Flavor Profile Evaluation of Soaked Greengage Wine with Different Base Liquor Treatments Using Principal Component Analysis and Heatmap Analysis

Abstract

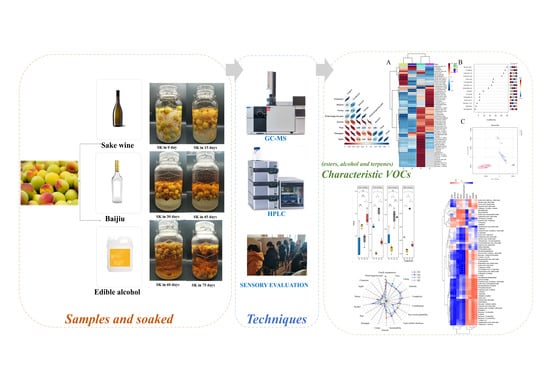

:1. Introduction

2. Material and Methods

2.1. Preparation of Greengage

2.2. Soaked Greengage Wine Brew

2.3. Physicochemical Analyses

2.4. CIELAB Analysis

2.5. Organic Acids in Greengage Wine

2.6. Headspace Solid-Phase Microextraction (HS-SPME)

2.7. Determination of Volatile Organic Compounds (VOCs) Using GC-MS

2.8. Odor Activity Value

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Basic Physicochemical Characteristics

3.2. Analysis of Color Change during Soaking

3.3. Organic Acids in Greengage Wine

3.4. Flavor Compounds

3.5. Sensory Evaluation

3.6. Pearson Correlation Analysis of Aroma Sensory Attributes

3.7. Correlation between Aroma-Active Compounds and Sensory Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, X.P.; Tang, Y.; Song, Y.Y.; Du, G.; Li, J. Comprehensive Review of Phytochemical Constituents, Pharmacological Properties, and Clinical Applications of Prunus mume. Front. Pharmacol. 2021, 12, 679378. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Huang, Z.; Addo, K.A.; Yu, Y. Evaluation of postharvest quality of plum (Prunus salicina L. cv. ‘French’) treated with layer-by-layer edible coating during storage. Sci. Hortic. 2022, 304, 111310. [Google Scholar] [CrossRef]

- Wang, X.; Du, J.; Zhou, J. Antibiotic activities of extracts from Prunus mume fruit against food-borne bacterial pathogens and its active components. Ind. Crops Prod. 2019, 133, 409–413. [Google Scholar] [CrossRef]

- Xia, D.; Wu, X.; Shi, J.; Yang, Q.; Zhang, Y. Phenolic compounds from the edible seeds extract of Chinese Mei (Prunus mume Sieb. et Zucc) and their antimicrobial activity. LWT-Food Sci. Technol. 2011, 44, 347–349. [Google Scholar] [CrossRef]

- Yan, X.T.; Li, W.; Sun, Y.N.; Yang, S.Y.; Lee, S.H.; Chen, J.B.; Jang, H.D.; Kim, Y.H. Identification and biological evaluation of flavonoids from the fruits of Prunus mume. Bioorg. Med. Chem. Lett. 2014, 24, 1397–1402. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Zhang, M.; Fang, Z.; Liu, Y. Effects of low frequency ultrasonic treatment on the maturation of steeped greengage wine. Food Chem. 2014, 162, 264–269. [Google Scholar] [CrossRef]

- Jian-jian, Z. Production technology and healthy function of plum wine. China Brew. 2005, 2, 46–48. [Google Scholar]

- Xin-an, Z. Determination of Benzaldehyde Content in Plum Fruit Wine by High Performance Liquid Chromatography (HPLC). Liquor-Mak. Sci. Technol. 2009, 5, 110–112. [Google Scholar]

- Hoang, N.X.; Ferng, S.; Ting, C.-H.; Huang, W.-H.; Chiou, R.Y.-Y.; Hsu, C.-K. Optimizing the initial moromi fermentation conditions to improve the quality of soy sauce. LWT-Food Sci. Technol. 2016, 74, 242–250. [Google Scholar] [CrossRef]

