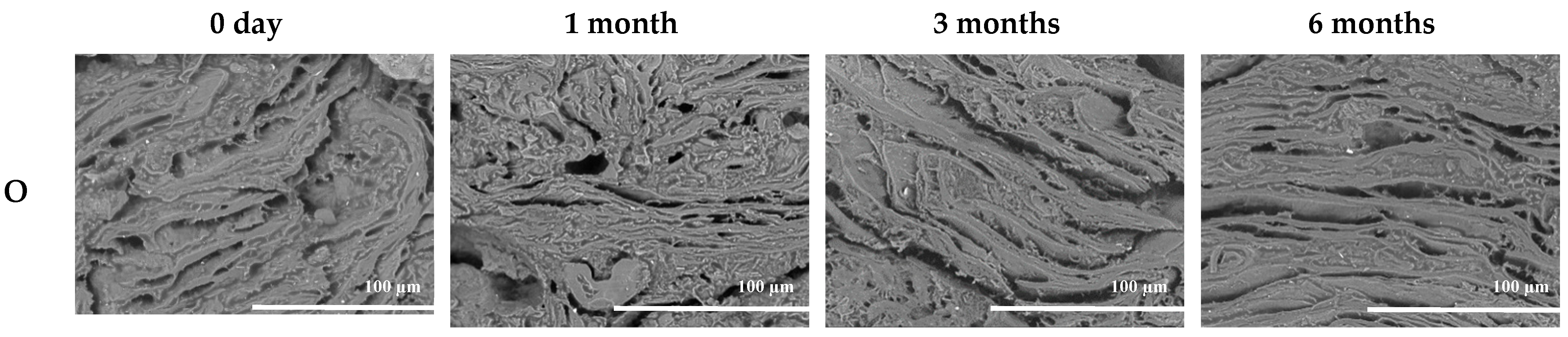

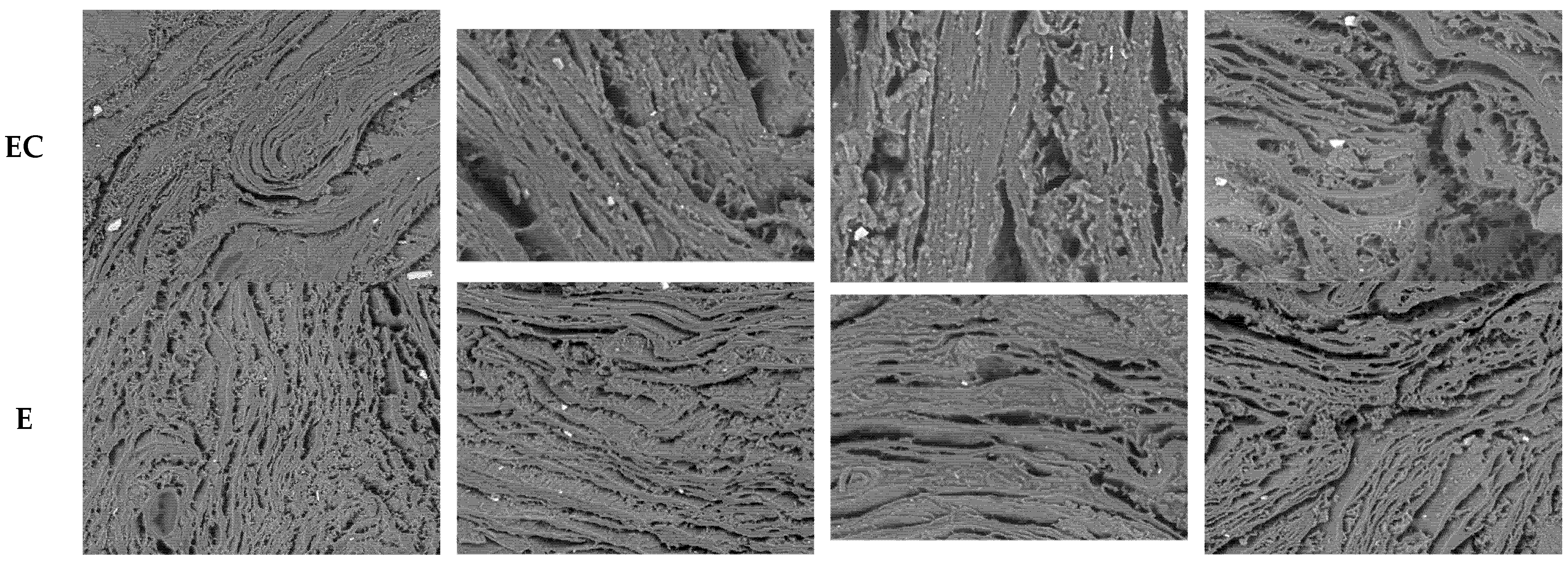

3.6. Microstructure

3.7. Volatile Basic Nitrogen

3.8. Thiobarbituric Acid Reactive Substances

3.9. Microbial Analysis

3.10. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hwang, J.; You, J.; Moon, J.; Jeong, J. Factors affecting consumers’ alternative meats buying intentions: Plant-based meat alternative and cultured meat. Sustainability 2020, 12, 5662. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-based meat alternatives: Compositional analysis, current development and challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Kolodziejczak, K.; Onopiuk, A.; Szpicer, A.; Poltorak, A. Meat Analogues in the Perspective of Recent Scientific Research: A Review. Foods 2021, 11, 105. [Google Scholar] [CrossRef]

- Sha, L.; Xiong, Y.L. Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- de Carvalho, F.A.L.; Munekata, P.E.S.; Pateiro, M.; Campagnol, P.C.B.; Dominguez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of replacing backfat with vegetable oils during the shelf-life of cooked lamb sausages. LWT Food Sci Technol. 2020, 122, 109052. [Google Scholar] [CrossRef]

- Shin, D.J.; Lee, H.J.; Jo, C.; Choe, J. Fat replacement in chicken sausages manufactured with broiler and old laying hens by different vegetable oils. Poult. Sci. 2020, 99, 2811–2818. [Google Scholar] [CrossRef]

- López-Pedrouso, M.; Lorenzo, J.; Gullón, B.; Campagnol, P.C.B.; Franco, D. Novel strategy for developing healthy meat products replacing saturated fat with oleogels. Curr. Opin. Food Sci. 2021, 40, 40–45. [Google Scholar] [CrossRef]

- McClements, D.J. Theoretical prediction of emulsion color. Adv. Colloid Interface Sci. 2002, 97, 63–89. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, L.; Zhang, Y.; Li, H.; Zhao, D.; Cao, J.; Liu, X. Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods 2022, 11, 1950. [Google Scholar] [CrossRef]

