Characterization of Reduced-Fat Mayonnaise and Comparison of Sensory Perception, Rheological, Tribological, and Textural Analyses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of the Mayonnaise

2.3. Composition and pH

2.4. Texture and Spreadability

2.5. Rheological Properties

2.6. Tribological Properties

2.7. Selected Sensory Attributes

2.8. Data and Statistical Analysis

3. Results and Discussion

3.1. Composition and pH

3.2. Texture and Spreadability

3.3. Rheological Properties

3.4. Tribological Properties

3.5. Selected Sensory Attributes

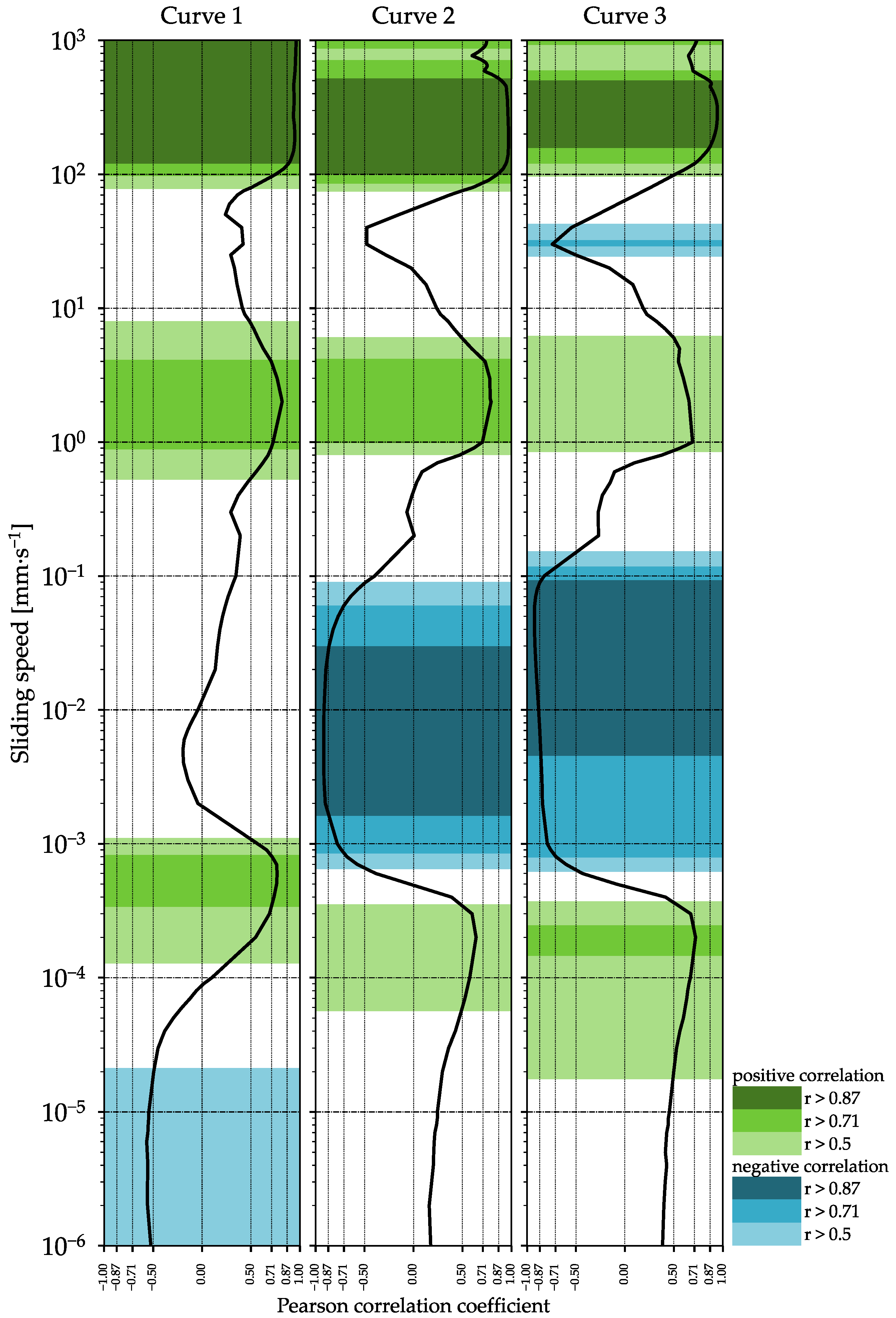

3.6. Correlations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blüher, M. Obesity: Global epidemiology and pathogenesis. Nat. Rev. Endocrinol. 2019, 15, 288–298. [Google Scholar] [CrossRef] [PubMed]