- Franitza, L.; Granvogl, M.; Schieberle, P. Characterization of the Key Aroma Compounds in Two Commercial Rums by Means of the Sensomics Approach. J. Agric. Food Chem. 2016, 64, 637–645. [Google Scholar] [CrossRef]

- Chen, K.; Liu, C.; Wang, Y.; Wang, Z.; Li, F.; Ma, L.; Li, J. Predominance of indigenous non-Saccharomyces yeasts in the traditional fermentation of greengage wine and their significant contribution to the evolution of terpenes and ethyl esters. Food Res. Int. 2021, 143, 110253. [Google Scholar] [CrossRef] [PubMed]

- Tian, T.; Sun, J.; Wu, D.; Xiao, J.; Lu, J. Objective measures of greengage wine quality: From taste-active compound and aroma-active compound to sensory profiles. Food Chem. 2021, 340, 128179. [Google Scholar] [CrossRef] [PubMed]

- Kesa, A.L.; Pop, C.R.; Mudura, E.; Salanta, L.C.; Pasqualone, A.; Darab, C.; Burja-Udrea, C.; Zhao, H.; Coldea, T.E. Strategies to Improve the Potential Functionality of Fruit-Based Fermented Beverages. Plants 2021, 10, 2263. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Yang, P.; Song, H.; Guan, X. Research progress in comprehensive two-dimensional gas chromatography-mass spectrometry and its combination with olfactometry systems in the flavor analysis field. J. Food Compos. Anal. 2022, 114, 104790. [Google Scholar] [CrossRef]

- Song, H.; Liu, J. GC-O-MS technique and its applications in food flavor analysis. Food Res. Int. 2018, 114, 187–198. [Google Scholar] [CrossRef]

- Bokulich, N.A.; Thorngate, J.H.; Richardson, P.M.; Mills, D.A. Microbial biogeography of wine grapes is conditioned by cultivar, vintage, and climate. Proc. Natl. Acad. Sci. USA 2014, 111, E139–E148. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Tian, T.T.; Li, J.M.; Zhang, B.C.; Yu, Y.; Wang, Y.Y.; Niu, H. Variations in Main Flavor Compounds of Freshly Distilled Brandy during the Second Distillation. Int. J. Food Eng. 2014, 10, 809–820. [Google Scholar] [CrossRef]

- Xu, M.; Jin, Z.; Lan, Y.; Rao, J.; Chen, B. HS-SPME-GC-MS/olfactometry combined with chemometrics to assess the impact of germination on flavor attributes of chickpea, lentil, and yellow pea flours. Food Chem. 2019, 280, 83–95. [Google Scholar] [CrossRef]

- Zhu, J.C.; Chen, F.; Wang, L.Y.; Niu, Y.W.; Chen, H.X.; Wang, H.L.; Xiao, Z.B. Characterization of the Key Aroma Volatile Compounds in Cranberry (Vaccinium macrocarpon Ait.) Using Gas Chromatography-Olfactometry (GC-O) and Odor Activity Value (OAV). J. Agric. Food Chem. 2016, 64, 4990–4999. [Google Scholar] [CrossRef]

- Tian, T.; Yang, H.; Yang, F.; Li, B.; Sun, J.; Wu, D.; Lu, J. Optimization of fermentation conditions and comparison of flavor compounds for three fermented greengage wines. LWT-Food Sci. Technol. 2018, 89, 542–550. [Google Scholar] [CrossRef]

- Qiu, S.; Chen, K.; Liu, C.; Wang, Y.; Chen, T.; Yan, G.; Li, J. Non-Saccharomyces yeasts highly contribute to characterisation of flavour profiles in greengage fermentation. Food Res. Int. 2022, 157, 111391. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Liu, M.; Yang, L.; Zhang, X. Influence of ripening stage and meteorological parameters on the accumulation pattern of polyphenols in greengages (Prunus mume Sieb. Et Zucc) by widely targeted metabolomic. Curr. Res. Food Sci. 2022, 5, 1837–1844. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.M.; Silverstein, D.A.; Farrell, J.E.; Wandell, B.A. Color image quality metric S-CIELAB and its application on halftone texture visibility. In Proceedings of the IEEE COMPCON 97, San Jose, CA, USA, 23–26 February 1997; pp. 44–48. [Google Scholar] [CrossRef]