- Domínguez, R.; Lorenzo, J.M.; Pateiro, M.; Munekata, P.E.; Alves dos Santos, B.; Basso Pinton, M.; Cichoski, A.J.; Bastianello Campagnol, P.C. Main animal fat replacers for the manufacture of healthy processed meat products. Crit. Rev. Food Sci. Nutr. 2022, 1–20. [Google Scholar] [CrossRef]

- Alejandre, M.; Passarini, D.; Astiasarán, I.; Ansorena, D. The effect of low-fat beef patties formulated with a low-energy fat analogue enriched in long-chain polyunsaturated fatty acids on lipid oxidation and sensory attributes. Meat Sci. 2017, 134, 7–13. [Google Scholar] [CrossRef]

- George, R.M. Freezing proceseses used in the food industry. Trends Food Sci Technol. 1993, 4, 134–138. [Google Scholar] [CrossRef]

- Jha, P.K.; Vidot, K.; Xanhakis, E.; Falourd, X.; Fontaine, J.; Jury, V.; Bail, A. Benchmarking of techniques used to assess the freeze damage in potatoes. J. Food Eng. 2019, 262, 60–74. [Google Scholar] [CrossRef]

- Li, D.; Zhao, H.; Muhammad, A.L.; Song, L.; Guo, M.; Liu, D. The comparison of ultrasound-assisted thawing, air thawing and water immersion thawing on the quality of slow/fast freezing bighead carp (Aristichthys nobilis) fillets. Food Chem. 2020, 320, 126614. [Google Scholar] [CrossRef] [PubMed]

- Ariyaprakai, S. Freeze Thaw Stability and Heat Stability of Coconut Oil-in-Water Emulsions and Coconut Milk Emulsions Stabilized by Enzyme-Modified Soy Lecithin. Food Biophys. 2022, 17, 557–567. [Google Scholar] [CrossRef]

- Zang, X.; Yue, C.; Liu, M.; Zheng, H.; Xia, X.; Yu, G. Improvement of freeze-thaw stability of oil-in-water emulsions prepared with modified soy protein isolates. LWT 2019, 102, 122–130. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the physicochemical and structural properties and the sensory characteristics of meat analogues prepared with various non-animal based liquid additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef] [Green Version]

