Physical Chemical and Textural Characteristics and Sensory Evaluation of Cookies Formulated with Date Seed Powder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

2.2.1. Date Seed Powder

2.2.2. Cookies Preparation

2.3. Proximate Composition

2.4. Physical Analysis

2.4.1. Colour Analysis

2.4.2. Texture Analysis

2.4.3. Sensory Evaluation

2.5. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analysis

3.1.1. Date Seed Powder Chemical Composition

3.1.2. Proximate Composition of Cookies

3.2. Physical Properties of Cookies

3.2.1. Colour Analysis

3.2.2. Texture Analysis

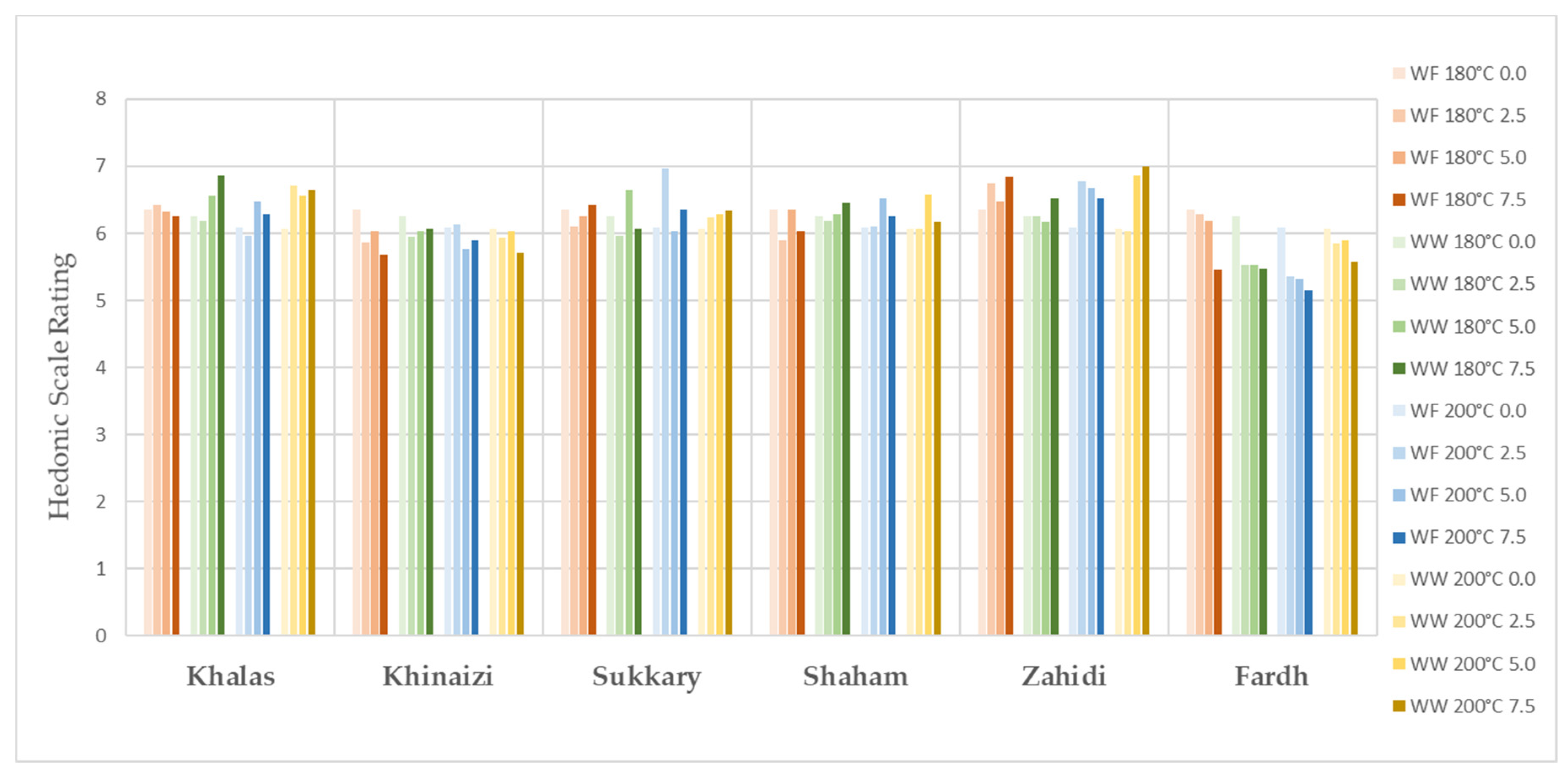

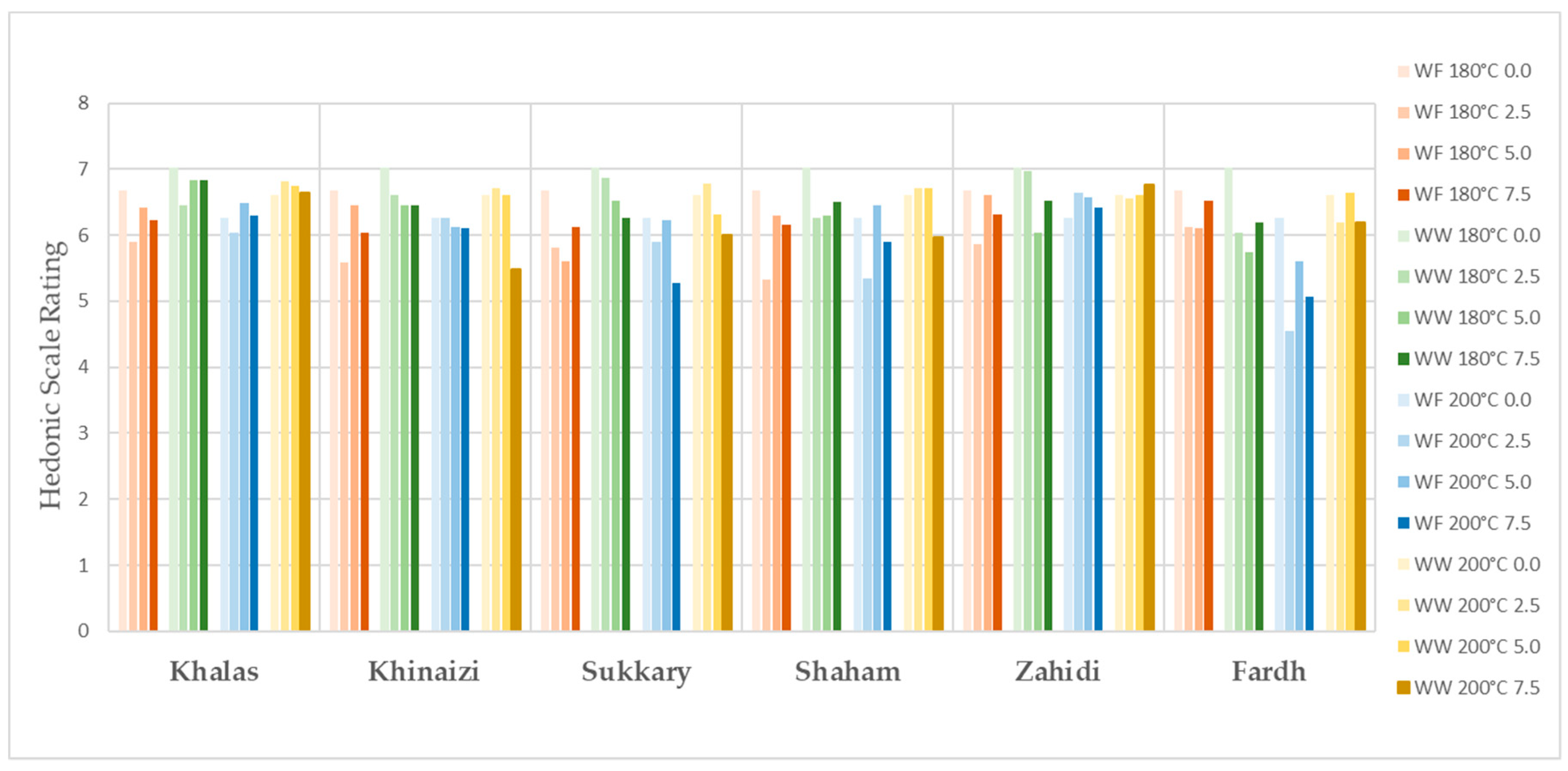

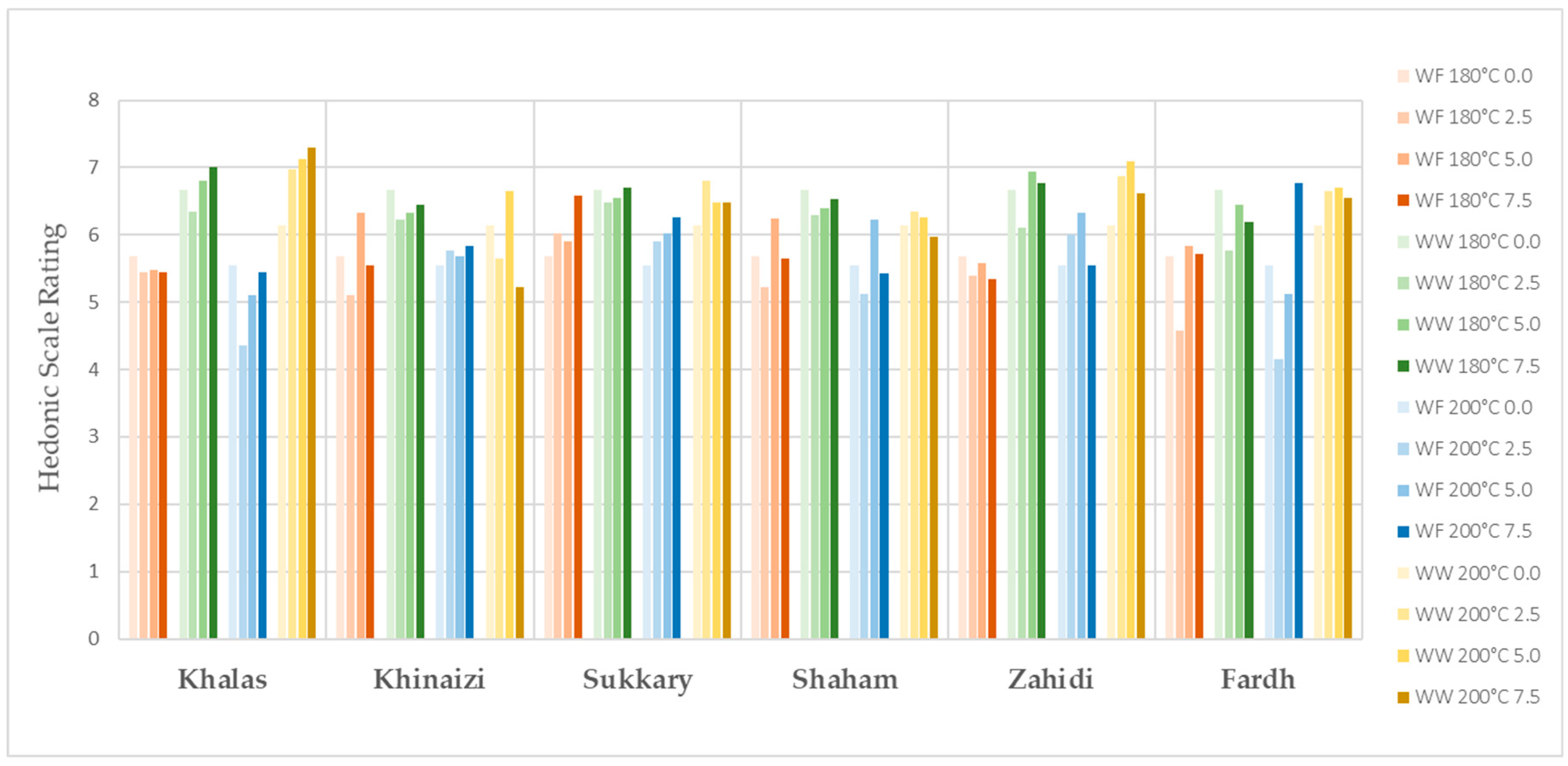

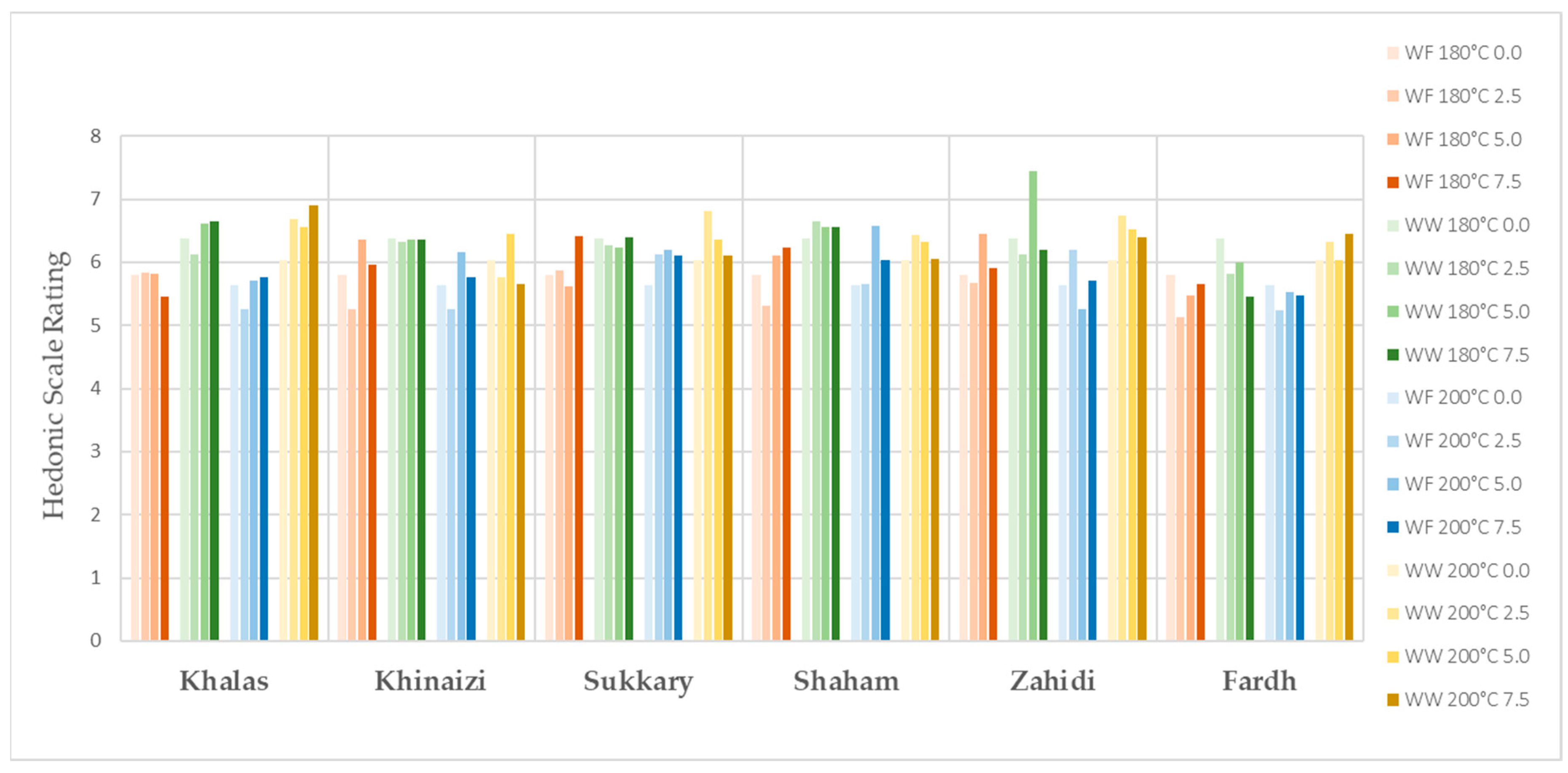

3.2.3. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al Juhaimi, F.; Ghafoor, K.; Ozcan, M.M. Physical and chemical properties, antioxidant activity, total phenol and mineral profile seeds of seven different date fruit (Phoenix dactylifera) varieties. Int. J. Food Sci. Nutr. 2012, 63, 84–89. [Google Scholar] [CrossRef]

