Oat Yogurts Enriched with Synbiotic Microcapsules: Physicochemical, Microbiological, Textural and Rheological Properties during Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starter Cultures

2.2. Vegetable Oat Beverage

2.3. Synbiotic Microcapsules

2.4. Reagents

2.5. Preparation of Synbiotic Yoghurt

2.6. Survivability of Microencapsulated Probiotics in Vegetable Yogurt

2.7. Cell Viability Rate (R%)

2.8. Determination of pH and Total Titratable Acidity

2.9. Color Analysis

2.10. Texture Analysis

2.11. Rheological Analysis

2.12. Determination of Free Amino Acids

2.13. Determination of Organic Acids

2.14. Sensory Analyses

2.15. Statistical Analysis

3. Results and Discussion

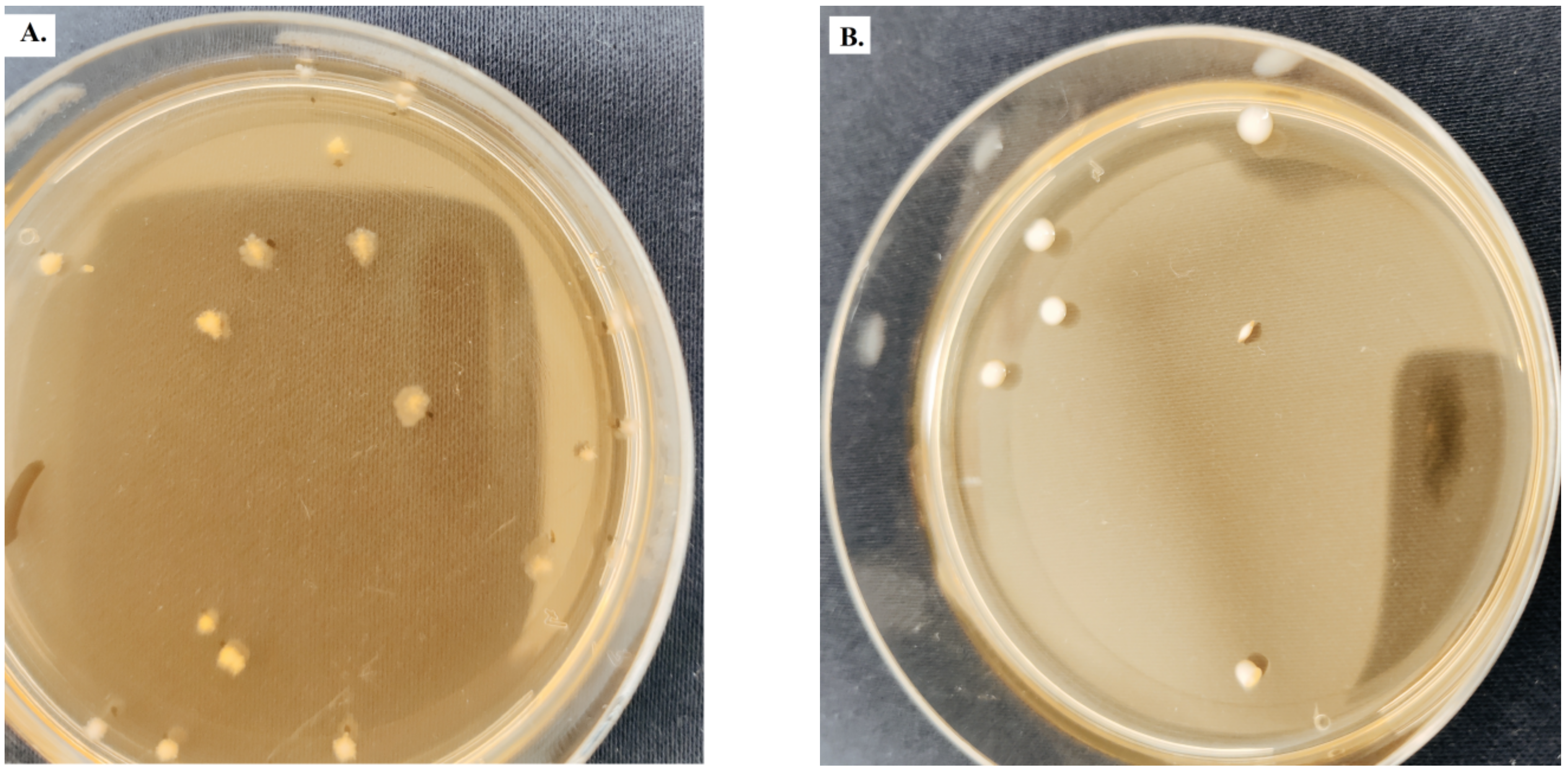

3.1. Viability Study of Probiotic Strains in Oat Milk Yogurt

3.2. The Viability of the Probiotics Strains on Simulated In Vitro Gastric Juice

3.3. Physico-Chemical Properties of Oat Yogurt

3.3.1. Color

3.3.2. Study of the Evolution of Titratable Acidity and pH

3.3.3. Study of the Influence of Synbiotic Microcapsules on the Texture of Yogurt from Oats

3.3.4. Rheological Properties of Oat Yogurt

3.4. Sensory Analysis

3.5. Study of Organic Acid Content

3.6. Study of Amino Acid Content

3.7. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, B.T.; Bujna, E.; Fekete, N.; Tran, A.T.M.; Rezessy-Szabo, J.M.; Prasad, R.; Nguyen, Q.D. Probiotic beverage from pineapple juice fermented with Lactobacillus and Bifidobacterium strains. Front. Nutr. 2019, 6, 54. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pimentel, T.C.; Madrona, G.S.; Garcia, S.; Prudencio, S.H. Probiotic viability, physicochemical characteristics and acceptability during refrigerated storage of clarified apple juice supplemented with Lactobacillus paracasei ssp. paracasei and oligofructose in different package type. LWT -Food Sci. Technol. 2015, 63, 415–422. [Google Scholar] [CrossRef]