- Jo, Y.-J.; Huang, W.; Chen, L. Fabrication and characterization of lentil protein gels from fibrillar aggregates and the gelling mechanism study. Food Funct. 2020, 11, 10114–10125. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Li, Z.; Zhang, L.; Mao, C.; Song, Z.; Li, X.; Liu, C. Preparation and characterization of konjac glucomannan and gum arabic composite gel. Int. J. Biol. Macromol. 2021, 183, 2121–2130. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, E.J.; Park, D.H.; Choi, M.-J. Two-stage air thawing as an effective method for controlling thawing temperature and improving the freshness of frozen pork loin. LWT Food Sci Technol. 2021, 140, 110668. [Google Scholar] [CrossRef]

- Ong, S.; Loo, L.; Pang, M.; Tan, R.; Teng, Y.; Lou, X.; Chin, S.K.; Naik, M.Y.; Yu, H. Decompartmentalisation as a simple color manipulation of plant-based marbling meat alternatives. Biomaterials 2021, 277, 121107. [Google Scholar] [CrossRef]

- Li, F.; Zhoong, Q.; Kong, B.; Wang, B.; Pan, N.; Xia, X. Deterioration in quality of quick-frozen pork patties induced by changes in protein structure and lipid and protein oxidation during frozen storage. Int. Food Res. J. 2020, 133, 109142. [Google Scholar] [CrossRef]

- Wang, B.; Li, F.; Pan, N.; Kong, B.; Xia, X. Effect of ice structuring protein on the quality of quick-frozen patties subjected to multiple freeze-thaw cycles. Meat Sci. 2021, 172, 108335. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Bai, X.; Du, X.; Pan, N.; Shi, S.; Xia, X. Comparison of Effects from Ultrasound Thawing, Vacuum Thawing and Microwave Thawing on the Quality Properties and Oxidation of Porcine Longissimus Lumborum. Foods 2022, 11, 1368. [Google Scholar] [CrossRef]

- Choi, M.J.; Abduzukhurov, T.; Park, D.H.; Kim, E.J.; Hong, G.P. Effects of deep freezing temperature for long-term storage on quality characteristics and freshness of lamb meat. Korean J. Food Sci. Anim. Resour. 2018, 38, 959. [Google Scholar] [CrossRef] [Green Version]

- Kim, E.J.; Lee, S.; Park, D.H.; Kim, H.; Choi, M.J. Physicochemical properties of pork neck and chicken leg meat under various freezing temperatures in a deep freezer. Food Sci. Anim. Resour. 2020, 40, 444. [Google Scholar] [CrossRef] [PubMed]

- Martino, M.N.; Zaritzky, N.E. Ice recrystallization in a model system and in frozen muscle tissue. Cryobiology 1989, 26, 138–148. [Google Scholar] [CrossRef]

- Xia, W.; Ma, L.; Chen, X.; Li, X.; Zhang, Y. Physicochemical and structural properties of composite gels prepared with myofibrillar protein and lecithin at various ionic strengths. Food Hydrocol. 2018, 82, 135–143. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Herrero, A.; Pintado, T.; Solas, M.T.; Ruiz-Capillas, C. Influence of emulsified olive oil stabilizing system used for pork backfat replacement in frankfurters. Food Res. Int. 2010, 113, 107–115. [Google Scholar] [CrossRef]

- Kim, D.H. The Food Chemistry, Version 1.0; Tamgoo Publishing Co.: Seoul, Republic of Korea, 2010; pp. 1–3, 23, 544–547. [Google Scholar]

- Jonkers, N.; van Dommelen, J.A.W.; Geers, M.G.D. Intrinsic mechanical properties of food in relation to texture parameters. Mech. Time-Depend. Mater. 2022, 26, 323–346. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and Chemical Characteristics of Soy Protein Meat Analog Extruded at High Moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.; Choi, M.-J.; Cho, Y. Improved Physicochemical Properties of Pork Patty Supplemented with Oil-in-Water Nanoemulsion. Food Sci. Anim. Resour. 2020, 40, 262–273. [Google Scholar] [CrossRef] [Green Version]

- Qi, J.; Li, C.; Chen, Y.; Gao, F.; Xu, X.; Zhou, G. Changes in meat quality of ovine longissimus dorsi muscle in response to repeated freeze and thaw. Meat Sci. 2012, 92, 619–626. [Google Scholar] [CrossRef]

