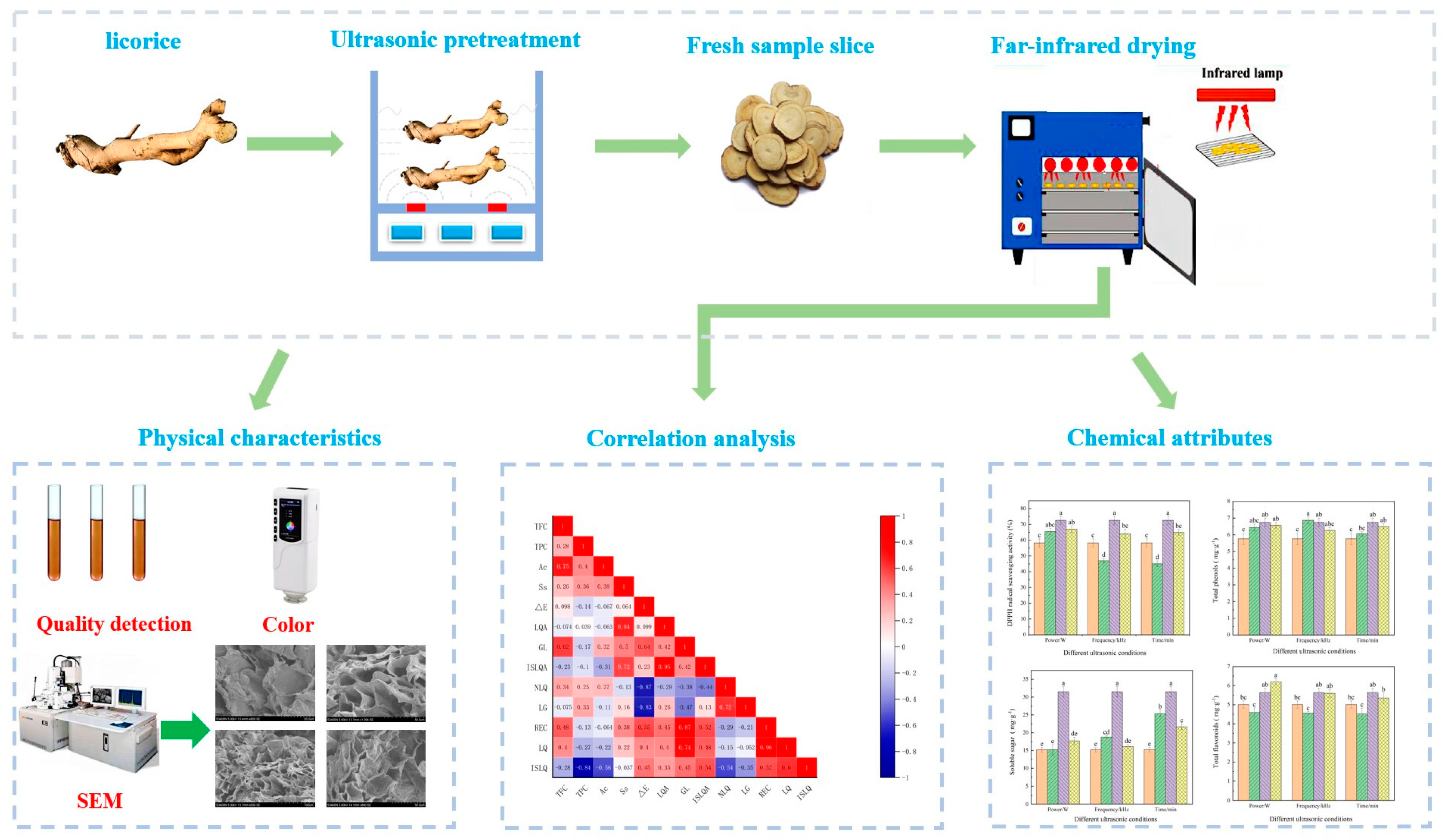

Effect of Ultrasonic Pretreatment on the Far-Infrared Drying Process and Quality Characteristics of Licorice

