Effect of Highland Barley on Rheological Properties, Textural Properties and Starch Digestibility of Chinese Steamed Bread

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of the Grain Quality of the Wheat and Three Highland Barley Varieties

2.2.1. Determination of the Basic Components in Grains of Wheat and the Three Highland Barley Varieties

The Main Chemical Compositions

Analysis of Size Distribution of B-Type Starch Granules

Amylose Content

The Ratio of High-Molecular-Weight to Low-Molecular-Weight Glutenin Subunits (H/L)

2.2.2. Determination of the Nutritional Ingredients of the Wheat and Three Highland Barley Varieties

β-Glucan Content

Total Polyphenol Content (TPC)

Total Flavonoid Content (TFC)

2.3. Determination of Quality Characteristics of Composite Powder

2.3.1. UPP% and the Ratio of Glutenin to Gliadin (Glu/Gli)

2.3.2. Micro-Structure of Gluten

2.3.3. Rheological Properties of Dough

2.3.4. Mixing Properties of Dough

2.4. Determination of the Composite CSBs’ Characteristics

2.4.1. Preparation of the Composite CSBs

2.4.2. Specific Volume Determination

2.4.3. Textural Profile Analysis

2.4.4. In Vitro Starch Digestibility

2.4.5. Sensory Evaluation

2.5. Statistical Analysis

3. Results and Discussion

3.1. Grain Quality of the Wheat and Three Highland Barley Varieties

3.1.1. Basic Components in the Grains of the Wheat and Three Highland Barley Varieties

3.1.2. Nutrients of the Wheat and Three Highland Barley Varieties

3.2. Quality Characteristics of Composite Powder

3.2.1. The Glutenins to Gliadins Ratio (Glu/Gli) and UPP%

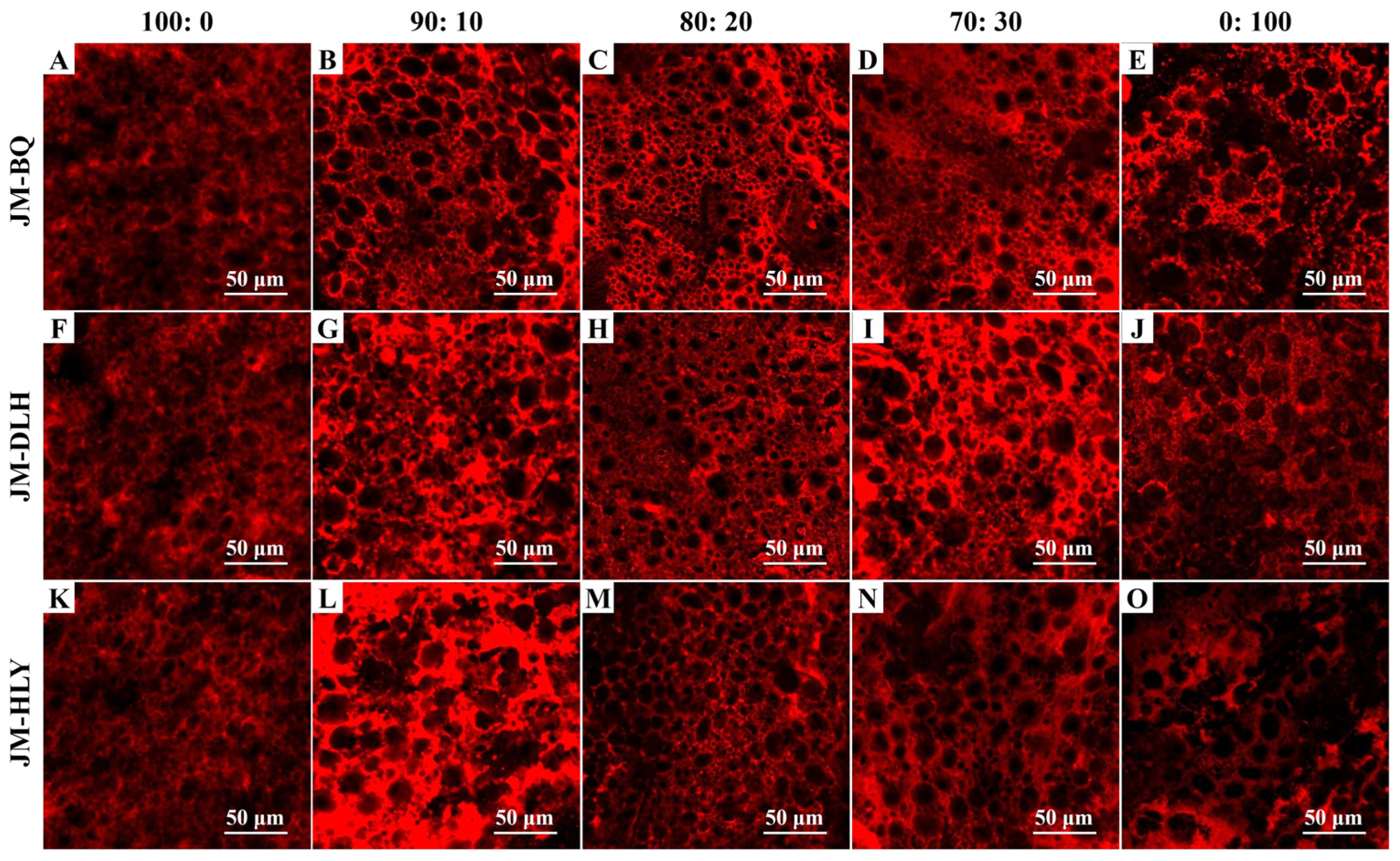

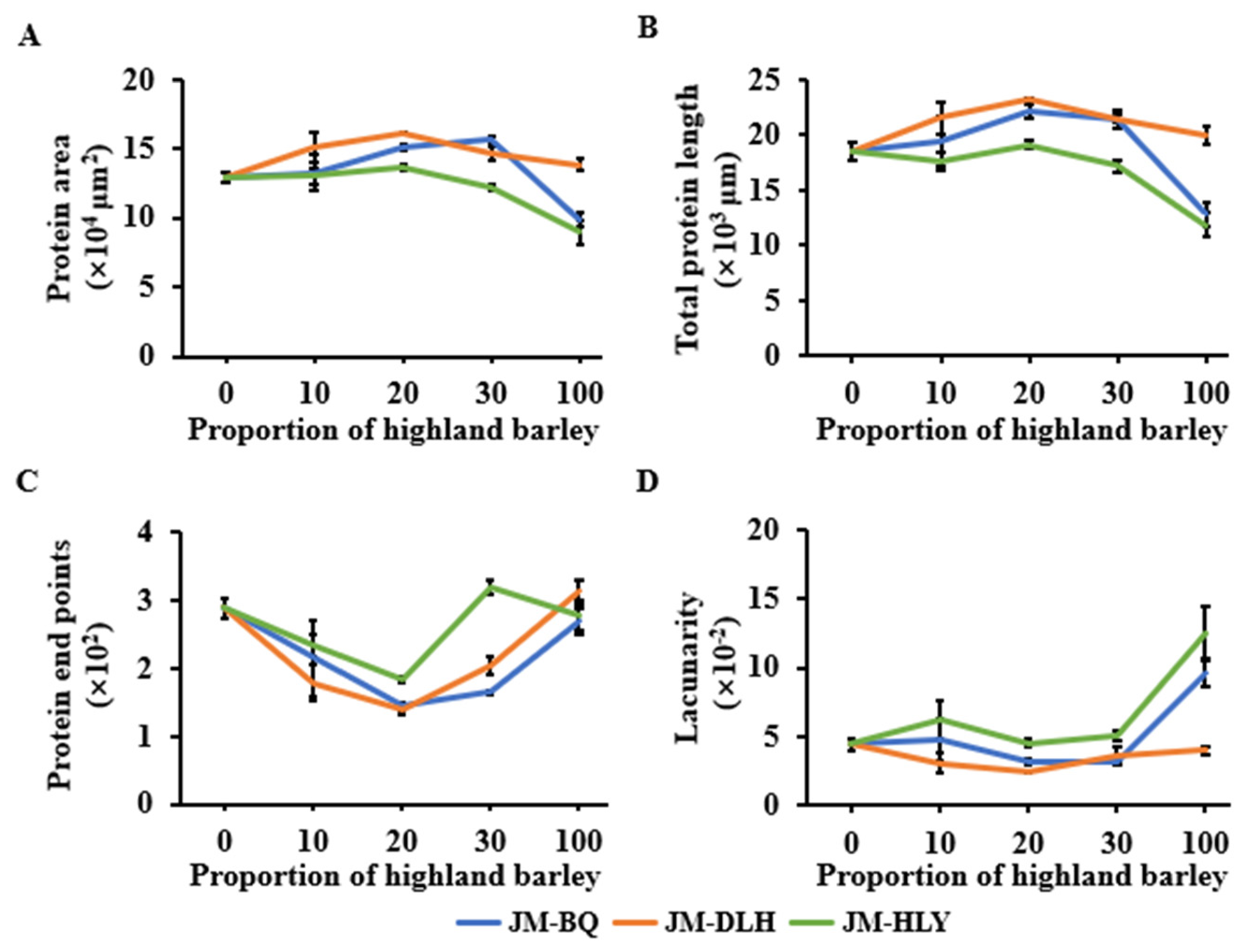

3.2.2. Micro-Structure of Gluten

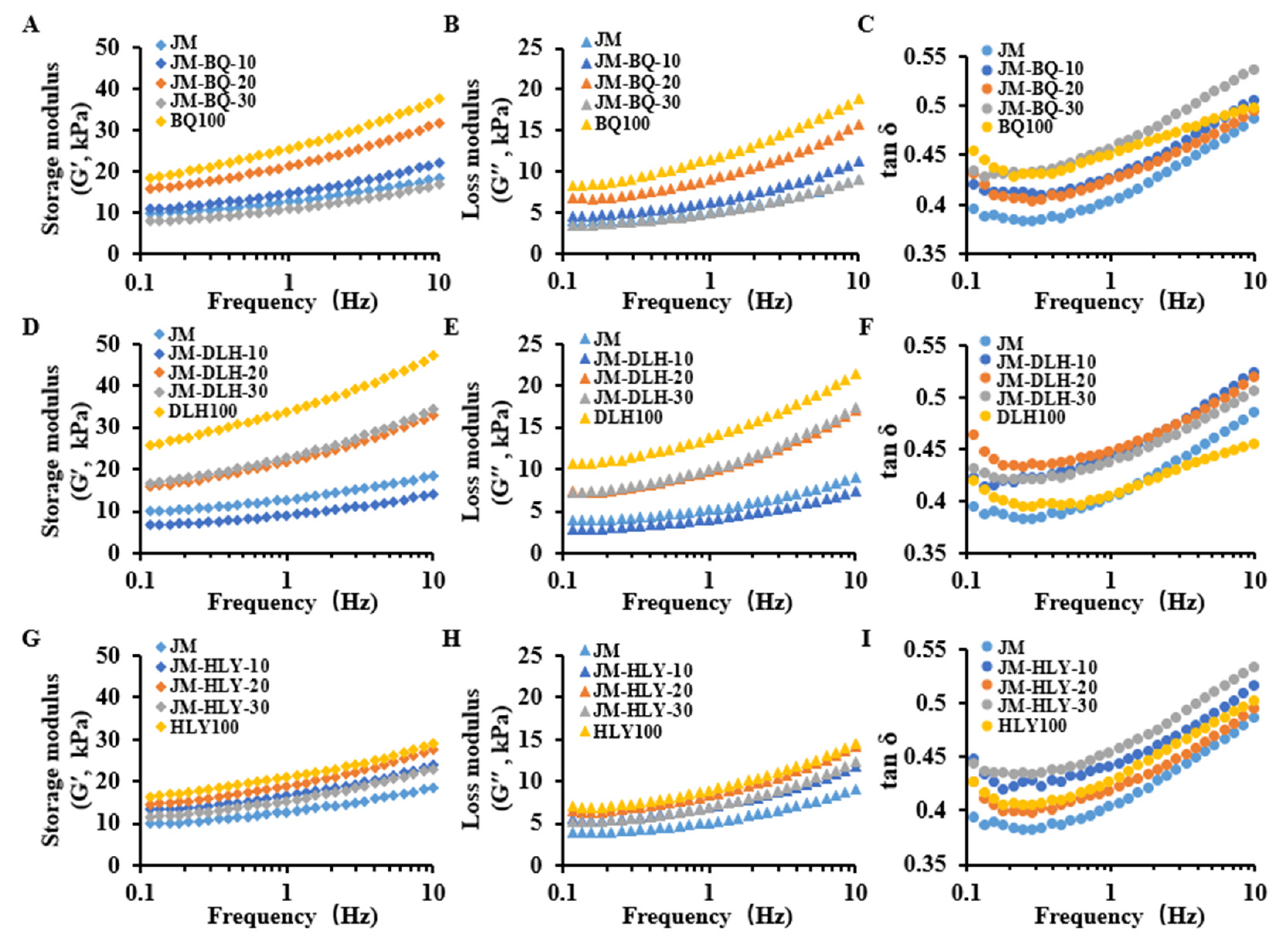

3.2.3. Rheological Properties

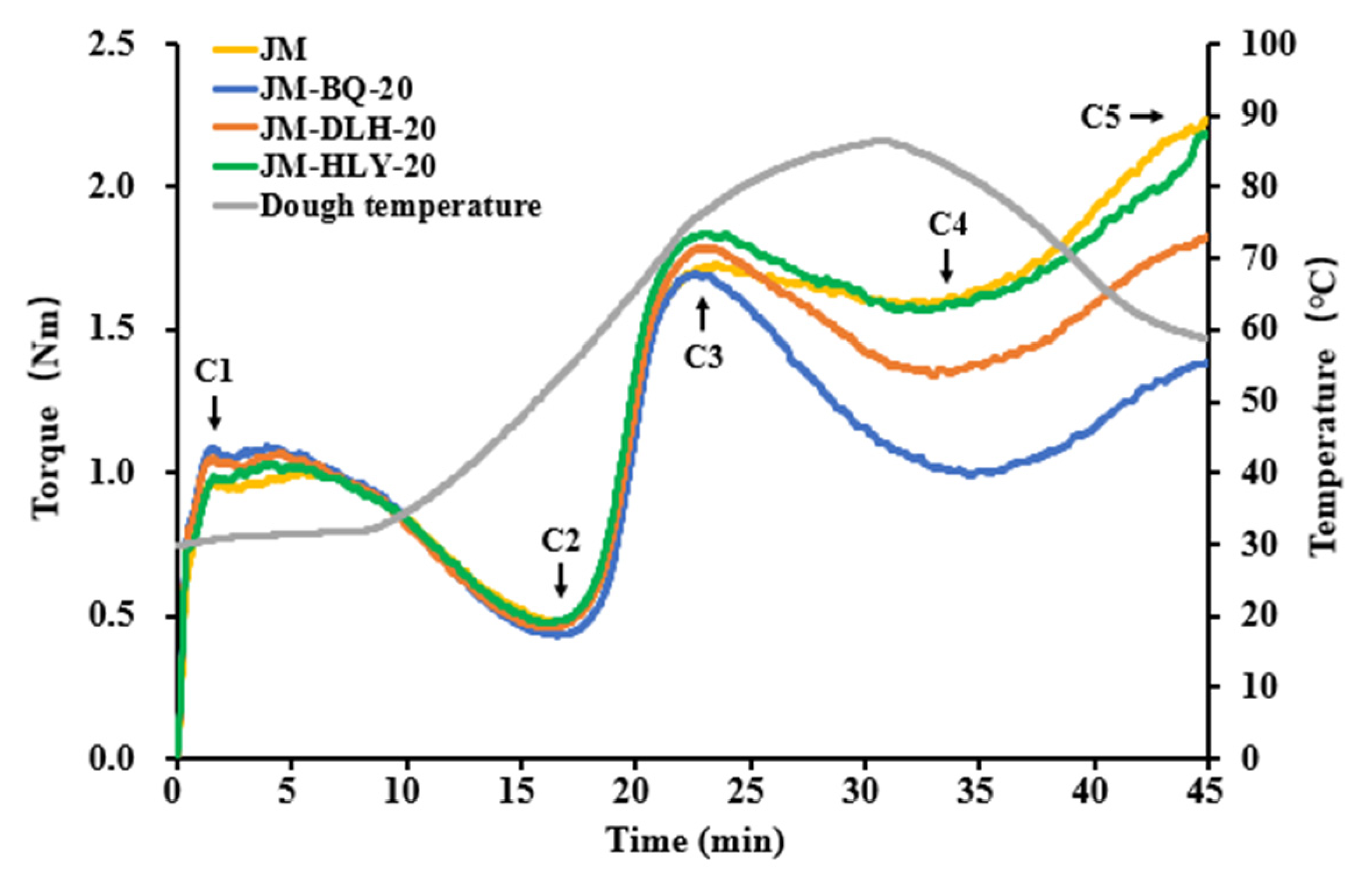

3.2.4. Mixing Properties

3.3. The Quality Characteristics of Composite CSBs

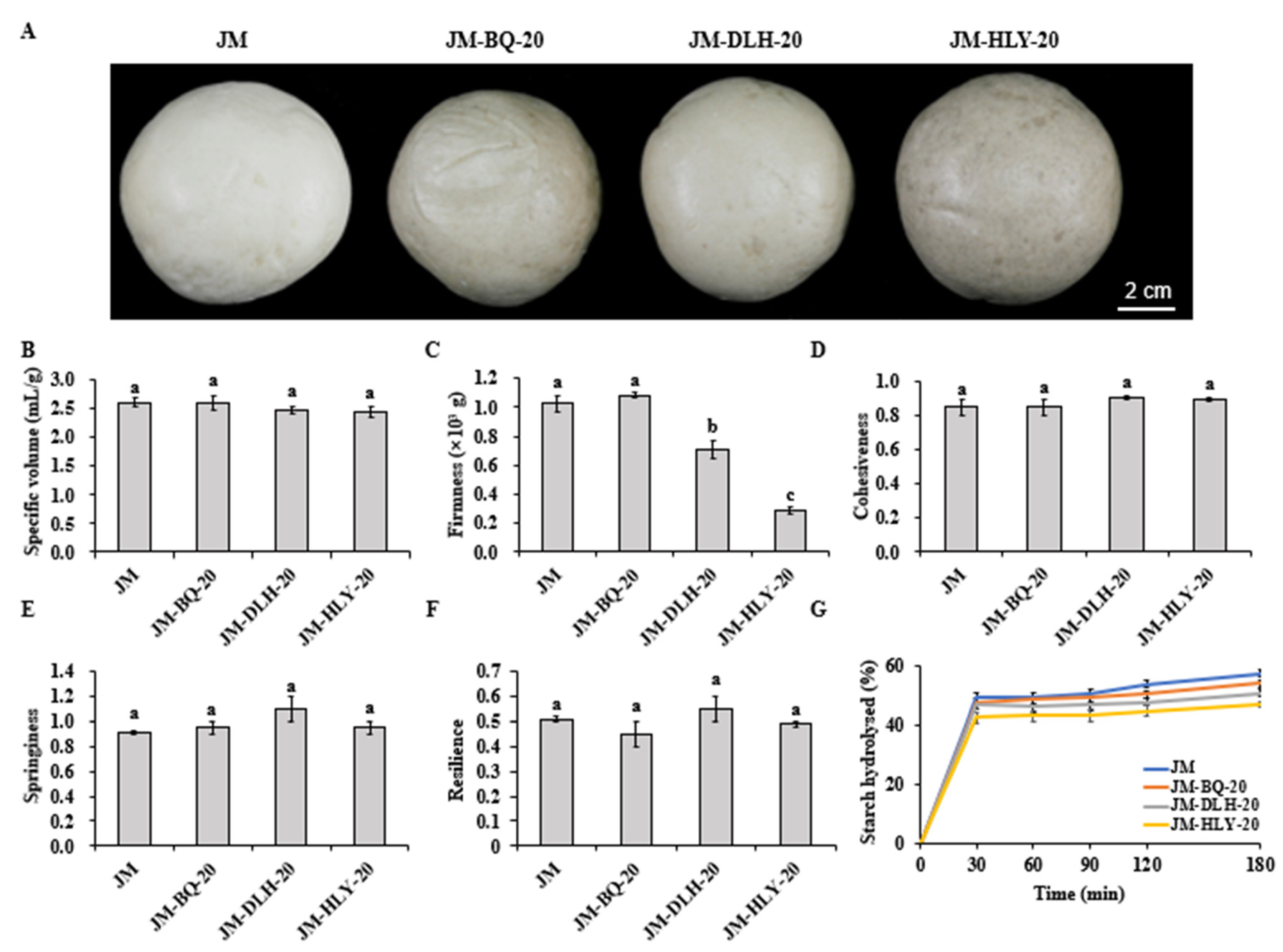

3.3.1. Specific Volume and Sensory Analysis

3.3.2. Textural Properties

3.3.3. In Vitro Starch Digestibility

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, F. Influence of ingredients and chemical components on the quality of Chinese steamed bread. Food Chem. 2014, 163, 154–162. [Google Scholar] [CrossRef]