- Tippala, T.; Koomkrong, N.; Kayan, A. Influence of freeze-thawed cycles on pork quality. Anim. Biosci. 2021, 34, 1375–1381. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, Q.; Sun, D.W. Measuring and controlling ice crystallization in frozen foods: A review of recent developments. Trends Food Sci. Technol. 2019, 90, 13–25. [Google Scholar] [CrossRef]

- Mok, J.H.; Choi, W.; Park, S.H.; Lee, S.H.; Jun, S. Emerging pulsed electric field (PEF) and static magnetic field (SMF) combination technology for food freezing. J. Int. Acad. Refrig. 2015, 50, 137–145. [Google Scholar] [CrossRef]

- Sujiwo, J.; Kim, H.J.; Song, S.O.; Jang, A. Relationship between quality and freshness traits and torrymeter value of beef loin during cold storage. Meat Sci. 2019, 149, 102–125. [Google Scholar] [CrossRef] [PubMed]

- Kruk, Z.A.; Yun, H.; Rutley, D.L.; Lee, E.J.; Kim, Y.J.; Jo, C. The effect of high pressure on microbial population, meat quality and sensory characteristics of chicken breast fillet. Food Control. 2011, 22, 6–12. [Google Scholar] [CrossRef]

- Hejazy, M.; Khatibi, S.A.; Shamsi, Z. The Effect of Frying Process on the Level of Malondialdehyde in Different Meat Products. J. Nutr. Food Secur. 2021, 6, 367–373. [Google Scholar] [CrossRef]

- Jo, Y.-J.; Jwon, Y.-J.; Min, S.-G.; Choi, M.-J. Changes in quality characteristics of pork patties containing multilayered fish oil emulsion during refrigerated storage. Korean J. Food Sci. Anim. Resour. 2015, 35, 71–79. [Google Scholar] [CrossRef]

- Balzan, S.; Taticchi, A.; Cardazzo, B.; Urbani, S.; Servili, M.; Di Lecce, G.; Zabalza, I.B.; Rodriguez-Estrada, M.T.; Novelli, E.; Fasolato, L. Effect of phenols extracted from a by-product of the oil mill on the shelf-life of raw and cooked fresh pork sausages in the absence of chemical additives. LWT-Food Sci. Technol. 2017, 85, 89–95. [Google Scholar] [CrossRef]

- Karr, K.J.; Maretzki, A.N.; Knabel, S.J. Meat and poultry companies assess Usdas hazard analysis and critical control point system. Food Technol. 1994, 48, 117–122. [Google Scholar]

- Barbosa-Cánovas, G.V.; Fontana, A.J.; Schmidt, S.J.; Labuza, T.P. Effects of Water Activity (Aw) on Microbial Stability as a Hurdle in Food Preservation. In Water Activity in Foods: Fundamentals and Applications, 2nd ed.; Tapia, M.S., Alzamora, S.M., Chirife, J., Eds.; Wiley-Blackwell: Chicago, IL, USA, 2020; pp. 323–355. [Google Scholar]

- Kulawik, P.; Migdal, W.; Gambus, F.; Cieslik, E.; Ozogul, F.; Tkaczewska, J.; Szczurowska, K.; Walkowska, I. Microbiological and chemical safety concerns regarding frozen fillets obtained from Pangasius sutchi and Nile tilapia exported to European countries. J. Sci. Food Agric. 2016, 96, 1373–1379. [Google Scholar] [CrossRef]

- Kim, H.; Bae, J.; Wi, G.; Kim, H.T.; Cho, Y.; Choi, M.-J. Physicochemical Properties and Sensory Evaluation of Meat Analog Mixed with Different Liquid Materials as an Animal Fat Substitute. Food Eng. Prog. 2019, 23, 62–68. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Wang, H.; Janz, J.A. Effect of Canola Oil Emulsion Injection on Processing Characteristics and Consumer Acceptability of Three Muscles from Mature Beef. Meat Sci. 2019, 20, 100–105. [Google Scholar] [CrossRef]

| Treatments * | Meat Analog Ingredients (%) | Fat Replacer Ingredients (%) | ||||

