Advanced Glycation End Products: A Comprehensive Review of Their Detection and Occurrence in Food

Abstract

1. Introduction

2. Types of AGEs

2.1. CML and CEL

2.2. Pentosidine

2.3. Pyrraline

3. Measurement of AGEs in Food

3.1. Instrument Analysis

3.1.1. HPLC-Detectors

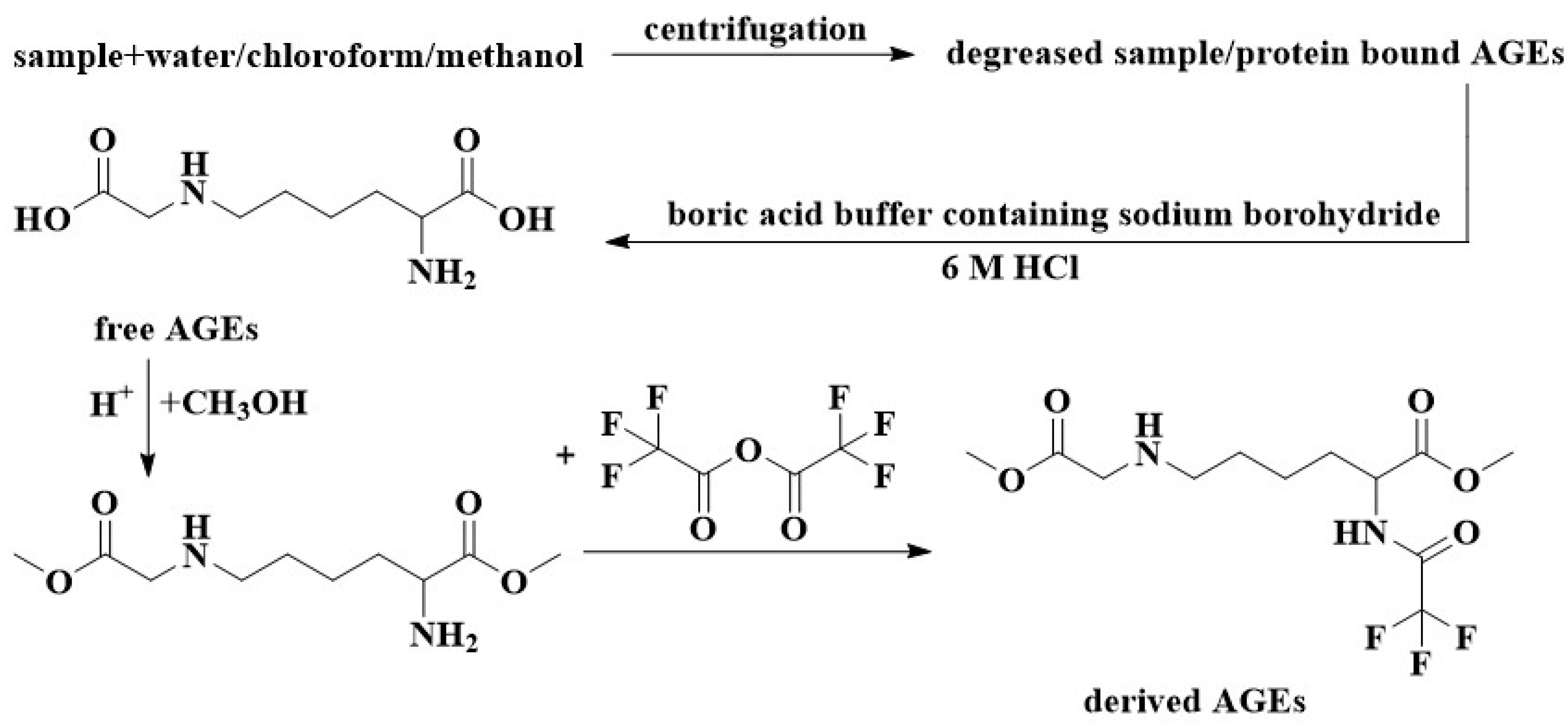

3.1.2. GC

3.2. Immunoassay Analysis

ELISA

3.3. Other Methods

3.4. Comparison of the Detection Techniques

4. Levels of AGEs in Common Foods

4.1. Cereal Products

4.1.1. Raw Materials

4.1.2. Ingredients

4.1.3. Processing Time and Temperature

4.2. Meat Products

4.2.1. Heat Treatment Process

4.2.2. Type of Meat

4.2.3. Ingredients and Additives

4.3. Dairy Products

4.3.1. Type of Dairy Products

4.3.2. Sterilization Methods

4.3.3. Storage Conditions

4.4. Coffee, Cocoa and Tea Products

4.4.1. Coffee Products

4.4.2. Cocoa Products

4.4.3. Tea Products

5. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Poulsen, M.W.; Hedegaard, R.V.; Andersen, J.M.; de Courten, B.; Bugel, S.; Nielsen, J.; Skibsted, L.H.; Dragsted, L.O. Advanced glycation endproducts in food and their effects on health. Food Chem. Toxicol. 2013, 60, 10–37. [Google Scholar] [CrossRef] [PubMed]

- Nesreen, A.; Franck, C. Impact of Maillard reaction products on nutrition and health: Current knowledge and need to understand their fate in the human digestive system. Crit. Rev. Food Sci. Nutr. 2019, 59, 474–487. [Google Scholar] [CrossRef]

- Singh, R.; Barden, A.; Mori, T.; Beilin, L. Advanced glycation end-products: A review. Diabetologia 2001, 44, 129–146. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.-S.; Shi, L.; Wang, P.-C.; Liu, X.; Fang, M.; Wu, Y.-N.; Gong, Z.-Y. Determination of Nε-(carboxymethyl)lysine in commercial dairy products in China with liquid chromatography tandem mass spectroscopy. J. Food Meas. Charact. 2022, 16, 714–721. [Google Scholar] [CrossRef]

- Prestel, S.; de Falco, B.; Blidi, S.; Fiore, A.; Sturrock, K. Evaluation of the effect of berry extracts on carboxymethyllysine and lysine in ultra-high temperature treated milk. Food Res. Int. 2020, 130, 108923. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Quan, W.; Jia, X.; He, Z.; Wang, Z.; Zeng, M.; Chen, J. Profiles of initial, intermediate, and advanced stages of harmful Maillard reaction products in whole-milk powders pre-treated with different heat loads during 18 months of storage. Food Chem. 2021, 351, 129361. [Google Scholar] [CrossRef] [PubMed]

- Niu, L.; Yu, H.; Zhang, L.; Zhao, Q.; Lai, K.; Liu, Y.; Huang, Y. Advanced glycation end-products in raw and commercially sterilized pork tenderloin and offal. J. Food Compos. Anal. 2022, 112, 104681. [Google Scholar] [CrossRef]

- Wei, Q.; Liu, T.; Sun, D.-W. Advanced glycation end-products (AGEs) in foods and their detecting techniques and methods: A review. Trends Food Sci. Technol. 2018, 82, 32–45. [Google Scholar] [CrossRef]