- Al-Farsi, M.A.; Lee, C.Y. Optimization of phenolics and dietary fibre extraction from date seeds. Food Chem. 2008, 108, 977–985. [Google Scholar] [CrossRef] [PubMed]

- Besbes, S.; Blecker, C.; Deroanne, C.; Drira, N.E.; Attia, H. Date seeds: Chemical composition and characteristic profiles of the lipid fraction. Food Chem. 2004, 84, 577–584. [Google Scholar] [CrossRef]

- Golshan, T.A.; Solaimani, D.N.; Yasini Ardakani, S.A. Physicochemical properties and applications of date seed and its oil. Int. Food Res. J. 2017, 24, 1399–1406. [Google Scholar]

- Basuni, A.M.M.; Al-Marzooq, M.A. Production of mayonnaise from date pit oil. Food Nutr. Sci. 2011, 2, 938–943. [Google Scholar] [CrossRef] [Green Version]

- Ghnimi, S.; Umer, S.; Karim, A.; Kamal-Eldin, A. Date fruit (Phoenix dactylifera L.): An underutilized food seeking industrial valorization. NFS 2017, 6, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Al Juhaimi, F.; Ozcan, M.M.; Adiamo, O.Q.; Alsawmahi, O.N.; Ghafoor, K.; Babiker, E.E. Effect of date varieties on physico-chemical properties, fatty acid composition, tocopherol contents, and phenolic compounds of some date seed and oils. J. Food Process. Preserv. 2018, 42, e13584. [Google Scholar] [CrossRef]