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials and Reagents

2.2. Chemicals

2.3. Ultrasonic Pretreatment

2.4. Drying Test Method

2.5. Calculation of Drying Parameters

2.5.1. Moisture Content of the Dry Base

2.5.2. Moisture Ratio

2.5.3. Drying Rate

2.6. Determination of Quality Indicators

2.6.1. Preparation of Sample Extracts

2.6.2. Determination of Total Phenolic Content

2.6.3. Determination of Antioxidant Activity

2.6.4. Determination of Soluble Sugar

2.6.5. Determination of Total Flavonoids

2.6.6. Color and Luster

2.6.7. Microstructure

2.7. Determination of Bioactive Constituent Content in Licorice

2.8. Statistical Analysis

3. Results and Analysis

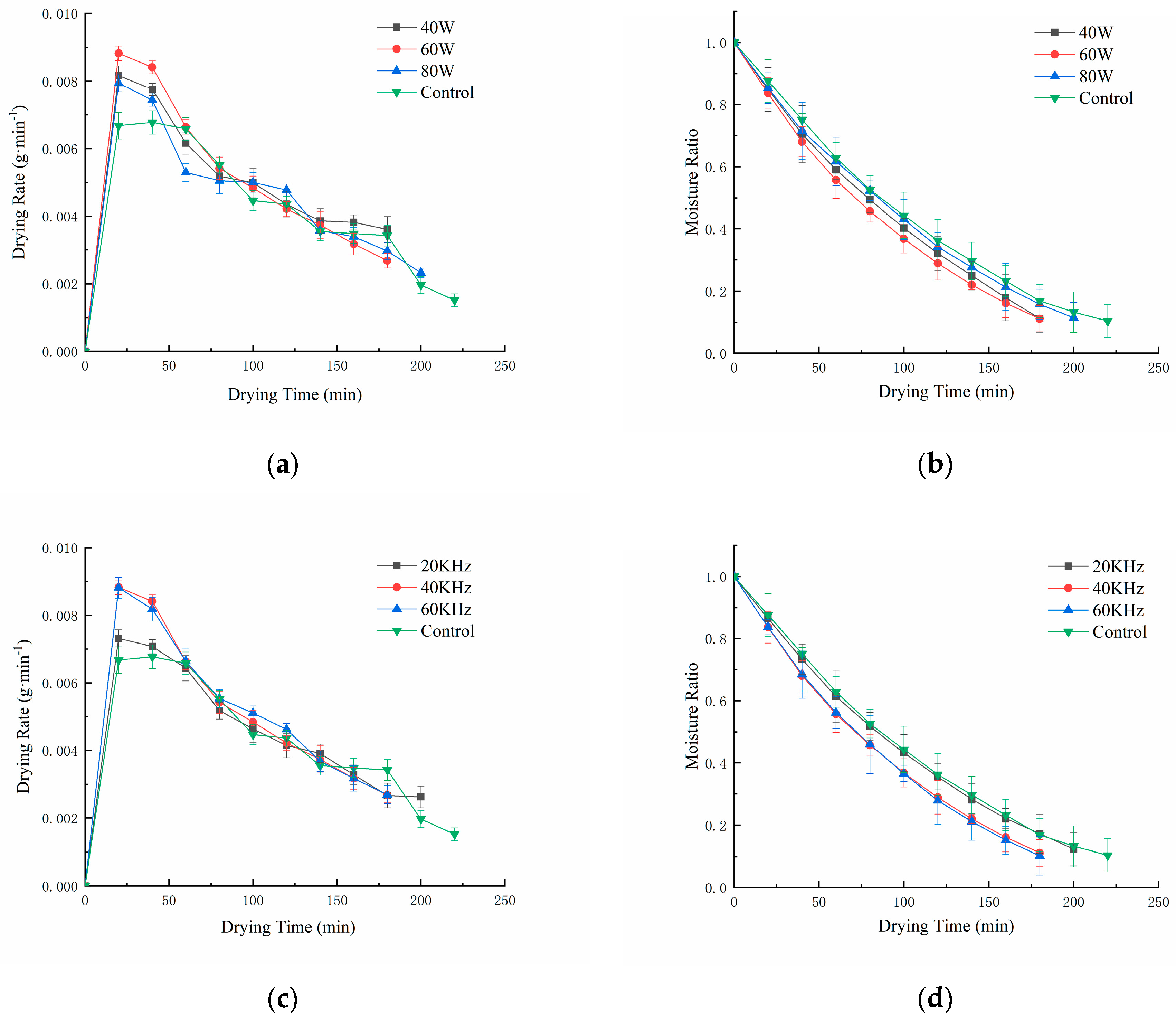

3.1. Effects of Drying Characteristics

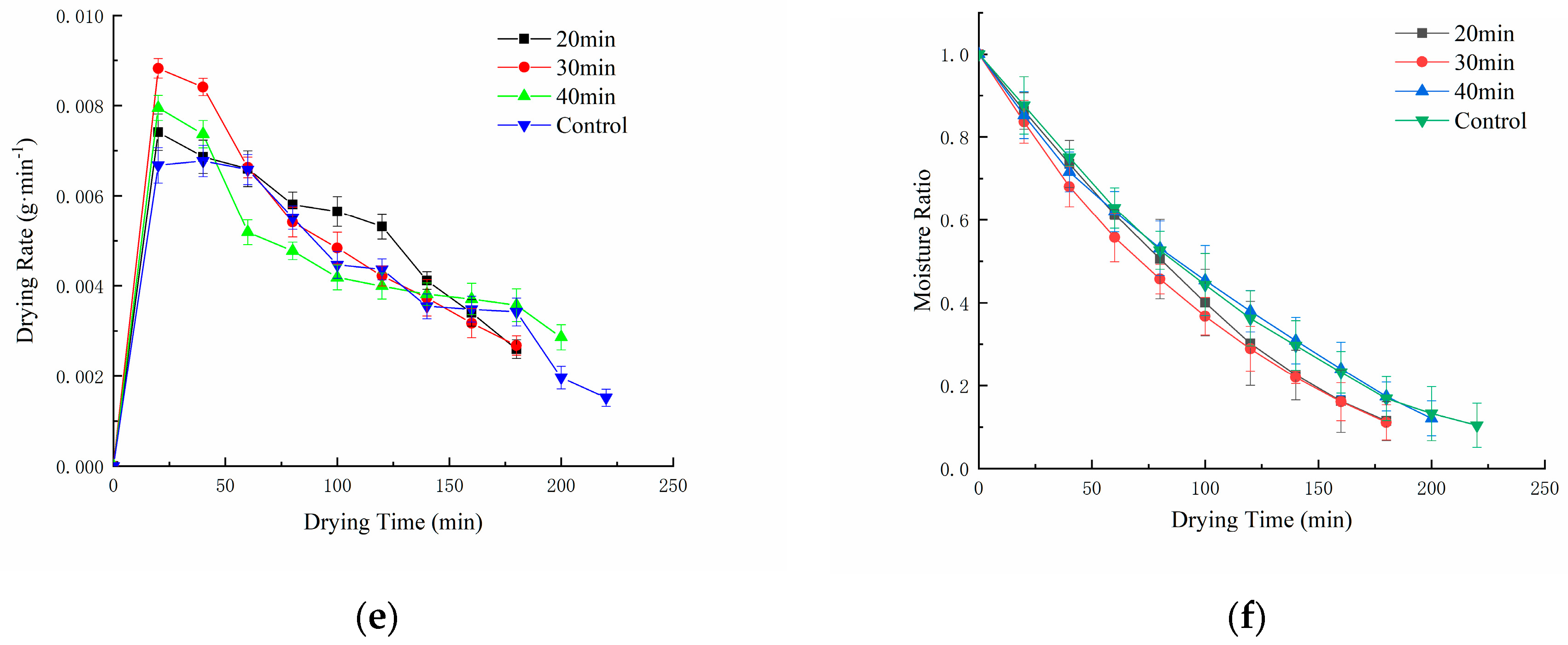

3.2. Influence of Quality

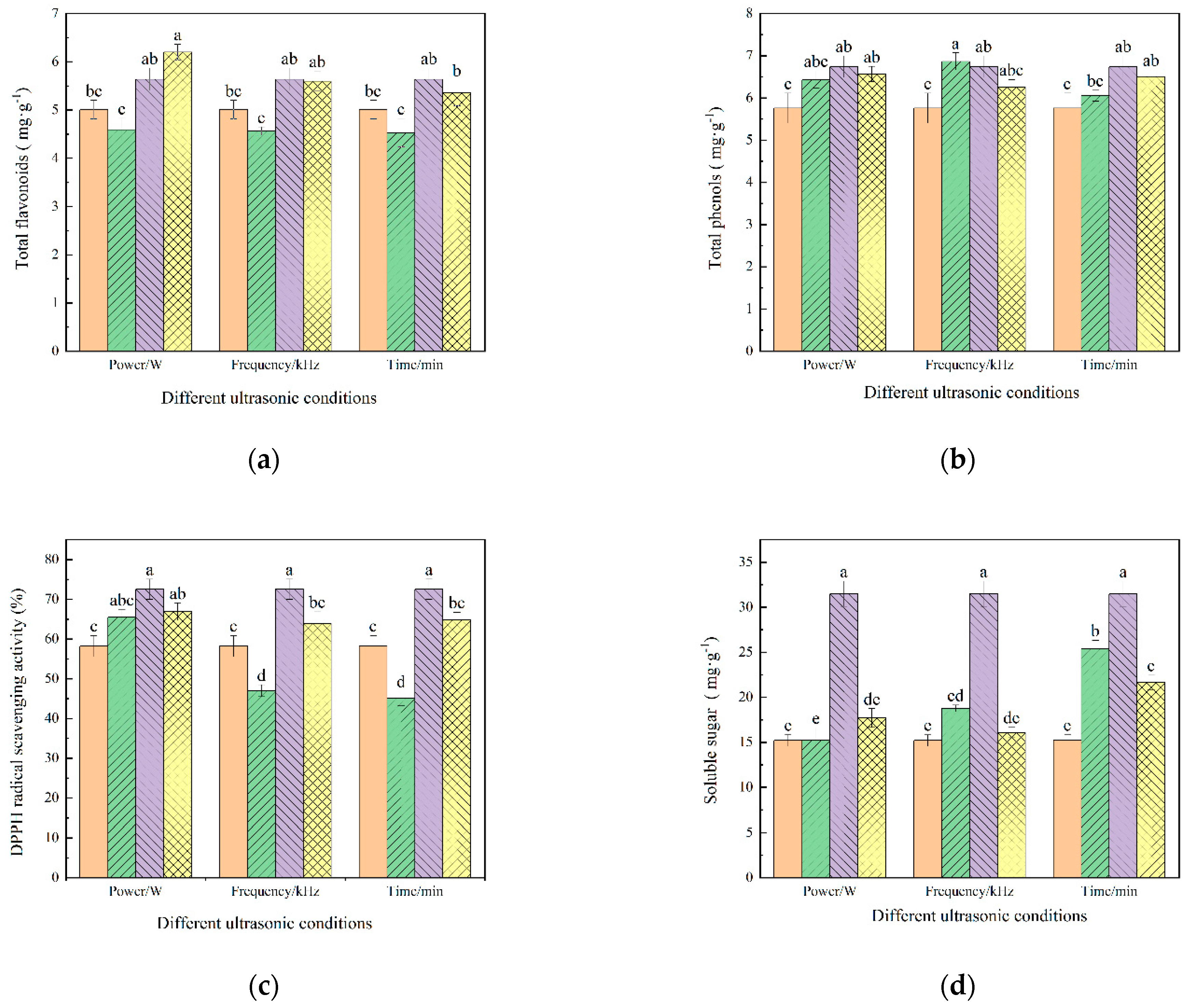

3.2.1. Influence of Total Flavonoid Content

3.2.2. Effect of Total Phenolic Content