- Panghal, A.; Janghu, S.; Virkar, K.; Gat, Y.; Kumar, V.; Chhikara, N. Potential non-dairy probiotic products—A healthy approach. Food Biosci. 2018, 21, 80–89. [Google Scholar]

- Pereira, A.L.F.; Rodrigues, S. Turning Fruit Juice into Probiotic Beverages. In Fruit Juices: Extraction, Composition, Quality and Analysis; Academic Press: San Diego, CA, USA, 2018. [Google Scholar]

- Salmerón, I.; Thomas, K.; Pandiella, S.S. Effect of potentially probiotic lactic acid bacteria on the physicochemical composition and acceptance of fermented cereal beverages. J. Funct. Foods 2015, 15, 106–115. [Google Scholar] [CrossRef]

- Kumar, B.V.; Vijayendra, S.V.N.; Reddy, O.V.S. Trends in dairy and non-dairy probiotic products—A review. J. Food Sci. Technol. 2015, 52, 6112–6124. [Google Scholar]

- Sengupta, S.; Koley, H.; Dutta, S.; Bhowal, J. Hepatoprotective effects of synbiotic soy yogurt on mice fed a high-cholesterol diet. Nutrition 2019, 63–64, 36–44. [Google Scholar] [CrossRef]

- Gupta, S.; Abu-Ghannam, N. Probiotic fermentation of plant based products: Possibilities and opportunities. Crit. Rev. Food Sci. Nutr. 2012, 52, 183–199. [Google Scholar]

- Hoseney, R.C.; Rogers, D.E. The Formation and Properties of Wheat Flour Doughs. Crit. Rev. Food Sci. Nutr. 1990, 29, 73–93. [Google Scholar] [CrossRef]

- Krauss, R.M.; Eckel, R.H.; Howard, B.; Appel, L.J.; Daniels, S.R.; Deckelbaum, R.J.; Erdman, J.; Kris-Etherton, P.; Goldberg, I.J.; Kotchen, T.A.; et al. AHA Dietary Guidelines Revision 2000: A statement for healthcare professionals from the Nutrition Committee of the American Heart Association. Circulation 2000, 102, 2284–2299. [Google Scholar]