- Hamilton, J.; Knox, B.; Hill, D.; Parr, H. Reduced fat products: Consumer perceptions and preferences. Br. Food J. 2000, 102, 494–506. [Google Scholar] [CrossRef]

- McEwan, J.A.; Sharp, T.M. Technical, economic and consumer barriers to the consumption of reduced fat bakery products. Nutr. Food Sci. 2000, 30, 16–18. [Google Scholar] [CrossRef]

- Running, C.A.; Craig, B.A.; Mattes, R.D. Oleogustus: The Unique Taste of Fat. Chem. Senses 2015, 40, 507–516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, Z.; Boye, J.I. Advances in the Design and Production of Reduced-Fat and Reduced-Cholesterol Salad Dressing and Mayonnaise: A Review. Food Bioprocess Technol. 2013, 6, 648–670. [Google Scholar] [CrossRef]

- Frères, R. Nutriose® FM 06 Maize Dextrin: Product Data Sheet; Version 11; Roquette Frères: Lestrem, France, 2010. [Google Scholar]

- Lefranc-Millot, C.; Wils, D.; Deremaux, L.; Macioce, V.; Saniez-Degrave, M.-H. NUTRIOSE®, more than just a soluble fibre. In Dietary Fibre: New Frontiers for Food and Health; van der Kamp, J.W., Jones, J., McCleary, B., Topping, D., Eds.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2010; pp. 295–308. ISBN w978-90-8686-128-6. [Google Scholar]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making sense of the “clean label” trends: A review of consumer food choice behavior and discussion of industry implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- Schädle, C.N.; Eisner, P.; Bader-Mittermaier, S. The combined effects of different fat replacers and rennet casein on the properties of reduced-fat processed cheese. J. Dairy Sci. 2020, 103, 3980–3993. [Google Scholar] [CrossRef]

- Lefranc-Millot, C. NUTRIOSE® 06: A useful soluble dietary fibre for added nutritional value. Nutr. Bull. 2008, 33, 234–239. [Google Scholar] [CrossRef]

- Ruan, Q.; Yang, X.; Zeng, L.; Qi, J. Physical and tribological properties of high internal phase emulsions based on citrus fibers and corn peptides. Food Hydrocoll. 2019, 95, 53–61. [Google Scholar] [CrossRef]

- Flamminii, F.; Di Mattia, C.D.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and Sensory Properties of Mayonnaise Enriched with Encapsulated Olive Leaf Phenolic Extracts. Foods 2020, 9, 997. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, Y.; Ji, Z.; Chen, J. Lubrication and Sensory Properties of Emulsion Systems and Effects of Droplet Size Distribution. Foods 2021, 10, 3024. [Google Scholar] [CrossRef] [PubMed]

- Stokes, J.R. Oral Tribology. In Food Oral Processing: Fundamentals of Eating and Sensory Perception; Chen, J., Engelen, L., Eds.; Wiley Blackwell A John Wiley & Sons Ltd. Publication: Chichester, UK; Ames, IA, USA, 2012; pp. 265–288. [Google Scholar]

- Pondicherry, K.S.; Rummel, F.; Laeuger, J. Extended stribeck curves for food samples. Biosurf. Biotribol. 2018, 4, 34–37. [Google Scholar] [CrossRef]

- Pradal, C.; Stokes, J.R. Oral tribology: Bridging the gap between physical measurements and sensory experience. Curr. Opin. Food Sci. 2016, 9, 34–41. [Google Scholar] [CrossRef] [Green Version]

- Agyei-Amponsah, J.; Macakova, L.; DeKock, H.L.; Emmambux, M.N. Effect of Substituting Sunflower Oil with Starch-Based Fat Replacers on Sensory Profile, Tribology, and Rheology of Reduced-Fat Mayonnaise-Type Emulsions. Starch-Stärke 2021, 73, 2000092. [Google Scholar] [CrossRef]