- Amany, M.M.B.; Shaker, M.A.; Abeer, A.K. Antioxidant activities of date pits in a model meat system. Int. Food Res. 2012, 19, 223–227. [Google Scholar]

- Jemziya, M.B.F.; Mahendran, T. Quality characteristics and sensory evaluation of cookies produced from composite blends of sweet potato (Ipomoea batatas L.) and wheat (Triticum aestivum L.) flour. SLJFA 2015, 1, 23–30. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, A.; Saxena, D.C.; Singh, S. Physical, textural, and sensory characteristics of wheat and amaranth flour blend cookies. Cogent Food Agric. 2016, 2, 1125773. [Google Scholar] [CrossRef]

- Baumgartner, B.; Özkaya, B.; Saka, I.; Özkaya, H. Functional and physical properties of cookies enriched with dephytinized oat bran. J. Cereal Sci. 2018, 80, 24–30. [Google Scholar] [CrossRef]

- Khouryieh, H.; Aramouni, F. Physical and sensory characteristics of cookies prepared with flaxseed flour. J. Sci. Food Agric. 2012, 92, 2366–2372. [Google Scholar] [CrossRef] [PubMed]

- Hrušková, M.; Švec, I. Cookie making potential of composite flour containing wheat, barley and hemp. Czech. J. Food Sci. 2015, 33, 545–555. [Google Scholar] [CrossRef] [Green Version]

