Nutritional, Functional, Textural and Sensory Evaluation of Spirulina Enriched Green Pasta: A Potential Dietary and Health Supplement

Abstract

:1. Introduction

2. Material and Methods

2.1. Cultivation and Production of Spirulina

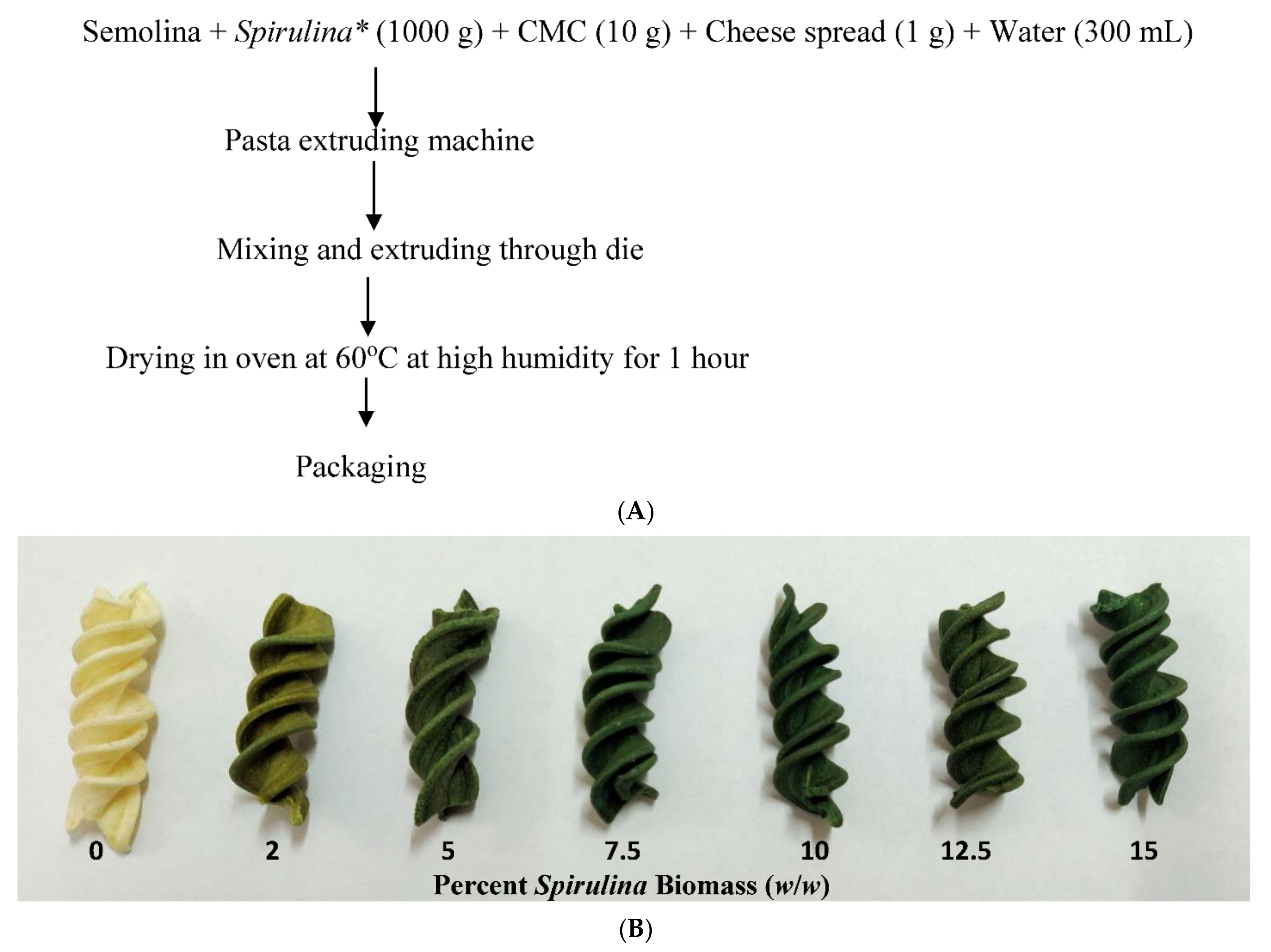

2.2. Pasta Preparation

2.3. Nutritional Evaluation

2.4. Minerals

2.5. Cooking Quality of Pasta

2.6. Textural Analysis

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition of Spirulina Platensis