- Dresselhuis, D.M.; de Hoog, E.H.A.; Cohen Stuart, M.A.; van Aken, G.A. Application of oral tissue in tribological measurements in an emulsion perception context. Food Hydrocoll. 2008, 22, 323–335. [Google Scholar] [CrossRef]

- Liu, K.; Tian, Y.; Stieger, M.; van der Linden, E.; van de Velde, F. Evidence for ball-bearing mechanism of microparticulated whey protein as fat replacer in liquid and semi-solid multi-component model foods. Food Hydrocoll. 2016, 52, 403–414. [Google Scholar] [CrossRef]

- Joyner (Melito), H.S.; Pernell, C.W.; Daubert, C.R. Impact of Oil-in-Water Emulsion Composition and Preparation Method on Emulsion Physical Properties and Friction Behaviors. Tribol. Lett. 2014, 56, 143–160. [Google Scholar] [CrossRef]

- Hamilton, I.E.; Norton, I.T. Modification to the lubrication properties of xanthan gum fluid gels as a result of sunflower oil and triglyceride stabilised water in oil emulsion addition. Food Hydrocoll. 2016, 55, 220–227. [Google Scholar] [CrossRef]

- Anvari, M.; Joyner (Melito), H.S. Effect of formulation on structure-function relationships of concentrated emulsions: Rheological, tribological, and microstructural characterization. Food Hydrocoll. 2017, 72, 11–26. [Google Scholar] [CrossRef]

- Malone, M.; Appelqvist, I.; Norton, I. Oral behaviour of food hydrocolloids and emulsions. Part 1. Lubrication and deposition considerations. Food Hydrocoll. 2003, 17, 763–773. [Google Scholar] [CrossRef]

- De Wijk, R.A.; Prinz, J.F. Mechanisms underlying the role of friction in oral texture. J. Texture Stud. 2006, 37, 413–427. [Google Scholar] [CrossRef]

- Depree, J.A.; Savage, G.P. Physical and flavour stability of mayonnaise. Trends Food Sci. Technol. 2001, 12, 157–163. [Google Scholar] [CrossRef]

- Lee, I.; Lee, S.; Lee, N.; Ko, S. Reduced-Fat Mayonnaise Formulated with Gelatinized Rice Starch and Xanthan Gum. Cereal Chem. 2013, 90, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Habashi, V.; Elhamirad, A.H.; Pedramnia, A. Textural properties of low fat mayonnaise with whey protein concentrate and Tragacanth gum as egg and fat substitutes. Foods Raw Mater. 2021, 9, 19–23. [Google Scholar] [CrossRef]

- Shen, R.; Luo, S.; Dong, J. Application of oat dextrine for fat substitute in mayonnaise. Food Chem. 2011, 126, 65–71. [Google Scholar] [CrossRef]

- Carcelli, A.; Crisafulli, G.; Carini, E.; Vittadini, E. Can a physically modified corn flour be used as fat replacer in a mayonnaise? Eur. Food Res. Technol. 2020, 246, 2493–2503. [Google Scholar] [CrossRef]

- Mun, S.; Kim, Y.-L.; Kang, C.-G.; Park, K.-H.; Shim, J.-Y.; Kim, Y.-R. Development of reduced-fat mayonnaise using 4αGTase-modified rice starch and xanthan gum. Int. J. Biol. Macromol. 2009, 44, 400–407. [Google Scholar] [CrossRef]

- Román, L.; Martínez, M.M.; Gómez, M. Assessing of the potential of extruded flour paste as fat replacer in O/W emulsion: A rheological and microstructural study. Food Res. Int. 2015, 74, 72–79. [Google Scholar] [CrossRef]

- AOAC. Method 925.10. Solids (total) and moisture in flour. In Official Methods of Analysis of the Association of Official Analytical Chemists (AOAC); Latimer, G.W., Horwitz, W., Eds.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- AOAC. Method 968.06. Protein (crude) in animal feed. In Official Methods of Analysis of the Association of Official Analytical Chemists (AOAC); Latimer, G.W., Horwitz, W., Eds.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- DGF. Deutsche Einheitsmethoden: Zur Untersuchung von Fetten, Fettprodukten, Tensiden und Verwandten Stoffen; 23rd update delivery to the 2nd ed.; Wissenschaftliche Verlagsgesellschaft: Stuttgart, Germany, 2018; ISBN 978-3-8047-3808-9. [Google Scholar]

