Nutritional Function and Flavor Evaluation of a New Soybean Beverage Based on Naematelia aurantialba Fermentation

Abstract

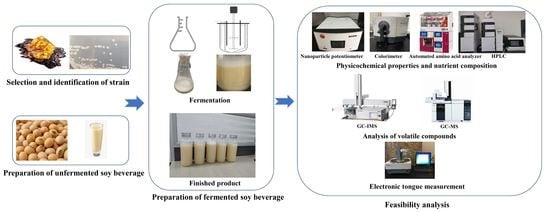

:1. Introduction

2. Materials and Methods

2.1. Preparation of Soy Beverages

2.2. Changes in Physicochemical Properties of Soy Beverages

2.3. Analysis of Nutrients

2.4. Analysis of Antioxidant Capacity

2.5. Electronic Tongue Measurement

2.6. Analysis of Volatile Compounds

2.6.1. Headspace Gas Chromatography-Ion Mobility Spectrometry (HS-GC-IMS) Analysis

2.6.2. Headspace Solid-Phase Microextraction Gas Chromatography–Mass Spectrometry (HS-SPME-GC-MS) Analysis

2.7. Analysis of Relative Odor Activity Value

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties and Nutrient Composition of the Soybean Beverage

3.1.1. Analysis of Physicochemical Properties of the Soybean Beverage

3.1.2. Analysis of Soy Beverage Nutrient Composition

3.2. Antioxidant Capacity of Soy Beverages

3.3. Volatile Fingerprints of Soybean Beverage by HS-GC-IMS

3.4. Volatile Fingerprints of Soybean Beverage by HS-SPME-GC-MS

3.5. Analysis of the Relative Odor Activity Values

3.6. Analysis of the Relative Odor Activity Values

3.7. Sensory Property of Soy Beverages

3.8. Electronic Tongue Measurement

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef] [PubMed]

- Aschemann-Witzel, J.; Gantriis, R.F.; Fraga, P.; Perez-Cueto, F.J. Plant-based food and protein trend from a business perspective: Markets, consumers, and the challenges and opportunities in the future. Crit. Rev. Food Sci. Nutr. 2020, 61, 3119–3128. [Google Scholar] [CrossRef]

- Freeland-Graves, J.H.; Nitzke, S. Position of the academy of nutrition and dietetics: Total diet approach to healthy eating. J. Acad. Nutr. Diet. 2013, 113, 307–317. [Google Scholar] [CrossRef] [PubMed]

- Paul, A.A.; Kumar, S.; Kumar, V.; Sharma, R. Milk Analog: Plant based alternatives to conventional milk, production, potential and health concerns. Crit. Rev. Food Sci. Nutr. 2020, 60, 3005–3023. [Google Scholar] [CrossRef]

- Yuan, S.; Chang, S.K.-C. Selected odor compounds in soymilk as affected by chemical composition and lipoxygenases in five soybean materials. J. Agric. Food Chem. 2007, 55, 426–431. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Zhang, Q.; Zhang, N.; Bak, K.H.; Soladoye, O.P.; Aluko, R.E.; Fu, Y.; Zhang, Y. Insights into formation, detection and removal of the beany flavor in soybean protein. Trends Food Sci. Technol. 2021, 112, 336–347. [Google Scholar] [CrossRef]

- Wang, J.; Kuang, H.; Zhang, Z.; Yang, Y.; Yan, L.; Zhang, M.; Song, S.; Guan, Y. Generation of seed lipoxygenase-free soybean using CRISPR-Cas9. Crop J. 2020, 8, 432–439. [Google Scholar] [CrossRef]

- Ma, L.; Li, B.; Han, F.; Yan, S.; Wang, L.; Sun, J. Evaluation of the chemical quality traits of soybean seeds, as related to sensory attributes of soymilk. Food Chem. 2015, 173, 694–701. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Liu, R.; Hu, Y.; Xu, B. Flavor profiles of soymilk processed with four different processing technologies and 26 soybean cultivars grown in China. Int. J. Food Prop. 2017, 20, S2887–S2898. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, K.; Ray, M.; Adak, A.; Halder, S.K.; Das, A.; Jana, A.; Parua, S.; Vágvölgyi, C.; Mohapatra, P.K.D.; Pati, B.R. Role of probiotic Lactobacillus fermentum KKL1 in the preparation of a rice based fermented beverage. Bioresour. Technol. 2015, 188, 161–168. [Google Scholar] [CrossRef]

- Nedele, A.-K.; Gross, S.; Rigling, M.; Zhang, Y. Reduction of green off-flavor compounds: Comparison of key odorants during fermentation of soy drink with Lycoperdon pyriforme. Food Chem. 2020, 334, 127591. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Wanhalinna, V.; Zannini, E.; Arendt, E.K. Foods for special dietary needs: Non-dairy plant-based milk substitutes and fermented dairy-type products. Crit. Rev. Food Sci. Nutr. 2016, 56, 339–349. [Google Scholar] [CrossRef]

- Cao, Z.-H.; Green-Johnson, J.M.; Buckley, N.D.; Lin, Q.-Y. Bioactivity of soy-based fermented foods: A review. Biotechnol. Adv. 2019, 37, 223–238. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.-Y.; Thakur, K.; Feng, J.-Y.; Cai, J.-S.; Zhang, J.-G.; Hu, F.; Wei, Z.-J. B-vitamin enriched fermented soymilk: A novel strategy for soy-based functional foods development. Trends Food Sci. Technol. 2020, 105, 339–349. [Google Scholar] [CrossRef]

