1. Introduction

The global biscuits market is segmented by category into sweet biscuits and crackers and savoury biscuits. The global market was evaluated at USD 106.232 billion in 2020, and it is estimated to reach a compound annual growth rate of 4.97% during the period 2021–2026 [

1]. Sweet biscuits include plain biscuits, cookies, sandwich biscuits, chocolate-coated biscuits and other sweet biscuits. Each country and region produces its own types of sweet biscuits, with their differences depending on the local availability of the ingredients used in their recipes.

Cantuccini are traditional sweet biscuits originally from Tuscany (Italy) but now found throughout Italy. They are dry biscuits that are filled with almonds, which are made by cutting slices of dough while still hot, before being the dough slices to the oven for a few minutes to reach their final consistency.

Cantuccini have a European Protected Geographical Indication (PGI) [

2], which is attributed to products for which at least one of the stages of production, processing or preparation takes place in the region. The Italian product specification [

3] includes the following requirements: the use of almonds (at least 17%), crystalline or granulated sugar (20–40%) and cow’s butter (at quantities greater than 1.5%). However, if the producer does not apply the PGI certification to their Cantuccini, the recipe can be modified.

Lipids in bakery products play a fundamental role from both technical and edible point of views. Lipids used in the bakery industry are oils or fats, which are respectively liquid or solid or semi-solid at room temperature. The differences in physical consistency are due to the triacylglycerol composition and in particular to the fatty acids and their melting points. Saturated fatty acids are solid or semi-solid at room temperature, whereas unsaturated fatty acids are liquid. The shorter the chain length and the lower the number of double bonds, the lower the melting point. Fats are easier to transport and less susceptible to oxidation than oils. At the same time, saturated fatty acids (SFAs), which are widely present in fats, and cholesterol (widely present in animal fats) are considered responsible for cardiovascular diseases [

4]. The lipid content in biscuits usually ranges from 10 to 20% of the total weight, and consequently a daily portion of 50 g (i.e., 3–5 biscuits) contains 5–10 g of lipids. In light of the above, it is essential to reduce the amounts of saturated fats and animal fats in the human diet. In addition, it is well known that nowadays there is a high demand for high nutritional value foods. Extra virgin olive oil (EVOO) contains less than 0.5% cholesterol out of the total sterol content [

5], 14–22% SFAs out of the total fatty acid content [

6,

7], a good oleic/linoleic acid ratio [

8] and antioxidants such as phenols and tocopherols [

9]. EVOO is one of the most common foods in the Mediterranean diet, and in 2018 Calabria was the second Italian region for olive oil production (46,964 tons) out of the total Italian production of 264,101 tons [

10].

From an edible point of view, the fat in biscuits is important for its nutritional value, for its tendency for oxidation and for the consequential radical formation. From a technical point of view, when fats are mixed with flour that has not yet been hydrated, particles of fats wrap around the particles of flour, reducing the dough’s elasticity [

11]. High elasticity is not advisable in biscuit dough because it causes the dough to shrink after lamination [

12]. In studies on beaten pastry dough, fat was found to influence both the stability and size of air bubbles before baking and at initial baking stages [

13,

14,

15]. In the initial baking process, fat prevents the coalescence of bubbles that are destroyed with the increase in baking temperature. The longer the bubbles remain in a dough, the larger the final volume of the baked products [

16]. Fats can help leaven a product due to the incorporation of air [

17].

In addition, fat has a lubricating action, which prevents the product from sticking to baking trays and causes the melting sensation when a biscuit is eaten.

To date in the literature, there have been no studies on the physical–chemical–sensory evolution of Cantuccini during storage. Scarce information exists on biscuits [

18] and cookies [

19] incorporated with EVOO as a total or partial shortening substitution.

The aim of this paper was to study the shelf-life of Cantuccini biscuits produced using the original recipe containing only cow’s butter and margarine, as well as the effects of partial shortening replacement with extra virgin olive oil over one year’s storage.