- Luevano-Contreras, C.; Chapman-Novakofski, K. Dietary advanced glycation end products and aging. Nutrients 2010, 2, 1247–1265. [Google Scholar] [CrossRef]

- Lund, M.N.; Ray, C.A. Control of Maillard Reactions in Foods: Strategies and Chemical Mechanisms. J. Agric. Food Chem. 2017, 65, 4537–4552. [Google Scholar] [CrossRef]

- Wu, C.H.; Huang, S.M.; Lin, J.A.; Yen, G.C. Inhibition of advanced glycation endproduct formation by foodstuffs. Food Funct. 2011, 2, 224–234. [Google Scholar] [CrossRef] [PubMed]

- Eggen, M.D.; Glomb, M.A. Analysis of Glyoxal- and Methylglyoxal-Derived Advanced Glycation End Products during Grilling of Porcine Meat. J. Agric. Food Chem. 2021, 69, 15374–15383. [Google Scholar] [CrossRef] [PubMed]

- Loidl-Stahlhofen, A.; Spiteller, G. α-Hydroxyaldehydes, products of lipid peroxidation. Biochimical et. Biophys. Acta 1994, 1211, 156–160. [Google Scholar] [CrossRef] [PubMed]

- Mlakar, A.; Spiteller, G. Reinvestigation of lipid peroxidation of linolenic acid. Biochim. Biophys. Acta 1994, 1214, 209–220. [Google Scholar] [CrossRef]

- Niyati-Shirkhodaee, F.; Shibamoto, T. Gas Chromatographic Analysis of Glyoxal and Methylglyoxal Formed from Lipids and Related Compounds upon Ultraviolet Irradiation. J. Agric. Food Chem. 1993, 41, 227–240. [Google Scholar] [CrossRef]

- Dum, J.A.; Ahmed, M.U.; Murtiashaw, M.H.; Richardson, J.M.; Walla, M.D.; Thorpe, S.R.; Baynes, J.W. Reaction of Ascorbate with Lysine and Protein under Autoxidizing Conditions: Formation of NE-( Carboxymethy1)lysine by Reaction between Lysine and Products of Autoxidation of Ascorbate. Biochemistry 1990, 29, 10964–10970. [Google Scholar] [CrossRef]

- Wells-Knecht, K.J.; Zyzak, D.V.; Litchfield, J.E.; Thorpe, S.R.; Baynes, J.W. Mechanism of Autoxidative Glycosylation: Identification of Glyoxal and Arabinose as Intermediates in the Autoxidative Modification of Proteins by Glucose. Biochemistry 1995, 34, 3702–3709. [Google Scholar] [CrossRef]

- Fu, M.; Requena, J.R.; Jenkins, A.J.; Lyons, T.J.; Baynes, J.W.; Thorpe, S.R. The Advanced Glycation End Product, N-(Carboxymethyl)lysine, Is a Product of both Lipid Peroxidation and Glycoxidation Reactions. J. Biol. Chem. 1996, 271, 9982–9986. [Google Scholar] [CrossRef]

- Kasper, M.; Schieberle, P. Labeling studies on the formation pathway of Nepsilon-carboxymethyllysine in maillard-type reactions. Ann. N. Y. Acad. Sci. 2005, 1043, 59–62. [Google Scholar] [CrossRef]

- Hayashi, T.; Namiki, M. Role of Sugar Fragmentation in an Early Stage Browning of Amino-carbonyl Reaction of Sugar with Amino Acid. Agric. Biol. Chem. 2014, 50, 1965–1970. [Google Scholar] [CrossRef]

- Nguyen, H.T.; van der Fels-Klerx, H.J.; van Boekel, M.A.J.S. Nϵ-(carboxymethyl)lysine: A Review on Analytical Methods, Formation, and Occurrence in Processed Food, and Health Impact. Food Rev. Int. 2013, 30, 36–52. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, X.; Ye, B.; Yan, H.; Zhao, Y.; Liu, L. Effect of unsaturated fatty acids on glycation product formation pathways (I) the role of oleic acid. Food Res. Int. 2020, 136, 109560. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.U.; Frye, E.B.; Degenhardt, T.P.; Thorpe, S.R.; Baynes, J.W. Nε-(Carboxyethyl)lysine, a product of the chemical modification of proteins by methylglyoxal, increases with age in human lens proteins. Biochem. J. 1997, 324, 565–570. [Google Scholar] [CrossRef]

- Thorpe, S.R.; Baynes, J.W. CML: A brief history. Int. Congr. Ser. 2002, 1245, 91–99. [Google Scholar] [CrossRef]

- Ahmed, M.U.; Thorpe, S.R.; Baynes, J.W. Identification of N epsilon-carboxymethyllysine as a degradation product of fructoselysine in glycated protein. J. Biol. Chem. 1986, 261, 4889–4894. [Google Scholar] [CrossRef] [PubMed]

- Sell, D.R.; Monnier, V.M. Isolation, Purification and Partial Characterization of Novel Fluorophores from Aging Human Insoluble Collagen-Rich Tissue. Connect. Tissue Res. 1989, 19, 77–92. [Google Scholar] [CrossRef]

- Grandhee, S.K.; Monnier, V.M. Mechanism of formation of the Maillard protein cross-link pentosidine. Glucose, fructose, and ascorbate as pentosidine precursors. J. Biol. Chem. 1991, 266, 11649–11653. [Google Scholar] [CrossRef]

- Dyer, D.G.; Blackledge, J.A.; Thorpe, S.R.; Baynes, J.W. Formation of pentosidine during nonenzymatic browning of proteins by glucose. Identification of glucose and other carbohydrates as possible precursors of pentosidine in vivo. J. Biol. Chem. 1991, 266, 11654–11660. [Google Scholar] [CrossRef]

- Hayase, F.; Nagaraj, R.H.; Miyata, S.; Njoroge, F.G.; Monnier, V.M. Aging of Proteins: Immunological Detection of a Glucose-derived Pyrrole Formed during Maillard Reaction in vivo. J. Biol. Chem. 1989, 264, 3758–3764. [Google Scholar] [CrossRef]

- Yu, H.; Zhong, Q.; Xie, Y.; Guo, Y.; Cheng, Y.; Yao, W. Kinetic study on the generation of furosine and pyrraline in a Maillard reaction model system of d-glucose and l-lysine. Food Chem. 2020, 317, 126458. [Google Scholar] [CrossRef]

- Gao, J.; Sun, Y.; Li, L.; Zhou, Q.; Wang, M. The antiglycative effect of apple flowers in fructose/glucose-BSA models and cookies. Food Chem. 2020, 330, 127170. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Chung, Y.S.; Chang, S.Y.; Jung, Y.S.; Kim, S.H. Simple Quantification of Pentosidine in Human Urine and Plasma by High-Performance Liquid Chromatography. Int. J. Anal. Chem. 2017, 2017, 1389807. [Google Scholar] [CrossRef]