- Shon, Y.-H.; Nam, K.-S. Inhibition of cytochrome P450 isozymes and ornithine decarboxylase activities by polysaccharides from soybeans fermented with Phellinus igniarius or Agrocybe cylindracea. Biotechnol. Lett. 2004, 26, 43–55. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, L. Changes in some components of soymilk during fermentation with the basidiomycete Ganoderma lucidum. Food Chem. 2009, 112, 1–5. [Google Scholar] [CrossRef]

- Du, X.; Zhang, Y.; Mu, H.; Lv, Z.; Yang, Y.; Zhang, J. Structural elucidation and antioxidant activity of a novel polysaccharide (TAPB1) from Tremella aurantialba. Food Hydrocoll. 2015, 43, 459–464. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhang, X.; Ma, M.; Long, T.; Xiao, C.; Zhang, J.; Liu, J.; Zhao, L. Immunoenhancing glucuronoxylomannan from Tremella aurantialba Bandoni et Zang and its low-molecular-weight fractions by radical depolymerization: Properties, structures and effects on macrophages. Carbohydr. Polym. 2020, 238, 116184. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.; Sun, Y.; Fu, H.; Zhang, S.; Chen, J.; Xu, X. Antioxidant and immunostimulatory activities of polysaccharides extracted from Tremella aurantialba mycelia. Mol. Med. Rep. 2016, 14, 4857–4864. [Google Scholar] [CrossRef]

- Zhang, Z.; Lian, B.; Huang, D.; Cui, F. Compare activities on regulating lipid-metabolism and reducing oxidative stress of diabetic rats of Tremella aurantialba broth’s extract (TBE) with its mycelia polysaccharides (TMP). J. Food Sci. 2009, 74, H15–H21. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.-J.; Deng, G.-F.; Xu, X.-R.; Wu, S.; Li, S.; Xia, E.-Q.; Li, F.; Chen, F.; Ling, W.-H.; Li, H.-B. Antioxidant capacities, phenolic compounds and polysaccharide contents of 49 edible macro-fungi. Food Funct. 2012, 3, 1195–1205. [Google Scholar] [CrossRef]

- Bandoni, R.J. Conjugation in Tremella mesenterica. Can. J. Bot. 1963, 41, 467–474. [Google Scholar] [CrossRef]

- Ingold, C. Basidiospore germination in Tremella foliacea. Trans. Br. Mycol. Soc. 1982, 79, 561–563. [Google Scholar] [CrossRef]

- Sun, T.; Wang, R.; Sun, D.; Li, S.; Xu, H.; Qiu, Y.; Lei, P.; Sun, L.; Xu, X.; Zhu, Y. High-efficiency production of Tremella aurantialba polysaccharide through basidiospore fermentation. Bioresour. Technol. 2020, 318, 124268. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, Y.; Jiang, H.; Yang, K.; Wang, S.; Wang, R.; Li, S.; Lei, P.; Xu, H.; Qiu, Y.; et al. Whole genome sequencing and annotation of naematelia aurantialba (Basidiomycota, Edible-Medicinal Fungi). J. Fungi 2022, 8, 6. [Google Scholar] [CrossRef]

- Dai, C.; Huang, X.; Lv, R.; Zhang, Z.; Sun, J.; Aheto, J.H. Analysis of volatile compounds of Tremella aurantialba fermentation via electronic nose and HS-SPME-GC-MS. J. Food Saf. 2018, 38, e12555. [Google Scholar] [CrossRef]

- Hassan, K.A.; Mujtaba, M.A. Antibacterial efficacy of garlic oil nano-emulsion. AIMS Agric. Food 2019, 4, 194–205. [Google Scholar] [CrossRef]

- Li, H.; Xu, H.; Li, S.; Feng, X.; Xu, H.; Ouyang, P. Effects of dissolved oxygen and shear stress on the synthesis and molecular weight of welan gum produced from Alcaligenes sp. CGMCC2428. Process Biochem. 2011, 46, 1172–1178. [Google Scholar] [CrossRef]

- Oliveira, L.C.; Schmiele, M.; Steel, C.J. Development of whole grain wheat flour extruded cereal and process impacts on color, expansion, and dry and bowl-life texture. LWT 2017, 75, 261–270. [Google Scholar] [CrossRef]

- Jiang, K.; Tang, B.; Wang, Q.; Xu, Z.; Sun, L.; Ma, J.; Li, S.; Xu, H.; Lei, P. The bio-processing of soybean dregs by solid state fermentation using a poly γ-glutamic acid producing strain and its effect as feed additive. Bioresour. Technol. 2019, 291, 121841. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, L.; Xiao, G.; Feng, J.; Zhou, H.; Huang, F. Changes in some nutritional components of soymilk during fermentation by the culinary and medicinal mushroom Grifola frondosa. LWT 2015, 62, 468–473. [Google Scholar] [CrossRef]

- Jaganath, I.B.; Crozier, A. Dietary flavonoids and phenolic compounds. Plant Phenolics Hum. Health Biochem. Nutr. Pharmacol. 2010, 1, 1–50. [Google Scholar]