- Winning, H.; Viereck, N.; Nørgaard, L.; Larsen, J.; Engelsen, S.B. Quantification of the degree of blockiness in pectins using 1H NMR spectroscopy and chemometrics. Food Hydrocoll. 2007, 21, 256–266. [Google Scholar] [CrossRef]

- Jirsa, O.; Sedláčková, I.; Vaculová, K. Quantification of β-glucans in Barley—Review. Kvas. Prum. 2018, 64, 2–5. [Google Scholar] [CrossRef] [Green Version]

- Gupta, M.; Bajaj, B.K. Development of fermented oat flour beverage as a potential probiotic vehicle. Food Biosci. 2017, 20, 104–109. [Google Scholar] [CrossRef]

- Mårtensson, O.; Andersson, C.; Andersson, K.; Öste, R.; Holst, O. Formulation of an oat-based fermented product and its comparison with yoghurt. J. Sci. Food Agric. 2001, 81, 1314–1321. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; González-Martínez, C.; Rodríguez-García, J.; Chiralt, A. Optimisation of oat milk formulation to obtain fermented derivatives by using probiotic Lactobacillus reuteri microorganisms. Food Sci. Technol. Int. 2015, 21, 145–157. [Google Scholar] [CrossRef]

- Mantzouridou, F.; Karousioti, A.; Kiosseoglou, V. Formulation optimization of a potentially prebiotic low-in-oil oat-based salad dressing to improve Lactobacillus paracasei subsp. paracasei survival and physicochemical characteristics. LWT-Food Sci. Technol. 2013, 53, 560–568. [Google Scholar] [CrossRef]

- Gueimonde, M.; Delgado, S.; Mayo, B.; Ruas-Madiedo, P.; Margolles, A.; De Los Reyes-Gavilán, C.G. Viability and diversity of probiotic Lactobacillus and Bifidobacterium populations included in commercial fermented milks. Food Res. Int. 2004, 37, 839–850. [Google Scholar] [CrossRef]

- Ibrahim, S.A.; Carr, J.P. Viability of bifidobacteria in commercial yogurt products in North Carolina during refrigerated storage. Int. J. Dairy Technol. 2006, 59, 272–277. [Google Scholar] [CrossRef]

- Lin, W.H.; Hwang, C.F.; Chen, L.W.; Tsen, H.Y. Viable counts, characteristic evaluation for commercial lactic acid bacteria products. Food Microbiol. 2006, 23, 74–81. [Google Scholar] [CrossRef]

- Nualkaekul, S.; Cook, M.T.; Khutoryanskiy, V.V.; Charalampopoulos, D. Influence of encapsulation and coating materials on the survival of Lactobacillus plantarum and Bifidobacterium longum in fruit juices. Food Res. Int. 2013, 53, 304–311. [Google Scholar] [CrossRef]

- Luca, L.; Oroian, M. Influence of different prebiotics on viability of Lactobacillus casei, Lactobacillus plantarum and Lactobacillus rhamnosus encapsulated in alginate microcapsules. Foods 2021, 10, 710. [Google Scholar] [CrossRef]

- Luca, L.; Oroian, M. The effect of microencapsulation and potato starch on the survival of Lactobacillus strains. Food Environ. Saf. J. 2020, 19, 139–147. [Google Scholar]

- Oyeniran, A.; Ibrahim, S.A.; Gyawali, R.; Tahergorabi, R.; Zimmerman, T.; Krastanov, A. A modified reinforced clostridial medium for the isolation and enumeration of Lactobacillus delbrueckii ssp. bulgaricus in a mixed culture. J. Dairy Sci. 2020, 103, 5030–5042. [Google Scholar] [CrossRef]

- Dimitrellou, D.; Kandylis, P.; Lević, S.; Petrović, T.; Ivanović, S.; Nedović, V.; Kourkoutas, Y. Encapsulation of Lactobacillus casei ATCC 393 in alginate capsules for probiotic fermented milk production. LWT 2019, 116, 108501. [Google Scholar] [CrossRef]