3.2.3. Effect of Antioxidant Capacity (DPPH)

3.2.4. Effect of Soluble Sugars

3.3. Effect of Ultrasonic Treatment on Bioactive Constituents Content

3.4. Color and Luster

3.5. Correlation Analysis

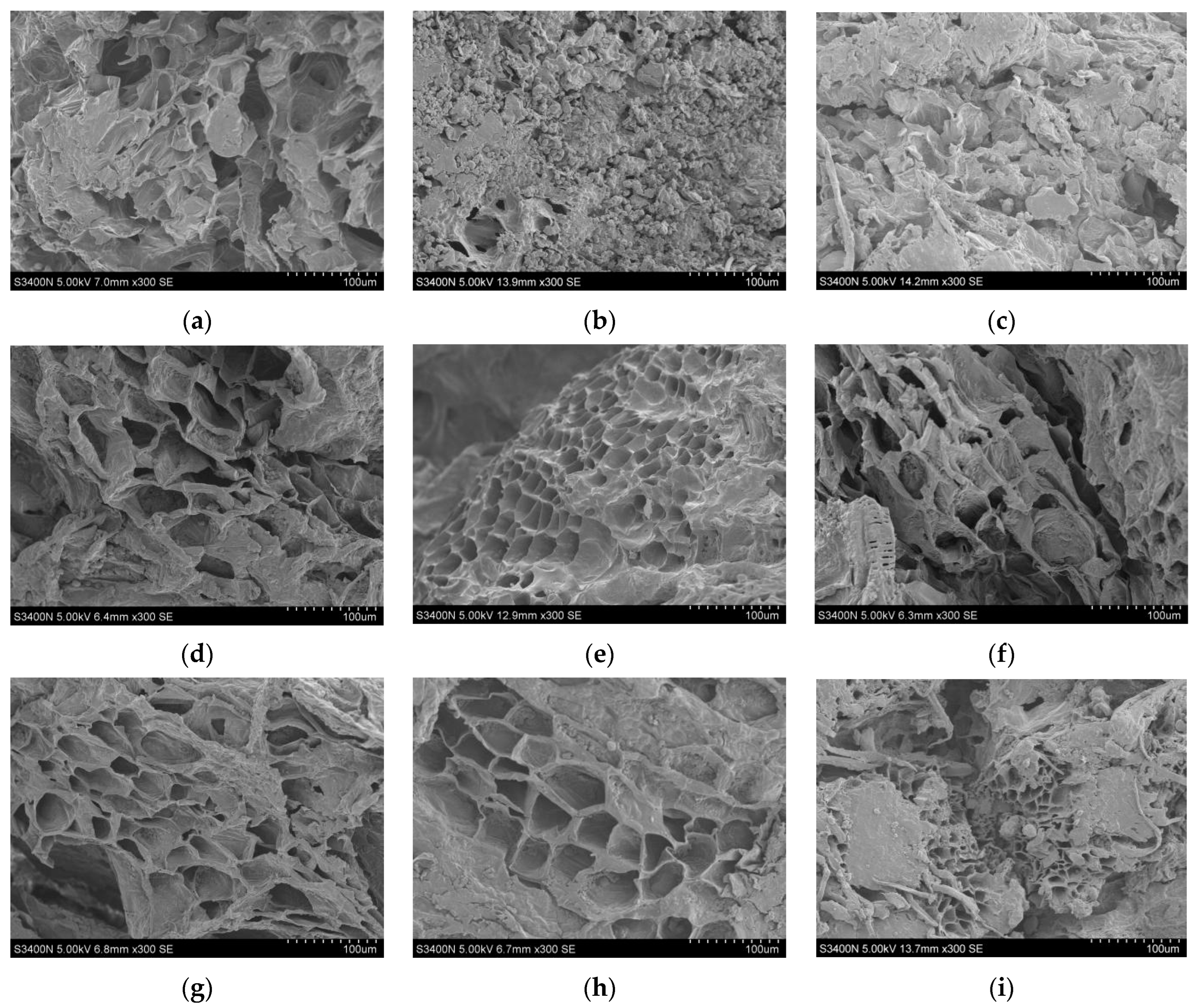

3.6. Microstructural Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Pharmacopoeia Committee. Chinese Pharmacopoeia; China Pharmaceutical Science and Technology Press: Beijing, China, 2020. [Google Scholar]