- Jan, R.; Saxena, D.C.; Singh, S. Physico-chemical, textural, sensory and antioxidant characteristics of gluten–Free cookies made from raw and germinated Chenopodium (Chenopodium album) flour. LWT-Food Sci. Technol. 2016, 71, 281–287. [Google Scholar] [CrossRef]

- Ashoush, I.S.; Gadallah, M.G. Utilization of mango peels and seed kernels powders as sources of phytochemicals in biscuit. World J. Dairy Food Sci. 2011, 6, 35–42. [Google Scholar]

- Gómez, M.; Martinez, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Critical Rev. Food Sci. Nutri. 2018, 58, 2119–2135. [Google Scholar] [CrossRef]

- Platat, C.; Habib, H.M.; Hashim, I.B.; Kamal, H.; AlMaqbali, F.; Souka, U.; Ibrahim, W.H. Production of functional pita bread using date seed powder. J. Food Sci. Technol. 2015, 10, 6375–6384. [Google Scholar] [CrossRef] [Green Version]

- Ambigaipalan, P.; Shahidi, F. Date seed flour and hydrolysates affect physicochemical properties of muffin. Food Biosci. 2015, 12, 54–60. [Google Scholar] [CrossRef]

- Almana, H.A.; Mahmoud, R.M. Palm date seeds as an alternative source of dietary fibre in Saudi bread. Ecol. Food Nutri. 1994, 32, 261–270. [Google Scholar] [CrossRef]

- Bouaziz, M.A.; Amara, W.B.; Attia, H.; Blecker, C.; Besbes, S. Effect of the addition of defatted date seeds on wheat dough performance and bread quality. J. Texture Stud. 2010, 41, 511–531. [Google Scholar] [CrossRef]

- Suresh, S.; Guizani, N.; Al-Ruzeiki, M.; Al-Hadhrami, A.; Al-Dohani, H.; Al-Kindi, I.; Rahman, M.S. Thermal characteristics, chemical composition and polyphenol contents of date-pits powder. J. Food Eng. 2013, 119, 668–679. [Google Scholar] [CrossRef]

- Storup, K.; Mattfolk, K.; Voinea, D.; Jakobsen, B.; Bain, M.; Reverté Casas, M.; Oliveira, P. Combating Food Waste: An Opportunity for the EU to Improve the Resource-Efficiency of the Food Supply Chain. Eur. Court. Audit. Eur. Union 2016, 34, 6–7. [Google Scholar]

- US Environmental Protection Agency. Food Recovery Hierarchy. In Sustainable Management of Food; US Environmental Protection Agency: Washington, DC, USA, 2015. [Google Scholar]

- Grasso, S.; Liu, S.; Methven, L. Quality of muffins enriched with upcycled defatted sunflower seed flour. LWT 2020, 119, 108893. [Google Scholar] [CrossRef]

- Grasso, S.; Pintado, T.; Pérez-Jiménez, J.; Ruiz-Capillas, C.; Herrero, A.M. Characterisation of Muffins with Upcycled Sunflower Flour. Foods. 2021, 10, 426. [Google Scholar] [CrossRef]

- Heo, Y.; Kim, M.J.; Lee, J.W.; Moon, B. Muffins enriched with dietary fibre from kimchi by-product: Baking properties, physical–chemical properties, and consumer acceptance. Food Sci. Nutr. 2019, 7, 1778–1785. [Google Scholar] [CrossRef]

- Approved Methods of Analysis. AACC. Method 10-54.01. Baking Quality of Cookie Flour-Micro Wire-Cut Formulation, 11th ed.; Cereals & Grains Association: St. Paul, MN, USA, 1999; ISBN 978-1-891127-68-2. [Google Scholar]

- The Association of Official Analytical Chemists. AOAC (2003) Official Methods of Analysis; AOAC International: Washington, DC, USA, 2003. [Google Scholar]

- The Association of Official Analytical Chemists. AOAC (1995) Official Methods of Analysis, 15th ed.; AOAC International: Washington, DC, USA, 1995. [Google Scholar]

- Habib, H.M.; Ibrahim, W.H. Nutritional quality evaluation of eighteen date pit varieties. Int. J. Food Sci. Nutr. 2009, 60, 99–111. [Google Scholar] [CrossRef]

- Ismail, B.; Haffar, I.; Baalbaki, R.; Mechref, Y.; Henry, J. Physico-chemical characteristics and total quality of five date varieties grown in the United Arab Emirates. Int. J. Food Sci. Technol. 2006, 41, 919–926. [Google Scholar] [CrossRef]

- Platat, C.; Habib, H.M.; Al Maqbali, F.D.; Jaber, N.N.; Ibrahim, W.H. Identification of date seeds varieties patterns to optimize nutritional benefits of date seeds. J. Nutr. Food Sci. S. 2014, 8. [Google Scholar] [CrossRef]

- Saafi, E.B.; Trigui, M.; Thabet, R.; Hammami, M.; Achour, L. Common date palm in Tunisia: Chemical composition of pulp and pits. Int. J. Food Sci. Technol. 2008, 43, 2033–2037. [Google Scholar] [CrossRef]

- Bouaziz, F.; Ben Abdeddayem, A.; Koubaa, M.; Ellouz Ghorbel, R.; Ellouz Chaabouni, S. Date seeds as a natural source of dietary fibres to improve texture and sensory properties of wheat bread. Foods. 2020, 9, 737. [Google Scholar] [CrossRef]

- Bölek, S. Effects of waste fig seed powder on quality as an innovative ingredient in biscuit formulation. J. Food Sci. 2021, 86, 55–60. [Google Scholar] [CrossRef] [PubMed]

- Nehdi, I.; Omri, S.; Khalil, M.I.; Al-Resayes, S.I. Characteristics and chemical composition of date palm (Phoenix canariensis) seeds and seed oil. Ind. Crops Prod. 2010, 32, 360–365. [Google Scholar] [CrossRef]

- Ahfaiter, H.; Zeitoun, A.; Abdallah, A.E. Physicochemical Properties and Nutritional Value of Egyptian Date Seeds and Its Applications in Some Bakery Products. J. Adv. Agr. Res. 2018, 23, 260–279. [Google Scholar]

- Pareyt, B.; Delcour, J.A. The role of wheat flour constituents, sugar, and fat in low moisture cereal based products: A review on sugar-snap cookies. Crit. Rev. Food Sci. Nutr. 2008, 48, 824–839. [Google Scholar] [CrossRef] [PubMed]