|---|---|---|---|---|---|---|

| TVP | SPI | Binder | Distilled Water | Canola Oil | Tween® 80 | |

| O | 74.67 | 3.00 | 2.33 | - | 20.00 | - |

| EC | 74.67 | 3.00 | 2.33 | 11.88 | 8.00 | 0.12 |

| E | 74.67 | 3.00 | 2.33 | 11.88 | 8.00 | 0.12 |

| Storage Temperature (°C) | Color | Treatments * | Storage (Months) | ||||

|---|---|---|---|---|---|---|---|

| 0 | 0.5 | 1 | 3 | 6 | |||

| −18 | Lightness (L*) | O | 48.47 ± 1.23D | 63.58 ± 4.62aA | 63.86 ± 1.05A | 58.72 ± 0.86aB | 56.11 ± 1.52C |

| EC | 48.74 ± 1.28C | 56.82 ± 1.84bAB | 53.33 ± 2.20B | 58.10 ± 0.53abA | 56.34 ± 1.85AB | ||

| E | 48.62 ± 2.02D | 65.72 ± 3.48aA | 64.49 ± 1.83A | 57.38 ± 1.54bB | 55.44 ± 0.95C | ||

| Redness (a*) | O | 5.50 ± 0.40aB | 5.82 ± 0.12aB | 7.73 ± 0.79aA | 5.12 ± 1.97B | 3.89 ± 0.14abC | |

| EC | 5.19 ± 0.33bA | 3.82 ± 0.49bB | 5.24 ± 1.65bA | 5.63 ± 2.12A | 3.82 ± 0.22bB | ||

| E | 5.56 ± 0.12aB | 5.82 ± 0.08aB | 7.68 ± 0.46aA | 4.56 ± 1.28C | 4.08 ± 0.24aC | ||

| Yellowness (b*) | O | 17.02 ± 0.36BC | 17.71 ± 0.18aA | 17.64 ± 1.42AB | 16.73 ± 0.73C | 17.32 ± 0.10aAB | |

| EC | 17.52 ± 0.87A | 16.33 ± 0.69cB | 16.75 ± 0.74B | 16.41 ± 0.71B | 16.61 ± 0.45bB | ||

| E | 17.40 ± 0.92AB | 17.74 ± 0.15bAB | 17.88 ± 1.32A | 17.08 ± 0.97B | 17.16 ± 0.27aAB | ||

| −60 | Lightness (L*) | O | 48.47 ± 1.23C | 58.98 ± 3.61bA | 56.58 ± 2.83B | 56.16 ± 2.40B | 56.72 ± 2.57aB |

| EC | 48.74 ± 1.28D | 56.46 ± 2.27bC | 58.79 ± 0.37A | 55.99 ± 0.74B | 53.31 ± 1.93bC | ||

| E | 48.62 ± 2.02D | 64.04 ± 4.69aA | 57.09 ± 2.84B | 55.26 ± 3.27BC | 54.26 ± 0.60bC | ||

| Redness (a*) | O | 5.50 ± 0.40aB | 5.92 ± 0.15aA | 3.49 ± 0.35E | 4.48 ± 0.86aC | 4.01 ± 0.26bD | |

| EC | 5.19 ± 0.33bA | 3.61 ± 0.45bC | 3.60 ± 0.16C | 3.50 ± 0.13bC | 4.59 ± 0.71aB | ||

| E | 5.56 ± 0.12aA | 5.84 ± 0.12aA | 3.24 ± 0.37C | 4.48 ± 0.84aB | 4.66 ± 0.24aB | ||

| Yellowness (b*) | O | 17.02 ± 0.36B | 17.84 ± 0.24aA | 15.98 ± 0.66C | 16.52 ± 1.05aB | 17.06 ± 0.63bB | |

| EC | 17.52 ± 0.87A | 16.28 ± 1.20bB | 16.12 ± 0.48B | 15.54 ± 0.35bB | 17.61 ± 0.69abA | ||

| E | 17.40 ± 0.92AB | 17.77 ± 0.18aAB | 15.74 ± 0.85C | 17.13 ± 1.09aB | 17.83 ± 0.60A | ||