- Chávarri, M.; Marañón, I.; Ares, R.; Ibáñez, F.C.; Marzo, F.; del Carmen Villarán, M. Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int. J. Food Microbiol. 2010, 142, 185–189. [Google Scholar] [CrossRef] [PubMed]

- Rather, S.A.; Akhter, R.; Masoodi, F.A.; Gani, A.; Wani, S.M. Effect of double alginate microencapsulation on in vitro digestibility and thermal tolerance of Lactobacillus plantarum NCDC201 and L. casei NCDC297. LWT-Food Sci. Technol. 2017, 83, 50–58. [Google Scholar] [CrossRef]

- Pauliuc, D.; Dranca, F.; Oroian, M. Antioxidant activity, total phenolic content, individual phenolics and physicochemical parameters suitability for Romanian honey authentication. Foods 2020, 9, 306. [Google Scholar] [CrossRef] [Green Version]

- Özcelik, S.; Kuley, E.; Özogul, F. Formation of lactic, acetic, succinic, propionic, formic and butyric acid by lactic acid bacteria. LWT-Food Sci. Technol. 2016, 73, 536–542. [Google Scholar] [CrossRef]

- World Health Organization. Joint WHO/FAO Expert Consultation WHO Technical Report Series 916: Diet, Nutrition and the Prevention of Chronic Diseases; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

- Del Piano, M.; Carmagnola, S.; Ballarè, M.; Sartori, M.; Orsello, M.; Balzarini, M.; Tari, R.; Anderloni, A.; Strozzi, G.P.; Mogna, L.; et al. Is microencapsulation the future of probiotic preparations? The increased efficacy of gastro-protected probiotics. Gut Microbes 2011, 2, 120–123. [Google Scholar] [CrossRef] [Green Version]

- Kedia, G.; Vázquez, J.A.; Pandiella, S.S. Enzymatic digestion and in vitro fermentation of oat fractions by human lactobacillus strains. Enzyme Microb. Technol. 2008, 43, 355–361. [Google Scholar] [CrossRef] [Green Version]

- Luana, N.; Rossana, C.; Curiel, J.A.; Kaisa, P.; Marco, G.; Rizzello, C.G. Manufacture and characterization of a yogurt-like beverage made with oat flakes fermented by selected lactic acid bacteria. Int. J. Food Microbiol. 2014, 185, 17–26. [Google Scholar] [CrossRef]

- Gupta, S.; Cox, S.; Abu-Ghannam, N. Process optimization for the development of a functional beverage based on lactic acid fermentation of oats. Biochem. Eng. J. 2010, 52, 199–204. [Google Scholar] [CrossRef]

- Helland, M.H.; Wicklund, T.; Narvhus, J.A. Growth and metabolism of selected strains of probiotic bacteria in milk- and water-based cereal puddings. Int. Dairy J. 2004, 14, 957–965. [Google Scholar] [CrossRef]

- Brückner-Gühmann, M.; Benthin, A.; Drusch, S. Enrichment of yoghurt with oat protein fractions: Structure formation, textural properties and sensory evaluation. Food Hydrocoll. 2019, 86, 146–153. [Google Scholar] [CrossRef]

- Årsköld, E.; Svensson, M.; Grage, H.; Roos, S.; Rådström, P.; van Niel, E.W.J. Environmental influences on exopolysaccharide formation in Lactobacillus reuteri ATCC 55730. Int. J. Food Microbiol. 2007, 116, 159–167. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.H.; Wu, C.S.; Wang, M.; Xu, B.N.; Du, L.J. Effect of drying of jujubes (Ziziphus jujuba Mill.) on the contents of sugars, organic acids, α-tocopherol, β-carotene, and phenolic compounds. J. Agric. Food Chem. 2012, 60, 9642–9648. [Google Scholar] [CrossRef]