3.2. Nutritional Composition of Spirulina Enriched Pasta (SEP)

3.2.1. Proteins

3.2.2. Fats

3.2.3. Carbohydrates

3.2.4. Micronutrients

3.2.5. Principal Component Analysis

3.3. Total Phenolics, Flavonoids and In Vitro Antioxidant Activity

3.4. Cooking Quality

3.5. Textural Analysis

3.6. Sensory Attributes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jensen, G.S. Blue-green algae as an immuno-enhancer and bio modulator. J. Am. Nutraceutical Assoc. 2001, 3, 24–30. [Google Scholar]

- Tamiya, H. Mass culture of algae. Ann. Rev. Plant Physiol. 1957, 8, 309–344. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, L.; Miron, A.; Klímová, B.; Wan, D.; Kuča, K. The antioxidant, immunomodulatory, and anti-inflammatory activities of Spirulina: An overview. Arch. Toxicol. 2016, 90, 1817–1840. [Google Scholar] [CrossRef] [PubMed]

- Varga, L.; Szigeti, J.; Kovacs, R.; Foldes, T.; Buti, S. Influence of a Spirulina platensis biomass on the microflora of fermented ABT milks during storage (R1). J. Dairy Sci. 2002, 85, 1031–1038. [Google Scholar] [CrossRef]

- Andrica, F.M.; Marți, T.D.; Pânzaru, I.; Coricovac, D.; Dehelean, C.; Drăgan, S. Preliminary study on the Evaluation of Spirulina on TPA induced Mouse Ear Inflammation. J. Agro Aliment. Processes Technol. 2015, 21, 268–273. [Google Scholar]

- Guil-Guerrero, J.L.; Navarro-Juárez, R.; López-Martínez, J.C.; Campra-Madrid, P.; Rebolloso-Fuentes, M.M. Functional properties of the biomass of three microalgal species. J. Food Eng. 2004, 65, 511–517. [Google Scholar] [CrossRef]

- Li, D.M.; Qi, Y.Z. Spirulina Industry in China: Present status and future prospects. J. Appl. Phycol. 1997, 9, 25–28. [Google Scholar] [CrossRef]

- Soni, R.A.; Sudhakar, K.; Rana, R.S.; Baredar, P. Food Supplements Formulated with Spirulina. In Algae; Springer: Singapore, 2020; pp. 201–226. [Google Scholar]

- Soni, R.A.; Sudhakar, K.; Rana, R.S. Spirulina—From growth to nutritional product: A review. Trends Food Sci. Technol. 2017, 69, 157–171. [Google Scholar] [CrossRef] [Green Version]

- Sloan, E. The top 10 functional food trends. Food Technol. 2008, 4, 24–44. [Google Scholar]

- Batista, A.P.; Niccolai, A.; Fradinho, P.; Fragoso, S.; Bursic, I.; Rodolfi, L.; Raymundo, A. Microalgae biomass as an alternative ingredient in cookies: Sensory, physical and chemical properties, antioxidant activity and in vitro digestibility. Algal Res. 2017, 26, 161–171. [Google Scholar] [CrossRef]

- Santos, T.D.; de Freitas, B.C.B.; Moreira, J.B.; Zanfonato, K.; Costa, J.A.V. Development of powdered food with the addition of Spirulina for food supplementation of the elderly population. Innov. Food Sci. Emerg. 2016, 37, 216–220. [Google Scholar] [CrossRef]

- Lafarga, T.; Acién-Fernández, F.G.; Castellari, M.; Villaró, S.; Bobo, G.; Aguiló-Aguayo, I. Effect of microalgae incorporation on the physicochemical, nutritional, and sensorial properties of an innovative broccoli soup. Lebensm. Wiss. Technol. 2019, 111, 167–174. [Google Scholar] [CrossRef]

- Lucas, B.F.; de Morais, M.G.; Santos, T.D.; Costa, J.A.V. Spirulina for snack enrichment: Nutritional, physical and sensory evaluations. Lebensm. Wiss. Technol. 2018, 90, 270–276. [Google Scholar] [CrossRef]

- De Marco, E.R.; Steffolani, M.E.; Martínez, C.S.; León, A.E. Effects of Spirulina biomass on the technological and nutritional quality of bread wheat pasta. LWT-Food Sci. Technol. 2014, 58, 102–108. [Google Scholar] [CrossRef]