| Storage Temperature (°C) | Treatments * | Storage (Months) | ||||

|---|---|---|---|---|---|---|

| 0 | 0.5 | 1 | 3 | 6 | ||

| −18 | O | - | 0.52 ± 0.19 | 0.52 ± 0.17 | 0.52 ± 0.11 | 0.59 ± 0.04 |

| EC | - | 0.42 ± 0.27B | 0.78 ± 0.11A | 0.60 ± 0.07AB | 0.58 ± 0.08AB | |

| E | - | 0.53 ± 0.29 | 0.62 ± 0.26 | 0.68 ± 0.21 | 0.51 ± 0.11 | |

| −60 | O | - | 0.48 ± 0.05 | 0.40 ± 0.09 | 0.33 ± 0.19 | 0.47 ± 0.22 |

| EC | - | 0.45 ± 0.24 | 0.52 ± 0.21 | 0.43 ± 0.13 | 0.54 ± 0.27 | |

| E | - | 0.37 ± 0.20 | 0.34 ± 0.05 | 0.55 ± 0.2 | 0.66 ± 0.17 | |

| Storage Temperature (°C) | Treatments * | Storage (Months) | ||||

|---|---|---|---|---|---|---|

| 0 | 0.5 | 1 | 3 | 6 | ||

| −18 | O | 98.17 ± 0.89A | 97.10 ± 0.14bAB | 97.02 ± 0.38bAB | 97.15 ± 0.39AB | 96.25 ± 1.35B |

| EC | 98.16 ± 0.07AB | 98.00 ± 0.29aAB | 98.28 ± 0.29aA | 97.79 ± 0.29B | 96.51 ± 0.29C | |

| E | 97.95 ± 0.36A | 97.86 ± 0.19aAB | 97.35 ± 0.23bB | 97.56 ± 0.54AB | 96.09 ± 0.35C | |

| −60 | O | 98.17 ± 0.89A | 97.23 ± 0.17bB | 96.92 ± 0.35bB | 97.06 ± 0.21bB | 95.67 ± 0.27bC |

| EC | 98.16 ± 0.07AB | 98.19 ± 0.31aAB | 98.45 ± 0.17aA | 97.88 ± 0.15aB | 96.95 ± 0.22aC | |

| E | 97.95 ± 0.36AB | 98.26 ± 0.0aA | 97.51 ± 0.60bB | 97.42 ± 0.38bB | 96.10 ± 0.30bC | |

| Storage Temperature (°C) | Treatments * | Storage (Months) | ||||

|---|---|---|---|---|---|---|

| 0 | 0.5 | 1 | 3 | 6 | ||

| −18 | O | 48.98 ± 0.69bA | 48.40 ± 0.22bA | 46.74 ± 0.26cB | 48.56 ± 0.30bA | 48.58 ± 1.04bA |

| EC | 60.75 ± 1.52a | 61.14 ± 0.86a | 61.10 ± 0.93a | 61.87 ± 0.53a | 62.12 ± 0.14a | |

| E | 60.22 ± 0.25aAB | 60.79 ± 1.49aAB | 58.80 ± 1.29bB | 59.83 ± 3.31aAB | 62.28 ± 0.36aA | |

| −60 | O | 48.98 ± 0.69bB | 47.84 ± 0.48cCD | 47.52 ± 0.34cD | 48.55 ± 0.79bBC | 49.97 ± 0.12bA |

| EC | 60.75 ± 1.52aA | 58.98 ± 0.50aB | 59.65 ± 0.64aAB | 60.90 ± 0.18aA | 60.58 ± 0.90aA | |

| E | 60.22 ± 0.25aB | 57.23 ± 1.09bC | 58.06 ± 0.35bC | 61.01 ± 0.58aAB | 61.35 ± 0.48aA | |

| Storage Temperature (°C) | TPA | Treatments * | Storage (Months) | ||||

|---|---|---|---|---|---|---|---|

| 0 | 0.5 | 1 | 3 | 6 | |||

| −18 | Hardness (N) | O | 60.85 ± 6.99aB | 62.53 ± 7.51aB | 61.19 ± 4.18aB | 65.27 ± 5.88aB | 75.31 ± 5.21aA |

| EC | 44.65 ± 4.01bD | 56.54 ± 3.77aB | 52.26 ± 4.17bBC | 62.78 ± 7.83bA | 48.89 ± 4.64bCD | ||

| E | 37.67 ± 4.27c | 36.64 ± 5.54b | 35.64 ± 7.42c | 39.20 ± 5.66b | 44.07 ± 13.1b | ||

| Cohesiveness | O | 0.71 ± 0.03aA | 0.58 ± 0.02aBC | 0.61 ± 0.06aB | 0.54 ± 0.04aD | 0.54 ± 0.04aCD | |

| EC | 0.59 ± 0.03bA | 0.45 ± 0.03cB | 0.46 ± 0.02bB | 0.44 ± 0.02bB | 0.45 ± 0.03bB | ||

| E | 0.51 ± 0.04cA | 0.50 ± 0.01bAB | 0.48 ± 0.02bBC | 0.47 ± 0.01bC | 0.47 ± 0.02bBC | ||