- Gänzle, M.G.; Follador, R. Metabolism of oligosaccharides and starch in lactobacilli: A review. Front. Microbiol. 2012, 3, 340. [Google Scholar]

- Onyango, C.; Okoth, M.W.; Mbugua, S.K. Effect of drying lactic fermented Uji (an East African sour porridge) on some carboxylic acids. J. Sci. Food Agric. 2000, 80, 1854–1858. [Google Scholar] [CrossRef]

- Martinez, F.A.C.; Balciunas, E.M.; Salgado, J.M.; González, J.M.D.; Converti, A.; de Souza Oliveira, R.P. Lactic acid properties, applications and production: A review. Trends Food Sci. Technol. 2013, 30, 70–83. [Google Scholar]

T0—the moment of analysis from the day of obtaining the yogurt;

T0—the moment of analysis from the day of obtaining the yogurt;  T7,

T7,  T14,

T14,  T21 and

T21 and  T28—yogurt analysis moments relative to day T0.

T28—yogurt analysis moments relative to day T0.

T0—the moment of analysis from the day of obtaining the yogurt;

T0—the moment of analysis from the day of obtaining the yogurt;  T7,

T7,  T14,

T14,  T21 and

T21 and  T28—yogurt analysis moments relative to day T0.

T28—yogurt analysis moments relative to day T0.

| Microcapsules Type with 2% Alginate | Dimension (μm) | Cell Load (log10 cfu/g) |

|---|---|---|

| 2% glucose | 215.00–404.00 | 11.90 ± 0.16 |

| 2% oligofructose | 203.00–474.00 | 12.03 ± 0.20 |

| 2% starch | 230.00–495.00 | 12.53 ± 0.05 |

| 2% inulin | 211.00–482.00 | 12.32 ± 0.09 |

| Parameter | Storage Period (Days) | Value F | Type of Yogurt | Value F | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | I M | I G | I INU | I OLI | I STH | |||

| L * | 74.98 ± 0.02 ab | 74.64 ± 0.01 ab | 73.47 ± 0.03 a | 76.09 ± 0.01 b | 76.67 ± 0.02 b | 4.08 * | 74.98 ± 0.02 a | 74.37 ± 0.02 a | 75.44 ± 0.01 a | 75.39 ± 0.01 a | 75.67 ± 0.01 a | 0.57 ns |

| a * | −4.96 ± 0.01 a | −5.01 ± 0.02 a | −4.69 ± 0.03 b | −4.50 ± 0.01 c | −4.95 ± 0.02 a | 59.78 *** | −4.76 ± 0.01 a | −4.88 ± 0.02 a | −4.83 ± 0.05 a | −4.85 ± 0.05 a | −4.79 ± 0.06 a | 0.72 ns |

| b * | 14.39 ± 0.02 b | 14.46 ± 0.02 b | 15.57 ± 0.04 d | 15.11 ± 0.02 c | 14.03± 0.05 a | 71.71 *** | 14.63 ± 0.02 a | 14.79 ± 0.04 a | 14.77 ± 0.03 a | 14.57 ± 0.01 a | 14.82 ± 0.02 a | 0.44 ns |

| pH | 3.75 ± 0.10 c | 3.70 ± 0.08 bc | 3.69 ± 0.12 bc | 3.62 ± 0.12 ab | 3.55 ± 0.10 a | 8.335 | 3.82 ± 0.01 c | 3.67 ± 0.01 b | 3.53 ± 0.01 a | 3.60 ± 0.01 ab | 3.68 ± 0.01 b | 24.86 *** |

| Titratable acidity % lactic acid | 0.17 ± 0.02 a | 0.25 ± 0.04 b | 0.31 ± 0.01 bc | 0.40 ± 0.1 d | 0.42 ± 0.07 c | 0.29 *** | 0.22 ± 0.01 a | 0.34 ± 0.01 b | 0.30 ± 0.01 ab | 0.33 ± 0.01 b | 0.30 ± 0.02 ab | 0.08 * s 3.18 * s |