- Troise, A.D.; Colantuono, A.; Fiore, A. Spray-dried olive mill wastewater reduces Maillard reaction in cookies model system. Food Chem. 2020, 323, 126793. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zheng, L.; Zheng, X.; Yang, Y.; Xiao, D.; Zhang, H.; Ai, B.; Sheng, Z. Chitosan inhibits advanced glycation end products formation in chemical models and bakery food. Food Hydrocoll. 2022, 128, 107600. [Google Scholar] [CrossRef]

- Qin, R.K.; Wu, R.L.; Shi, H.A.; Jia, C.H.; Rong, J.H.; Liu, R. Formation of AGEs in fish cakes during air frying and other traditional heating methods. Food Chem. 2022, 391, 133213. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Lund, M.N.; Li, B.; Hu, Y.; Zhang, X. Reduction of Nepsilon-(carboxymethyl) lysine by (-)-epicatechin and (-)-epigallocatechin gallate: The involvement of a possible trapping mechanism by catechin quinones. Food Chem. 2018, 266, 427–434. [Google Scholar] [CrossRef]

- Wu, R.L.; Jiang, Y.; Qin, R.K.; Shi, H.N.; Jia, C.H.; Rong, J.H.; Liu, R. Study of the formation of food hazard factors in fried fish nuggets. Food Chem. 2022, 373, 131562. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Yang, Z.; Hao, Y.; Wang, Z.; Han, L.; Li, M.; Zhang, N.; Chen, H.; Liu, Y.; Li, H.; et al. Effect of alkylresorcinols on the formation of Nepsilon-(carboxymethyl)lysine and sensory profile of wheat bread. Food Sci. Nutr. 2021, 9, 489–498. [Google Scholar] [CrossRef]

- Asif, A.; Zeeshan, N.; Mehmood, S. Antioxidant and antiglycation activities of traditional plants and identification of bioactive compounds from extracts of Hordeum vulgare by LC-MS and GC-MS. J. Food Biochem. 2020, 44, e13381. [Google Scholar] [CrossRef]

- Wang, M.Q.; Yuan, X.W.; Zheng, Y.; Wu, Z.Y.; Li, H.B.; Li, H.J.; Yu, J.H. Maillard reaction indicators formation, changes and possible intake in infant formula produced by different thermal treatments during domestic use. Food Chem. 2022, 395, 133576. [Google Scholar] [CrossRef]

- Li, H.B.; Zhang, Y.Y.; Li, C.S.; Xu, S.Y.; Song, W.B.; Li, H.J.; Yu, J.H. Content and evolution of Maillard reaction products in commercial brown fermented milk during storage. Int. Dairy J. 2022, 129, 105343. [Google Scholar] [CrossRef]

- Huang, S.H.; Dong, X.L.; Zhang, Y.L.; Chen, Y.R.; Yu, Y.J.; Huang, M.; Zheng, Y.D. Formation of advanced glycation end products in raw and subsequently boiled broiler muscle: Biological variation and effects of postmortem ageing and storage. Food Sci. Hum. Wellness 2022, 11, 255–262. [Google Scholar] [CrossRef]

- Fang, R.; Zhu, Z.S.; Bassey, A.P.; Khan, I.A.; Huang, M. Glyoxal induced advanced glycation end products formation in chicken meat emulsion instead of oxidation. Food Sci. Hum. Wellness 2022, 11, 828–836. [Google Scholar] [CrossRef]

- Prosser, C.G.; Carpenter, E.A.; Hodgkinson, A.J. N(epsilon)-carboxymethyllysine in nutritional milk formulas for infants. Food Chem. 2019, 274, 886–890. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Ojeda, A.; Jaramillo-Ortiz, S.; Wrobel, K.; Wrobel, K.; Barbosa-Sabanero, G.; Luevano-Contreras, C.; de la Maza, M.P.; Uribarri, J.; Del Castillo, M.D.; Garay-Sevilla, M.E. Comparative evaluation of three different ELISA assays and HPLC-ESI-ITMS/MS for the analysis of N(epsilon)-carboxymethyl lysine in food samples. Food Chem. 2018, 243, 11–18. [Google Scholar] [CrossRef]

- Yu, H.; Zhong, Q.L.; Guo, Y.H.; Xie, Y.F.; Cheng, Y.L.; Yao, W.R. Potential of resveratrol in mitigating advanced glycation end-products formed in baked milk and baked yogurt. Food Res. Int. 2020, 133, 109191. [Google Scholar] [CrossRef]

- Poojary, M.M.; Zhang, W.; Olesen, S.B.; Rauh, V.; Lund, M.N. Green Tea Extract Decreases Arg-Derived Advanced Glycation Endproducts but Not Lys-Derived AGEs in UHT Milk during 1-Year Storage. J. Agric. Food Chem. 2020, 68, 14261–14273. [Google Scholar] [CrossRef]

- Peake, B.; Ghetia, M.; Gerber, C.; Costabile, M.; Deo, P. Role of saturated and unsaturated fatty acids on dicarbonyl-albumin derived advanced glycation end products in vitro. Amino Acids 2022, 54, 721–732. [Google Scholar] [CrossRef]

- Nomi, Y.; Sato, T.; Mori, Y.; Matsumoto, H. Evaluation of Fructo-, Inulin-, and Galacto-Oligosaccharides on the Maillard Reaction Products in Model Systems with Whey Protein. J. Agric. Food Chem. 2022, 70, 9154–9165. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, B.; Ye, Y.; Zhu, H. Methylglyoxal-hydroimidazolones (MG-Hs) instead of Nvarepsilon-(carboxymethyl)-l-lysine (CML) is the major advanced glycation end-product during drying process in black tea. Food Chem. 2020, 333, 127499. [Google Scholar] [CrossRef]

- Zhang, J.J.; Liu, Z.J.; Huang, Y.Q.; Lai, K.Q.; Lin, H.; Liu, Y.L.; Wang, F.X. Effects of sodium bicarbonate and sodium phosphates on the formation of advanced glycation end-products in minced pork during cold storage. J. Food Meas. Charact. 2022, 16, 4425–4432. [Google Scholar] [CrossRef]

- Shen, Z.W.; Li, S.C.; Wu, J.H.; Wang, F.X.; Li, X.H.; Yu, J.; Liu, Y.L.; Ma, X.Y. Effect of different oil incorporation on gelling properties, flavor and advanced glycation end-products of silver carp surimi sausages. J. Food Meas. Charact. 2022, 16, 5007–5022. [Google Scholar] [CrossRef]

- Sen, D.; Gokmen, V. Kinetic modeling of Maillard and caramelization reactions in sucrose-rich and low moisture foods applied for roasted nuts and seeds. Food Chem. 2022, 395, 133583. [Google Scholar] [CrossRef] [PubMed]

- Manig, F.; Hellwig, M.; Pietz, F.; Henle, T. Studies about the Dietary Impact on "Free" Glycation Compounds in Human Saliva. Foods 2022, 11, 2112. [Google Scholar] [CrossRef]