- Javanmard, M.; Chin, N.L.; Mirhosseini, S.H.; Endan, J. Characteristics of gelling agent substituted fruit jam: Studies on the textural, optical, physicochemical and sensory properties. Int. J. Food Sci. Technol. 2012, 47, 1808–1818. [Google Scholar] [CrossRef]

- Swenson, B.J.; Wendorff, W.L.; Lindsay, R.C. Effects of ingredients on the functionality of fat-free process cheese spreads. J. Food Sci. 2000, 65, 822–825. [Google Scholar] [CrossRef]

- Liu, H.; Xu, X.M.; Guo, S. Rheological, texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT-Food Sci. Technol. 2007, 40, 946–954. [Google Scholar] [CrossRef]

- Stokes, J.R. ‘Oral’ Rheology. In Food Oral Processing: Fundamentals of Eating and Sensory Perception; Chen, J., Engelen, L., Eds.; Wiley Blackwell, A John Wiley & Sons, Ltd., Publication: Chichester, UK; Ames, IA, USA, 2012; pp. 227–264. [Google Scholar]

- Cook, D.J.; Linforth, R.S.T.; Taylor, A.J. Effects of hydrocolloid thickeners on the perception of savory flavors. J. Agric. Food Chem. 2003, 51, 3067–3072. [Google Scholar] [CrossRef] [PubMed]

- Tárrega, A.; Durán, L.; Costell, E. Flow behaviour of semi-solid dairy desserts. Effect of temperature. Int. Dairy J. 2004, 14, 345–353. [Google Scholar] [CrossRef]

- Miller, J.L.; Watkin, K.L. The influence of bolus volume and viscosity on anterior lingual force during the oral stage of swallowing. Dysphagia 1996, 11, 117–124. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Bhandari, B.; Prakash, S. Tribological method to measure lubricating properties of dairy products. J. Food Eng. 2016, 168, 27–34. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e.V. Sensorische Analyse-Prüfverfahren-Rangordnungsprüfung; 67.240 (DIN ISO 8587:2006-11); Beuth Verlag GmbH: Berlin, Germany, 2006. [Google Scholar]

- Agyei-Amponsah, J.; Macakova, L.; DeKock, H.L.; Emmambux, M.N. Sensory, Tribological, and Rheological Profiling of “Clean Label” Starch–Lipid Complexes as Fat Replacers. Starch-Stärke 2019, 71, 1800340. [Google Scholar] [CrossRef]

- Sachs, L. Applied Statistics: A Handbook of Techniques; Springer: New York, NY, USA, 1982; ISBN 978-1-4684-0125-7. [Google Scholar]

- Stevens, S.S. The psychophysical law. In Psychophysics: Introduction to Its Perceptual, Neural, and Social Prospects; Stevens, S.S., Ed.; Wiley-Interscience Publication: New York, NY, USA, 1975; pp. 1–36. ISBN 9780887386435. [Google Scholar]

- Arancibia, C.; Costell, E.; Bayarri, S. Impact of Structural Differences on Perceived Sweetness in Semisolid Dairy Matrices. J. Texture Stud. 2013, 44, 346–356. [Google Scholar] [CrossRef]

- Chang, C.; Li, J.; Li, X.; Wang, C.; Zhou, B.; Su, Y.; Yang, Y. Effect of protein microparticle and pectin on properties of light mayonnaise. LWT-Food Sci. Technol. 2017, 82, 8–14. [Google Scholar] [CrossRef]

- Taslikh, M.; Mollakhalili-Meybodi, N.; Alizadeh, A.M.; Mousavi, M.-M.; Nayebzadeh, K.; Mortazavian, A.M. Mayonnaise main ingredients influence on its structure as an emulsion. J. Food Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Dickinson, E. Food Emulsions and Foams, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 1987; ISBN 9781855737853. [Google Scholar]

- McClements, D.J. Food Emulsions: Principles, Practices, and Techniques, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-4987-2669-6. [Google Scholar]