- Aksoylu, Z.; Çağindi, Ö.; Köse, E. Effects of blueberry, grape seed powder and poppy seed incorporation on physicochemical and sensory properties of biscuit. J. Food Qual. 2015, 38, 164–174. [Google Scholar] [CrossRef]

- Sindhuja, A.; Sudha, M.L.; Rahim, A. Effect of incorporation of amaranth flour on the quality of cookies. Eur. Food Res. Technol. 2005, 221, 597–601. [Google Scholar] [CrossRef]

- Saeed, S.M.; Urooj, S.; Ali, S.A.; Ali, R.; Mobin, L.; Ahmed, R.; Sayeed, S.A. Impact of the incorporation of date pit flour an underutilized biowaste in dough and its functional role as a fat replacer in biscuits. J. Food Process. Preserv. 2021, 45, e15218. [Google Scholar] [CrossRef]

- Gómez, M.; Ronda, F.; Blanco, C.A.; Caballero, P.A.; Apesteguía, A. Effect of dietary fibre on dough rheology and bread quality. Eur. Food Res. Technol. 2003, 216, 51–56. [Google Scholar] [CrossRef]

- Al-Farsi, M.; Alasalvar, C.; Al-Abid, M.; Al-Shoaily, K.; Al-Amry, M.; Al-Rawahy, F. Compositional and functional characteristics of dates, syrups, and their by-products. Food Chem. 2007, 104, 943–947. [Google Scholar] [CrossRef]

- Segnini, S.; Dejmek, P.; Öste, R. A low cost video technique for colour measurement of potato chips. Lebensm-Wiss. U.-Technol. 1999, 32, 216–222. [Google Scholar] [CrossRef]

- Abdullah, M.Z.; Guan, L.C.; Lim, K.C.; Karim, A.A. The applications of computer vision system and tomographic radar imaging for assessing physical properties of food. J. Food Eng. 2004, 61, 125–135. [Google Scholar] [CrossRef]

- Assis, L.M.; Zavareze, E.; Radúnz, A.; Dias, Á.; Gutkoski, L.; Elias, M. Nutritional, technological and sensory properties of cookies with substitution of wheat flour by oat flour or parboilized rice flour. Alim. Nutr. Araraquara 2009, 20, 15–24. [Google Scholar]

| Variety | Moisture | Ash | Crude Fat | Crude Protein | Carbohydrate |

|---|---|---|---|---|---|

| Khalas | 5.08 ± 0.10 a | 3.31 ± 0.26 bc | 9.81 ± 0.37 ab | 8.13 ± 2.45 a | 73.68 ± 2.20 c |

| Khinaizi | 4.06 ± 0.32 ab | 3.52 ± 0.26 b | 8.26 ± 38.47 c | 6.84 ± 0.86 a | 77.31 ± 38.44 abc |

| Sukkari | 1.24 ± 0.18 d | 2.04 ± 0.16 d | 9.94 ± 2.98 ab | 8.30 ± 1.11 a | 78.48 ± 3.61 ab |

| Shaham | 4.08 ± 0.58 ab | 3.37 ± 0.12 bc | 7.70 ± 0.12 bc | 6.14 ± 0.38 a | 78.70 ± 0.79 ab |

| Zahidi | 2.53 ± 0.87 c | 2.65 ± 0.04 cd | 12.68 ± 0.08 a | 6.92 ± 0.46 a | 75.22 ± 1.26 ab |

| Fardh | 3.72 ± 0.21 bc | 6.90 ± 0.63 a | 8.03 ± 0.16 bc | 7.29 ± 1.12 a | 74.06 ± 1.16 c |

| Baking Temp, Flour Type, Addition Level | Khalas | Khinaizi | Sukkari | Shaham | Zahidi | Fardh | |

|---|---|---|---|---|---|---|---|

| 180 °C White Flour | 0 | 3.25 ± 0.19 bc | 3.25 ± 0.19 a | 3.25 ± 0.19 bc | 3.25 ± 0.19 c | 3.25 ± 0.19 b | 3.25 ± 0.19 a |

| 2.5 | 3.14 ± 0.44 cB | 3.03 ± 0.07 aB | 4.01 ± 0.27 aAB | 4.41 ± 0.13 aA | 4.00 ± 0.10 aAB | 3.80 ± 0.46 aAB | |

| 5.0 | 3.85 ± 0.08 abA | 3.31 ± 0.28 aAB | 3.4 ± 0.36 abAB | 3.89 ± 0.24 bA | 2.78 ± 0.14 cB | 3.55 ± 0.28 aA | |

| 7.5 | 3.95 ± 0.14 aA | 2.90 ± 0.06 aBC | 2.66 ± 0.06 cC | 3.38 ± 0.06 cAB | 2.76 ± 0.18 cBC | 3.18 ± 0.47 aBC | |

| 180 °C Whole Wheat Flour | 0 | 2.70 ± 0.09 b | 2.70 ± 0.09 a | 2.70 ± 0.09 a | 2.70 ± 0.09 a | 2.70 ± 0.09 a | 2.72 ± 0.09 a |

| 2.5 | 3.42 ± 0.05 aA | 2.34 ± 0.13 aB | 2.07 ± 0.13 bBC | 1.69 ± 0.24 bC | 2.09 ± 0.23 bBC | 1.07 ± 0.22 bD | |

| 5.0 | 3.09 ± 0.17 abA | 2.20 ± 0.09 aB | 1.96 ± 0.13 bBC | 2.06 ± 0.05 bBC | 1.82 ± 0.09 bC | 0.33 ± 0.09 bcD | |

| 7.5 | 2.98 ± 0.31 bA | 1.14 ± 0.46 bBC | 1.19 ± 0.08 cBC | 1.19 ± 0.13 cBC | 1.76 ± 0.19 bB | 0.50 ± 0.33 cC | |

| 200 °C White Flour | 0 | 2.87 ± 0.11 bc | 2.87 ± 0.11 a | 2.87 ± 0.11 b | 2.87 ± 0.11 b | 2.87 ± 0.11 a | 2.87 ± 0.11 b |

| 2.5 | 3.12 ± 0.08 abB | 2.72 ± 0.16 aBC | 3.19 ± 0.05 aB | 3.89 ± 0.33 aA | 2.53 ± 0.03 bC | 4.07 ± 0.32 aA | |

| 5.0 | 2.81 ± 0.04 cB | 2.91 ± 0.02 aB | 2.67 ± 0.05 cB | 3.55 ± 0.24 aA | 2.05 ± 0.26 cC | 2.45 ± 0.21 bcBC | |