2. Materials and Methods

2.1. Cantuccini Packaging

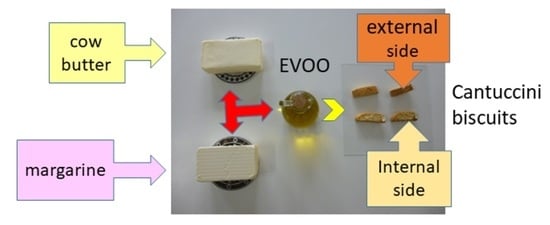

Each package contained 35 biscuits weighing 200 g in total. For this experiment, biscuits were made using two recipes, which differed only in the type of fats or oils used. In the first (original) recipe, 7% fat was used (out of the total ingredients), at a ratio of 50% cow’s butter to 50% margarine. In the second (modified) recipe, 11% fat was used (out of the total ingredients), at a ratio of 30% cow’s butter to 70% extra virgin olive oil. This modified recipe was applied after testing the consistency and pleasantness of the Cantuccini. This ratio was applied so as not to distort the type of product and to provide the right compromise between tradition and innovation. The shortening reduction led to the need for an increase in the EVOO to maintain the original characteristics of the biscuits as much as possible. The technical data on the packaging were: duplex laminate; width: 410 mm; cut off: 285 mm; thickness: 74 μm; material identification code: PP 5; core diameter: 76 mm; outer diameter: 280 mm; unit weight: 68.9 g/m2; weight per pack: 8.05 g; heat sealing: both sides; oxygen barrier: very low >150; water vapour barrier: high (0.50–3.00); thermal treatment: none; composition: outer layer: COEXPP 30 μm; inner layer i.e., side in contact: COEXPP BL MAS 40 μm.

2.2. Cantuccini Preparation

The original recipe (OR) for Cantuccini biscuits contained 50% cow’s butter and 50% margarine. The modified recipe (MR) contained 30% cow’s butter and 70% extra virgin olive oil. Sugar, margarine, butter and honey were placed in a mixer. The ingredients were mixed until smooth. At this point the eggs, baking powder and flour (00 type) were added. Finally, when the mixture was homogeneous, the whole almonds were added. The dough was kneaded until it was homogeneous, without lumps and of a good consistency. The dough was left for twenty minutes. At this point, pieces of dough weighing 2 kg were passed under the leveler before being cut into small pieces, which were placed in the baking pans and baked at 200 °C for 20 min. The Cantuccini were removed from the oven and cooled to room temperature before packaging.

2.3. Biscuits Analyses

2.3.1. Texture Analysis

The hardness and fracturability of Cantuccini were determined using a texture analyzer (TA-XT2 Texture Analyzer, Stable Microsystems, Surrey, UK) equipped with a 25 kg load cell and a three-point bending rig (HDP/3PB). The parameters of hardness and fracturability were calculated as absolute values.

2.3.2. Colour—Instrumental Determination

Colour was determined using a colourimeter (Konica Minolta, model CM-A177) measuring L*, Chroma a* (a*) and Chroma b* (b*). If a colour is expressed in CIELAB, L* denotes lightness, a* defines the red/green value and b* the yellow/blue value. In this experiment, colour determination was conducted on both the external (the top of the biscuit) and internal sides (the side of the cut) of Cantuccini biscuits.

2.3.3. Water Activity (aw)

Aw is the ratio between the vapour pressure of a food system when it is not influenced by the environment (Pv) and the saturation vapour pressure of distilled water (Pa) in the same conditions [

20]. The aw determination was made at 20 °C by means of an Aqualab Model series 3TE Decagon Devices, Inc. (Pullman, Washington, WA, USA).

2.3.4. Relative Humidity (RH)

The RH (moisture content) was determined according to the method proposed by [

21], with heating at 103 °C ± 2 °C until constant weight.