| Springiness (mm) | O | 5.49 ± 0.05aA | 5.26 ± 0.04aC | 5.28 ± 0.12aBC | 5.33 ± 0.06aBC | 5.35 ± 0.09aB | |

| EC | 5.05 ± 0.11bA | 4.57 ± 0.05bC | 4.48 ± 0.11abC | 4.51 ± 0.14bC | 4.71 ± 0.09bB | ||

| E | 4.62 ± 0.14cA | 4.46 ± 0.07cBC | 3.87 ± 1.38bC | 4.52 ± 0.15bAB | 4.50 ± 0.08cABC | ||

| Chewiness (mJ) | O | 236.48 ± 30.3aA | 201.14 ± 14.9B | 175.28 ± 75.9aB | 196.00 ± 20.1aB | 218.34 ± 14.5aAB | |

| EC | 132.56 ± 13.3bA | 117.63 ± 3.99ABC | 107.58 ± 9.45bC | 125.36 ± 19.8bAB | 109.90 ± 19.0bBC | ||

| E | 88.45 ± 16.6c | 80.88 ± 14.8 | 73.44 ± 12.6b | 77.48 ± 16.9c | 87.43 ± 28.4b | ||

| −60 | Hardness (N) | O | 60.85 ± 6.99a | 61.01 ± 9.25a | 60.05 ± 5.67a | 67.07 ± 5.73a | 61.71 ± 10.2a |

| EC | 44.65 ± 4.01b | 46.24 ± 6.99b | 46.86 ± 4.77b | 51.28 ± 11.3b | 49.19 ± 3.54b | ||

| E | 37.67 ± 4.27cAB | 35.53 ± 5.19cAB | 32.71 ± 4.11cB | 33.46 ± 4.98cB | 40.60 ± 7.33bA | ||

| Cohesiveness | O | 0.71 ± 0.03aA | 0.57 ± 0.02aB | 0.59 ± 0.09aB | 0.57 ± 0.03aB | 0.55 ± 0.06B | |

| EC | 0.59 ± 0.03bA | 0.44 ± 0.02cB | 0.45 ± 0.03bB | 0.45 ± 0.04aB | 0.43 ± 0.02bB | ||

| E | 0.51 ± 0.04aB | 0.49 ± 0.02bB | 0.61 ± 0.02aA | 0.46 ± 0.02aC | 0.45 ± 0.02bC | ||

| Springiness (mm) | O | 5.49 ± 0.05 | 5.27 ± 0.06a | 5.32 ± 0.07a | 5.32 ± 0.06a | 5.37 ± 0.04a | |

| EC | 4.50 ± 1.59A | 4.36 ± 0.14bB | 5.06 ± 0.15aB | 4.26 ± 0.15bB | 4.29 ± 0.08bB | ||

| E | 4.62 ± 0.14 | 4.13 ± 0.10c | 4.33 ± 0.07b | 4.16 ± 0.18b | 4.31 ± 0.16b | ||

| Chewiness (mJ) | O | 236.48 ± 30.3aA | 189.54 ± 24.2aB | 197.30 ± 24.90aB | 203.89 ± 16.9aB | 178.65 ± 15.95aB | |

| EC | 132.56 ± 13.3bA | 95.53 ± 12.5bB | 91.90 ± 12.78bB | 98.39 ± 24.0bB | 91.80 ± 10.50bB | ||

| E | 88.45 ± 16.6cAB | 72.94 ± 12.5cCD | 94.64 ± 13.73bA | 60.09 ± 6.92cD | 79.30 ± 15.72BC | ||

| VBN (mg/%) | Storage Temperature (°C) | Treatments * | Storage (Months) | ||||

| 0 | 0.5 | 1 | 3 | 6 | |||

| −18 | O | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.06 ± 0.14 | 0.12 ± 0.00 | 0.00 ± 0.00 | |

| EC | 0.06 ± 0.14 | 0.06 ± 0.14 | 0.00 ± 0.00 | 0.12 ± 0.00 | 0.00 ± 0.00 | ||

| E | 0.06 ± 0.14 | 0.06 ± 0.14 | 0.00 ± 0.00 | 0.12 ± 0.00 | 0.00 ± 0.00 | ||

| −60 | O | - | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.12 ± 0.00 | 0.00 ± 0.00 | |

| EC | - | 0.00 ± 0.14 | 0.06 ± 0.14 | 0.12 ± 0.00 | 0.00 ± 0.00 | ||

| E | - | 0.06 ± 0.14 | 0.00 ± 0.00 | 0.12 ± 0.00 | 0.00 ± 0.00 | ||

| TBARs (mg/kg) | Storage Temperature (°C) | Treatments * | Storage (Months) | ||||