- Berenguer, M.; Vegara, S.; Barrajon, E.; Saura, D.; Valero, M.; Marti, N. Physicochemical characterization of pomegranate wines fermented with three different Saccharomyces cerevisiae yeast strains. Food Chem. 2016, 190, 848–855. [Google Scholar] [CrossRef] [PubMed]

- Darias-Martin, J.J.; Rodriguez, O.; Diaz, E.; Lamuela-Raventos, R.M. Effect of skin contact on the antioxidant phenolics in white wine. Food Chem. 2000, 71, 483–487. [Google Scholar] [CrossRef]

- Han, X.; Peng, Q.; Yang, H.; Hu, B.; Shen, C.; Tian, R. Influence of different carbohydrate sources on physicochemical properties and metabolites of fermented greengage (Prunus mume) wines. LWT-Food Sci. Technol. 2020, 121, 108929. [Google Scholar] [CrossRef]

- Spence, C. Wine psychology: Basic & applied. Cogn. Res. Princ. Implic. 2020, 5, 22. [Google Scholar] [CrossRef]

- Rajkovic, M.B.; Perić, L. The determination of furaldehyde and benzaldehyde in plum brandy. Hem. Ind. 2005, 59, 78–83. [Google Scholar] [CrossRef]

- Guo, L.; Luo, Y.; Zhou, Y.; Bianba, C.; Guo, H.; Zhao, Y.; Fu, H. Exploring microbial dynamics associated with flavours production during highland barley wine fermentation. Food Res. Int. 2020, 130, 108971. [Google Scholar] [CrossRef]

- Coelho, E.M.; Da Silva Padilha, C.V.; Miskinis, G.A.; De Sá, A.G.B.; Pereira, G.E.; De Azevêdo, L.C.; Dos Santos Lima, M. Simultaneous analysis of sugars and organic acids in wine and grape juices by HPLC: Method validation and characterization of products from northeast Brazil. J. Food Compos. Anal. 2018, 66, 160–167. [Google Scholar] [CrossRef]

- Liu, A.; Yang, X.; Guo, Q.; Li, B.; Zheng, Y.; Shi, Y.; Zhu, L. Microbial Communities and Flavor Compounds during the Fermentation of Traditional Hong Qu Glutinous Rice Wine. Foods 2022, 11, 1097. [Google Scholar] [CrossRef]

- Zampini, M.; Wantling, E.; Phillips, N.; Spence, C. Multisensory flavor perception: Assessing the influence of fruit acids and color cues on the perception of fruit-flavored beverages. Food Qual. Prefer. 2008, 19, 335–343. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, P.; Xiao, Z.; Zhu, J.; Sun, X.; Wang, R. Evaluation of the perceptual interaction among ester aroma compounds in cherry wines by GC-MS, GC-O, odor threshold and sensory analysis: An insight at the molecular level. Food Chem. 2019, 275, 143–153. [Google Scholar] [CrossRef] [PubMed]

- Ickes, C.M.; Cadwallader, K.R. Effects of Ethanol on Flavor Perception in Alcoholic Beverages. Chemosens. Percept. 2017, 10, 119–134. [Google Scholar] [CrossRef]

- Li, X.; Qi, L.; Zang, N.; Zhao, L.; Sun, Y.; Huang, X.; Wang, H.; Yin, Z.; Wang, A. Integrated metabolome and transcriptome analysis of the regulatory network of volatile ester formation during fruit ripening in pear. Plant Physiol. Biochem. 2022, 185, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Mertens, N.; Mai, F.; Glomb, M.A. Influence of Nucleophilic Amino Acids on Enzymatic Browning Systems. J. Agric. Food Chem. 2019, 67, 1719–1725. [Google Scholar] [CrossRef]

- Imahori, Y.; Yamamoto, K.; Tanaka, H.; Bai, J. Residual effects of low oxygen storage of mature green fruit on ripening processes and ester biosynthesis during ripening in bananas. Postharvest. Biol. Technol. 2013, 77, 19–27. [Google Scholar] [CrossRef]