- Teklehaimanot, W.H.; Duodu, K.G.; Emmambux, M.N. Maize and teff starches modified with stearic acid as potential fat replacer in low calorie mayonnaise-type emulsions. Starch-Stärke 2013, 65, 773–781. [Google Scholar] [CrossRef] [Green Version]

- Domene-López, D.; García-Quesada, J.C.; Martin-Gullon, I.; Montalbán, M.G. Influence of Starch Composition and Molecular Weight on Physicochemical Properties of Biodegradable Films. Polymers 2019, 11, 1084. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lefranc-Millot, C.; Wils, D.; Roturier, J.-M.; Le Bihan, C.; Saniez-Degrave, M.-H. Nutriose® soluble fiber. In Fiber Ingredients: Food Applications and Health Benefits; Cho, S.S., Samuel, P., Eds.; CRC Press: Boca Ratón, FL, USA, 2009; pp. 19–40. ISBN 978-1-4200-4384-6. [Google Scholar]

- Rao, M.A. Rheology of Fluid, Semisolid, and Solid Foods: Principles and Applications, 3rd ed.; Imprint; Springer: New York, NY, USA, 2014; ISBN 978-1-4614-9229-0. [Google Scholar]

- Mezger, T.G. Das Rheologie-Handbuch: Für Anwender von Rotations- und Oszillations-Rheometern, 2nd revised ed.; Vincentz Network: Hannover, Germany, 2006; ISBN 978-3-87870-175-0. [Google Scholar]

- Krzeminski, A.; Tomaschunas, M.; Köhn, E.; Busch-Stockfisch, M.; Weiss, J.; Hinrichs, J. Relating creamy perception of whey protein enriched yogurt systems to instrumental data by means of multivariate data analysis. J. Food Sci. 2013, 78, S314–S319. [Google Scholar] [CrossRef] [PubMed]

- Shama, F.; Sherman, P. Identification of stimuli controlling the sensory evaluation of viscosity: II. Oral methods. J. Texture Stud. 1973, 4, 111–118. [Google Scholar] [CrossRef]

- Kokini, J.L.; Kadane, J.B.; Cussler, E.L. Liquid texture perceived in the mouth. J. Texture Stud. 1977, 8, 195–218. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, R.; Zeng, J.; Li, G.; Li, X. Characterization of dextrins with different dextrose equivalents. Molecules 2010, 15, 5162–5173. [Google Scholar] [CrossRef] [Green Version]

- Siemons, I.; Politiek, R.G.A.; Boom, R.M.; van der Sman, R.G.M.; Schutyser, M.A.I. Dextrose equivalence of maltodextrins determines particle morphology development during single sessile droplet drying. Food Res. Int. 2020, 131, 108988. [Google Scholar] [CrossRef]

- Dokic, P.; Dokic-Baucal, L.; Sovilj, V.; Katona, J. Influence of maltodextrin dextrose equivalent value on rheological and dispersion properties of sunflower oil in water emulsions. Acta Period. Technol. 2004, 35, 17–24. [Google Scholar] [CrossRef]

- McClements, D.J.; Demetriades, K. An integrated approach to the development of reduced-fat food emulsions. Crit. Rev. Food Sci. Nutr. 1998, 38, 511–536. [Google Scholar] [CrossRef]

- Raymundo, A.; Franco, J.M.; Empis, J.; Sousa, I. Optimization of the composition of low-fat oil-in-water emulsions stabilized by white lupin protein. J. Am. Oil Chem. Soc. 2002, 79, 783–790. [Google Scholar] [CrossRef]

- Katsaros, G.; Tsoukala, M.; Giannoglou, M.; Taoukis, P. Effect of storage on the rheological and viscoelastic properties of mayonnaise emulsions of different oil droplet size. Heliyon 2020, 6, e05788. [Google Scholar] [CrossRef]

- Selway, N.; Stokes, J.R. Soft materials deformation, flow, and lubrication between compliant substrates: Impact on flow behavior, mouthfeel, stability, and flavor. Annu. Rev. Food Sci. Technol. 2014, 5, 373–393. [Google Scholar] [CrossRef] [PubMed]