- Wang, C.; Jin, Y.; Jin, Y. Promoting effect of licorice extract on spermatogonial proliferation and spermatocytes differentiation of neonatal mice in vitro. Vitr. Cell. Dev. Biol. Anim. 2016, 52, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Asl, M.; Hosseinzadeh, H. Review of pharmacological effects of Glycyrrhiza sp. and its bioactive compounds. Phytother. Res. 2008, 22, 709–724. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.H.; Qi, Y.R.; Wu, Z.F.; Wang, Y.Q.; Wang, X.C.; Wang, F.; Yang, M. Comparative study of microwave-vacuum and vacuum drying on the physicochemical properties and antioxidant capacity of licorice extract powder. Powder Technol. 2017, 317, 430–437. [Google Scholar] [CrossRef]

- Asım, B.; Ömer, Ş. Microwave drying kinetics of a thinlayer liquorice root. Dry. Technol. 2012, 30, 859–864. [Google Scholar]

- Icier, F.; Ozmen, D.; Cevik, M.; Cokgezme, O.F. Drying of Licorice Root by Novel Radiative Methods. J. Food Process. Preserv. 2021, 45, e15214. [Google Scholar] [CrossRef]

- Sun, R.; Hikosaka, S.; Goto, E.; Sawa, H.; Saito, T.; Kudo, T.; Ohno, T.; Yoshimatsu, K.; Kawano, N.; Inui, T.; et al. Effects of post-harvest storage and drying temperatures on four medicinal compounds in the root of Chinese licorice (Glycyrrhiza uralensis). Environ. Control. Biol. 2013, 51, 149–155. [Google Scholar] [CrossRef]

- Çakmak, R.; Tekeoğlu, O.; Bozkır, H.; Ergün, A.R.; Baysal, T. Effects of electrical and sonication pretreatments on the drying rate and quality of mushrooms. LWT 2016, 69, 197–202. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, Y.; Zhang, J.; Xi, H.; Duan, X. Effects of far-infrared radiation temperature on drying characteristics, water status, microstructure and quality of kiwifruit slices. J. Food Meas. Charact. 2019, 13, 3086–3096. [Google Scholar] [CrossRef]

- Huang, X.; Li, W.; Wang, Y.; Wan, F. Drying characteristics and quality of Stevia rebaudiana leaves by far-infrared radiation. LWT 2021, 140, 110638. [Google Scholar] [CrossRef]

- Jiang, C.; Wan, F.; Zang, Z.; Zhang, Q.; Xu, Y.; Huang, X. Influence of far-infrared vacuum drying on drying kinetics and quality characteristics of Cistanche slices. J. Food Process. Preserv. 2022, 11, 866. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Liu, C.; Li, D.; Jiang, N.; Liu, C. Effects of ultrasound pretreat-ment on drying kinetics and quality parameters of button mushroom slices. Dry. Technol. 2016, 34, 1791–1800. [Google Scholar] [CrossRef]

- Garcia-Perez, J.V.; Ortuño, C.; Puig, A.; Carcel, J.A.; Perez-Munuera, I. Enhancement of Water Transport and Microstructural Changes Induced by High-Intensity Ultrasound Application on Orange Peel Drying. Food Bioprocess Technol. 2012, 5, 2256–2265. [Google Scholar] [CrossRef]

- Yuan, L.; He, X.; Lin, R.; Cheng, S. Effect of ultrasonic pretreatment on moisture state and hot air drying characteristics of kiwifruit. J. Agric. Eng. 2021, 37, 263–272. [Google Scholar]

- Liu, Y.; Zeng, Y.; Hu, X.; Sun, X. Effect of Ultrasonic Power on Water Removal Kinetics and Moisture Migration of Kiwifruit Slices During Contact Ultrasound Intensified Heat Pump Drying. Food Bioprocess Technol. 2020, 13, 430–441. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Z.; Xu, W.; Song, C.; Li, J.; Song, F. Effects of ultrasound pretreatment followed by far-infrared drying on physicochemical properties, antioxidant activity and aroma compounds of saffron (Crocus sativus L.). Food Biosci. 2021, 42, 101186. [Google Scholar] [CrossRef]

- Zhang, Q.; Wan, F.; Zang, Z.; Jiang, C.; Xu, Y.; Huang, X. Effect of ultrasonic far-infrared synergistic drying on the characteristics and qualities of wolfberry (Lycium barbarum L.). Ultrason. Sonochem. 2022, 89, 106134. [Google Scholar] [CrossRef]

- Xi, H.; Liu, Y.; Guo, L.; Hu, R. Effect of ultrasonic power on drying process and quality properties of far-infrared radiation drying on potato slices. Food Sci. Biotechnol. 2020, 29, 93–101. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis; No. 934.06; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Zhang, Z.; Li, L.; Li, D. Characterization and kinetic modeling of thin-layer vacuum microwave drying of lotus root slices. Jiangsu Agric. Sci. 2019, 47, 201. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, P.; Wang, Y.; Kadam, S.U.; Han, Y.; Wang, J.; Zhou, J. Power ultra-sound as a pretreatment to convective drying of mulberry (Morus alba L.) leaves: Impact on drying kinetics and selected quality properties. Ultrason. Sonochem. 2016, 31, 310–318. [Google Scholar] [CrossRef]

- Wan, F.; Luo, Y.; Li, W. Effects of different pretreatment methods on the far-infrared drying characteristics and quality of Lycium barbarum. Chin. Herb. Med. 2020, 51, 4183. [Google Scholar] [CrossRef]