2.3.5. Sensory Analysis

A 20-member sensory panel was involved (ten men and ten women aged 19 to 60 years). The panelists were trained to consider six attributes, namely colour, appearance, taste, flavour, texture and overall acceptability. Each attribute was evaluated on a 10-point hedonic scale (1–10) ranging from 10 (like extremely) to 1 (dislike extremely) for each characteristic and with 5 representing minimum quality. The test was conducted in a sensory laboratory with individual booths and Cantuccini biscuits were given in white plates in a room prepared as suggested by ‘Sensory Analysis—General Guidance for the Design of Test Rooms’ [

22]. The panelists conducted their evaluation in triplicate with a 2 day time lapse at 24 °C room temperature, with samples tempered for 60 min. No odour and minimal noise were perceived by the panelists. The colour of the walls and furnishings in the testing area was white. Only one assessor was present, managing a group of five panelists in a 30 min session.

Colour expressed the degree of toasting. Appearance defined the shape of the biscuit. Taste and flavour defined the freshness of Cantuccini. Texture defined the crunchiness and overall acceptability was the sum of the previous five attributes. The sensory analysis was conducted prior to inform the panelists with regard to the Cantuccini composition.

2.4. Analysis of Fat

2.4.1. Fat Extraction

Firstly, the almonds were separated from the biscuits and then reduced to a powder. Secondly, the lipid fraction was extracted from the powder of biscuits using a Soxhlet apparatus with

n-hexane as the extracting solvent. Lastly, the solvent was evaporated using a Rotavapour apparatus under vacuum at 25 °C and fat was stored until analyses [

23].

2.4.2. Determination of Colour

A Minolta Chroma Meter CR-400 instrument and a Minolta transparent (base and side) special glass container (5.0 cm, 6.0 cm high) with a cylindrical shape was used. One centimetre of fat was added to the glass container and the colour was determined. A further 1 cm was added and the colour was determined again. These two measurements were conducted in triplicate. The CIELab scale was used:

L* (brigthness) ranges between 0 (black) and 100 (white);

a* ranges between −90 (green) and +90 (red);

b* ranges between −90 (blue) and +90 (yellow). The chroma was calculated using the formula discussed by Pathare et al. [

24].