- Pagnussatt, F.A.; Spier, F.; Bertolin, T.E.; Costa, J.A.V.; Gutkoski, L.C. Technological and nutritional assessment of dry pasta with oatmeal and the microalga Spirulina platensis. Braz. J. Food Technol. 2014, 17, 296–304. [Google Scholar] [CrossRef]

- Zarrouk, C. Contribution à l‘étuded‘unecyanophycée. Influence de Divers Facteurs Physiques et Chimiques sur la Croissance et Photosynthese de Spirulina maxima Geitler. Ph.D. Thesis, University of Paris, Paris, France, 1966. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 15th ed.; Williams, S., Ed.; Office of The Federal Register Washington, D.C.: Arlington, VA, USA, 1984. [Google Scholar]

- Sosulski, F.W.; Imafidon, G.I. Amino acid composition and Nitrogen to Protein conversion factors for Animal and Plant Foods. J. Agric. Food Chem. 1990, 34, 1351–1356. [Google Scholar] [CrossRef]

- Folch, J.; Lees, M.; Stanley, G.S. A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Ichihara, K.; Fukubayashi, Y. Preparation of fatty acid methyl esters for gas liquid chromatography. J. Lipid Res. 2010, 51, 635–640. [Google Scholar] [CrossRef] [Green Version]

- Ludwig, T.G.; Goldberg, H.J. The anthrone method for the determination of carbohydrates in foods and in oral rinsing. J. Dent. Res. 1956, 35, 90–94. [Google Scholar] [CrossRef]

- Merril, A.L.; Watt, B.K. Energy Value of Foods: Basis and Derivation; United States Department of Agriculture: Washington, DC, USA, 1973. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 1999; Volume 299, pp. 152–178. [Google Scholar]

- Barnum, D.W. Spectrophotometric determination of catechol, epinephrine, dopa, dopamine and other aromatic vic-diols. Anal. Chim. Acta 1977, 89, 157–166. [Google Scholar] [CrossRef]

- Benzie, I.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Apak, R.; Güclü, K.; Özyürek, M.; Celik, S.E. Mechanism of antioxidant capacity assays and the CUPRAC (cupric ion reducing antioxidant capacity assay. Microchim. Acta 2008, 160, 413–419. [Google Scholar] [CrossRef]

- Watanabe, F.S.; Olsen, S.R. Test of an ascorbic acid method for determining phosphorus in water and NaHCO3 extracts from soil 1. Soil Sci. Soc. Am. J. 1965, 29, 677–678. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the AACC, (Methods 08-01, 30-25, 44-15A, 46-10, 54-10, 54-21), 10th ed.; American Association of Cereal Chemists: Saint Paul, MN, USA, 2000. [Google Scholar]

- Tańska, M.; Konopka, I.; Ruszkowska, M. Sensory, physico-chemical and water sorption properties of corn extrudates enriched with Spirulina. Plant Food Hum. Nutr. 2017, 72, 250–257. [Google Scholar] [CrossRef] [Green Version]

- El-Hameed, A.; Mahmoud, K.; El-Maatti, A.; El-Saidy, S.M.; Ahmed, S.M. Effect of adding Spirulina platensis in pasta products (spaghetti). J. Agric. Res. 2018, 45, 293–300. [Google Scholar] [CrossRef]

- Morsy, O.M.; Sharoba, A.M.; El-Desouky, A.I.; Bahlol, H.E.M.; Abd El Mawla, E.M. Production and evaluation of some extruded food products using Spirulina alga. Ann. Agric. Sci. Moshtohor 2014, 52, 329–342. [Google Scholar]

- Selmo, M.S.; Salas-Mellado, M.M. Technological quality of bread from rice flour with Spirulina. Int. Food Res. J. 2014, 21, 1523–1528. [Google Scholar]

- ICMR-NIN Expert Group on Nutrient Requirements for Indians. Recommended Dietary Allowances (RDA) and Estimated Average Requirements (EAR)-2020; ICMR-National Institute of Nutrition: Secunderabad, India, 2020. [Google Scholar]

- Code of Federal Regulations Title 21. Available online: www.accessdata.fda.gov/ (accessed on 10 November 2021).