- Gu, J.; Zhang, H.; Zhang, J.; Wen, C.; Ma, H.; Duan, Y.; He, Y. Preparation, characterization and bioactivity of polysaccharide fractions from Sagittaria sagittifolia L. Carbohydr. Polym. 2020, 229, 115355. [Google Scholar] [CrossRef]

- Su, Y.; Li, L. Structural characterization and antioxidant activity of polysaccharide from four auriculariales. Carbohydr. Polym. 2020, 229, 115407. [Google Scholar] [CrossRef]

- Phuhongsung, P.; Zhang, M.; Bhandari, B. 4D printing of products based on soy protein isolate via microwave heating for flavor development. Food Res. Int. 2020, 137, 109605. [Google Scholar] [CrossRef]

- Menis-Henrique, M.E.C. Methodologies to advance the understanding of flavor chemistry. Curr. Opin. Food Sci. 2020, 33, 131–135. [Google Scholar] [CrossRef]

- Li, M.; Du, H.; Lin, S. Flavor changes of tricholoma matsutake singer under different processing conditions by using HS-GC-IMS. Foods 2021, 10, 531. [Google Scholar] [CrossRef]

- Chen, Y.; Li, P.; Liao, L.; Qin, Y.; Jiang, L.; Liu, Y. Characteristic fingerprints and volatile flavor compound variations in Liuyang Douchi during fermentation via HS-GC-IMS and HS-SPME-GC-MS. Food Chem. 2021, 361, 130055. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, M.; Jin, B.; Yang, J.; Li, S. Performance evaluation and microbial community analysis of the biofilter for removing grease and volatile organic compounds in the kitchen exhaust fume. Bioresour. Technol. 2021, 319, 124132. [Google Scholar] [CrossRef] [PubMed]

- Tieman, D.; Zhu, G.; Resende, M.F.; Lin, T.; Nguyen, C.; Bies, D.; Rambla, J.L.; Beltran, K.S.O.; Taylor, M.; Zhang, B. A chemical genetic roadmap to improved tomato flavor. Science 2017, 355, 391–394. [Google Scholar] [CrossRef] [PubMed]

- Yi, C.; Li, Y.; Zhu, H.; Liu, Y.; Quan, K. Effect of Lactobacillus plantarum fermentation on the volatile flavors of mung beans. LWT 2021, 146, 111434. [Google Scholar] [CrossRef]

- Hothorn, T.; Zeileis, A. Partykit: A modular toolkit for recursive partytioning in R. J. Mach. Learn. Res. 2015, 16, 3905–3909. [Google Scholar]

- Shi, F.; Tian, X.; McClements, D.J.; Chang, Y.; Shen, J.; Xue, C. Influence of molecular weight of an anionic marine polysaccharide (sulfated fucan) on the stability and digestibility of multilayer emulsions: Establishment of structure-function relationships. Food Hydrocoll. 2021, 113, 106418. [Google Scholar] [CrossRef]

- Wei, Y.; Cai, Z.; Wu, M.; Guo, Y.; Tao, R.; Li, R.; Wang, P.; Ma, A.; Zhang, H. Comparative studies on the stabilization of pea protein dispersions by using various polysaccharides. Food Hydrocoll. 2020, 98, 105233. [Google Scholar] [CrossRef]

- Sun, W.; Zheng, Y.; Chen, S.; Chen, J.; Zhang, H.; Fang, H.; Ye, X.; Tian, J. Applications of polysaccharides as stabilizers in acidified milks. Food Rev. Int. 2021; 1–17, ahead-of-print. [Google Scholar] [CrossRef]

- Shao, P.; Feng, J.; Sun, P.; Xiang, N.; Lu, B.; Qiu, D. Recent advances in improving stability of food emulsion by plant polysaccharides. Food Res. Int. 2020, 137, 109376. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Monteagudo, S.I.; Kamat, S.; Patel, N.; Konuklar, G.; Rangavajla, N.; Balasubramaniam, V. Improvements in emulsion stability of dairy beverages treated by high pressure homogenization: A pilot-scale feasibility study. J. Food Eng. 2017, 193, 42–52. [Google Scholar] [CrossRef] [Green Version]

- Adediran, A.; Aforijiku, S. Carbohydrate fermentation profile and physiological studies of lactic acid bacteria from native raw cow milk. J. Adv. Microbiol. Res. 2020, 20, 83–93. [Google Scholar] [CrossRef]

- Niyigaba, T.; Liu, D.; Habimana, J.D.D. The extraction, functionalities and applications of plant polysaccharides in fermented foods: A review. Foods 2021, 10, 3004. [Google Scholar] [CrossRef]

- Lin, C.; Lin, Y.; Xiao, J.; Lan, Y.; Cao, Y.; Chen, Y. Effect of momordica saponin-and cyclocarya paliurus polysaccharide-enriched beverages on oxidative stress and fat accumulation in caenorhabditis elegans. J. Sci. Food Agric. 2021, 101, 3366–3375. [Google Scholar] [CrossRef]