- Liu, L.C.; Liu, L.; Xie, J.H.; Shen, M.Y. Formation mechanism of AGEs in Maillard reaction model systems containing ascorbic acid. Food Chem. 2022, 378, 132108. [Google Scholar] [CrossRef]

- Jost, T.; Henning, C.; Heymann, T.; Glomb, M.A. Comprehensive Analyses of Carbohydrates, 1,2-Dicarbonyl Compounds, and Advanced Glycation End Products in Industrial Bread Making. J. Agric. Food Chem. 2021, 69, 3720–3731. [Google Scholar] [CrossRef]

- Marousez, L.; Sprenger, N.; De Lamballerie, M.; Jaramillo-Ortiz, S.; Tran, L.; Micours, E.; Gottrand, F.; Howsam, M.; Tessier, F.J.; Ley, D.; et al. High hydrostatic pressure processing of human milk preserves milk oligosaccharides and avoids formation of Maillard reaction products. Clin Nutr. 2022, 41, 1–8. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Wang, S.; Wang, X.Y.; Dong, S.Y.; Zhao, Y.H.; Zeng, M.Y. The relationship between the formation of advanced glycation end products and quality attributes of fried sturgeon fillets. LWT-Food Sci. Technol. 2022, 159. [Google Scholar] [CrossRef]

- Li, M.Y.; Lu, J.N.; Huang, Y.S.; Wang, W.J.; Xie, J.H.; Xie, M.Y.; Shen, M.Y. Quantitative assessment of furosine, furfurals, and advanced glycation end products in different types of commercially available cheeses. Food Control 2022, 136. [Google Scholar] [CrossRef]

- Bai, S.; You, L.Q.; Wang, Y.R.; Luo, R.M. Effect of Traditional Stir-Frying on the Characteristics and Quality of Mutton Sao Zi. Front Nutr. 2022, 9, 925208. [Google Scholar] [CrossRef]

- Bai, S.; You, L.Q.; Ji, C.; Zhang, T.G.; Wang, Y.R.; Geng, D.; Gao, S.; Bi, Y.Z.; Luo, R.M. Formation of volatile flavor compounds, maillard reaction products and potentially hazard substance in China stir-frying beef sao zi. Food Res. Int. 2022, 159, 111545. [Google Scholar] [CrossRef]

- Çelik, E.E.; Gökmen, V. Formation of Maillard reaction products in bread crust-like model system made of different whole cereal flours. Eur. Food Res. Technol. 2020, 246, 1207–1218. [Google Scholar] [CrossRef]

- Li, Y.; Xue, C.; Quan, W.; Qin, F.; Wang, Z.; He, Z.; Zeng, M.; Chen, J. Assessment the influence of salt and polyphosphate on protein oxidation and Nepsilon-(carboxymethyl)lysine and Nepsilon-(carboxyethyl)lysine formation in roasted beef patties. Meat Sci. 2021, 177, 108489. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Li, Y.; Dong, L.; Shi, R.; Wu, Z.; Liu, L.; Zhang, J.; Wu, Z.; Pan, D. Quantitative determination of Nε-(carboxymethyl)lysine in sterilized milk by isotope dilution UPLC-MS/MS method without derivatization and ion pair reagents. Food Chem. 2022, 385, 132697. [Google Scholar] [CrossRef] [PubMed]

- Gong, R.-z.; Wang, Y.-h.; Wang, Y.-f.; Chen, B.; Gao, K.; Sun, Y.-s. Simultaneous Determination of Nε-(carboxymethyl) Lysine and Nε-(carboxyethyl) Lysine in Different Sections of Antler Velvet after Various Processing Methods by UPLC-MS/MS. Molecules 2018, 23, 3316. [Google Scholar] [CrossRef]

- Hellwig, M.; Henle, T. Quantification of the Maillard reaction product 6-(2-formyl-1-pyrrolyl)-l-norleucine (formyline) in food. Eur. Food Res. Technol. 2012, 235, 99–106. [Google Scholar] [CrossRef]

- Chen, G.; Smith, J.S. Determination of advanced glycation endproducts in cooked meat products. Food Chem. 2015, 168, 190–195. [Google Scholar] [CrossRef]

- Drusch, S.; Faist, V.; Erbersdobler, H.F. Determination of NE-carboxymethyllysine in milk products by a modified reversed-phase HPLC method. Food Chem. 1999, 65, 547–553. [Google Scholar] [CrossRef]

- Schettgen, T.; Tings, A.; Brodowsky, C.; Muller-Lux, A.; Musiol, A.; Kraus, T. Simultaneous determination of the advanced glycation end product N (epsilon)-carboxymethyllysine and its precursor, lysine, in exhaled breath condensate using isotope-dilution-hydrophilic-interaction liquid chromatography coupled to tandem mass spectrometry. Anal. Bioanal. Chem. 2007, 387, 2783–2791. [Google Scholar] [CrossRef]

- Ochi, N. Simultaneous determination of eight underivatized biogenic amines in salted mackerel fillet by ion-pair solid-phase extraction and volatile ion-pair reversed-phase liquid chromatography-tandem mass spectrometry. J. Chromatogr. A 2019, 1601, 115–120. [Google Scholar] [CrossRef]

- Sun, X.; Tang, J.; Wang, J.; Rasco, B.A.; Lai, K.; Huang, Y. Formation of free and protein-bound carboxymethyllysine and carboxyethyllysine in meats during commercial sterilization. Meat Sci. 2016, 116, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Qin, R.; Jia, C.; Rong, J.; Hu, Y.; Liu, R. Hydrocolloid effects on Nε-carboxymethyllysine and acrylamide of deep-fried fish nuggets. Food Biosci. 2021, 39, 100797. [Google Scholar] [CrossRef]

- Charissou, A.; Ait-Ameur, L.; Birlouez-Aragon, I. Evaluation of a gas chromatography/mass spectrometry method for the quantification of carboxymethyllysine in food samples. J. Chromatogr. A 2007, 1140, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Malgorzata, W.; Konrad, P.M.; Zielinski, H. Effect of roasting time of buckwheat groats on the formation of Maillard reaction products and antioxidant capacity. Food Chem. 2016, 196, 355–358. [Google Scholar] [CrossRef]

- Ashraf, J.M.; Ahmad, S.; Choi, I.; Ahmad, N.; Farhan, M.; Tatyana, G.; Shahab, U. Recent advances in detection of AGEs: Immunochemical, bioanalytical and biochemical approaches. IUBMB Life 2015, 67, 897–913. [Google Scholar] [CrossRef]

- Reen, D.J. The enzyme-linked immunosorbent assay (ELISA) *. Bull. World Health Organ. 1976, 54, 129–139. [Google Scholar]