- Wu, C.; Liu, R.S.; Huang, W.N.; Rayas-Duarte, P.; Wang, F.; Yao, Y. Effect of sourdough fermentation on the quality of Chinese Northern-style steamed breads. J. Cereal Sci. 2012, 56, 127–133. [Google Scholar] [CrossRef]

- Chang, X.H.; Huang, X.Y.; Tian, X.Y.; Wang, C.Q.; Aheto, J.H.; Ernest, B.; Yi, R. Dynamic characteristics of dough during the fermentation process of Chinese steamed bread. Food Chem. 2019, 312, 126050. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.M.; Yu, B.; Zhang, H.Y.; Sui, J.; Guo, L.; El-Aty, A.M.A.; Cui, B. The formation and in vitro enzymatic digestibility of starch-lipid complexes in steamed bread free from and supplemented with different fatty acids: Effect on textural and retrogradation properties during storage. Int. J. Biol. Macromol. 2020, 166, 1210–1219. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Horvath, C.; Chen, L.; Chen, J.; Zheng, B. Understanding the nutrient composition and nutritional functions of highland barley (Qingke): A review. Trends Food Sci. Technol. 2020, 103, 109–117. [Google Scholar] [CrossRef]

- Zeng, X.Q.; Long, H.; Wang, Z.; Zhao, S.C.; Tang, Y.W.; Huang, Z.Y.; Wang, Y.L.; Xu, Q.J.; Mao, L.K.; Deng, G.B.; et al. The draft genome of Tibetan hulless barley reveals adaptive patterns to the high stressful Tibetan Plateau. Proc. Natl. Acad. Sci. USA 2015, 112, 1095–1100. [Google Scholar] [CrossRef] [PubMed]

- Moza, J.; Gujral, H.S. Starch digestibility and bioactivity of high altitude hulless barley. Food Chem. 2016, 194, 561–568. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishna, R.; Sarkar, D.; Schwarz, P.; Shetty, K. Phenolic linked anti-hyperglycemic bioactives of barley (Hordeum vulgare L.) cultivars as nutraceuticals targeting type 2 diabetes. Ind. Crop Prod. 2017, 107, 509–517. [Google Scholar] [CrossRef]

- Abdel-Aal, E.S.M.; Choo, T.M.; Dhillon, S.; Rabalski, I. Free and bound phenolic acids and total phenolics in black, blue, and yellow barley and their contribution to free radical scavenging capacity. Cereal Chem. 2012, 89, 198–204. [Google Scholar] [CrossRef]