- Lee, M.-H.; Kim, M.; Kim, M.; Kwak, J.H.; Chang, D.H.; Yu, W.K.; Lee, S.-H.; Lee, J.H. Consumption of dairy yogurt with the polysaccharide rhamnogalacturonan from the peel of the Korean citrus hallabong enhances immune function and attenuates the inflammatory response. Food Funct. 2016, 7, 2833–2839. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, W.; Chen, D.; Zhou, C.; Song, Y.; Zhang, Y.; Ni, Y.; Li, Q. Microbiological and physicochemical analysis of pumpkin juice fermentation by the basidiomycetous fungus Ganoderma lucidum. J. Food Sci. 2015, 80, C241–C251. [Google Scholar] [CrossRef]

- Islam, T.; Yu, X.; Xu, B. Phenolic profiles, antioxidant capacities and metal chelating ability of edible mushrooms commonly consumed in China. LWT 2016, 72, 423–431. [Google Scholar] [CrossRef]

- Puchau, B.; Zulet, M.A.; de Echávarri, A.G.; Hermsdorff, H.H.M.; Martínez, J.A. Dietary total antioxidant capacity: A novel indicator of diet quality in healthy young adults. J. Am. Coll. Nutr. 2009, 28, 648–656. [Google Scholar] [CrossRef] [Green Version]

- Du, X.; Zhang, J.; Lv, Z.; Ye, L.; Yang, Y.; Tang, Q. Chemical modification of an acidic polysaccharide (TAPA1) from Tremella aurantialba and potential biological activities. Food Chem. 2014, 143, 336–340. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Maecker, R.; Vyhmeister, E.; Meisen, S.; Martinez, A.R.; Kuklya, A.; Telgheder, U. Identification of terpenes and essential oils by means of static headspace gas chromatography-ion mobility spectrometry. Anal. Bioanal. Chem. 2017, 409, 6595–6603. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y., Jr. Effects of Micronization, Ethanol Washing, and Enzymatic Hydrolysis Processing Alone or in Combination on Trypsin Inhibitors, Lipoxygenase Activities and Selected “Beany” Flavour Related Compounds in Soybean Flour. Master’s Thesis, University of Manitoba, Winnipeg, MB, Canada, 2015. [Google Scholar]

- Vermeulen, N.; Czerny, M.; Gänzle, M.G.; Schieberle, P.; Vogel, R.F. Reduction of (E)-2-nonenal and (E, E)-2, 4-decadienal during sourdough fermentation. J. Cereal Sci. 2007, 45, 78–87. [Google Scholar] [CrossRef]

- El Youssef, C.; Bonnarme, P.; Fraud, S.; Péron, A.-C.; Helinck, S.; Landaud, S. Sensory improvement of a pea protein-based product using microbial co-cultures of lactic acid bacteria and yeasts. Foods 2020, 9, 349. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brunton, N.P.; Cronin, D.A.; Monahan, F.J.; Durcan, R. A comparison of solid-phase microextraction (SPME) fibres for measurement of hexanal and pentanal in cooked turkey. Food Chem. 2000, 68, 339–345. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, D.; Dong, Y.; Ju, H.; Wu, C.; Lin, S. Characteristic volatiles fingerprints and changes of volatile compounds in fresh and dried Tricholoma matsutake Singer by HS-GC-IMS and HS-SPME-GC–MS. J. Chromatogr. B 2018, 1099, 46–55. [Google Scholar] [CrossRef]

- Ames, J.M. Control of the Maillard reaction in food systems. Trends Food Sci. Technol. 1990, 1, 150–154. [Google Scholar] [CrossRef]

- Hiraide, M.; Miyazaki, Y.; Shibata, Y. The smell and odorous components of dried shiitake mushroom, Lentinula edodes I: Relationship between sensory evaluations and amounts of odorous components. J. Wood Sci. 2004, 50, 358–364. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, Y.; Huang, J.; Zeng, H.; Zheng, B. Effects of different drying methods on the product quality and volatile compounds of whole shiitake mushrooms. Food Chem. 2016, 197, 714–722. [Google Scholar] [CrossRef]

- Hidalgo, F.J.; Zamora, R. Formation of phenylacetic acid and benzaldehyde by degradation of phenylalanine in the presence of lipid hydroperoxides: New routes in the amino acid degradation pathways initiated by lipid oxidation products. Food Chem. X 2019, 2, 100037. [Google Scholar] [CrossRef]

- Mennella, J.A.; Bobowski, N.K.; Reed, D.R. The development of sweet taste: From biology to hedonics. Rev. Endocr. Metab. Disord. 2016, 17, 171–178. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Tao, Y.; Zhang, X.; Shao, S.; Han, Y.; Chu, D.-T.; Xie, G.; Ye, X. Metabolic profile of ginkgo kernel juice fermented with lactic aicd bacteria: A potential way to degrade ginkgolic acids and enrich terpene lactones and phenolics. Process Biochem. 2019, 76, 25–33. [Google Scholar] [CrossRef]

- De Filippis, F.; Troise, A.D.; Vitaglione, P.; Ercolini, D. Different temperatures select distinctive acetic acid bacteria species and promotes organic acids production during Kombucha tea fermentation. Food Microbiol. 2018, 73, 11–16. [Google Scholar] [CrossRef] [PubMed]