- Manuel, B.V.; Francisco, O.; Francisco, M.; Alfredo, M. Changes in phenolic compounds in garlic (Allium sativum L.) owing to the cultivar and location of growth. Plant Foods Hum. Nutr. 2011, 66, 218–223. [Google Scholar]

- Chen, Z.; Jiang, J.; Ju, X. Active ingredients and their antioxidant activities in various edible rice. Food Ind. Sci. Technol. 2018, 39, 71. [Google Scholar] [CrossRef]

- Cristina, N.; Andrea, M.; Gabriele, F.G.; Lucia, M. In vitro Antioxidant Activity of Aged Extracts of some Italian Allium Species. Plant Foods Hum. Nutr. 2011, 66, 11. [Google Scholar]

- Feng, Y.; Cao, D.; Guo, Y. Determination of polysaccharides in Panax notoginseng by anthrone sulfuric acid colorimetric method. J. Northwestern Univ. (Nat. Sci. Ed.) 2013, 43, 921. [Google Scholar]

- Ma, L.M.; Anuar, K.S.; Sadegh, M.; Nurestri, A.M.S. Phytochemical constituents, nutritional values, phenolics, flavonols, flavonoids, antioxidant and cytotoxicity studies on Phaleria macrocarpa (Scheff.) Boerl fruits. BMC Complement. Altern. Med. 2014, 14, 152. [Google Scholar]

- Wang, Y.; Li, J.; Xuan, L.; Liu, Y.; Shao, L.; Ge, H.; Gu, J.; Wei, C.; Zhao, M. Astragalus Root dry extract restores connexin43 expression by targeting miR-1 in viral myocarditis. Phytomedicine 2018, 46, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pretreatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef]

- Rojas, M.L.; Leite, T.S.; Cristianini, M.; Alvim, I.D.; Augusto, P.E. Peach juiceprocessed by the ultrasound technology: Changes in its microstructure improve its physical properties and stability. Food Res. Int. 2016, 82, 22–33. [Google Scholar] [CrossRef]

- Zhang, Y.; Abatzoglou, N. Review: Fundamentals, applications and potentials of ultrasound-assisted drying. Chem. Eng. Res. Des. 2020, 154, 21–46. [Google Scholar] [CrossRef]

- Wu, B.; Guo, X.; Guo, Y.; Ma, H.; Zhou, C. Enhancing jackfruit infrared drying by combining ultrasound treatments: Effect on drying characteristics, quality properties and microstructure. Food Chem. 2021, 358, 129845. [Google Scholar] [CrossRef]

- Xu, B.; Tiliwa, E.S.; Wei, B.; Wang, B.; Hu, Y.; Zhang, L.; Mujumdar, A.; Zhou, C.; Ma, H. Multi-frequency power ultrasound as a novel approach improves intermediate-wave infrared drying process and quality attributes of pineapple slices. Ultrason. Sonchem. 2022, 88, 106083. [Google Scholar] [CrossRef] [PubMed]

- Wiktor, A.; Sledz, M.; Nowacka, M.; Rybak, K.; Witrowa-Rajchert, D. The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Appl. Acoust. 2016, 103, 136–142. [Google Scholar] [CrossRef]

- Tayyab, R.M.; Liu, K.; Ahmed, J.M.; Safdar, B.; Lv, D.; Wei, D. Developing ultrasound-assisted hot-air and infrared drying technology for sweet potatoes. Ultrason. Sonochem. 2022, 86, 106047. [Google Scholar] [CrossRef]

- Hayat, K.; Zhang, X.; Chen, H.; Xia, S.; Jia, C.; Zhong, F. Liberation and separation of phenolic compounds from citrus mandarin peels by microwave heating and its effect on antioxidant activity. Sep. Purif. Technol. 2010, 73, 371–376. [Google Scholar] [CrossRef]

- Chang, C.-H.; Lin, H.-Y.; Chang, C.-Y.; Liu, Y.-C. Comparisons on the antioxidant properties of fresh, freeze-dried and hot-air-dried tomatoes. J. Food Eng. 2006, 77, 478–485. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, H.; Xu, J.; Zhuang, W.; Zheng, B.; Lo, Y.M.; Tian, Y. Microwave vacuum drying of lotus (Nelumbo nucifera Gaertn.) seeds: Effects of ultrasonic pretreatment on color, antioxidant activity, and rehydration capacity. LWT 2021, 149, 111603. [Google Scholar] [CrossRef]

- Kroehnke, J.; Szadzińska, J.; Stasiak, M.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Musielak, G. Ultrasound- and microwave-assisted convective drying of carrots—Process kinetics and product’s quality analysis. Ultrason. Sonochem. 2018, 48, 249–258. [Google Scholar] [CrossRef]

- Bryan, G.G.; Guy, S.; Katleen, R.; John, V.C. Combined alkaline hydrolysis and ultra-sound-assisted extraction for the release of nonextractable phenolics from cauliflower (Brassica oleracea var. botrytis) waste. J. Agric. Food Chem. 2014, 62, 3371–3376. [Google Scholar]

- Ashokkumar, M.; Sunartio, D.; Kentish, S.; Mawson, R.; Simons, L.; Vilkhu, K.; Versteeg, C. Modification of food ingredients by ultrasound to improve functionality: A preliminary study on a model system. Innov. Food Sci. Emerg. Technol. 2008, 9, 155–160. [Google Scholar] [CrossRef]