| 7.5 | 3.30 ± 0.16 aA | 2.88 ± 0.07 aB | 1.69 ± 0.06 dD | 2.89 ± 0.13 bB | 2.02 ± 0.04 cCD | 2.28 ± 0.22 cC | |

| 200 °C Whole Wheat Flour | 0 | 2.06 ± 0.02 ab | 2.06 ± 0.02 a | 2.06 ± 0.02 a | 2.06 ± 0.02 a | 2.06 ± 0.02 a | 2.06 ± 0.02 a |

| 2.5 | 2.52 ± 0.15 aA | 2.24 ± 0.28 aAB | 1.21 ± 0.04 bC | 1.68 ± 0.11 bBC | 1.35 ± 0.13 bC | 0.62 ± 0.35 bD | |

| 5.0 | 2.31 ± 0.06 abA | 2.20 ± 0.03 aA | 1.17 ± 0.05 bC | 2.19 ± 0.01 aA | 1.40 ± 0.19 bB | 0.41 ± 0.00 bD | |

| 7.5 | 1.95 ± 0.32b bA | 1.44 ± 0.38 bAB | 0.84 ± 0.17 cBC | 1.19 ± 0.27 cAB | 1.42 ± 0.23 bAB | 0.26 ± 0.38 bC | |

| Baking Temp, Flour Type, Addition Level | Khalas | Khinaizi | Sukkari | Shaham | Zahidi | Fardh | |

|---|---|---|---|---|---|---|---|

| 180 °C White Flour | 0 | 1.50 ± 0.07 a | 1.50 ± 0.07 a | 1.50 ± 0.07 a | 1.50 ± 0.07 a | 1.50 ± 0.07 a | 1.50 ± 0.07 a |

| 2.5 | 1.68 ± 0.18 aA | 1.42 ± 0.07 aA | 1.32 ± 0.11 aA | 1.87 ± 0.44 aA | 1.96 ± 0.04 aA | 1.08 ± 0.81 aA | |

| 5.0 | 1.37 ± 0.43 aB | 1.40 ± 0.05 aB | 1.42 ± 0.03 aAB | 1.54 ± 0.02 aAB | 1.95 ± 0.04 aA | 1.33 ± 0.23 aB | |

| 7.5 | 1.46 ± 0.05 aBC | 1.53 ± 0.05 aB | 1.36 ± 0.04 aB | 1.56 ± 0.05 aC | 2.07 ± 0.06 bA | 0.93 ± 0.01 aD | |

| 180 °C Whole Wheat Flour | 0 | 1.63 ± 0.04 a | 1.63 ± 0.04 a | 1.63 ± 0.04 a | 1.63 ± 0.04 a | 1.63 ± 0.04 a | 1.63 ± 0.04 a |

| 2.5 | 1.65 ± 0.04 bA | 1.61 ± 0.02 aA | 1.65 ± 0.05 aA | 1.74 ± 0.12 aA | 1.63 ± 0.1 aA | 1.62 ± 0.08 aA | |

| 5.0 | 1.66 ± 0.04 bB | 1.66 ± 0.01 aB | 1.63 ± 0.06 aB | 1.55 ± 0.03 aB | 2.08 ± 0.23 bA | 1.59 ± 0.09 aB | |

| 7.5 | 1.81 ± 0.04 bB | 1.66 ± 0.03 aBCD | 1.53 ± 0.04 aCD | 1.60 ± 0.08 aD | 2.08 ± 0.12 bA | 1.76 ± 0.06 aBC | |

| 200 °C White Flour | 0 | 1.32 ± 0.04 a | 1.32 ± 0.04 a | 1.32 ± 0.04 a | 1.32 ± 0.04 a | 1.32 ± 0.04 a | 1.32 ± 0.04 a |

| 2.5 | 1.50 ± 0.12 aB | 0.79 ± 0.17 bC | 1.22 ± 0.07 aB | 1.31 ± 0.26 aB | 1.96 ± 0.04 abA | 1.55 ± 0.03 aB | |

| 5.0 | 1.53 ± 0.02 aB | 0.84 ± 0.12 bD | 1.32 ± 0.1 aBC | 1.42 0.04 aC | 1.8 ± 0.04 bA | 1.49 ± 0.05 bBC | |

| 7.5 | 1.44 ± 0.14 aB | 0.88 ± 0.07 bC | 1.33 ± 0.02 aB | 1.50 ± 0.11 aB | 2.08 ± 0.18 cA | 0.79 ± 0.03 cC | |

| 200 °C Whole Wheat Flour | 0 | 1.60 ± 0.01 a | 1.60 ± 0.01 a | 1.60 ± 0.01 a | 1.60 ± 0.01 a | 1.60 ± 0.01 a | 1.60 ± 0.01 a |

| 2.5 | 1.53 ± 0.09 aAB | 1.12 ± 0.12 abC | 1.55 ± 0.04 aABC | 1.44 ± 0.03 aAB | 1.26 ± 0.26 aBC | 1.67 ± 0.08 abA | |

| 5.0 | 1.59 ± 0.01 aAB | 0.99 ± 0.16 abC | 1.58 ± 0.08 aBC | 1.25 ± 0.17 abAB | 1.48 ± 0.05 aAB | 1.76 ± 0.18 abA | |

| 7.5 | 1.67 ± 0.08 aA | 0.55 ± 0.42 bB | 1.54 ± 0.02 aA | 1.55 ± 0.02 bA | 1.5 ± 0.03 aA | 1.88 ± 0.07 bA | |

| Baking Temp Flour Type and Addition Level | Khalas | Khinaizi | Sukkari | Shaham | Zahidi | Fardh | |

|---|---|---|---|---|---|---|---|

| 180 °C White Flour | 0 | 19.34 ± 0.97 a | 19.34 ± 0.97 a | 19.34 ± 0.97 a | 19.34 ± 0.97 a | 19.34 ± 0.97 a | 19.34 ± 0.97 a |

| 2.5 | 19.15 ± 0.49 aA | 19.34 ± 1.95 aA | 20.71 ± 0.68 aA | 19.37 ± 0.15 aA | 20.07 ± 0.48 aA | 19.65 ± 0.28 aA | |

| 5.0 | 19.44 ± 0.60 aA | 20.60 ± 0.10 aA | 19.67 ± 2.60 aA | 20.16 ± 0.57 aA | 19.62 ± 0.21 aA | 19.52 ± 0.48 aA | |

| 7.5 | 20.46 ± 0.35 aA | 20.58 ± 0.64 aA | 20.87 ± 0.25 aA | 20.91 ± 0.29 aA | 20.11 ± 0.68 aA | 20.60 ± 0.43 aA | |