- Ikeda, K.; Higashi, T.; Sano, H.; Jinnouchi, Y.; Yoshida, M.; Araki, T.; Ueda, S.; Horiuchi, S. N-(Carboxymethyl)lysine Protein Adduct Is a Major Immunological Epitope in Proteins Modified with Advanced Glycation End Products of the Maillard Reaction. Biochemistry 1996, 35, 8. [Google Scholar] [CrossRef]

- Goldberg, T.; Cai, W.; Peppa, M.; Dardaine, V.; Baliga, B.S.; Uribarri, J.; Vlassara, H. Advanced glycoxidation end products in commonly consumed foods. J. Am. Diet. Assoc. 2004, 104, 1287–1291. [Google Scholar] [CrossRef]

- Uribarri, J.; Woodruff, S.; Goodman, S.; Cai, W.; Chen, X.; Pyzik, R.; Yong, A.; Striker, G.E.; Vlassara, H. Advanced glycation end products in foods and a practical guide to their reduction in the diet. J. Am. Diet. Assoc. 2010, 110, 911–916. [Google Scholar] [CrossRef]

- Tareke, E.; Forslund, A.; Lindh, C.H.; Fahlgren, C.; Östman, E. Isotope dilution ESI-LC-MS/MS for quantification of free and total Ne-(1-Carboxymethyl)-L-Lysine and free Ne-(1-Carboxyethyl)-L-Lysine: Comparison of total Ne-(1-Carboxymethyl)-L-Lysine levels measured with new method to ELISA assay in gruel samples. Food Chem. 2013, 141, 4253–4259. [Google Scholar] [CrossRef]

- Henle, T.; Klostermeyer, H. Determination of protein-bound 2-amino-6-(2-formyl-l-pyrrolyl)-hexanoic acid ("pyrraline") by ion exchange chromatography and photodiode array detection. Z Leb. Unters 1993. [Google Scholar] [CrossRef]

- Dutta, U.; Dain, J.A. Capillary electrophoretic analysis of advanced glycation endproducts formed from the reaction of reducing sugars with the amino group of glucosamine. Anal. Biochem. 2005, 343, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Birlouez-Aragon, I.; Locquet, N.; de St Louvent, E.; Bouveresse, D.J.; Stahl, P. Evaluation of the maillard reaction in infant formulas by means of front-face fluorescence. Ann. N. Y. Acad. Sci. 2005, 1043, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Niquet-Leridon, C.; Jacolot, P.; Niamba, C.N.; Grossin, N.; Boulanger, E.; Tessier, F.J. The rehabilitation of raw and brown butters by the measurement of two of the major Maillard products, N(epsilon)-carboxymethyl-lysine and 5-hydroxymethylfurfural, with validated chromatographic methods. Food Chem. 2015, 177, 361–368. [Google Scholar] [CrossRef] [PubMed]

- Zilic, S.; Aktag, I.G.; Dodig, D.; Gokmen, V. Investigations on the formation of Maillard reaction products in sweet cookies made of different cereals. Food Res. Int. 2021, 144, 110352. [Google Scholar] [CrossRef]

- Palermo, M.; Fiore, A.; Fogliano, V. Okara promoted acrylamide and carboxymethyl-lysine formation in bakery products. J. Agric. Food Chem. 2012, 60, 10141–10146. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, X.; Zhang, Z.; Ma, L.; Liu, G.; Wang, Q.; Chen, F.; Cheng, K.W. Development of an Isotope Dilution UHPLC-QqQ-MS/MS-Based Method for Simultaneous Determination of Typical Advanced Glycation End Products and Acrylamide in Baked and Fried Foods. J. Agric. Food Chem. 2021, 69, 2611–2618. [Google Scholar] [CrossRef]

- Treibmann, S.; Hellwig, A.; Hellwig, M.; Henle, T. Lysine-Derived Protein-Bound Heyns Compounds in Bakery Products. J. Agric. Food Chem. 2017, 65, 10562–10570. [Google Scholar] [CrossRef]

- Hu, H.; Wang, Y.; Shen, M.; Huang, Y.; Li, C.; Nie, S.; Xie, M. Effects of baking factors and recipes on the quality of butter cookies and the formation of advanced glycation end products (AGEs) and 5-hydroxymethylfurfural (HMF). Curr. Res. Food Sci. 2022, 5, 940–948. [Google Scholar] [CrossRef]

- Cheng, L.; Jin, C.; Zhang, Y. Investigation of variations in the acrylamide and N(epsilon) -(carboxymethyl) lysine contents in cookies during baking. J. Food Sci. 2014, 79, T1030–T1038. [Google Scholar] [CrossRef]

- Trevisan, A.J.; de Almeida Lima, D.; Sampaio, G.R.; Soares, R.A.; Markowicz Bastos, D.H. Influence of home cooking conditions on Maillard reaction products in beef. Food Chem. 2016, 196, 161–169. [Google Scholar] [CrossRef]

- Lu, J.; Li, M.; Shen, M.; Xie, J.; Xie, M. Advanced Glycation End Products and Nitrosamines in Sausages Influenced by Processing Parameters, Food Additives and Fat during Thermal Processing. Foods 2023, 12, 394. [Google Scholar] [CrossRef]

- Li, L.; Kong, S.; Liu, Y.; Huang, Y.; Li, Y.; Lai, K. Effects of acetic acid, ethanol, and sodium chloride on the formation of Nε-carboxymethyllysine, Nε-carboxyethyllysine and their precursors in commercially sterilized pork. J. Food Meas. Charact. 2021, 15, 5337–5344. [Google Scholar] [CrossRef]

- Treibmann, S.; Spengler, F.; Degen, J.; Lobner, J.; Henle, T. Studies on the Formation of 3-Deoxyglucosone- and Methylglyoxal-Derived Hydroimidazolones of Creatine during Heat Treatment of Meat. J. Agric. Food Chem. 2019, 67, 5874–5881. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, R.; Yang, X.; Gao, Z.; Yuan, Y.; Yue, T. Changes in aroma components and potential Maillard reaction products during the stir-frying of pork slices. Food Control 2021, 123. [Google Scholar] [CrossRef]

- Sun, X.; Li, X.; Tang, J.; Lai, K.; Rasco, B.A.; Huang, Y. Formation of protein-bound N(epsilon)-carboxymethyllysine and N(epsilon)-carboxyethyllysine in ground pork during commercial sterilization as affected by the type and concentration of sugars. Food Chem. 2021, 336, 127706. [Google Scholar] [CrossRef] [PubMed]

- Niu, L.; Sun, X.; Tang, J.; Wang, J.; Wang, J.; Rasco, B.A.; Lai, K.; Fan, Y.; Huang, Y. Combination effects of salts and cold storage on the formation of protein-bound N(varepsilon)-(carboxymethyl)lysine and N(varepsilon)-(carboxyethyl)lysine in raw and subsequently commercially sterilized ground pork. Food Chem. 2018, 264, 455–461. [Google Scholar] [CrossRef]