- Kim, M.J.; Hyun, J.N.; Kim, J.A.; Park, J.C.; Kim, M.Y.; Kim, J.G.; Lee, S.J.; Chun, S.C.; Chung, I.M. Relationship between phenolic compounds, anthocyanins content and antioxidant activity in colored barley germplasm. J. Agric. Food Chem. 2007, 55, 4802–4809. [Google Scholar] [CrossRef]

- Shen, Y.B.; Zhang, H.; Cheng, L.L.; Wang, L.; Qian, H.F.; Qi, X.G. In vitro and in vivo antioxidant activity of polyphenols extracted from black highland barley. Food Chem. 2016, 194, 1003–1012. [Google Scholar] [CrossRef]

- Song, J.; Chen, H.; Wei, Y.F.; Liu, J. Synthesis of carboxymethylated β-glucan from naked barley bran and its antibacterial activity and mechanism against Staphylococcus aureus. Carbohydr. Polym. 2020, 242, 116418. [Google Scholar] [CrossRef]

- Guo, H.; Lin, S.; Lu, M.; Gong, J.D.B.; Wang, L.; Zhang, Q.; Lin, D.R.; Qin, W.; Wu, D.T. Characterization, in vitro binding properties, and inhibitory activity on pancreatic lipase of β-glucans from different Qingke (Tibetan hulless barley) cultivars. Int. J. Biol. Macromol. 2018, 120, 2517–2522. [Google Scholar] [CrossRef]

- Tong, L.T.; Zhong, K.; Liu, L.; Zhou, X.R.; Qiu, J.; Zhou, S. Effects of dietary hull-less barley β-glucan on the cholesterol metabolism of hypercholesterolemic hamsters. Food Chem. 2015, 169, 344–349. [Google Scholar] [CrossRef]

- Martínez-Subirà, M.; Romero, M.P.; Puig, E.; Macià, A.; Romagosa, I.; Moralejo, M. Purple, high β-glucan, hulless barley as valuable ingredient for functional food. LWT-Food Sci. Technol. 2020, 131, 109582. [Google Scholar] [CrossRef]

- Zhu, F.; Sakulnak, R.; Wang, S. Effect of black tea on antioxidant, textural, and sensory properties of Chinese steamed bread. Food Chem. 2016, 194, 1217–1223. [Google Scholar] [CrossRef]

- Chen, Y.H.; Yang, X.S.; Guo, H.M.; Li, J.C.; Ren, G.X. Effect of extruded adzuki bean flour on the quality and α-glucosidase inhibitory activity of Chinese steamed bread. Food Sci. Nutr. 2019, 7, 3244–3252. [Google Scholar] [CrossRef]

- Wu, G.C.; Shen, Y.B.; Qi, Y.J.; Zhang, H.; Wang, L.; Qian, H.F.; Qi, X.G.; Li, Y.; Johnson, S.K. Improvement of in vitro and cellular antioxidant properties of Chinese steamed bread through sorghum addition. LWT-Food Sci. Technol. 2018, 91, 77–83. [Google Scholar] [CrossRef]

- Cao, Y.F.; Zhang, H.J.; Yang, Z.; Zhang, M.; Guo, P.; Li, H.J. Influence of the fermentation time and potato pulp addition on the technological properties and volatile compounds of wheat dough and steamed bread. LWT-Food Sci. Technol. 2020, 128, 109377. [Google Scholar] [CrossRef]

- Moza, J.; Gujral, H.S. Mixolab, retrogradation and digestibility behavior of chapatti made from hulless barley flours. J. Cereal Sci. 2018, 79, 383–389. [Google Scholar] [CrossRef]

- Zhao, B.; Shang, J.Y.; Wang, L.L.; Liu, L.Y.; Tong, L.T.; Zhou, X.R.; Wang, S.S.; Zhang, Y.H.; Zhou, S.M. Evaluation of ingredient mixing procedure on quality characteristics of noodles enriched with half hulless barley flour. Int. J. Food Sci. Technol. 2020, 55, 3350–3360. [Google Scholar] [CrossRef]

- Yu, L.W.; Ma, Y.R.; Zhao, Y.Y.; Pan, Y.L.; Tian, R.M.; Yao, X.H.; Yao, Y.H.; Cao, X.Y.; Geng, L.; Wang, Z.H.; et al. Effect of hulless barley flours on dough rheological properties, baking quality, and starch digestibility of wheat bread. Front. Nutr. 2021, 8, 785847. [Google Scholar] [CrossRef] [PubMed]

- Hao, M.; Beta, T. Development of Chinese steamed bread enriched in bioactive compounds from barley hull and flaxseed hull extracts. Food Chem. 2012, 133, 1320–1325. [Google Scholar] [CrossRef]

- Gujral, H.S.; Sharma, B.; Khatri, M. Influence of replacing wheat bran with barley bran on dough rheology, digestibility and retrogradation behavior of chapatti. Food Chem. 2018, 240, 1154–1160. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.H.; Gao, X.; Li, L.Q.; Du, D.F.; Cheng, X.; Zhao, Y.; Liu, Y.; Li, X.J. Effects of HMW-GS at Glu-B1 locus on the polymerization of glutenin during grain development and on the secondary and micro-structures of gluten in wheat (Triticum aestivum L.). J. Cereal Sci. 2016, 72, 101–107. [Google Scholar] [CrossRef]

- Feng, N.; He, Z.H.; Zhang, Y.; Xia, X.C.; Zhang, Y. QTL mapping of starch granule size in common wheat using recombinant inbred lines derived from a PH82-2/Neixiang188 cross. Crop J. 2013, 1, 166–171. [Google Scholar] [CrossRef]

- Li, S.P.; Liu, Y.C.; Tong, J.Y.; Yu, L.W.; Ding, M.Y.; Zhang, Z.M.; Rehman, A.; Majzoobi, M.; Wang, Z.H.; Gao, X. The overexpression of high-molecular-weight glutenin subunit Bx7 improves the dough rheological properties by altering secondary and micro-structures of wheat gluten. Food Res. Int. 2020, 130, 108914. [Google Scholar] [CrossRef]