| 180 °C Whole Wheat Flour | 0 | 25.69 ± 0.31 a | 25.69 ± 0.31 a | 25.69 ± 0.31 a | 25.69 ± 0.31 a | 25.69 ± 0.31 a | 25.69 ± 0.31 a |

| 2.5 | 26.04 ± 0.78 aA | 24.81 ± 0.10 aA | 25.59 ± 0.99 aA | 26.27 ± 0.92 aA | 25.84 ± 0.49 aA | 24.58 ± 0.57 bA | |

| 5.0 | 26.64 ± 0.32 aA | 25.72 ± 0.46 aAB | 25.5 ± 1.18 aAB | 26.52 ± 0.29 aA | 26.12 ± 0.14 aAB | 24.65 ± 0.29 bB | |

| 7.5 | 26.21 ± 0.56 aA | 25.17 ± 1.82 aA | 26.79 ± 0.31 aA | 25.84 ± 0.4 aA | 26.44 ± 0.31 aA | 25.24 ± 0.35 abA | |

| 200 °C White Flour | 0 | 20.26 ± 0.76 a | 20.26 ± 0.76 a | 20.26 ± 0.76 a | 20.26 ± 0.76 a | 20.26 ± 0.76 a | 20.26 ± 0.76 a |

| 2.5 | 20.79 ± 1.54 aA | 21.31 ± 0.27 aA | 21.29 ± 0.82 aA | 20.54 ± 0.26 aA | 20.36 ± 0.87 aA | 17.05 ± 1.33 bB | |

| 5.0 | 20.20 ± 0.52 aA | 20.43 ± 0.42 aA | 20.30 ± 0.15 aA | 20.81 ± 0.32 aA | 20.39 ± 0.65 aA | 21.30 ± 1.16 aA | |

| 7.5 | 19.95 ± 0.15 aB | 21.52 ± 0.41 aAB | 22.68 ± 1.54 aA | 20.89 ± 0.2 aAB | 20.36 ± 0.79 aB | 22.83 ± 0.53 aA | |

| 200 °C Whole Wheat Flour | 0 | 26.38 ± 0.63 a | 26.38 ± 0.63 ab | 26.38 ± 0.63 a | 26.38 ± 0.63 a | 26.38 ± 0.63 a | 26.38 ± 0.63 a |

| 2.5 | 25.54 ± 0.53 aA | 26.27 ± 0.58 abA | 25.74 ± 0.08 aA | 25.64 ± 0.23 aA | 25.76 ± 0.50 aA | 25.21 ± 0.54 abA | |

| 5.0 | 25.55 ± 0.29 aAB | 25.65 ± 0.42 bA | 26.34 ± 0.44 aA | 25.66 ± 1.13 aA | 27.01 ± 0.02 aA | 23.63 ± 0.60 bB | |

| 7.5 | 26.13 ± 0.33 aA | 26.97 ± 0.29 aA | 26.24 ± 0.68 aA | 25.84 ± 1.28 aA | 27.25 ± 0.74 aA | 26.06 ± 0.19 aA | |

| White Flour | Whole Wheat Flour | ||||||

|---|---|---|---|---|---|---|---|

| Lightness | 93.27 A | 87.00 B | |||||

| Khalas | Khinaizi | Sukkari | Shaham | Zahidi | Fardh | ||

| 37.72 F | 42.78 B | 45.13 A | 42.40 C | 37.90 E | 41.99 D | ||

| Baking temp flour type and addition level | |||||||

| 180 °C White Flour | 0 | 70.20 ± 2.28 a | 70.20 ± 2.28 a | 70.20 ± 2.28 a | 70.20 ± 2.28 a | 70.20± 2.28 a | 70.20 ± 2.28 a |

| 2.5 | 48.32 ± 0.76 bD | 50.27 ± 1.27 bBC | 50.83 ± 0.10 bB | 48.28 ± 0.72 bD | 53.13 ± 0.09 bA | 48.81 ± 0.33 bCD | |

| 5.0 | 42.54 ± 1.55 cBC | 41.78 ± 0.39 cC | 44.71 ± 0.69 cAB | 41.79 ± 0.84 cC | 45.77 ± 0.10 cA | 41.78 ± 1.37 cC | |

| 7.5 | 40.55 ± 1.56 cA | 39.39 ± 0.33 cA | 41.39 ± 0.06 cA | 38.73 ± 0.47 cA | 39.61 ± 1.24 dA | 38.70 ± 0.52 cA | |

| 180 °C Whole Wheat Flour | 0 | 60.25 ± 0.25 a | 60.25 ± 0.25 a | 60.25 ± 0.25 a | 60.25 ± 0.25 a | 60.25 ± 0.25 a | 60.25 ± 0.25 a |

| 2.5 | 49.70 ± 0.55 bA | 47.21 ± 0.38 bB | 47.71 ± 0.79 bB | 47.20 ± 1.01 bB | 47.60 ± 0.31 bB | 47.52 ± 0.41 bB | |

| 5.0 | 42.36 ± 1.31 cAB | 41.99 ± 0.32 cAB | 43.32 ± 0.56 cA | 41.26 ± 0.28 cB | 42.99 ± 0.30 cA | 42.52 ± 0.10 bAB | |

| 7.5 | 40.06 ± 0.70 dAB | 38.05 ± 0.43 dAB | 38.62 ± 0.52 dAB | 38.81 ± 0.36 dAB | 41.79 ± 1.07 cA | 35.03 ± 4.30 cB | |

| 200 °C White Flour | 0 | 71.14 ± 1.40 a | 71.14 ± 1.40 a | 71.14 ± 1.40 a | 71.14 ± 1.40 a | 71.14 ± 1.40 a | 71.14 ± 1.40 a |

| 2.5 | 46.44 ± 0.33 bD | 50.02 ± 0.56 bB | 48.86 ± 0.60 bBC | 48.60 ± 0.58 bC | 52.11 ± 0.16 bA | 47.91 ± 0.52 bC | |

| 5.0 | 40.66 ± 1.32 cB | 42.38 ± 0.44 cB | 45.02 ± 0.40 cA | 42.22 ± 0.12 cB | 46.28 ± 0.60 cA | 41.48 ± 0.20 cB | |

| 7.5 | 39.96 ± 1.14 cAB | 39.70 ± 0.44 dABC | 40.29 ± 0.48 dA | 37.98 ± 0.84 dC | 38.37 ± 0.49 dABC | 38.29 ± 0.52 dBC | |