- Ranc, H.; Elkhyat, A.; Servais, C.; Mac-Mary, S.; Launay, B.; Humbert, P. Friction coefficient and wettability of oral mucosal tissue: Changes induced by a salivary layer. Colloids Surf. A Physicochem. Eng. Asp. 2006, 276, 155–161. [Google Scholar] [CrossRef]

- Bellamy, M.; Godinot, N.; Mischler, S.; Martin, N.; Hartmann, C. Influence of emulsion composition on lubrication capacity and texture perception. Int. J. Food Sci. Technol. 2009, 44, 1939–1949. [Google Scholar] [CrossRef]

- Dresselhuis, D.M.; Klok, H.J.; Cohen Stuart, M.A.; de Vries, R.J.; van Aken, G.A.; de Hoog, E.H.A. Tribology of o/w Emulsions Under Mouth-like Conditions: Determinants of Friction. Food Biophys. 2007, 2, 158–171. [Google Scholar] [CrossRef] [Green Version]

- Oppermann, A.K.L.; Verkaaik, L.C.; Stieger, M.; Scholten, E. Influence of double (w1/o/w2) emulsion composition on lubrication properties. Food Funct. 2017, 8, 522–532. [Google Scholar] [CrossRef] [Green Version]

- Wilson, W.R.D.; Sakaguchi, Y.; Schmid, S.R. A Mixed Flow Model for Lubrication with Emulsions. Tribol. Trans. 1994, 37, 543–551. [Google Scholar] [CrossRef]

- Schmid, S.; Wilson, W. Lubrication mechanisms for oil-in-water emulsions. Lubr. Eng. 1996, 52, 168–175. [Google Scholar]

- Reich, R.; Urbanski, J. Experimental Support for the Dynamic Concentration Theory of Forming an Oil Reservoir at the Inlet of the Roll Bite by Measuring the Onset Speed of Starvation as a Function of Oil Concentration and Droplet Size. Tribol. Trans. 2004, 47, 489–499. [Google Scholar] [CrossRef]

- Tieu, A.K.; Kosasih, P.B. Experimental and numerical study of O/W emulsion lubricated strip rolling in mixed film regime. Tribol. Lett. 2006, 25, 23–32. [Google Scholar] [CrossRef]

- de Vicente, J.; Spikes, H.A.; Stokes, J.R. Viscosity Ratio Effect in the Emulsion Lubrication of Soft EHL Contact. J. Tribol. 2006, 128, 795–800. [Google Scholar] [CrossRef]

- Boehm, M.W.; Yakubov, G.E.; Delwiche, J.F.; Stokes, J.R.; Baier, S.K. Enabling the Rational Design of Low-Fat Snack Foods: Insights from In Vitro Oral Processing. J. Agric. Food Chem. 2019, 67, 8725–8734. [Google Scholar] [CrossRef] [PubMed]

- Godoi, F.C.; Bhandari, B.R.; Prakash, S. Tribo-rheology and sensory analysis of a dairy semi-solid. Food Hydrocoll. 2017, 70, 240–250. [Google Scholar] [CrossRef] [Green Version]

- Laguna, L.; Barrowclough, R.A.; Chen, J.; Sarkar, A. New Approach to Food Difficulty Perception: Food Structure, Food Oral Processing and Individual’s Physical Strength. J. Texture Stud. 2016, 47, 413–422. [Google Scholar] [CrossRef]

- Selway, N.; Stokes, J.R. Insights into the dynamics of oral lubrication and mouthfeel using soft tribology: Differentiating semi-fluid foods with similar rheology. Food Res. Int. 2013, 54, 423–431. [Google Scholar] [CrossRef]

- Joyner (Melito), H.S.; Pernell, C.W.; Daubert, C.R. Impact of formulation and saliva on acid milk gel friction behavior. J. Food Sci. 2014, 79, E867–E880. [Google Scholar] [CrossRef] [PubMed]

- Ningtyas, D.W.; Bhandari, B.; Bansal, N.; Prakash, S. Sequential aspects of cream cheese texture perception using temporal dominance of sensations (TDS) tool and its relation with flow and lubrication behaviour. Food Res. Int. 2019, 120, 586–594. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bayarri, S.; Smith, T.; Hollowood, T.A.; Hort, J. The role of rheological behaviour in flavour perception in model oil/water emulsions. Eur. Food Res. Technol. 2007, 226, 161–168. [Google Scholar] [CrossRef]