- Berenguer, M.; Vegara, S.; Barrajón, E.; Saura, D.; Valero, M.; Martí, N. Physicochemical characterization of pomegranate wines fermented with three different Saccharomyces cerevisiae yeast strains. Food Chem. 2016, 190, 848–855. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; Tang, F.; Zhao, X.; Guo, Z.; Zhang, Z.; Dong, Y.; Shan, C. Different lactic acid bacteria strains affecting the flavor profile of fermented jujube juice. J. Food Process. Preserv. 2019, 43, e14095. [Google Scholar] [CrossRef]

| Parameter | FSB | UFSB | |

|---|---|---|---|

| particle size distribution (nm) | D50 | 926 ± 32 A | 198 ± 20 B |

| Zeta potential (mv) | −32.5 ± 2.10 A | −12.4 ± 2.40 B | |

| pH | 4.00 ± 0.03 A | 6.50 ± 0.02 B | |

| appearance | milk white, faint yellow | milk white, faint yellow | |

| viscosity (mPa·s) | 804 ± 5.6 A | 3.40 ± 0.5 B | |

| L*a*b color space | L* | 78.5 ± 0.58 A | 77.6 ± 1.05 A |

| a* | −1.41 ± 0.02 A | −1.21 ± 0.13 B | |

| b* | 8.32 ± 0.09 A | 7.13 ± 0.09 B | |

| protein (g/kg) | 17.0 ± 1.3 A | 28.0 ± 1.5 B | |

| fatty acid (g/kg) | 20.0 ± 0.43 A | 21.2 ± 6.4 A | |

| total sugar (g/L) | 13.1 ± 0.21 A | 2.94 ± 0.18 B | |

| reducing sugar (g/L) | 4.28 ± 0.41 A | 1.03 ± 0.28 B | |

| glucose (g/L) | 3.12 ± 0.12 A | 0.17 ± 0.05 B | |

| dietary fiber (%) | 4.20 ± 0.50 A | 4.60 ± 0.80 A | |

| total acid (g/kg) | 5.40 ± 0.06 A | 3.40 ± 0.04 B | |

| total amino acids (μg/mL) | 32.8 ± 0.008 A | 32.0 ± 0.011 B | |

| total polyphenol (mg/L) | 2313 ± 6.48 A | 1285 ± 8.24 B | |

| total flavonoid (mg/L) | 1080 ± 3.59 A | 603 ± 2.65 B | |

| NAPS (g/L) | 8.68 ± 0.12 A | 0 B |

| Count | Compounds | RI | Rt (s) | Dt (a.u.) | Odor Description | Relative Amount (%) | |

|---|---|---|---|---|---|---|---|

| UFSB | FSB | ||||||

| Aldehydes | |||||||

| 1 | 2,4-Decadienal | 1285 | 1352 | 1.42 | fatty green | 1.20 ± 0.011 A | 1.03 ± 0.054 B |

| 2 | (E)-2-Decenal (M) | 1233 | 1148 | 1.48 | fatty, fish, hay | 0.520 ± 0.052 A | 0.530 ± 0.025 A |

| 3 | (E)-2-Nonenal (D) | 1147 | 879 | 1.41 | fatty green | 0.280 ± 0.052 A | 0.330 ± 0.030 A |

| 4 | n-Nonanal (M) | 1106 | 772 | 1.48 | rose fresh fruity | 2.33 ± 0.080 A | 1.76 ± 0.057 B |

| 5 | n-Nonanal (D) | 1106 | 772 | 1.94 | 0.310 ± 0.035 A | 0.280 ± 0.016 A | |

| 6 | (E)-2-Octenal (M) | 1072 | 695 | 1.34 | fatty green | 2.85 ± 0.430 A | 4.44 ± 0.239 B |

| 7 | (E)-2-Octenal (D) | 1072 | 694 | 1.81 | 0.480 ± 0.023 A | 1.93 ± 0.205 B | |

| 8 | (E, E)-2,4-heptadienal (M) | 1036 | 621 | 1.19 | fatty green | 0.620 ± 0.036 A | 1.06 ± 0.095 B |

| 9 | (E, E)-2,4-heptadienal (D) | 1035 | 619 | 1.61 | 0.090 ± 0.002 A | 0.370 ± 0.032 B | |

| 10 | 2,4-Heptadienal | 1019 | 590 | 1.20 | green fruity | 0.330 ± 0.092 A | 0.380 ± 0.124 A |

| 11 | Octanal (M) | 1015 | 581 | 1.42 | green fatty | 1.20 ± 0.044 A | 1.77 ± 0.029 B |

| 12 | Octanal (D) | 1014 | 580 | 1.82 | 0.210 ± 0.021 A | 0.650 ± 0.037 B | |

| 18 | (E)-2-Heptenal (M) | 964 | 485 | 1.26 | green fatty | 3.59 ± 0.245 A | 4.37 ± 0.068 B |

| 19 | (E)-2-Heptenal (D) | 964 | 484 | 1.66 | 2.34 ± 0.088 A | 9.72 ± 0.031 B | |

| 20 | Benzaldehyde | 981 | 518 | 1.15 | bitter almond, sweet cherry | 0.900 ± 0.159 A | 0.650 ± 0.128 A |

| 21 | Heptanal (M) | 905 | 387 | 1.36 | fatty green | 1.45 ± 0.118 A | 1.33 ± 0.020 B |

| 22 | Heptanal (D) | 904 | 385 | 1.69 | 0.580 ± 0.023 A | 1.27 ± 0.035 B | |

| 27 | (E)-2-hexenal (M) | 858 | 325 | 1.18 | green fatty | 3.55 ± 0.057 A | 1.59 ± 0.037 B |