| 0 | 0.5 | 1 | 3 | 6 | |||

| −18 | O | 0.18 ± 0.01BC | 0.18 ± 0.02BC | 0.18 ± 0.01C | 0.19 ± 0.01cB | 0.24 ± 0.01bA | |

| EC | 0.18 ± 0.01B | 0.18 ± 0.01B | 0.18 ± 0.01B | 0.39 ± 0.01aA | 0.39 ± 0.02aA | ||

| E | 0.18 ± 0.01C | 0.19 ± 0.02C | 0.17 ± 0.01C | 0.32 ± 0.03bB | 0.43 ± 0.07aA | ||

| −60 | O | 0.18 ± 0.01BC | 0.17 ± 0.01BC | 0.16 ± 0.01bC | 0.19 ± 0.00cB | 0.33 ± 0.04cA | |

| EC | 0.18 ± 0.01C | 0.17 ± 0.01C | 0.18 ± 0.01aC | 0.39 ± 0.01aB | 0.50 ± 0.03aA | ||

| E | 0.18 ± 0.00C | 0.17 ± 0.00C | 0.17 ± 0.01bC | 0.30 ± 0.01bB | 0.45 ± 0.05bA | ||

| Storage Temperature (°C) | Treatments * | Storage (Months) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 0.5 | 1 | 3 | 6 | |||

| Total Viable Counts (log CFU/mL) | −18 | O | 1.26 ± 0.24AB | 1.00 ± 0.00B | 1.12 ± 0.16bAB | 1.00 ± 0.00B | 1.58 ± 0.35aA |

| EC | 1.28 ± 0.27 | 1.30 ± 0.00 | 1.35 ± 0.50a | 1.15 ± 0.21 | 1.43 ± 0.13ab | ||

| E | 1.53 ± 0.14 | 1.15 ± 0.21 | 1.37 ± 0.29b | 1.26 ± 0.24 | 1.15 ± 0.30b | ||

| −60 | O | 1.26 ± 0.24A | 1.10 ± 0.17aA | 1.15 ± 0.21 | 1.00 ± 0.00B | 1.31 ± 0.38A | |

| EC | 1.28 ± 0.27AB | 0.00 ± 0.00bC | 1.00 ± 0.00 | 1.00 ± 0.00B | 1.63 ± 0.13A | ||

| E | 1.53 ± 0.14A | 1.00 ± 0.00aB | 1.40 ± 0.3 | 1.00 ± 0.00B | 1.37 ± 0.31AB | ||

| Escherichia coli (log CFU/mL) | −18 | O | ND | ND | ND | ND | ND |

| E | ND | ND | ND | ND | ND | ||

| EC | ND | ND | ND | ND | ND | ||

| −60 | O | ND | ND | ND | ND | ND | |

| E | ND | ND | ND | ND | ND | ||

| EC | ND | ND | ND | ND | ND | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, H.; Kim, H.; Lee, J.; Jo, Y.-J.; Choi, M.-J.; Ko, E.-Y. Physico-Chemical Properties and Storage Stability of an Emulsion as a Fat Replacer in Meat Analogs during the Freezing Storage. Foods 2022, 11, 3977. https://doi.org/10.3390/foods11243977

Jeong H, Kim H, Lee J, Jo Y-J, Choi M-J, Ko E-Y. Physico-Chemical Properties and Storage Stability of an Emulsion as a Fat Replacer in Meat Analogs during the Freezing Storage. Foods. 2022; 11(24):3977. https://doi.org/10.3390/foods11243977

Chicago/Turabian StyleJeong, Hyeseung, Haesanna Kim, Jiseon Lee, Yeon-Ji Jo, Mi-Jung Choi, and Eun-Young Ko. 2022. "Physico-Chemical Properties and Storage Stability of an Emulsion as a Fat Replacer in Meat Analogs during the Freezing Storage" Foods 11, no. 24: 3977. https://doi.org/10.3390/foods11243977

APA StyleJeong, H., Kim, H., Lee, J., Jo, Y. -J., Choi, M. -J., & Ko, E. -Y. (2022). Physico-Chemical Properties and Storage Stability of an Emulsion as a Fat Replacer in Meat Analogs during the Freezing Storage. Foods, 11(24), 3977. https://doi.org/10.3390/foods11243977