- Agustini, T.W.; Ma’ruf, W.F.; Wibowo, B.A. Study on the effect of different concentration of Spirulina platensis paste added into dried noodle to its quality characteristics. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 55, p. 012068. [Google Scholar]

- Almahrouqi, H.A.; Sukumaran, P.; Naqqiuddin, M.A.; Omar, H.; Ismail, A. The effect of salinity on growth, biochemical composition and fatty acid profile of SpiruliIna (Arthrospira platensis) grown in sheltered outdoor conditions in Oman. J. Algal Biomass Util. 2015, 6, 61–67. [Google Scholar]

- Aung, T.; Halsey, J.; Kromhout, D.; Gerstein, H.C.; Marchioli, R.; Tavazzi, L.; Chew, E.Y. Associations of omega-3 fatty acid supplement use with cardiovascular disease risks: Meta-analysis of 10 trials involving 77,917 individuals. JAMA Cardiol. 2018, 3, 225–233. [Google Scholar] [CrossRef] [Green Version]

- Kris-Etherton, P.M.; Grieger, J.A.; Etherton, T.D. Dietary reference intakes for DHA and EPA. Prostaglandins Leukot. Essent. Fat. Acids 2009, 81, 99–104. [Google Scholar] [CrossRef]

- Pizzorno, J.E.; Murray, M.T.; Joiner-Bey, H. The Clinician’s Handbook of Natural Medicine Book, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Vatsala, S.; Sudesh, J. Quality Characteristics of Noodles Enriched with Spirulina platensis Powder. Int. J. Agric. Sci. 2017, 9, 4091–4094. [Google Scholar]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M. Incorporation of Chlorella vulgaris and Spirulina maxima biomass in pasta products-Part 1: Preparation and evaluation. J. Sci. Food Agric. 2010, 90, 1656–1664. [Google Scholar] [CrossRef] [PubMed]

- Burcu, A.K.; Avsaroglu, E.; Isik, O.; Özyurt, G.; Kafkas, E.; Etyemez, M. Nutritional and physicochemical characteristics of bread enriched with microalgae Spirulina platensis. Int. J. Eng. Res. Appl. 2016, 6, 30–38. [Google Scholar]

- Özyurt, G.; Uslu, L.; Yuvka, I.; Gökdoğan, S.; Atci, G.; Ak, B.; Işik, O. Evaluation of the cooking quality characteristics of pasta enriched with Spirulina platensis. J. Food Qual. 2015, 38, 268–272. [Google Scholar] [CrossRef]

- Richmond, A. Biological principles of mass cultivation. In Handbook of Microalgal Culture: Biotechnology and Applied Phycology; Richmon, A., Ed.; Blackwell Science Ltd.: Oxford, UK, 2004; pp. 125–177. [Google Scholar]

- Bhat, R.; Goh, K.M. Sonication treatment convalesce the overall quality of hand-pressed strawberry juice. Food Chem. 2017, 215, 470–476. [Google Scholar] [CrossRef]

- Vatsala, S.; Sudesh, J. Vitamins, minerals, protein digestibility and antioxidant activity of bread enriched with Spirulina platensis powder. J. Agric. Sci. 2017, 7, 1292–1297. [Google Scholar]

- Kumar, A.; Mohanty, V.; Yashaswini, P. Development of high protein nutrition bar enriched with Spirulina plantensis for undernourished children. Curr. Res. Nutr. Food Sci. J. 2018, 6, 835–844. [Google Scholar] [CrossRef] [Green Version]

- Abd El Baky, H.H.; El-Baroty, G.S.; Ibrahem, E.A. Functional characters evaluation of biscuits sublimated with pure phycocyanin isolated from Spirulina and Spirulina biomass. Nutr. Hosp. 2015, 32, 231–241. [Google Scholar]

- Rocchetti, G.; Lucini, L.; Chiodelli, G.; Giuberti, G.; Gallo, A.; Masoero, F.; Trevisan, M. Phenolic profile and fermentation patterns of different commercial gluten-free pasta during in vitro large intestine fermentation. Food Res. Int. 2017, 97, 78–86. [Google Scholar] [CrossRef]

- Muresan, C.; Pop, A.; Man, S.; Socaci, S.; Fărcas, A.; Nagy, M.; Rus, B. The influence of different proportions of Spirulina (Arthrospiraplantensis) on the quality of pasta. J. Agroaliment. Processes Technol. 2016, 22, 24–27. [Google Scholar]