| 28 | (E)-2-hexenal (D) | 855 | 322 | 1.51 | 3.58 ± 0.217 A | 2.88 ± 0.062 B | |

| 29 | 2-Furfural (M) | 833 | 298 | 1.09 | sweet woody almond | 0.260 ± 0.028 A | 0.260 ± 0.100 A |

| 30 | 2-Furfural (D) | 831 | 295 | 1.33 | 0.040 ± 0.0003 A | 0.130 ± 0.035 B | |

| 31 | hexanal | 796 | 260 | 1.55 | green fatty | 17.3 ± 0.708 A | 7.38 ± 0.039 B |

| 32 | (E)-2-pentenal | 756 | 224 | 1.36 | green fruity | 1.27 ± 0.095 A | 1.05 ± 0.002 B |

| 33 | pentanal (M) | 699 | 180 | 1.19 | fruity berry | 1.49 ± 0.074 A | 0.620 ± 0.030 B |

| 34 | pentanal (D) | 701 | 182 | 1.43 | 0.730 ± 0.02 A | 1.70 ± 0.109 B | |

| 38 | butanal | 605 | 135 | 1.29 | pungent cocoa green | 0.890 ± 0.039 A | 0.900 ± 0.021 A |

| 54 | benzeneacetaldehyde | 1071 | 693 | 1.26 | green sweet cocoa | 0.230 ± 0.004 A | 0.260 ± 0.018 A |

| 13 | 1-Octen-3-ol | 998 | 552 | 1.16 | mushroom | 2.06 ± 0.072 A | 3.48 ± 0.082 B |

| 25 | 1-hexanol (M) | 886 | 359 | 1.32 | fruity alcoholic sweet green | 2.55 ± 0.032 A | 0.500 ± 0.065 B |

| 26 | 1-hexanol (D) | 884 | 357 | 1.64 | 0.600 ± 0.094 A | 0.080 ± 0.016 B | |

| 35 | 2-Methyl-1-propanol | 632 | 146 | 1.37 | ethereal winey cortex | 0.250 ± 0.012 A | 5.49 ± 0.124 B |

| 40 | ethanol (M) | 483 | 94.5 | 1.05 | strong alcoholic | 10.5 ± 0.367 A | 5.51 ± 0.062 B |

| 41 | ethanol (D) | 486 | 95.2 | 1.14 | 1.99 ± 0.251 A | 1.74 ± 0.080 A | |

| 50 | 1-butanol (M) | 668 | 163 | 1.17 | sweet balsam whiskey | 0.430 ± 0.042 A | 1.10 ± 0.023 B |

| 51 | 1-butanol (D) | 667 | 162 | 1.39 | 0.040 ± 0.004 A | 1.53 ± 0.017 B | |

| 52 | 3-Methyl-1-butanol (M) | 744 | 214 | 1.24 | alcoholic fruity | 1.35 ± 0.059 A | 0.990 ± 0.030 B |

| 53 | 3-Methyl-1-butanol (D) | 745 | 215 | 1.50 | 0.410 ± 0.023 A | 7.70 ± 0.062 B | |

| 43 | 1-penten-3-ol | 692 | 175 | 1.34 | fruity green | 0.450 ± 0.007 A | 0.900 ± 0.004 B |

| 44 | 1-Pentanol | 777 | 243 | 1.51 | sweet balsam | 0.650 ± 0.044 A | 0.660 ± 0.011 A |

| 14 | 2-Pentylfuran | 999 | 553 | 1.25 | green beany vegetable | 5.28 ± 0.040 A | 1.09 ± 0.132 B |

| 15 | 3-Octanone | 993 | 543 | 1.31 | sweet mushroom | 0.170 ± 0.020 A | 0.200 ± 0.002 A |

| 16 | 1-Octen-3-one (M) | 987 | 531 | 1.27 | mushroom | 0.150 ± 0.007 A | 0.370 ± 0.040 B |

| 17 | 1-Octen-3-one (D) | 986 | 528 | 1.68 | 0.120 ± 0.076 A | 0.590 ± 0.050 B | |

| 23 | 2-heptanone (M) | 895 | 372 | 1.26 | fruity sweet | 0.750 ± 0.017 A | 0.910 ± 0.008 B |

| 24 | 2-heptanone (D) | 896 | 373 | 1.63 | 1.14 ± 0.106 A | 1.79 ± 0.037 B | |

| 39 | 2-Butanone | 592 | 130 | 1.24 | fruity | 0.200 ± 0.042 A | 0.330 ± 0.014 B |

| 42 | Acetone | 512 | 103 | 1.13 | apple pear | 7.75 ± 0.893 A | 5.01 ± 0.168 B |

| 43 | 1-penten-3-one | 689 | 173 | 1.08 | pungent peppery onion | 0.250 ± 0.039 A | 0.100 ± 0.003 B |

| 47 | 2,3-butanedione | 591 | 130 | 1.17 | sweet creamy | 0.210 ± 0.049 A | 0.270 ± 0.008 A |

| 48 | 2-pentanone (M) | 687 | 172 | 1.12 | sweet fruity | 0.080 ± 0.006 A | 0.110 ± 0.001 B |

| 49 | 2-pentanone (D) | 691 | 175 | 1.36 | 0.480 ± 0.002 A | 0.820 ± 0.011 B | |