- Xie, S.; Hu, F.; Song, C.-z.; Xi, Z.; Zhang, Z.-w. Aromatic profiles of young wines from berries at different heights on grapevines. Food Sci. Technol. Int. 2016, 36, 248–258. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, J.; Liu, X.; Zhang, C.; Zhao, Z.; Li, X.; Sun, B. Flavor mystery of Chinese traditional fermented baijiu: The great contribution of ester compounds. Food Chem. 2021, 369, 130920. [Google Scholar] [CrossRef]

- Yang, H.Y.; Shao-Hua, W.U.; Wang, X.H.; Peng, Q. Analysis of Flavoring Compositions in Green Plum Fruit Fermenting Wine and in Green Plum Fruit Steeping Wine by GC-MS. Liquor-Mak. Sci. Technol. 2005, 9, 80–83. [Google Scholar]

- Jiang, H.; Zhang, M.; Ye, J.; Qian, M.; Li, X.; Zhao, W.; Bai, W. HS-SPME-GC-MS and OAV analyses of characteristic volatile flavour compounds in salt-baked drumstick. LWT-Food Sci. Technol. 2022, 170, 114041. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Z. Volatile Compounds of Young Wines from Cabernet Sauvignon, Cabernet Gernischet and Chardonnay Varieties Grown in the Loess Plateau Region of China. Molecules 2010, 15, 9184–9196. [Google Scholar] [CrossRef] [PubMed]

- Niimi, J.; Tomic, O.; Næs, T.; Jeffery, D.W.; Bastian, S.E.P.; Boss, P.K. Application of sequential and orthogonalised-partial least squaRes. (SO-PLS) regression to predict sensory properties of Cabernet Sauvignon wines from grape chemical composition. Food Chem. 2018, 256, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Du, J.; Xiong, Y.; Cao, Q.; Wang, Z.; Li, H.; Zhang, F.; Chen, Y.; Liu, Y. Characterization of the key aroma compounds in Chinese JingJiu by quantitative measurements, aroma recombination, and omission experiment. Food Chem. 2021, 352, 129450. [Google Scholar] [CrossRef] [PubMed]

| Treatment | FS | SK | TS | BJ |

|---|---|---|---|---|

| Total sugar (g/L) | 360.09 ± 2.88 a | 358.47 ± 6.85 a | 345.21 ± 6.85 b | 333.09 ± 7.88 c |

| Total acid (g/L) | 15.50 ± 0.50 a | 13.90 ± 1.10 b | 13.30 ± 0.50 b | 15.50 ± 0.50 a |

| Alcohol degree. (%v/v) | 6.71 ± 0.13 c | 7.44 ± 0.16 c | 22.94 ± 0.64 b | 25.74 ± 0.59 a |

| pH | 2.70 ± 0.01 b | 3.40 ± 0.73 a | 2.98 ± 0.01 ab | 3.05 ± 0.01 ab |

| CIEL | 95.02 ± 0.57 a | 93.97 ± 0.29 c | 92.41 ± 1.31 b | 92.14 ± 0.89 b |

| CIEa | 1.58 ± 0.32 b | 1.98 ± 0.07 a | 2.67 ± 0.26 a | 2.88 ± 0.3 a |

| CIEb | 10.06 ± 0.71 c | 15.14 ± 0.04 b | 16.59 ± 0.16 a | 17.14 ± 0.11 a |

| Chroma (C) | 10.18 ± 0.75 c | 15.27 ± 0.05 b | 16.81 ± 0.12 a | 17.38 ± 0.05 a |

| Hue angle (h) | 81.16 ± 1.22 b | 82.56 ± 0.24 a | 80.85 ± 0.97 b | 80.44 ± 1.02 b |

| Oxalic acid (g/L) | 0.52 ± 0.01 b | 0.54 ± 0.01 b | 0.65 ± 0.01 a | 0.46 ± 0.00 c |

| Tartaric acid (g/L) | 0.81 ± 0.01 a | 0.08 ± 0.00 d | 0.19 ± 0.00 b | 0.10 ± 0.00 c |