- Firouz, M.S.; Farahmandi, A.; Hosseinpour, S. Recent advances in ultrasound application as a novel technique in analysis, processing and quality control of fruits, juices and dairy products industries: A review. Ultrason. Sonochem. 2019, 57, 73–88. [Google Scholar] [CrossRef]

- McClements, D. Advances in the application of ultrasound in food analysis and processing. Trends Food Sci. Technol. 1995, 6, 293–299. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Fu, D.; Gu, S.; Wang, D. Extraction, Optimization and Antimicrobial Activity of IWSP from Oleaginous Microalgae Chlamydomonas sp. YB-204. Food Sci. Technol. Res. 2017, 23, 819–826. [Google Scholar] [CrossRef]

- Ota, M.; Xu, F.; Li, Y.L.; Shang, M.Y.; Makino, T.; Cai, S.Q. Comparison of chemical constituents among licoriceroasted licorice, and roasted licorice with honey. J. Nat. Med. 2018, 72, 80–95. [Google Scholar] [CrossRef] [PubMed]

- Sung, M.W.; Li, P.C. Chemical analysis of raw, dryroasted, and honey-roasted licorice by capillary electrophoresis. Electrophoresis 2004, 25, 3434–3440. [Google Scholar] [CrossRef]

- Wen, W.; Li, L.; Li, D.; Zhang, L.; Zhou, D.; Yang, Y.; Yang, J.; Yu, B.; Ju, A. Differential analysis of chemical composition of licorice concoction products based on liquid mass spectrometry and plant metabolomics. Chin. J. Exp. Formul. 2020, 26, 104–110. [Google Scholar]

- Vadivambal, R.; Jayas, D.S. Changes in quality of microwave-treated agricultural products—A review. Biosyst. Eng. 2007, 98, 1–16. [Google Scholar] [CrossRef]

- Maskan, M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Fratianni, A.; Niro, S.; Alam, M.D.R.; Cinquanta, L.; Di Matteo, M.; Adiletta, G.; Panfili, G. Effect of a physical pre-treatment and drying on carotenoids of goji berries (Lycium barbarian L.). LWT 2018, 92, 313–328. [Google Scholar] [CrossRef]

- Deng, L.-Z.; Pan, Z.; Mujumdar, A.; Zhao, J.-H.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. High-humidity hot air impingement blanching (HHAIB) enhances drying quality of apricots by inactivating the enzymes, reducing drying time and altering cellular structure. Food Control. 2018, 96, 104–111. [Google Scholar] [CrossRef]

), 40 W (

), 40 W ( ), 60 W (

), 60 W ( ), 80 W (

), 80 W ( ). The vertical bars indicate the standard deviation from the mean. The letters reveal significant differences (p < 0.05) according to the Duncan test.

). The vertical bars indicate the standard deviation from the mean. The letters reveal significant differences (p < 0.05) according to the Duncan test.

), 40 W (

), 40 W ( ), 60 W (

), 60 W ( ), 80 W (

), 80 W ( ). The vertical bars indicate the standard deviation from the mean. The letters reveal significant differences (p < 0.05) according to the Duncan test.

). The vertical bars indicate the standard deviation from the mean. The letters reveal significant differences (p < 0.05) according to the Duncan test.

| Experimental Number | Ultrasonic Power (W) | Ultrasonic Frequency (kHz) | Ultrasonic Treatment Time (min) |

|---|---|---|---|

| 1 | 60 | 20 | 30 |

| 2 | 60 | 40 | 30 |

| 3 | 60 | 60 | 30 |

| 4 | 40 | 40 | 30 |

| 5 | 80 | 40 | 30 |

| 6 | 60 | 40 | 20 |

| 7 | 60 | 40 | 40 |

| Different Ultrasound Conditions | LA | GA | ILA | NIL | LG | RC | LQ | LLQ | |

|---|---|---|---|---|---|---|---|---|---|

| Control | 7.96 ± 0.12 cd | 26.12 ± 1.50 ab | 2.10 ± 0.05 bc | 0.93 ± 0.14 a | 2.23 ± 0.18 bc | 1.89 ± 0.22 bc | 27.04 ± 0.27 c | 1.14 ± 0.19 d | |

| 40 kHz 30 min | 40 W | 6.76 ± 0.18 d | 22.15 ± 1.05 d | 1.55 ± 0.12 d | 1.02 ± 0.20 a | 1.54 ± 0.05 e | 1.63 ± 0.11 c | 20.26 ± 0.75 d | 1.69 ± 0.14 cd |

| 60 W | 11.40 ± 1.02 ab | 27.25 ± 1.60 a | 2.59 ± 0.07 b | 1.02 ± 0.12 a | 2.08 ± 0.14 bcd | 2.41 ± 0.23 ab | 29.15 ± 0.37 b | 1.84 ± 0.11 c | |

| 80 W | 6.80 ±0.25 d | 27.47 ± 1.05 a | 1.63 ± 0.11 cd | 1.18 ± 0.16 a | 1.75 ± 0.15 cde | 2.61 ± 0.13 a | 32.78 ± 0.91 a | 1.97 ± 0.13 c | |