- Fardet, A.; Abecassis, J.; Hoebler, C.; Baldwin, P.M.; Buléon, A.; Bérot, S. Influence of technological modifications of the protein network from pasta on in vitro starch degradation. J. Cereal Sci. 1999, 30, 133–145. [Google Scholar] [CrossRef]

- Prabhasankar, P.; Ganesan, P.; Bhaskar, N.; Hirose, A.; Stephen, N.; Gowda, L. Edible Japanese seaweed, wakame (Undaria pinnatifida) as an ingredient in pasta: Chemical, functional and structural evaluation. Food Chem. 2009, 115, 501–508. [Google Scholar] [CrossRef]

- Dick, J.; Youngs, V. Evaluation of durum wheat, semolina and pasta in the United States. In Durum Wheat Chemistry Technology; Fabriani, G., Lintas, C., Eds.; AACC Monograph Series; AACC Press: St. Paul, MN, USA, 1988; pp. 237–248. [Google Scholar]

- Khan, I.; Yousif, A.; Johnson, S.; Gamlath, S. Effect of sorghum flour addition on resistant starch content, phenolic profile and antioxidant capacity of durum wheat pasta. Food Res. Int. 2013, 54, 578–586. [Google Scholar] [CrossRef] [Green Version]

- Rudra, S.G.; Anand, V.; Kaur, C.; Bhooshan, N.; Bhardwaj, R. Hydrothermal Treatment to Improve Processing Characteristics of Flour for Gluten-Free Pasta. Starch-Stärke 2020, 72, 1900320. [Google Scholar] [CrossRef]

- Shahbazizadeh, S.; Khosravi-Darani, K.; Sohrabvandi, S. Fortification of Iranian traditional cookies with Spirulina platensis. Ann. Res. Rev. Biol. 2014, 7, 144–154. [Google Scholar] [CrossRef]

| Constituent | Amount |

|---|---|

| Moisture (%, db) | 5.81 ± 0.17 |

| Energy (kcal in 100 g) | 412.78 ± 11.04 |

| Carbohydrates (%, db) | 21.87 ± 0.44 |

| Protein (%, db) | 65.71 ± 1.00 |

| Fat (%, db) | 6.94 ± 0.55 |

| Ash (%, db) | 8.34 ± 0.06 |

| Iron (mg/100 g) | 26.59 ± 0.80 |

| Calcium (mg/100 g) | 107.83 ± 2.50 |

| Zinc (mg/100 g) | 1.87 ± 0.03 |

| Component | Control | 2% | 5% | 7.50% | 10% | 12.50% | 15% |

|---|---|---|---|---|---|---|---|

| Moisture (%) | 6.21 ± 0.182 a | 5.89 ± 0.135 abc | 5.89 ± 0.215 abc | 5.72 ± 0.212 abc | 5.67 ± 0.016 bc | 5.52 ± 0.021 c | 6.05 ± 0.025 ab |

| Energy (kcal in 100 g) | 359.71 ± 2.74 c | 360.52 ± 1.81 c | 367.14 ± 1.45 b | 369.80 ± 1.61 b | 371.93 ± 2.37 b | 374.54 ± 1.19 b | 372.75 ± 2.47 b |

| Carbohydrates (%) | 71.68 ± 1.48 b | 70.30 ± 0.73 b | 69.64 ± 0.45 bc | 68.43 ± 0.83 bcd | 66.62 ± 0.18 cde | 65.84 ± 1.00 de | 63.49 ± 1.09 e |

| Protein (%) | 11.52 ± 0.38 g | 12.80 ± 0.13 f | 14.58 ± 0.10 e | 16.07 ± 0.13 d | 17.97 ± 0.31 c | 18.93 ± 0.39 b | 20.44 ± 0.18 a |

| Fat (%) | 2.99 ± 0.14 b | 3.12 ± 0.86 ab | 3.36 ± 0.26 ab | 3.53 ± 0.22 ab | 3.73 ± 0.25 ab | 3.94 ± 0.11 ab | 4.41 ± 0.10 a |

| Ash (%) | 0.57 ± 0.002 e | 1.04 ± 0.030 d | 1.13 ± 0.034 cd | 1.12 ± 0.066 cd | 1.23 ± 0.006 bc | 1.34 ± 0.005 ab | 1.39 ± 0.023 a |