- Li, F.; Zhuang, H.; Qiao, W.; Zhang, J.; Wang, Y. Effect of partial substitution of NaCl by KCl on physicochemical properties, biogenic amines and N-nitrosamines during ripening and storage of dry-cured bacon. J. Food Sci. Technol. 2016, 53, 3795–3805. [Google Scholar] [CrossRef]

- Zenker, H.E.; Raupbach, J.; Boeren, S.; Wichers, H.J.; Hettinga, K.A. The effect of low vs. high temperature dry heating on solubility and digestibility of cow’s milk protein. Food Hydrocoll. 2020, 109, 106098. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Quan, W.; Jia, X.; He, Z.; Wang, Z.; Adhikari, B.; Chen, J.; Zeng, M. Quantitation of furosine, furfurals, and advanced glycation end products in milk treated with pasteurization and sterilization methods applicable in China. Food Res. Int. 2021, 140, 110088. [Google Scholar] [CrossRef]

- Li, Y.; Jia, X.; Wang, Z.; He, Z.; Zeng, M.; Chen, J. Characterizing changes in Maillard reaction indicators in whole milk powder and reconstituted low-temperature pasteurized milk under different preheating conditions. J. Food Sci. 2022, 87, 193–205. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhang, L.; Gao, W.; Lai, C.; Dong, H. Robust Detection of Advanced Glycation Endproducts in Milk Powder Using Ultrahigh Performance Liquid Chromatography Tandem Mass Spectrometry (UHPLC-MS/MS). Food Anal. Methods 2021, 14, 1472–1481. [Google Scholar] [CrossRef]

- Zhang, W.; Poojary, M.M.; Rauh, V.; Ray, C.A.; Olsen, K.; Lund, M.N. Quantitation of alpha-Dicarbonyls and Advanced Glycation Endproducts in Conventional and Lactose-Hydrolyzed Ultrahigh Temperature Milk during 1 Year of Storage. J. Agric. Food Chem. 2019, 67, 12863–12874. [Google Scholar] [CrossRef]

- Poojary, M.M.; Zhang, W.; Greco, I.; De Gobba, C.; Olsen, K.; Lund, M.N. Liquid chromatography quadrupole-Orbitrap mass spectrometry for the simultaneous analysis of advanced glycation end products and protein-derived cross-links in food and biological matrices. J. Chromatogr. A 2020, 1615, 460767. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Sun, X.; Zhang, Y.; Yang, T.; Wang, C.; Zhang, J.; Duan, Z.; Shang, F.; Fan, J.; Liu, Y.; et al. Effect of pectin oligosaccharides supplementation on infant formulas: The storage stability, formation and intestinal absorption of advanced glycation end products. Food Chem. 2022, 373, 131571. [Google Scholar] [CrossRef]

- Zhang, H.; Troise, A.D.; Zhang, H.; Fogliano, V. Cocoa melanoidins reduce the formation of dietary advanced glycation end-products in dairy mimicking system. Food Chem. 2021, 345, 128827. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Chen, X.; Lin, T.; Yin, B.; Li, Q.; Wang, L.; Shao, J.; Yang, J. The level variation of N(epsilon)-(carboxymethyl)lysine is correlated with chlorogenic acids in Arabica L. Coffee beans under different process conditions. Food Chem. 2021, 343, 128458. [Google Scholar] [CrossRef]

- Loaec, G.; Jacolot, P.; Helou, C.; Niquet-Leridon, C.; Tessier, F.J. Acrylamide, 5-hydroxymethylfurfural and N(epsilon)-carboxymethyl-lysine in coffee substitutes and instant coffees. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2014, 31, 593–604. [Google Scholar] [CrossRef]

- Tas, N.G.; Gokmen, V. Effect of alkalization on the Maillard reaction products formed in cocoa during roasting. Food Res. Int. 2016, 89, 930–936. [Google Scholar] [CrossRef]

- Jiao, Y.; He, J.; Li, F.; Tao, G.; Zhang, S.; Zhang, S.; Qin, F.; Zeng, M.; Chen, J. N(epsilon)-(carboxymethyl)lysine and N(epsilon)-(carboxyethyl)lysine in tea and the factors affecting their formation. Food Chem. 2017, 232, 683–688. [Google Scholar] [CrossRef]

| Method | Column | Application Field | Marker | Limit of Detection | References |

|---|---|---|---|---|---|

| HPLC-DAD | Reverse-phase (RP)-C18 column (4.6 mm × 250 mm, 5 μm) | cookies | fluorescent AGEs | [31] | |

| HPLC-PDA | Sunfire C18 column (4.6 mm × 250 mm, 5 µm) | baked milk and baked yogurt | pyrraline | [46] | |

| UPLC-DAD | ACQUITY HSS T3 column (100 mm × 2.1 mm, 1.8 μm) | milk | pyrraline | 0.50 μg/g protein | [47] |

| HPLC-FLD | C18 reverse-phase column (250 × 4.6 mm, 5 μm) | human urine and plasma | pentosidine | 1 nM | [32] |

| HPLC-MS | Hydro-RP 80 Å LC column (150 × 4.6 mm) | dicarbonyl-BSA model system | CEL, CML, and MG-H1 | [48] | |

| HPLC-MS/MS | Hypercarb guard column (2.1 mm × 10 mm, 5 μm) tandem a C18 column (4.5 mm × 150 mm, 5 μm) | dairy products | CML | 0.1 μg/kg | [4] |

| HPLC-MS/MS | Atlantis silica HILIC column (150 mm × 2.1 mm, 3 μm) | pork tenderloin and offal | CML and CEL | [7] | |

| HPLC-MS/MS | Intrada amino acid column (2.0 mm × 150 mm, 3 μm) | model systems with whey protein | CML, G-H3, and MG-H3 | [49] | |

| HPLC-MS/MS | Phenomenex BioZen Peptide XB-C18 column (2.1 × 150 mm, 1.7 μm) | black tea | MG-Hs, GO-Hs, CML, CEL, and argpyrimidine | [50] | |

| HPLC-MS/MS | Atlantis silica HILIC column (150 × 2.1 mm, 3 μm) | minced pork | CML and CEL | CML: 4–5 µg/L; CEL: 12–15 µg/L | [51] |

| HPLC-MS/MS | Atlantis silica HILIC column (150 mm × 2.1 mm, 3 μm) | silver carp surimi sausages | CML and CEL | [52] | |

| HPLC-MS/MS | Sequant-ZIC-HILIC column (250 mm × 4.6 mm, 5 μm) | roasted nuts and seeds | CML and CEL | [53] | |

| HPLC-MS/MS | Phenomenex Kinetex C-18 column (50 × 2.1 mm, 1.7 µm) | human saliva | CML, CEL, MG-H1, and pyrraline | [54] | |

| HPLC-MS/MS | Phenomenex Synergi Hydro-RP column (150 mm × 2 mm, 4 μm) | MR model systems containing ascorbic acid | pyrraline, CML, and CEL | [55] | |