| 36 | ethyl acetate (M) | 606 | 136 | 1.10 | fruity sweet green | 3.20 ± 0.154 A | 0.770 ± 0.022 B |

| 37 | ethyl acetate (D) | 612 | 138 | 1.33 | 5.60 ± 0.213 A | 3.02 ± 0.054 B | |

| 45 | ethyl propanoate | 710 | 188 | 1.15 | sweet fruity | 0.120 ± 0.014 A | 0.050 ± 0.021 B |

| No. | RT | Compounds | RI | NIST_RI | Odor Description | Peak Intensity | |

|---|---|---|---|---|---|---|---|

| UFSB | FSB | ||||||

| Heterocyclic compound | |||||||

| 1 | 3.06 | Oxetane, 3-(1-methylethyl)- | 718.12 | 664 | - | ND | 1,621,445 ± 196,936 |

| 10 | 8.96 | 2-pentylfuran | 987.89 | 993 | green earthy beany | 6,498,125 ± 534,065 a | 712,224 ± 128,211 b |

| 14 | 10.8 | (E)-2-(1-pentenyl)-furan | 1051.11 | 1048 | roasted | 186,144 ± 31,660 a | 125,155 ± 7559 b |

| 22 | 13.5 | Thiophene, 2-pentyl- | 1143.43 | 1090 | fruit, sweet | ND | 628,882 ± 20,192 |

| 26 | 14.78 | Thiophene, 2-hexyl- | 1187.4 | 1277 | floral fruity gassy | ND | 251,010 ± 32,886 |

| 36 | 17.91 | 1-Pentanone, 1-(2-furanyl)- | 1299.53 | 1176 | sweet caramel | 184,692 ± 27,820 a | 557,517 ± 87,545 b |

| Alcohol | |||||||

| 8 | 8.67 | 1-Octen-3-ol | 977.65 | 982 | mushroom | 984,538 ± 121,842 a | 3,477,799 ± 1,627,475 b |

| Aldehyde | |||||||

| 7 | 8.11 | Benzaldehyde | 957.34 | 960 | bitter almond, sweet cherry | 1,346,850 ± 149,896 a | 16,021,725 ± 803,440 b |

| 11 | 9.58 | (E, E)-2,4-heptadienal | 1009.64 | 1011 | fatty green | 458,123 ± 83,423 a | 292,071 ± 65,426 b |

| 15 | 10.95 | 2-octenal | 1056.04 | 1060 | fatty green herbal | 510,065 ± 53,147 a | 150,411 ± 12,114 b |

| 24 | 14.01 | Benzaldehyde, 4-ethyl- | 1160.8 | 1171 | bitter almond | 316,945 ± 43,024 a | 72,065 ± 1910 b |

| 39 | 18.34 | 2,4-Decadienal, (E,E)- | 1315.79 | 1317 | fatty green | 1,186,788 ± 64,214 a | 57,711 ± 9133 b |

| Ester | |||||||

| 27 | 14.85 | Methyl salicylate | 1189.63 | 1234 | wintergreen mint | 134,718 ± 47,046 a | 80,900 ± 8110 b |

| 28 | 15 | Octanoic acid, ethyl ester | 1194.8 | 1198 | sweet fruity | 4,720,782 ± 406,796 a | 7,761,488 ± 1,037,991 b |

| 40 | 19.39 | 2(3H)-Furanone, dihydro-5-pentyl- | 1355.43 | 1366 | coconut creamy sweet buttery | 120,699 ± 23,131 a | 5,154,713 ± 83,079 b |

| CAS. | Compounds | Odor Thresholds (mg/kg) | ROAV | Odor Description | |||

|---|---|---|---|---|---|---|---|

| GC-IMS | GC-MS | ||||||

| UFSB | FSB | UFSB | FSB | ||||

| 100-52-7 | Benzaldehyde | 0.3 | <1 | <1 | - | - | bitter almond, sweet cherry |

| 110-62-3 | Pentanal | 0.012 | 1.0 | <1 | - | - | fruity berry |

| 111-71-7 | Heptanal | 0.01 | 1.2 | <1 | - | - | fatty green |

| 122-78-1 | Benzeneacetaldehyde | 0.004 | <1 | <1 | - | - | green sweet cocoa |

| 123-72-8 | Butanal | 0.00526 | 1.4 | <1 | - | - | pungent cocoa green |

| 124-13-0 | Octanal | 0.0001 | 100.0 | 75.4 | - | - | green fatty |

| 124-19-6 | n-Nonanal | 0.0035 | 5.5 | 2.2 | - | - | rose fresh fruity |

| 1576-87-0 | (E)-2-Pentenal | 0.98 | <1 | <1 | - | - | green fruity |

| 18829-55-5 | (E)-2-Heptenal | 0.013 | 2.3 | 1.4 | - | - | green fatty |

| 18829-56-6 | (E)-2-Nonenal | 0.000065 | 35.9 | 21.9 | - | - | fatty green |

| 2363-88-4 | 2,4-Decadienal | 0.0003 | 33.3 | 14.7 | - | - | fatty green |

| 2363-89-5 | 2-octenal | 0.0002 | - | - | 6.4 | 32.6 | fatty green herbal |

| 4313-03-5 | (E, E)-2,4-heptadienal | 0.0154 | <1 | <1 | <1 | <1 | fatty green |