| Iron (mg/100 g) | 1.28 ± 0.003 g | 1.81 ± 0.006 f | 2.55 ± 0.007 e | 3.19 ± 0.008 d | 3.86 ± 0.007 c | 4.44 ± 0.013 b | 5.081 ± 0.004 a |

| Calcium (mg/100 g) | 21.57 ± 0.208 g | 22.69 ± 0.081 f | 25.33 ± 0.021 e | 27.44 ± 0.070 d | 29.50 ± 0.031 C | 31.62 ± 0.035 b | 33.92 ± 0.055 a |

| Zinc (mg/100 g) | 1.13 ± 0.004 g | 1.14 ± 0.002 g | 1.17 ± 0.002 f | 1.18 ± 0.001 e | 1.21 ± 0.003 d | 1.25 ± 0.003 c | 1.27 ± 0.003 b |

| Phenolic content (mg GAE/100 g) | 50.25 ± 1.72 d | 54.63 ± 2.26 d | 66.68 ± 1.56 c | 68.25 ± 2.28 c | 71.50 ± 1.32 c | 81.75 ± 3.44 b | 88.75 ± 3.94 b |

| Flavonoids (pmol QE gram) | 63.65 ± 0.30 f | 92.06 ± 1.48 e | 119.60 ± 1.49 d | 124.54 ± 0.32 cd | 133.67 ± 2.50 c | 144.25 ± 4.13 b | 167.31 ± 5.23 a |

| DPPH (% inhibition) | 42.80 ± 1.76 c | 43.95 ± 1.82 bc | 44.64 ± 1.61 bc | 46.49 ± 0.17 abc | 47.76 ± 1.92 abc | 49.37 ± 1.30 ab | 50.69 ± 1.13 a |

| FRAP (µmol TE/g) | 2.52 ± 0.08 e | 2.84 ± 0.14 d | 2.96 ± 0.03 d | 3.78 ± 0.04 c | 4.56 ± 0.12 b | 4.62 ± 0.13 b | 5.12 ± 0.07 a |

| Attributes | Component Loading | PCA Summary Results | ||||

|---|---|---|---|---|---|---|

| Dim 1 | Dim 2 | Principal Components | Eigenvalue | % Variance | % Cumulative Variance | |

| Moisture | −0.538 | 0.838 | Dim 1 | 7.921 | 87.651 | 87.651 |

| Energy (kcal) | 0.960 | −0.169 | Dim 2 | 0.91 | 10.070 | 97.720 |

| Carbohydrates | −0.975 | −0.190 | Dim 3 | 0.159 | 1.759 | 99.480 |

| Protein | 0.996 | 0.064 | Dim 4 | 0.039 | 0.432 | 99.911 |

| Fat | 0.965 | 0.254 | Dim 5 | 0.007 | 0.077 | 99.989 |

| Ash | 0.920 | −0.178 | Dim 6 | 0.001 | 0.011 | 100.000 |

| Iron | 0.995 | 0.079 | ||||

| Calcium | 0.991 | 0.114 | ||||

| Zinc | 0.992 | 0.090 | ||||

| Attributes | Component Loading | PCA Summary Results | ||||

|---|---|---|---|---|---|---|

| Dim 1 | Dim 2 | Principal Components | Eigenvalue | % Variance | % Cumulative Variance | |

| Phenol content | 0.974 | 0.119 | Dim 1 | 3.860 | 96.669 | 96.669 |

| Flavonoids content | 0.954 | 0.187 | Dim 2 | 0.103 | 2.579 | 99.248 |

| DPPH inhibition | 0.985 | −0.096 | Dim 3 | 0.027 | 0.676 | 99.924 |

| FRAP | 0.951 | −0.210 | Dim 4 | 0.003 | 0.075 | 100 |

| Parameter | Control | 2% | 5% | 7.5% | 10% | 12.5% | 15% |

|---|---|---|---|---|---|---|---|

| Cooking Time (min.) | 5.35 ± 0.09 d | 5.35 ± 0.03 cd | 5.30 ± 0.06 bc | 5.30 ± 0.05 bc | 5.28 ± 0.06 b | 5.21 ± 0.04 a | 5.20 ± 0.06 a |