| HPLC-MS/MS | RP-18 (Xselect HSS T3, 250 mm × 3.0 mm, 5 μm) | bread | CEL, N6-lactoyl lysine, MG -H1, MG-H3, CEA, CML, GALA, CMA, G-H3, N6-formyl lysine, N6-acetyl lysine, pyrraline | CEL: 0.05 mg/kg; N6-lactoyl lysine: 0.02 mg/kg; MG-H1: 0.07 mg/kg; MG-H3: 0.05 mg/kg; CEA: 0.06 mg/kg; CML: 0.06 mg/kg; GALA: 0.06 mg/kg; CMA: 0.17 mg/kg; G-H3: 0.11 mg/kg; N6-formyl lysine: 0.03 mg/kg; N6-acetyl lysine: 0.01 mg/kg; pyrraline: 0.12 mg/kg | [56] |

| LC-MS/MS | Hypercarb column (100 × 2.1 mm, 5 μm) | human milk | CML and CEL | [57] | |

| LC-MS/MS | BEH Amide column (2.1 × 100 mm, 1.7 μm) | fried sturgeon fillets | CML and CEL | [58] | |

| LC-MS/MS | Hydro-RP 80A LC column (2 × 150 mm, 4 μm) | cheeses | CML and CEL | [59] | |

| LC-MS/MS | Hydro-RP80A column (250 mm × 2 mm, 4 μm) | mutton | CML and CEL | CML: 3.6 ng/mL; CEL: 1.9 ng/mL | [60] |

| LC-MS/MS | Phenomenex Synergi 4 μ Hydro-RP80A column (250 mm × 2 mm, 4 μm) | beef | CML and CEL | [61] | |

| UPLC-MS/MS | X-Bridge C18 (4.6 mm × 150 mm, 5 μm) | baked products | CML and CEL | [34] | |

| UPLC-MS/MS | BEH Amide column (100 × 2.1 mm, 1.7 μm) | fish cakes | CML, CEL, and MG-H1 | [35] | |

| UPLC-MS/MS | SB-C18 column (2.1 × 50 mm, 1.8 μm) | soy sauce, corn juice | CML | [36] | |

| UPLC-MS/MS | T3 column (150 mm × 4.6 mm × 3 µm) | bread | CML and CEL | CML: 0.75 μg/kg; CEL: 2.5 μg/kg | [62] |

| UPLC-MS/MS | T3 column (150 mm× 2.1 mm, 3.5 μm) | roasted beef patties | CML and CEL | CML: 0.052 μg/g; CEL: 0.098 μg/g | [63] |

| UPLC-MS/MS | BEH Amide column (100 × 2.1 mm, 1.7 μm) | sterilized milk | CML | CML: 0.05 mg/kg | [64] |

| UPLC-MS/MS | HILIC column | antler velvet | CML and CEL | CML: 4.1 ng/g; CEL: 4.3 ng/g | [65] |

| Antibodies | Application Field | Limit of Detection | References |

|---|---|---|---|

| 4G9 | dairy products | CML: 5 ng/mL | [73] |

| 6D12 | AGEs-protein | [77] | |

| 4G9 | food | [78] | |

| 4G9 and 3D11 | food | [79] | |

| 4G9 | porridge samples | [80] |

| Influencing Factors | Detection Methods | Cereal Products | AGE Content | References |

|---|---|---|---|---|

| Raw materials | LC-MS | flour tortilla, corn tortilla | CML: 2.09–2.51 μg/g | [45] |

| HPLC-FLD | bread (wheat, brown bread, rye bread, pumpernickel, and crispbreads) | CEL: 2.1−8.1 mg/kg; N6-lactoyl lysine: 0.15−0.72 mg/kg; CEA: 7−19 mg/kg; MG-H1: 13−27 mg/kg; MG-H3: 0.28−0.72 mg/kg; CML: 4.5−10.4 mg/kg; GALA: 0.23−0.59 mg/kg; CMA: 1.1−1.6 mg/kg; G-H3: 3.8−5.5 mg/kg; N6-formyl lysine: 2.8−5.6 mg/kg; N6-acetyl lysine: 1.3−3.6 mg/kg; pyrraline: 28−78 mg/kg | [56] | |

| UPLC-MS | bread crust (whole wheat, refined wheat, whole einkorn, whole corn, whole rye, whole oat) | CML: 15–140 mg/kg; CEL: 30–200 mg/kg | [62] | |

| LC-MS/MS | cookies (bread wheat, durum wheat, soft wheat, hard wheat, triticale, rye, hulless barley and hulless oat, white-, yellow- and red-colored standard seeded corn and blue-colored popping corn) | CML: 6.3–47.4 mg/kg; CEL: 2.3–38.9 mg/kg | [85] | |

| HPLC-MS/MS | cookies (okara cookies, cellulose cookies, pea fiber cookies, chitosan cookies) | CML: 6.32–22.84 mg/kg | [86] | |

| UPLC-QqQ-MS/MS | chicken cookies, baby biscuit, white lotus paste mooncakes, almond biscuit, cookies, bread, sweetheart pastry, fried breadstick, instant noodles | CML: 4.48–35.88 mg/kg; CEL: 1.99–14.49 mg/kg | [87] | |

| Ingredients | UPLC-MS/MS | sponge cakes | protein-bound CML: 80 mg/kg; free CML: 160 mg/kg; protein-bound-CEL: 15 mg/kg; free CEL: 40 mg/kg | [34] |

| HPLC-MS/MS | cookies (sucrose, glucose, fructose, honey, banana, invert sugar syrup) | CML: 1.71–42 mg/kg; CEL: 1.541–53 mg/kg; MG-H1: 8.8–218 mg/kg | [88] | |

| LC-MS/MS | cookies (sucrose, butter, egg liquid) | free CML: 50–250 μg/kg; free CEL: 80–220 μg/kg; protein-bound-CML: 4–6 mg/kg; protein-bound-CEL: 20–70 mg/kg | [89] | |

| Processing time | UPLC-MS | bread crust (5–30 min) | CML: 15–140 mg/kg; CEL: 30–200 mg/kg | [62] |

| LC-MS/MS | cookies (7–13 min) | CML: 6.3–47.4 mg/kg; CEL: 2.3–38.9 mg/kg | [85] | |

| LC-MS/MS | cookies (8–16 min) | free CML: 0–60 μg/kg; free CEL: 100–400 μg/kg free; protein-bound-CML: 0–20 μg/kg; protein-bound-CEL: 100–450 μg/kg | [89] | |

| UPLC-MS | cookies (0–10 min) | CML: 0–350 mg/kg | [90] | |

| Processing temperature | LC-MS/MS | cookies (130–180 °C) | free CML: 0–100 μg/kg; free CEL: 50–700 μg/kg; protein-bound-CML: 0–100 μg/kg; protein-bound-CEL: 100–700 μg/kg | [89] |

| UPLC-MS | cookies (155–230 °C) | CML: 0–350 mg/kg | [90] |

| Influencing Factors | Detection Method | Meat Products | AGE Content | References |