| 200 °C Whole Wheat Flour | 0 | 58.10 ± 1.79 a | 58.10 ± 1.79 a | 58.10 ± 1.79 a | 58.10 ± 1.79 a | 58.10 ± 1.79 a | 58.10 ± 1.79 a |

| 2.5 | 47.89 ± 1.04 bA | 47.59 ± 0.27 bA | 46.44 ± 0.32 bA | 47.02 ± 1.11 bA | 47.19 ± 1.36 bA | 46.14 ± 0.97 bA | |

| 5.0 | 41.30 ± 0.25 cB | 42.10 ± 0.30 cB | 43.25 ± 0.04 cA | 42.02 ± 0.52 cB | 43.46 ± 0.65 cA | 41.32 ± 0.44 cB | |

| 7.5 | 38.07 ± 2.71 cA | 38.25 ± 0.71 dA | 37.27 ± 0.62 dA | 38.96 ± 0.21 dA | 39.48 ± 0.40 dA | 37.05 ± 0.37 dA | |

| Baking Temp Flour Type and Addition Level | Khalas | Khinaizi | Sukkari | Shaham | Zahidi | Fardh | |

|---|---|---|---|---|---|---|---|

| 180 °C White Flour | 0 | 22.82 ± 1.05 a | 22.82 ± 1.05 a | 22.82 ± 1.05 a | 22.82 ± 1.05 a | 22.82 ± 1.05 a | 22.82 ± 1.05 a |

| 2.5 | 19.94 ± 2.02 abABC | 18.40 ± 0.16 bBC | 16.73 ± 1.33 bC | 22.10 ± 0.59 aAB | 23.02 ± 2.01 aA | 19.90 ± 1.20 bABC | |

| 5.0 | 17.72 ± 0.19 bA | 17.41 ± 1.78 bA | 16.28 ± 1.57 bA | 19.50 ± 2.56 aA | 17.59 ± 2.43 aA | 18.82 ± 0.68 bA | |

| 7.5 | 17.81 ± 0.22 bAB | 18.02 ± 0.97 bAB | 14.71 ± 0.14 bB | 19.31 ± 0.49 aA | 18.33 ± 3.12 aAB | 15.11 ± 0.85 cB | |

| 180 °C Whole Wheat Flour | 0 | 11.04 ± 1.20 a | 11.04 ± 1.20 a | 11.04 ± 1.20 a | 11.04 ± 1.20 a | 11.04 ± 1.20 a | 11.04 ± 1.20 a |

| 2.5 | 10.05 ± 0.89 aA | 10.62 ± 0.62 aA | 10.81 ± 0.60 abA | 10.83 ± 0.72 aA | 9.36 ± 1.38 aA | 9.43 ± 0.46 bA | |

| 5.0 | 9.70 ± 0.36 aA | 10.40 ± 0.35 aA | 9.21 ± 0.45 abA | 9.90 ± 0.41 aA | 9.60 ± 1.67 aA | 9.23 ± 0.38 bA | |

| 7.5 | 9.06 ± 0.39 aA | 9.74 ± 0.49 aA | 8.53 ± 1.11 bA | 9.69 ± 0.31 aA | 8.91 ± 1.61 aA | 8.14 ± 0.50 cA | |

| 200 °C White Flour | 0 | 21.90 ± 1.54 a | 21.90 ± 1.54 a | 21.90 ± 1.54 a | 21.90 ± 1.54 a | 21.90 ± 1.54 a | 21.90 ± 1.54 a |

| 2.5 | 19.83 ± 1.76 abAB | 17.22 ± 0.44 bB | 18.02 ± 1.63 bB | 23.61 ± 3.07 aA | 21.44 ± 1.97 aAB | 19.55 ± 0.85 bAB | |

| 5.0 | 17.34 ± 0.27 bAB | 17.40 ± 1.29 bAB | 15.91 ± 0.63 bcB | 20.02 ± 0.45 aA | 17.20 ± 2.79 aAB | 16.33 ± 0.87 bB | |

| 7.5 | 18.21 ± 0.90 bAB | 16.05 ± 0.89 bBC | 13.73 ± 0.72 cC | 19.70 ± 1.14 aA | 17.05 ± 1.47 bAB | 13.88 ± 1.01 bC | |

| 200 °C Whole Wheat Flour | 0 | 10.94 ± 0.79 a | 10.94 ± 0.79 a | 10.94 ± 0.79 a | 10.94 ± 0.79 a | 10.94 ± 0.79 a | 10.94 ± 0.79 a |

| 2.5 | 10.86 ± 0.28 abA | 11.07 ± 0.70 aA | 10.22 ± 0.61 abA | 10.74 ± 0.63 aA | 9.62 ± 1.30 aA | 9.85 ± 0.90 aA | |

| 5.0 | 9.42 ± 0.37 bcA | 10.11 ± 0.73 aA | 7.97 ± 0.37 bcA | 9.94 ± 0.54 aA | 9.85 ± 1.38 aA | 9.06 ± 0.35 aA | |

| 7.5 | 9.03 ± 0.68 cAB | 9.34 ± 0.55 aA | 8.31 ± 0.91 cAB | 9.62 ± 0.64 aA | 9.33 ± 1.43 aA | 6.84 ± 1.06 bB | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najjar, Z.; Alkaabi, M.; Alketbi, K.; Stathopoulos, C.; Ranasinghe, M. Physical Chemical and Textural Characteristics and Sensory Evaluation of Cookies Formulated with Date Seed Powder. Foods 2022, 11, 305. https://doi.org/10.3390/foods11030305

Najjar Z, Alkaabi M, Alketbi K, Stathopoulos C, Ranasinghe M. Physical Chemical and Textural Characteristics and Sensory Evaluation of Cookies Formulated with Date Seed Powder. Foods. 2022; 11(3):305. https://doi.org/10.3390/foods11030305

Chicago/Turabian StyleNajjar, Zein, Maitha Alkaabi, Khulood Alketbi, Constantinos Stathopoulos, and Meththa Ranasinghe. 2022. "Physical Chemical and Textural Characteristics and Sensory Evaluation of Cookies Formulated with Date Seed Powder" Foods 11, no. 3: 305. https://doi.org/10.3390/foods11030305

APA StyleNajjar, Z., Alkaabi, M., Alketbi, K., Stathopoulos, C., & Ranasinghe, M. (2022). Physical Chemical and Textural Characteristics and Sensory Evaluation of Cookies Formulated with Date Seed Powder. Foods, 11(3), 305. https://doi.org/10.3390/foods11030305