- Lin, S.; Guo, H.; Gong, J.D.B.; Lu, M.; Lu, M.Y.; Wang, L.; Zhang, Q.; Wu, D.T.; Qin, W. Phenolic profiles, β-glucan contents, and antioxidant capacities of colored Qingke (Tibetan hulless barley) cultivars. J. Cereal Sci. 2018, 81, 69–75. [Google Scholar] [CrossRef]

- Singh, S.; Singh, N. Relationship of polymeric proteins and empirical dough rheology with dynamic rheology of dough and gluten from different wheat varieties. Food Hydrocoll. 2013, 33, 342–348. [Google Scholar] [CrossRef]

- Gao, X.; Tong, J.Y.; Guo, L.; Yu, L.W.; Li, S.P.; Yang, B.P.; Wang, L.B.; Liu, Y.; Li, F.J.; Guo, J.; et al. Influence of gluten and starch granules interactions on dough mixing properties in wheat (Triticum aestivum L.). Food Hydrocoll. 2020, 106, 105885. [Google Scholar] [CrossRef]

- Azeem, M.; Mu, T.H.; Zhang, M. Effects of hydrocolloids and proteins on dough rheology and in vitro starch digestibility of sweet potato-wheat bread. LWT-Food Sci. Technol. 2021, 142, 110970. [Google Scholar] [CrossRef]

- Zhang, D.; Mu, T.; Sun, H. Comparative study of the effect of starches from five different sources on the rheological properties of gluten-free model doughs. Carbohydr. Polym. 2017, 176, 345–355. [Google Scholar] [CrossRef]

- Huang, W.N.; Li, L.L.; Wang, F.; Wan, J.J.; Tilley, M.; Ren, C.Z.; Wu, S.Q. Effects of transglutaminase on the rheological and Mixolab thermomechanical characteristics of oat dough. Food Chem. 2010, 121, 934–939. [Google Scholar] [CrossRef]

- Guo, X.N.; Yang, S.; Zhu, K.X. Influences of alkali on the quality and protein polymerization of buckwheat Chinese steamed bread. Food Chem. 2019, 283, 52–58. [Google Scholar] [CrossRef]

- Toutounji, M.R.; Butardo, V.M.; Zou, W.; Farahnaky, A.; Pallas, L.; Oli, P.; Blanchard, C.L. A high-throughput in vitro assay for screening rice starch digestibility. Foods 2019, 8, 601. [Google Scholar] [CrossRef]

- Li, M.F.; Liu, C.; Zheng, X.L.; Hong, J.; Bian, K.; Li, L.M. Interaction between A-type/B-type starch granules and gluten in dough during mixing. Food Chem. 2021, 358, 129870. [Google Scholar] [CrossRef]

- Li, C.; Dhital, S.; Gilbert, R.G.; Gidley, M.J. High-amylose wheat starch: Structural basis for water absorption and pasting properties. Carbohydr. Polym. 2020, 245, 116557. [Google Scholar] [CrossRef]

- Abdel-Haleem, A.M.H.; Agwa, A.M.; Mahgoub, S.A.; Shehata, W.M. Characterization of β-glucan gum for food applications as influenced by genotypic variations in three hulless barley varieties. J. Food Sci. 2020, 85, 1689–1698. [Google Scholar] [CrossRef]

- Ren, Y.; Xie, H.Y.; Liu, L.; Jia, D.Y.; Yao, K.; Chi, Y.L. Processing and prebiotics characteristics of β-glucan extract from highland barley. Appl. Sci. 2018, 8, 1481. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties. LWT-Food Sci Technol. 2013, 51, 211–217. [Google Scholar] [CrossRef]

- Li, M.F.; Yue, Q.H.; Liu, C.; Zheng, X.; Hong, J.L.; Li, L.; Bian, K.M. Effect of gliadin/glutenin ratio on pasting, thermal, and structural properties of wheat starch. J. Cereal Sci. 2020, 93, 102973. [Google Scholar] [CrossRef]

- Zhang, P.P.; He, Z.H.; Zhang, Y.; Xia, X.C.; Chen, D.S.; Zhang, Y. Association between % SDS-unextractable polymeric protein (%UPP) and end-use quality in Chinese bread wheat cultivars. Cereal Chem. 2008, 85, 696–700. [Google Scholar] [CrossRef]

- Jia, F.Y.; Ma, Z.; Wang, X.L.; Li, X.P.; Liu, L.; Hu, X.Z. Effect of kansui addition on dough rheology and quality characteristics of chickpea-wheat composite flour-based noodles and the underlying mechanism. Food Chem. 2019, 298, 125081. [Google Scholar] [CrossRef] [PubMed]

- Ohm, J.; Dykes, L.; Graybosch, R.A. Variation of protein molecular weight distribution parameters and their correlations with gluten and mixing characteristics for winter waxy wheat. Cereal Chem. 2019, 96, 302–312. [Google Scholar] [CrossRef]

- Ohm, J.B.; Simsek, S.; Mergoum, M. Variation of protein MWD parameters and their associations with free asparagine concentration and quality characteristics in hard red spring wheat. J. Cereal Sci. 2018, 79, 154–159. [Google Scholar] [CrossRef]

- Cao, Y.F.; Yang, Z.; Zhang, H.J.; Guo, P.; Dong, S.; Li, H.J. Influence of potato pulp on gluten network structure in wheat dough and steamed bread. Cereal Chem. 2019, 97, 226–234. [Google Scholar] [CrossRef]

- Ahmed, J.; Almusallam, A.S.; Al-Salman, F.; AbdulRahman, M.H.; Al-Salem, E. Rheological properties of water insoluble date fiber incorporated wheat flour dough. LWT-Food Sci. Technol. 2013, 51, 409–416. [Google Scholar] [CrossRef]

- Struck, S.; Straube, D.; Zahn, S.; Rohm, H. Interaction of wheat macromolecules and berry pomace in model dough: Rheology and microstructure. J. Food Eng. 2018, 223, 109–115. [Google Scholar] [CrossRef]

- Bernklau, I.; Lucas, L.; Jekle, M.; Becker, T. Protein network analysis—A new approach for quantifying wheat dough microstructure. Food Res. Int. 2016, 89, 812–819. [Google Scholar] [CrossRef]