|---|---|---|---|---|

| Heat treatment process | HPLC-MS/MS | raw pork | CML: 3.0 mg/kg; CEL: 0.9 mg/kg; GALA: 0.9 mg/kg | [12] |

| roast pork | CML: 9.2 mg/kg; CEL: 40 mg/kg; GALA: 5 mg/kg; MOLA: 6 mg/kg; GOLA: 1.2 mg/kg; MOLD: 0.5 mg/kg; GOLD: 0.25 mg/kg; MGLA: 0.2 mg/kg | |||

| HPLC-FLD | meat (fried, boiled and baked) | CML: 1.07–21.84 µg/g | [67] | |

| GC-MS | fried fish nuggets (180 °C, 4–6 min) | CML: 29.26–59.17 mg/kg | [72] | |

| UPLC-MS | beef (60–300 °C); (grilled, fried, boiled and baked) | CML: 0.8–13.4 mg/kg | [91] | |

| UPLC-MS/MS | sausage (70–130 °C; 1–4 h) | CML: 2–6.58μg/g; CEL: 6–16.32 μg/g | [92] | |

| Type of meat | HPLC-MS/MS | pork tenderloin, hearts, livers and kidneys | CML: 0.41–2.56 mg/kg; CEL: 0.22–2.56 mg/kg; protein-bound CML: 2.53–7.06 mg/kg; protein-bound CEL: 1.60–4.83 mg/kg | [7] |

| HPLC-FLD | beef steak, pork top loin, chicken breast, salmon, tilapia | CML: 1.07–2.05 µg/g | [67] | |

| Food additives | UPLC-MS/MS | sausage (0–5 g/100g salt; 0–15 mg/100g NaNO2) | CML: 2.37–6.52 µg/g; CEL: 5.54–6.56 µg/g | [92] |

| HPLC-MS/MS | commercially sterilized pork (acetic acid, ethanol, and NaCl) | CML: 2.29–15.35 mg/kg; CEL: 2.75–39.33 mg/kg | [93] |

| Influencing Factors | Detection Method | Dairy Products | AGE Content | References |

|---|---|---|---|---|

| Sterilization process | LC-MS | pasteurized milk and sterilized milk | free CML: 8.23–14.02 μg/kg; protein-bound CML: 2.58–5.56 mg/kg | [4] |

| LC-MS/MS | whole milk powder (low-temperature long-time (LTLT), high-temperature short-time pasteurization (HTST)) and high-heat process (ultra-pasteurization (ESL), ultra-high-temperature (UHT) treatments, and in-bottle sterilization (BS)) | CML: 20–40 mg/kg; CEL: 5–15 mg/kg; pyrraline: 0.15–0.20 mg/kg | [6] | |

| LC-MS/MS | milk (low/high-temperature) | CML: 2–40 nmol/mg; CEL: 0.2–1.1 nmol/mg; pentosidine: 16–21 pmol/mg | [99] | |

| UPLC-MS/MS | milk (LTLT, HTST, UHT and BS) | CML: 2–4 mg/kg milk; CEL: 0.4–0.8 mg/kg milk | [100] | |

| UPLC-MS/MS | milk powder and reconstituted milk (LT, HT, ESL, UHT, CS) | CML: 3–10 mg/kg; CEL: 0.75–2.75 mg/kg | [101] | |

| UPLC-MS/MS | milk powder | free CML: 0.36–5.22 mg/kg; free CEL: 0.12–1.80 mg/kg; free pyrraline: 0–0.37 mg/kg; protein-bound CML: 21.07–128.34 mg/kg; protein-bound CEL: 13.78–56.62 mg/kg; protein-bound pyrraline: 2.85–81.48 mg/kg | [102] | |

| Storage conditions | LC-MS/MS | whole milk powder (0–18 months) | CML: 20–150 mg/kg; CEL: 5–55 mg/kg; pyrraline: 0.15–0.55 mg/kg | [6] |

| ELISA | infant formulas (25 °C, 37 ℃; 0–28 days) | CML: 500–600 ng/mL | [40] | |

| UPLC-MS/MS; UPLC-DAD | UHT milk (22 ℃; 12 months) | CML: 25–50 μM; CEL: 2.5–13 μM; G-H1/3: 22–35 μM; G-H2: 4–8 μM; MG-H1/3: 15–35 μM; MG-H2: 0–0.6 μM | [47] | |

| ELISA | infant formula (7–28 d; 32% RH, 57% RH, 75% RH; 25 °C, 37 °C) | CML: 550–600 ng/mL | [103] | |

| LC-MS | UHT milk (6 months; 20 °C) | CML: 1.794 ng/mL; CEL: 7.29 ng/mL; G-H1/3: 1.63 ng/mL; G-H2: 2.49 ng/mL; MG-H1/3: 3.82 ng/mL; GOLD: 32.8 ng/mL | [104] | |

| UPLC-MS; HPLC-UV | infant formulas (65 °C; 48 days) | CML: 280 mg/kg; CEL: 180 mg/kg; MG-H: 190 mg/kg; GO-H: 280 mg/kg; GOLD: 40 mg/kg; MOLD: 20 mg/kg; pyrraline: 60 mg/kg | [105] | |

| UHPLC-MS/MS | whey proteins (35 °C; 7, 14, 21 days) | CML: 25–150 μM; CEL: 1–2 μM; MG-H1: 4–15 μM | [106] | |

| Types of dairy products | LC-MS | liquid milk, milk powder, condensed milk, milk fats, cheese, ice cream, and whey protein | free CML: 0.11–32.71 μg/kg; protein-bound CML: 0.01–134.28 mg/kg | [4] |

| UPLC-MS/MS; HPLC-PDA | baked milk and baked yogurt | CML: 0.2–1.7 mg/kg; CEL: 0.06–0.1 mg/kg | [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Zhuang, Y.; Zou, X.; Chen, M.; Cui, B.; Jiao, Y.; Cheng, Y. Advanced Glycation End Products: A Comprehensive Review of Their Detection and Occurrence in Food. Foods 2023, 12, 2103. https://doi.org/10.3390/foods12112103

Li L, Zhuang Y, Zou X, Chen M, Cui B, Jiao Y, Cheng Y. Advanced Glycation End Products: A Comprehensive Review of Their Detection and Occurrence in Food. Foods. 2023; 12(11):2103. https://doi.org/10.3390/foods12112103

Chicago/Turabian StyleLi, Lixian, Yingjun Zhuang, Xiuzhi Zou, Maolong Chen, Bo Cui, Ye Jiao, and Yunhui Cheng. 2023. "Advanced Glycation End Products: A Comprehensive Review of Their Detection and Occurrence in Food" Foods 12, no. 11: 2103. https://doi.org/10.3390/foods12112103

APA StyleLi, L., Zhuang, Y., Zou, X., Chen, M., Cui, B., Jiao, Y., & Cheng, Y. (2023). Advanced Glycation End Products: A Comprehensive Review of Their Detection and Occurrence in Food. Foods, 12(11), 2103. https://doi.org/10.3390/foods12112103