| Malic acid (g/L) | 2.31 ± 0.00 b | 2.05 ± 0.06 d | 2.84 ± 0.02 a | 2.17 ± 0.05 c |

| Lactic acid (g/L) | 0.86 ± 0.16 b | 0.65 ± 0.08 b | 1.21 ± 0.18 a | 1.20 ± 0.01 a |

| Acetic acid (g/L) | 1.33 ± 0.43 b | 1.72 ± 0.05 ab | 1.42 ± 0.16 ab | 1.91 ± 0.19 a |

| Critic acid (g/L) | 17.5 ± 0.57 b | 9.05 ± 0.39 d | 21.95 ± 2.19 a | 12.55 ± 0.96 c |

| Succinic acid(g/L) | 0.19 ± 0.03 b | 7.51 ± 1.37 a | 0.50 ± 0.01 b | 0.06 ± 0.00 b |

| Category | Odor Description | Threshold (μg/L) | Treatment | |||

|---|---|---|---|---|---|---|

| FS | SK | TS | BJ | |||

| Phenylethyl alcohol | Floral, sweet, rosy | 564.23 | <1 | 1.52 | n.d. | 1.92 |

| Benzoic acid, ethyl ester | Sweet, green, fruity, birch | 55.56 | 7.75 | 9.15 | 5.57 | 6.70 |

| Benzeneacetaldehyde | Honey, sweet, floral, chocolate | 6.3 | <1 | 1.07 | n.d. | n.d. |

| 2,3-Butanediol | Fruity, creamy | >100 | 2.91 | 1.19 | n.d. | n.d. |

| Benzaldehyde | Sweet, oily, almond, cherry, nutty | 750.89 | 8.67 | 9.48 | 4.72 | 4.91 |

| 1-Octen-3-ol | Mushroom, vegetative, | 1.5 | 2.32 | 1.53 | 2.13 | 3.83 |

| Octanoic acid, ethyl ester | Sweet, fruity, pineapple, creamy | 19.3 | 2.20 | <1 | 1.16 | 1.81 |

| Propanoic acid, 2-hydroxy-, ethyl ester | Sweet, fruity, creamy, pineapple | 50 | 2.40 | 25.94 | n.d. | 54.30 |

| Hexanoic acid, ethyl ester | Sweet, pineapple, fruity, banana | 5 | 1.54 | 2.34 | 2.34 | 6.47 |

| 1-Butanol, 2-methyl- | Alcoholic, fatty, cocoa | 15.9 | 92.83 | 190.44 | n.d. | 131.66 |

| 1-Butanol | Banana | 459.2 | 1.34 | 2.77 | n.d. | n.d. |

| 1-Propanol | Earthy, peanut, nutty, apple, pear | 8505.6 | 1.24 | 2.15 | n.d. | n.d. |

| Butanoic acid, ethyl ester | Fruity, sweet, apple | 0.9 | <1 | 104.73 | n.d. | 35.48 |

| Isobutyl acetate | Sweet, fruity, banana | 25 | <1 | 1.42 | n.d. | 1.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Liu, C.; Qiu, S.; Chen, K.; Wang, Y.; Hou, C.; Huang, R.; Li, J. Flavor Profile Evaluation of Soaked Greengage Wine with Different Base Liquor Treatments Using Principal Component Analysis and Heatmap Analysis. Foods 2023, 12, 2016. https://doi.org/10.3390/foods12102016

Zhao P, Liu C, Qiu S, Chen K, Wang Y, Hou C, Huang R, Li J. Flavor Profile Evaluation of Soaked Greengage Wine with Different Base Liquor Treatments Using Principal Component Analysis and Heatmap Analysis. Foods. 2023; 12(10):2016. https://doi.org/10.3390/foods12102016

Chicago/Turabian StyleZhao, Peipei, Chang Liu, Shuang Qiu, Kai Chen, Yingxiang Wang, Caiyun Hou, Rui Huang, and Jingming Li. 2023. "Flavor Profile Evaluation of Soaked Greengage Wine with Different Base Liquor Treatments Using Principal Component Analysis and Heatmap Analysis" Foods 12, no. 10: 2016. https://doi.org/10.3390/foods12102016