- Chen, X.J.; Liu, Y.; Xu, Z.K.; Zhang, C.C.; Liu, X.X.; Sui, Z.Q.; Corke, H. Microwave irradiation alters the rheological properties and molecular structure of hull-less barley starch. Food Hydrocoll. 2021, 120, 106821. [Google Scholar] [CrossRef]

- Liu, X.L.; Mu, T.H.; Sun, H.N.; Zhang, M.; Chen, J.W. Influence of potato flour on dough rheological properties and quality of steamed bread. J. Integr. Agric. 2016, 15, 2666–2676. [Google Scholar] [CrossRef]

- Guo, J.Y.; Liu, F.; Gan, C.F.; Wang, Y.Y.; Wang, P.; Li, X.L.; Hao, J.X. Effects of Konjac glucomannan with different viscosities on the rheological and microstructural properties of dough and the performance of steamed bread. Food Chem. 2022, 368, 130853. [Google Scholar] [CrossRef]

- Izydorczyk, M.; Hussain, A.; MacGregor, A.W. Effect of barley and barley components on rheological properties of wheat dough. J. Cereal Sci. 2001, 34, 251–260. [Google Scholar] [CrossRef]

- Mansoor, R.; Ali, T.M.; Hasnain, A. Effects of barley flour substitution on glycemic index, compositional, rheological, textural, and sensory characteristics of chickpea flour-based flat bread. Legume Sci. 2021, 3, 89. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Dynamic rheological properties of wheat flour dough and proteins. Trends Food Sci. Technol. 2006, 18, 132–138. [Google Scholar] [CrossRef]

- Skendi, A.; Papageorgiou, M.; Biliaderis, C.G. Effect of barley β-glucan molecular size and level on wheat dough rheological properties. J. Food Eng. 2008, 91, 594–601. [Google Scholar] [CrossRef]

- Dangi, N.; Yadav, B.S.; Yadav, R.B. Barley β-glucan concentrate and its acid hydrolysate for the modification of dough making and rheological properties of water chestnut flour. Int. J. Biol. Macromol. 2020, 164, 253–264. [Google Scholar] [CrossRef]

- Rosell, C.M.; Marco, C.; García-alvárez, J.; Salazar, J. Rheological properties of rice–soybean protein composite flours assessed by Mixolab and ultrasound. J. Food Process Eng. 2011, 34, 1838–1859. [Google Scholar] [CrossRef]

- Ndayishimiye, J.B.; Huang, W.N.; Wang, F.; Chen, Y.; Letsididi, R.; Rayas-Duarte, P.; Ndahetuye, J.B.; Tang, X.J. Rheological and functional properties of composite sweet potato—Wheat dough as affected by transglutaminase and ascorbic acid. J. Food Sci. Technol. 2016, 53, 1178–1188. [Google Scholar] [CrossRef]

- Rosell, C.M.; Santos, E.; Collar, C. Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the Mixolab. Eur. Food Res. Technol. 2010, 231, 535–544. [Google Scholar] [CrossRef]

- Sharma, B.; Gujral, H.S.; Solah, V. Effect of incorporating finger millet in wheat flour on Mixolab behavior, chapatti quality and starch digestibility. Food Chem. 2017, 231, 156–164. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, P.; O’Flaherty, J.; Brunton, N.; Arendt, E.; Gallagher, E. The utilisation of barley middlings to add value and health benefits to white breads. J. Food Eng. 2011, 105, 493–502. [Google Scholar] [CrossRef]

- Tatiana, B.; Janette, M.; Alena, V. Effects of adding legume flours on the rheological and breadmaking properties of dough. Foods 2021, 10, 1087. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, Z.X.; Li, X.X.; Li, M. Effect of tea polyphenols on the retrogradation of rice starch. Food Res. Int. 2008, 42, 221–225. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Krishnan, P.G. Effects of corn distillers dried grains on dough properties and quality of Chinese steamed bread. Food Sci. Nutr. 2020, 8, 3999–4008. [Google Scholar] [CrossRef]

- Liu, J.; Luo, D.L.; Chen, R.H.; Xu, B.C. Effects of short-chain inulin on quality of Chinese steamed bread. J. Food Qual. 2016, 39, 255–263. [Google Scholar] [CrossRef]

- Tan, H.L.; Tan, T.C.; Easa, A.M. Comparative study of cooking quality, microstructure, and textural and sensory properties between fresh wheat noodles prepared using sodium chloride and salt substitutes. LWT-Food Sci. Technol. 2018, 97, 396–403. [Google Scholar] [CrossRef]

- Liu, J.; Xu, B.J. A comparative study on texture, gelatinisation, retrogradation and potential food application of binary gels made from selected starches and edible gums. Food Chem. 2019, 296, 100–108. [Google Scholar] [CrossRef]

- Martínez, M.M.; Román, L.; Gómez, M. Implications of hydration depletion in the in vitro starch digestibility of white bread crumb and crust. Food Chem. 2018, 239, 295–303. [Google Scholar] [CrossRef]

- Fu, J.T.; Shiau, S.Y.; Chang, R.C. Effect of calamondin fiber on rheological, antioxidative and sensory properties of dough and steamed bread. J. Texture Stud. 2014, 45, 367–376. [Google Scholar] [CrossRef]

- Goh, R.; Gao, J.; Ananingsih, V.K.; Ranawana, V.; Henry, C.J.; Zhou, W.B. Green tea catechins reduced the glycaemic potential of bread: An in vitro digestibility study. Food Chem. 2015, 180, 203–210. [Google Scholar] [CrossRef]

- Chung, H.J.; Lim, H.S.; Lim, S.T. Effect of partial gelatinization and retrogradation on the enzymatic digestion of waxy rice starch. J. Cereal Sci. 2006, 43, 353–359. [Google Scholar] [CrossRef]