- Ross, A.I.; Tyler, P.; Borgognone, M.G.; Eriksen, B.M. Relationships between shear rheology and sensory attributes of hydrocolloid-thickened fluids designed to compensate for impairments in oral manipulation and swallowing. J. Food Eng. 2019, 263, 123–131. [Google Scholar] [CrossRef]

| Type of Glycosidic Linkages | (1) | (2) | (3) |

|---|---|---|---|

| (1,4) | 41 | 95 | 95 |

| (1,6) | 32 | 5 | 5 |

| (1,2) | 13 | 0 | 0 |

| (1,3) | 14 | 0 | 0 |

| Full Fat | 0% CD | 0.5% CD | 1% CD | 2% CD | 4% CD | 6% CD | 8% CD | 8% Malt | |

|---|---|---|---|---|---|---|---|---|---|

| (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | |

| Rapeseed oil | 50.3 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Water | 37.68 | 56.38 | 55.88 | 55.38 | 54.38 | 52.38 | 50.38 | 48.38 | 48.38 |

| Sunflower protein | 2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Corn starch | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Corn dextrin | 0 | 0 | 0.5 | 1 | 2 | 4 | 6 | 8 | 0 |

| Maltodextrin | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 8 |

| Skim milk powder | 0 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Xanthan gum | 0 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Citric acid | 0.12 | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 |

| Sugar | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 |

| Salt | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Mustard | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Vinegar | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Formulation | Firmness (mN) | Stickiness (mN) | Work of Shear (N∙s) | Work of Adhesion (N∙s) |