| 4748-78-1 | Benzaldehyde, 4-ethyl- | 0.12323 | - | - | <1 | <1 | bitter almond |

| 5910-85-0 | 2,4-Heptadienal | 0.15 | <1 | <1 | - | - | green fruity |

| 66-25-1 | Hexanal | 0.0045 | 31.9 | 7.0 | - | - | green fatty |

| 6728-26-3 | (E)-2-Hexenal | 0.04 | <1 | <1 | - | - | green fatty |

| 3913-81-3 | (E)-2-Decenal | 0.25 | <1 | <1 | - | - | fatty, fish, hay |

| 25152-84-5 | 2,4-Decadienal, (E,E)- | 0.000027 | - | - | 100.0 | 84.9 | fatty green |

| 2548-87-0 | (E)-2-Octenal | 0.004 | 5.9 | 4.7 | - | - | fatty green |

| 1998/1/1 | 2-Furfural | 9.562 | <1 | <1 | - | - | sweet woody almond |

| 104-61-0 | 2(3H)-Furanone, dihydro-5-pentyl- | 0.0097 | - | - | <1 | 23.4 | coconut creamy sweet buttery |

| 105-37-3 | Ethyl propanoate | 0.01 | <1 | <1 | - | - | sweet fruity |

| 106-32-1 | Octanoic acid, ethyl ester | 0.0193 | - | - | <1 | 17.6 | sweet fruity |

| 119-36-8 | Methyl salicylate | 0.04 | - | - | <1 | <1 | wintergreen mint |

| 104-62-1 | Formic acid, 2-phenylethyl ester | 0.27 | - | - | <1 | <1 | rose green hyacinth watercress herbal |

| 141-78-6 | Ethyl acetate | 7.5 | <1 | <1 | - | - | fruity sweet green |

| 106-68-3 | 3-Octanone | 0.0214 | <1 | <1 | - | - | sweet mushroom |

| 107-87-9 | 2-Pentanone | 153 | <1 | <1 | - | - | sweet fruity |

| 110-43-0 | 2-Heptanone | 0.14 | <1 | <1 | - | - | fruity sweet |

| 1629-58-9 | 1-Penten-3-one | 0.0013 | 1.6 | <1 | - | - | pungent peppery onion |

| 431-03-8 | 2,3-Butanedione | 0.001 | 1.7 | 1.1 | - | - | sweet creamy |

| 4312-99-6 | 1-Octen-3-one(M) | 0.000016 | 78.1 | 100 | - | - | mushroom |

| 67-64-1 | Acetone | 100 | <1 | <1 | - | - | apple pear |

| 78-93-3 | 2-Butanone | 35.4002 | <1 | <1 | - | - | fruity |

| 111-27-3 | 1-Hexanol | 0.2 | <1 | <1 | <1 | <1 | fruity alcoholic sweet green |

| 123-51-3 | 3-Methyl-1-butanol | 0.22 | <1 | <1 | - | - | alcoholic fruity |

| 3391-86-4 | 1-Octen-3-ol | 0.0015 | 11.4 | 9.9 | <1 | 100 | mushroom |

| 515-00-4 | Bicyclo[3.1.1]hept-2-ene-2-methanol, 6,6-dimethyl- | 0.007 | - | - | <1 | <1 | woody green |

| 616-25-1 | 1-Penten-3-ol | 0.3581 | <1 | <1 | - | - | fruity green |

| 626-93-7 | 2-Hexanol | 6.7 | - | - | <1 | <1 | fruity sweet green |

| 64-17-5 | Ethanol | 2900 | <1 | <1 | - | - | strong alcoholic |

| 71-36-3 | 1-Butanol | 0.5 | <1 | <1 | - | - | sweet balsam whiskey |

| 71-41-0 | 1-Pentanol | 0.3581 | <1 | <1 | - | - | sweet balsam |

| 78-83-1 | 2-Methyl-1-propanol | 8 | <1 | <1 | - | - | ethereal winey cortex |

| 3777-69-3 | 2-Pentylfuran | 0.0058 | 7.6 | <1 | 2.8 | 5.5 | green beany vegetable |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, T.; Jiang, H.; Yang, K.; Li, X.; Wang, S.; Yao, H.; Wang, R.; Li, S.; Gu, Y.; Lei, P.; et al. Nutritional Function and Flavor Evaluation of a New Soybean Beverage Based on Naematelia aurantialba Fermentation. Foods 2022, 11, 272. https://doi.org/10.3390/foods11030272

Sun T, Jiang H, Yang K, Li X, Wang S, Yao H, Wang R, Li S, Gu Y, Lei P, et al. Nutritional Function and Flavor Evaluation of a New Soybean Beverage Based on Naematelia aurantialba Fermentation. Foods. 2022; 11(3):272. https://doi.org/10.3390/foods11030272

Chicago/Turabian StyleSun, Tao, Hao Jiang, Kai Yang, Xingkai Li, Shiyu Wang, Haoyu Yao, Rui Wang, Sha Li, Yian Gu, Peng Lei, and et al. 2022. "Nutritional Function and Flavor Evaluation of a New Soybean Beverage Based on Naematelia aurantialba Fermentation" Foods 11, no. 3: 272. https://doi.org/10.3390/foods11030272