| Viscosity (Pa·s) | 3.07 ± 0.04 b | 3.60 ± 0.03 c | 3.67 ± 0.05 c | 2.91 ± 0.04 b | 2.57 ± 0.05 a | 21.12 *** | 3.08 ± 0.02 a | 3.19 ± 0.04 ab | 3.32 ± 0.04 b | 3.15 ± 0.07 ab | 3.08 ± 0.04 a | 1.17 ns |

| Adhesives (J) | 592.91 ± 43.3 c | 846.29 ± 194.73 a | 588.99 ± 113.23 c | 792.20 ± 107.13 ab | 683.52 ± 75.98 bc | 14.65 *** | 691.94 ± 4.89 a | 720.14 ± 26.93 a | 646.54 ± 11.87 a | 700.58 ± 10.21 a | 744.73 ± 19.55 a | 0.82 ns |

| Hardness (g) | 129.80 ± 10.91 a | 193.50 ± 50.34 b | 215.20 ± 49.36 b | 302.93 ± 49.59 c | 140.00 ± 25.39 a | 58.32 *** | 208.13 ± 4.01 a | 192.10 ± 1.21 a | 181.00 ± 2.01 a | 201.86 ± 1.81 a | 198.33 ± 1.01 a | 0.30 ns |

| Cohesion | 1.27 ± 0.17 bc | 1.28 ± 0.39 bc | 0.91 ± 0.33 a | 1.07 ± 0.45 ab | 1.48 ± 0.13 c | 6.93 *** | 1.09 ± 0.18 a | 1.32 ± 0.06 a | 1.22 ± 0.08 a | 1.17 ± 0.08 a | 1.22 ± 0.04 a | 0.74 ns |

| Oat aroma | 2.76 ± 0.20 a | 2.94 ± 0.02 a | 2.89 ± 0.15 a | 2.86 ± 0.09 a | 2.87 ± 0.13 a | 1.12 ns | 2.84 ± 0.09 ab | 2.92 ± 0.07 ab | 2.78 ± 0.12 a | 2.76 ± 0.17 a | 3.02 ± 0.05 b | 4.81 ** |

| Storage Time (Days) | I.OLI | I.G | I.STH | I.INU | |

|---|---|---|---|---|---|

| dE * | T0 | 0.79 | 0.71 | 0.65 | 1.15 |

| T7 | 0.22 | 0.36 | 0.66 | 0.56 | |

| T14 | 0.56 | 1.30 | 1.09 | 0.32 | |

| T21 | 0.55 | 1.02 | 1.05 | 0.48 | |

| T28 | 0.43 | 0.98 | 1.04 | 0.52 | |

| dC * | T0 | 0.66 | 0.55 | 0.45 | 1.05 |

| T7 | 0.08 | 0.24 | 0.54 | 0.50 | |

| T14 | 0.07 | 0.26 | 0.14 | 0.30 | |

| T21 | −0.02 | 0.01 | 0.14 | 0.38 | |

| T28 | −0.09 | 0.01 | 0.23 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luca, L.; Oroian, M. Oat Yogurts Enriched with Synbiotic Microcapsules: Physicochemical, Microbiological, Textural and Rheological Properties during Storage. Foods 2022, 11, 940. https://doi.org/10.3390/foods11070940

Luca L, Oroian M. Oat Yogurts Enriched with Synbiotic Microcapsules: Physicochemical, Microbiological, Textural and Rheological Properties during Storage. Foods. 2022; 11(7):940. https://doi.org/10.3390/foods11070940

Chicago/Turabian StyleLuca, Liliana, and Mircea Oroian. 2022. "Oat Yogurts Enriched with Synbiotic Microcapsules: Physicochemical, Microbiological, Textural and Rheological Properties during Storage" Foods 11, no. 7: 940. https://doi.org/10.3390/foods11070940

APA StyleLuca, L., & Oroian, M. (2022). Oat Yogurts Enriched with Synbiotic Microcapsules: Physicochemical, Microbiological, Textural and Rheological Properties during Storage. Foods, 11(7), 940. https://doi.org/10.3390/foods11070940