| Change in Length (%) | 30.97 ± 7.90 a | 26.13 ± 6.59 a | 25.92 ± 6.73 a | 27.03 ± 6.70 a | 24.98 ± 5.94 a | 23.76 ± 5.15 a | 24.67 ± 4.94 a |

| Change in Width (%) | 47.11 ± 6.88 ab | 59.33 ± 6.64 a | 40.00 ± 7.07 b | 58.00 ± 4.47 ab | 54.00 ± 8.94 ab | 58.00 ± 4.47 ab | 60.00 ± 5.00 a |

| Gruel loss (%) | 4.13 ± 0.15 e | 6.06 ± 0.31 a | 6.61 ± 0.33 b | 5.53 ± 0.33 cd | 5.13 ± 0.40 de | 6.66 ± 0.30 b | 6.22 ± 0.33 bc |

| Increase in wt after cooking (%) | 137.82 ± 3.41 e | 151.95 ±0.53 d | 161.66 ± 0.33 c | 162.10 ± 2.07 c | 182.22 ± 1.05 b | 190.70 ± 1.83 a | 193.99 ± 3.28 a |

| Volume displacement (%) | 10.00 ± 0.00 c | 9.67 ± 0.58 c | 9.33 ± 1.15 c | 8.67 ± 0.58 cd | 8.33 ± 0.58 cd | 8.00 ± 0.00 cd | 7.07 ± 0.12 d |

| Level of Incorporation of Spirulina | Firmness (g) | Cut Force (g) | Stickiness (g.s) | Consistency (g.s) | Cohesiveness (g) |

|---|---|---|---|---|---|

| Control | 4912.19 ± 201.08 a | 637.28 ± 27.56 a | 23.68 ± 1.25 c | 23.98 ± 2.77 a | 522.87 ± 16.92 b |

| 2.0% | 3712.86 ± 125.56 b | 585.18 ± 49.81 ab | 41.81 ± 0.95 a | 14.57 ± 2.63 bc | 573.125 ± 18.12 ab |

| 5.0% | 3689.38 ± 170.67 b | 562.01 ± 6.75 b | 39.86 ± 2.42 ab | 14.63 ± 2.54 b | 663.74 ± 11.06 a |

| 7.5% | 3674.50 ± 177.73 b | 538.24 ± 68.91 b | 26.41 ± 0.57 bc | 11.91 ± 1.22 bc | 403.135 ± 12.62 c |

| 10.0% | 2596.45 ± 157.36 c | 531.78 ± 31.10 c | 42.31 ± 1.90 a | 16.66 ± 0.23 b | 580.77 ± 6.41 ab |

| 12.5% | 2818.56 ± 135.46 c | 550.02 ± 18.36 bc | 36.31 ± 1.62 ab | 13.53 ± 0.96 bc | 508.89 ± 19.65 b |

| 15.0% | 2708.12 ± 136.76 c | 542.65 ± 27.46 bc | 25.17 ± 0.53 bc | 15.52 ± 1.13 b | 450.10 ± 14.50 bc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koli, D.K.; Rudra, S.G.; Bhowmik, A.; Pabbi, S. Nutritional, Functional, Textural and Sensory Evaluation of Spirulina Enriched Green Pasta: A Potential Dietary and Health Supplement. Foods 2022, 11, 979. https://doi.org/10.3390/foods11070979

Koli DK, Rudra SG, Bhowmik A, Pabbi S. Nutritional, Functional, Textural and Sensory Evaluation of Spirulina Enriched Green Pasta: A Potential Dietary and Health Supplement. Foods. 2022; 11(7):979. https://doi.org/10.3390/foods11070979

Chicago/Turabian StyleKoli, Deepak Kumar, Shalini Gaur Rudra, Arpan Bhowmik, and Sunil Pabbi. 2022. "Nutritional, Functional, Textural and Sensory Evaluation of Spirulina Enriched Green Pasta: A Potential Dietary and Health Supplement" Foods 11, no. 7: 979. https://doi.org/10.3390/foods11070979

APA StyleKoli, D. K., Rudra, S. G., Bhowmik, A., & Pabbi, S. (2022). Nutritional, Functional, Textural and Sensory Evaluation of Spirulina Enriched Green Pasta: A Potential Dietary and Health Supplement. Foods, 11(7), 979. https://doi.org/10.3390/foods11070979