|---|---|---|---|---|

| Full fat | 93.7 ± 2.8 d | −74.1 ± 3.1 a | 1.28 ± 0.09 e | −0.40 ± 0.03 a |

| 0% CD | 136.0 ± 3.1 c | −126.3 ± 3.0 b | 2.38 ± 0.07 d | −0.86 ± 0.04 b |

| 0.5% CD | 138.3 ± 4.7 c | −128.3 ± 3.9 b | 2.44 ± 0.13 cd | −0.88 ± 0.05 b |

| 1% CD | 141.6 ± 4.9 bc | −131.1 ± 5.7 bc | 2.44 ± 0.07 cd | −0.88 ± 0.03 b |

| 2% CD | 144.6 ± 7.0 b | −135.9 ± 6.8 c | 2.54 ± 0.20 c | −0.92 ± 0.08 b |

| 4% CD | 159.6 ± 5.1 a | −149.8 ± 5.9 d | 2.89 ± 0.16 b | −1.05 ± 0.06 c |

| 6% CD | 157.9 ± 10.4 a | −149.1 ± 10.8 d | 2.92 ± 0.23 b | −1.04 ± 0.10 c |

| 8% CD | 156.0 ± 12.3 a | −150.2 ± 13.1 d | 3.00 ± 0.26 ab | −1.09 ± 0.12 cd |

| 8% Malt | 157.8 ± 9.3 a | −154.3 ± 9.6 d | 3.12 ± 0.17 a | −1.15 ± 0.05 d |

| Formulation | Firmness | Stickiness | Creaminess |

|---|---|---|---|

| Full fat | 20 e | 16 d | 19 d |

| 0% CD | 38 de | 45 bc | 52 bc |

| 0.5% CD | 43 de | 42 c | 49 c |

| 1% CD | 46 cd | 57 abc | 49 c |

| 2% CD | 52 bcd | 55 abc | 52 bc |

| 4% CD | 70 abc | 71 a | 62 abc |

| 6% CD | 82 a | 64 abc | 58 abc |

| 8% CD | 73 ab | 75 a | 76 ab |

| 8% Malt | 71 abc | 70 ab | 78 a |

| 39.8 | 33.4 | 29.3 |

| Sensory Stickiness | Sensory Firmness | Sensory Creaminess | |

|---|---|---|---|

| Hysteresis area | 0.92 | 0.94 | 0.94 |

| Viscosity at 10 s−1 | 0.94 | 0.89 | 0.95 |

| Viscosity at 100 s−1 | 0.93 | 0.87 | 0.94 |

| Yield stress | 0.89 | 0.84 | 0.91 |

| Consistency | 0.94 | 0.87 | 0.91 |

| Kokini OSS | 0.94 | 0.89 | 0.94 |

| Work of shear | 0.96 | 0.92 | 0.96 |

| Work of adhesion | −0.95 | −0.89 | −0.96 |

| Firmness | 0.96 | 0.91 | 0.91 |

| Stickiness | −0.96 | −0.90 | −0.93 |

| Sensory Stickiness | Sensory Firmness | Sensory Creaminess | |||||||

|---|---|---|---|---|---|---|---|---|---|

| k | β | r | k | β | r | k | β | r | |

| Hysteresis area | 0.041 | 1.30 | 0.91 | 0.015 | 1.48 | 0.93 | 0.045 | 1.28 | 0.93 |

| Viscosity at 10 s−1 | 1.20 × 10−5 | 1.60 | 0.95 | 9.91 × 10−7 | 1.85 | 0.92 | 2.35 × 10−5 | 1.53 | 0.95 |

| Viscosity at 100 s−1 | 1.53×10−3 | 1.33 | 0.93 | 1.55 × 10−4 | 1.62 | 0.89 | 1.76 × 10−3 | 1.31 | 0.95 |

| Yield stress | 0.28 | 1.26 | 0.88 | 0.19 | 1.36 | 0.83 | 0.27 | 1.27 | 0.91 |

| Consistency | 0.19 | 1.61 | 0.95 | 0.017 | 2.38 | 0.94 | 0.57 | 1.30 | 0.91 |

| Kokini OSS | 0.022 | 1.55 | 0.94 | 5.38 × 10−3 | 1.83 | 0.91 | 0.029 | 1.50 | 0.95 |

| Work of shear | 10.91 | 1.70 | 0.96 | 7.69 | 2.04 | 0.94 | 11.87 | 1.61 | 0.97 |

| Work of adhesion | 61.26 | 1.52 | 0.96 | 61.34 | 1.80 | 0.92 | 61.01 | 1.48 | 0.97 |

| Firmness | 3.81 × 10−5 | 2.85 | 0.97 | 9.97 × 10−7 | 3.58 | 0.96 | 4.37 × 10−4 | 2.36 | 0.91 |

| Stickiness | 9.21 × 10−4 | 2.24 | 0.97 | 5.27 × 10−5 | 2.82 | 0.95 | 3.4 × 10−3 | 1.97 | 0.94 |

| Pearson Correlation Coefficient r | |

|---|---|

| Yield stress and work of shear | 0.94 |

| Yield stress and work of adhesion | −0.94 |

| Consistency and firmness | 0.99 |

| Viscosity at 10 s−1 and work of shear | 1.00 |

| Viscosity at 10 s−1 and firmness | 0.99 |

| Viscosity at 10 s−1 and sliding speed at maximum coefficient of friction (of curve 2/curve 3) | 0.96/0.93 |

| Viscosity at 10 s−1 and maximum COF of curve 3 | −0.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schädle, C.N.; Bader-Mittermaier, S.; Sanahuja, S. Characterization of Reduced-Fat Mayonnaise and Comparison of Sensory Perception, Rheological, Tribological, and Textural Analyses. Foods 2022, 11, 806. https://doi.org/10.3390/foods11060806

Schädle CN, Bader-Mittermaier S, Sanahuja S. Characterization of Reduced-Fat Mayonnaise and Comparison of Sensory Perception, Rheological, Tribological, and Textural Analyses. Foods. 2022; 11(6):806. https://doi.org/10.3390/foods11060806

Chicago/Turabian StyleSchädle, Christopher N., Stephanie Bader-Mittermaier, and Solange Sanahuja. 2022. "Characterization of Reduced-Fat Mayonnaise and Comparison of Sensory Perception, Rheological, Tribological, and Textural Analyses" Foods 11, no. 6: 806. https://doi.org/10.3390/foods11060806

APA StyleSchädle, C. N., Bader-Mittermaier, S., & Sanahuja, S. (2022). Characterization of Reduced-Fat Mayonnaise and Comparison of Sensory Perception, Rheological, Tribological, and Textural Analyses. Foods, 11(6), 806. https://doi.org/10.3390/foods11060806