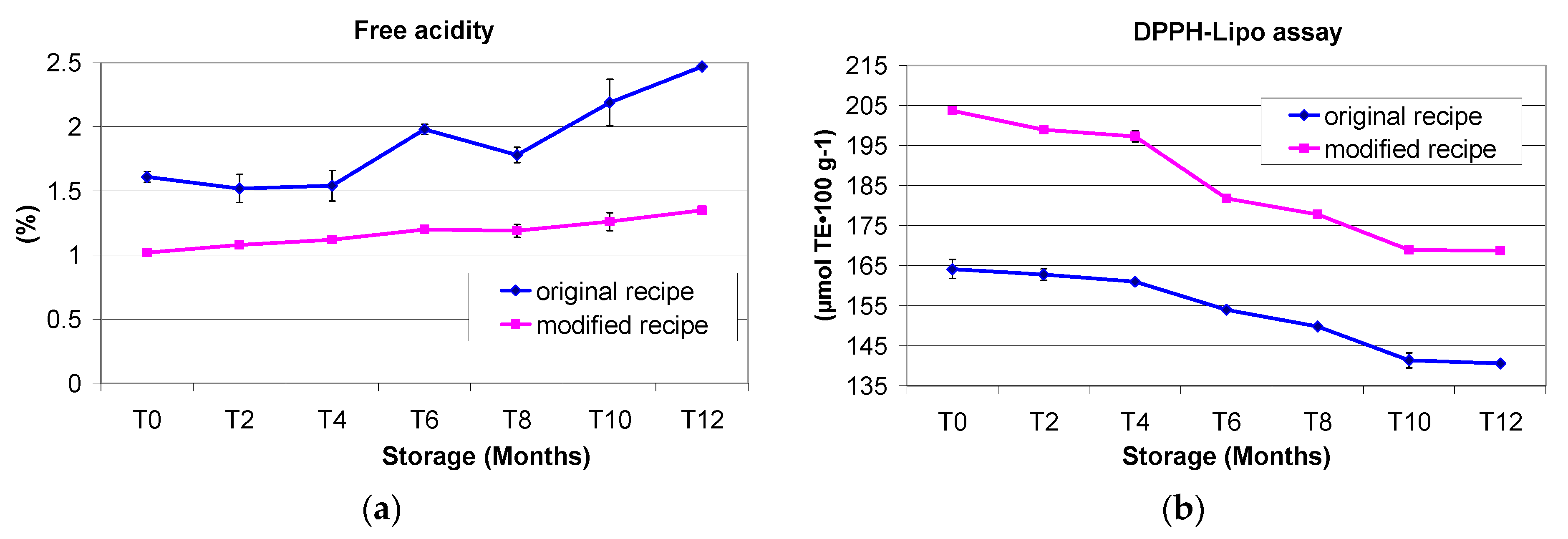

2.4.3. Free Acidity (FA)

A 1 g aliquot of the lipidic fraction was dissolved in a 50 mL ethanol/diethyl ether (1:1), after which titration was conducted with a 0.1 N NaOH solution. The results were expressed as g oleic acid/100 g (Consleg, Annex II) [

5].

2.4.4. Spectrophotometric Indexes in the UV

The lipid extract was dissolved in iso-octane and a 1% (

w/

v) and the solution was read at 232 nm, 266 nm, 268 nm and 274 nm, in a double-ray Agilent spectrophotometer model 89090A (Santa Clara, CA, USA) (Consleg, Annex IX) [

5].

2.4.5. Antioxidant Activity (DPPH Assay on the Extracted Fat)

The DPPH assay of the extracted fat was performed without extracting antioxidant compounds from the fat. It was conducted in an UV/Vis Spectrometer λ

2 from Perkin Elmer (Waltham, MA, USA) using the method proposed by Kalantzakis et al. [

25], modified as follows. The fat was diluted with ethyl acetate (1/10,

v/

v). Then, 0.25 mL of diluted oil was added to 2.25 mL of a 10

−4 M DPPH● solution, which was previously prepared with ethyl acetate. Thus, the absorbance of the mixture was immediately measured at 515 nm (abs t0) and after 30 min of shaking and incubation in the dark (abs t30). The % of inhibition was calculated as follows: ((abs t0 − abs t30)/abs t0)) * 100. The radical scavenging activity (% of inhibition) was compared with a Trolox calibration curve and results were then expressed as TEAC values (μmol TE∙100 g

−1 of fat extracted).

2.4.6. FAMEs

An aliquot of the lipid fraction was methylated using the annex XB method A [

5]. Gas chromatographic analysis of FAMEs was conducted as described in a previous work [

26] and the results are expressed as % m/m.

2.5. Statistical Analysis

All analyses were carried out on three batches of Cantuccini biscuits, each one produced on a different day. For each batch, two replicates were conducted, each one from a different package. In brief, each result was the mean of six analyses. Means, standard deviations, R2 values and r values were obtained using Excel 2010 software. The t-test was calculated at the 95% confidence interval. Analysis of variance (one-way ANOVA) and Tukey’s tests were performed to determine the significance of differences. A p-value < 0.05 was set as the significance level using SPSS software version 17.0.

4. Conclusions

The complete replacement of margarine and the partial replacement of butter with extra virgin olive oil in the original Cantuccini biscuit recipe led to improvements in water activity, relative humidity, hardness, K270 values, DPPH assay results and acidity, whereas worse results were found with regard to K232 and ΔK values. This means that the use of extra virgin olive oil in the recipe, in many cases studied in this work, improved the physical and chemical properties of biscuits but worsened the parameters related to the secondary products of oxidation (K270). The Cantuccini biscuit colour was instrumentally evaluated and found to be strictly related to both fats and EVOO and to the length of storage. The fatty acid methyl ester compositions varied dramatically and the use of EVOO increased the unsaturated fatty acid content, in particular monounsaturated fatty acids, with oleic acid being the prevailing compound. The sensory analysis showed an expected worsening of the biscuit quality but good acceptability of Cantuccini prepared with 70% EVOO. Extra virgin olive oil can be applied to prepare functional products that maintain the physical–chemical–sensory properties of Cantuccini.