| 60 W 30 min | 20 kHz | 9.45 ± 0.13 b | 22.31 ± 0.42 cd | 2.34 ± 0.12 b | 1.02 ± 0.14 a | 2.57 ± 0.13 b | 2.19 ± 0.18 abc | 28.19 ± 0.63 bc | 1.66 ± 0.19 cd |

| 40 kHz | 11.40 ± 1.02 ab | 27.25 ± 1.60 a | 2.59 ± 0.07 b | 1.02 ± 0.12 a | 2.08 ± 0.14 bcd | 2.41 ± 0.23 ab | 29.15 ± 0.37 b | 1.84 ± 0.11 c | |

| 60 kHz | 9.02 ± 0.33 b | 27.49 ± 0.54 a | 2.06 ± 0.19 bcd | 0.94 ± 0.14 a | 1.63 ± 0.21 de | 2.49 ± 0.09 ab | 31.90 ± 0.58 a | 3.03 ± 0.26 a | |

| 60 W 40 kHz | 20 min | 12.15 ± 0.22 a | 27.25 ± 0.46 a | 3.19 ± 0.23 b | 0.90 ± 0.15 a | 1.89 ± 0.06 bcd | 2.63 ± 0.20 a | 33.66 ± 0.77 a | 4.29 ± 0.30 a |

| 30 min | 11.40 ± 1.02 ab | 27.25 ± 1.60 a | 2.59 ± 0.07 b | 1.02 ± 0.12 a | 2.08 ± 0.14 bcd | 2.41 ± 0.23 ab | 29.15 ± 0.37 b | 1.84 ± 0.11 c | |

| 40 min | 9.77 ± 0.44 bc | 22.77 ± 1.65 cd | 2.08 ± 0.21 bcd | 1.39 ± 0.26 a | 3.35 ± 0.25 a | 2.02 ± 0.19 abc | 27.64 ± 0.83 bc | 1.65 ± 0.14 cd | |

| Different Ultrasound Factors | L* | a* | b* | ∆E | |

|---|---|---|---|---|---|

| Fresh Sample | 78.10 ± 0.03 b | 1.91 ± 0.32 a | 28.56 ± 0.90 a | — | |

| 40 kHz 30 min | 40 W | 81.39 ± 0.54 a | 2.23 ± 0.08 a | 24.60 ± 1.17 c | 4.93 ± 0.42 c |

| 60 W | 75.71 ± 0.68 c | 1.79 ± 0.41 a | 25.00 ± 0.38 bc | 4.42 ± 0.67 c | |

| 80 W | 77.73 ± 0.02 b | 2.18 ± 0.09 a | 23.45 ± 0.67 bc | 4.64 ± 0.82 c | |

| 60 W 30 min | 20 kHz | 78.83 ± 0.17 b | 2.00 ± 0.81 a | 22.93 ± 0.73 bc | 5.28 ± 0.81 c |

| 40 kHz | 75.71 ± 0.68 c | 1.79 ± 0.41 a | 25.00 ± 0.38 bc | 4.42 ± 0.67 c | |

| 60 kHz | 77.49 ± 0.76 b | 2.47 ± 0.08 a | 25.94 ± 1.79 abc | 3.97 ± 2.07 c | |

| 60 W 40 kHz | 20 min | 63.89 ± 0.51 e | 0.06 ± 0.16 b | 24.74 ± 0.37 bc | 14.87 ± 0.69 a |

| 30 min | 75.71 ± 0.68 c | 1.79 ± 0.41 a | 25.00 ± 0.38 bc | 4.42 ± 0.67 c | |

| 40 min | 68.35 ± 0.28 d | 2.07 ± 0.59 a | 26.27 ± 0.06 ab | 10.29 ± 0.14 b | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, J.; Zhang, Q.; Wang, T.; Xu, Y.; Zang, Z.; Wan, F.; Yue, Y.; Huang, X. Effect of Ultrasonic Pretreatment on the Far-Infrared Drying Process and Quality Characteristics of Licorice. Foods 2023, 12, 2414. https://doi.org/10.3390/foods12122414

Shang J, Zhang Q, Wang T, Xu Y, Zang Z, Wan F, Yue Y, Huang X. Effect of Ultrasonic Pretreatment on the Far-Infrared Drying Process and Quality Characteristics of Licorice. Foods. 2023; 12(12):2414. https://doi.org/10.3390/foods12122414

Chicago/Turabian StyleShang, Jianwei, Qian Zhang, Tongxun Wang, Yanrui Xu, Zepeng Zang, Fangxin Wan, Yuanman Yue, and Xiaopeng Huang. 2023. "Effect of Ultrasonic Pretreatment on the Far-Infrared Drying Process and Quality Characteristics of Licorice" Foods 12, no. 12: 2414. https://doi.org/10.3390/foods12122414

APA StyleShang, J., Zhang, Q., Wang, T., Xu, Y., Zang, Z., Wan, F., Yue, Y., & Huang, X. (2023). Effect of Ultrasonic Pretreatment on the Far-Infrared Drying Process and Quality Characteristics of Licorice. Foods, 12(12), 2414. https://doi.org/10.3390/foods12122414