- Kang, M.J.; Bae, I.Y.; Lee, H.G. Rice noodle enriched with okara: Cooking property, texture, and in vitro starch digestibility. Food Biosci. 2018, 22, 178–183. [Google Scholar] [CrossRef]

| Sample | Grain Quality Determined by Near-Infrared Reflectance | Size Distribution of B-Type Starch Granules (%) | Amylose Content (%) | H/L Ratio (%) | Nutritional Ingredient | ||||

|---|---|---|---|---|---|---|---|---|---|

| Moisture Content (%) | Protein Content (%) | Starch Content (%) | β-Glucan Content (%) | Polyphenol Content (mg GAE/g) | Flavonoids Content (mg GAE/g) | ||||

| JM | 9.82 ± 0.08b | 15.48 ± 0.19a | 61.43 ± 0.56a | 44.25 ± 1.38b | 28.09 ± 0.32a | 58.65 ± 0.60a | 0.50 ± 0.06c | 0.48 ± 0.09b | 0.33 ± 0.08c |

| BQ | 12.19 ± 0.12a | 14.40 ± 0.33b | 61.55 ± 0.79a | 42.49 ± 2.50b | 28.28 ± 2.25a | 50.37 ± 3.01b | 4.15 ± 0.10a | 1.08 ± 0.09a | 1.74 ± 0.09a |

| DLH | 12.60 ± 0.09a | 9.11 ± 0.19c | 50.88 ± 0.75b | 56.93 ± 2.64a | 34.92 ± 3.60a | 41.84 ± 0.61c | 3.83 ± 0.11ab | 1.24 ± 0.05a | 1.71 ± 0.12a |

| HLY a | 5.80 ± 0.30c | 15.27 ± 0.3a | 47.93 ± 0.07c | 47.29 ± 0.69b | 32.63 ± 2.30a | 24.89 ± 0.06d | 3.60 ± 0.14b | 1.02 ± 0.06a | 1.05 ± 0.10b |

| Sample | Water Absorption (%) | Dough Development Time (min) | Dough Stability Time (min) | C1 (Nm) | C2 (Nm) | C3 (Nm) | C4 (Nm) | C5 (Nm) | Gelatinization Temperature (°C) |

|---|---|---|---|---|---|---|---|---|---|

| JM | 64.75 ± 0.25b | 6.08 ± 0.58a | 8.45 ± 0.20a | 1.04 ± 0.04a | 0.49 ± 0.01a | 1.74 ± 0.01c | 1.61 ± 0.02a | 2.31 ± 0.08a | 78.90 ± 0.40a |

| JM-BQ-20 | 65.00 ± 0ab | 4.12 ± 0.20b | 7.26 ± 0.04b | 1.10 ± 0.01a | 0.43 ± 0c | 1.69 ± 0d | 0.99 ± 0c | 1.37 ± 0.01c | 77.05 ± 0.15b |

| JM-DLH-20 | 65.00 ± 0ab | 4.73 ± 0.16b | 7.53 ± 0.02ab | 1.09 ± 0.01a | 0.46 ± 0b | 1.8 ± 0.01b | 1.35 ± 0.01b | 1.82 ± 0.01b | 77.90 ± 0.30ab |

| JM-HLY-20 | 65.40 ± 0.20a | 4.19 ± 0.02b | 7.84 ± 0.04ab | 1.03 ± 0a | 0.47 ± 0ab | 1.84 ± 0a | 1.55 ± 0.01a | 2.15 ± 0.03a | 78.35 ± 0.15a |

| Sample | Specific Volume | Surface Structure | Colour | Shape | Internal Structure | Elasticity | Viscidity | Flavor | Total Score |

|---|---|---|---|---|---|---|---|---|---|

| JM | 18.0 ± 1.0a | 8.3 ± 0.2a | 9.1 ± 0.1a | 8.2 ± 0.7a | 13.3 ± 0.2a | 14.3 ± 0.2a | 9.0 ± 0a | 8.9 ± 0.1a | 89.0 ± 0.3a |

| JM-BQ-20 | 18.0 ± 1.0a | 4.7 ± 0.2b | 5.9 ± 0.1b | 6.0 ± 1.0a | 11.7 ± 0.2b | 12.5 ± 0.5b | 7.3 ± 0.3b | 8.1 ± 0.1b | 74.1 ± 0.5b |

| JM-DLH-20 | 16.5 ± 0.5a | 5.6 ± 0.3b | 6.8 ± 0.3b | 6.5 ± 0.5a | 12.1 ± 0b | 11.2 ± 0b | 7.8 ± 0.3b | 8.4 ± 0.1b | 74.7 ± 0.4b |

| JM-HLY-20 | 16.0 ± 1.0a | 6.5 ± 0.5b | 4.5 ± 0.5c | 7.8 ± 0.8a | 11.9 ± 0b | 15.5 ± 0.5a | 8.7 ± 0.2a | 8.7 ± 0.2ab | 79.4 ± 3.3b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Yu, L.; Guo, L.; Li, S.; Yao, X.; Yao, Y.; Cao, X.; Wu, K.; Gao, X. Effect of Highland Barley on Rheological Properties, Textural Properties and Starch Digestibility of Chinese Steamed Bread. Foods 2022, 11, 1091. https://doi.org/10.3390/foods11081091

Wu D, Yu L, Guo L, Li S, Yao X, Yao Y, Cao X, Wu K, Gao X. Effect of Highland Barley on Rheological Properties, Textural Properties and Starch Digestibility of Chinese Steamed Bread. Foods. 2022; 11(8):1091. https://doi.org/10.3390/foods11081091

Chicago/Turabian StyleWu, Daying, Liwei Yu, Lei Guo, Shiquan Li, Xiaohua Yao, Youhua Yao, Xinyou Cao, Kunlun Wu, and Xin Gao. 2022. "Effect of Highland Barley on Rheological Properties, Textural Properties and Starch Digestibility of Chinese Steamed Bread" Foods 11, no. 8: 1091. https://doi.org/10.3390/foods11081091

APA StyleWu, D., Yu, L., Guo, L., Li, S., Yao, X., Yao, Y., Cao, X., Wu, K., & Gao, X. (2022). Effect of Highland Barley on Rheological Properties, Textural Properties and Starch Digestibility of Chinese Steamed Bread. Foods, 11(8), 1091. https://doi.org/10.3390/foods11081091