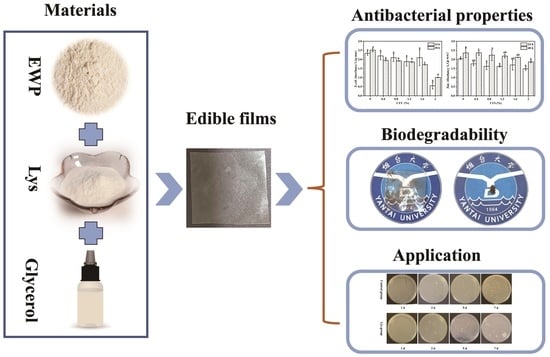

Characterization and Antibacterial Properties of Egg White Protein Films Loaded with ε-Polylysine: Evaluation of Their Degradability and Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Film Formation Procedure

2.3. Physicochemical Characterization of the Composite Films

2.3.1. Moisture content (MC), Swelling Capacity (SC), Water Solubility (WS) and Water Vapor Permeability (WVP)

2.3.2. Light Permeability

2.4. Structural Properties of the Composite Films

2.4.1. SEM

2.4.2. FTIR

2.5. Antibacterial Potential of the Composite Films

2.6. Degradation of the Composite Films

2.7. Application of the Composite Films

2.8. Statistical Analysis

3. Results and Discussion

3.1. WS, MC, SC and WVP of the Composite Film

3.2. Light Permeability of the Composite Film

3.3. Structural Properties

3.3.1. SEM Image Analysis

3.3.2. Fourier-Transform Infrared Spectroscopy Analysis

3.4. Antibacterial Properties

3.5. Biodegradability

3.6. Application

3.6.1. pH Values of the Chilled Pork during Storage

3.6.2. Color of the Chilled Pork during Storage

3.6.3. Total Bacterial Counts of the Chilled Pork during Storage

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hussain, I.; Ganiyu, S.A.; Alasiri, H.; Alhooshani, K. A state-of-the-art review on waste plastics-derived aviation fuel: Unveiling the heterogeneous catalytic systems and techno-economy feasibility of catalytic pyrolysis. Energy Convers. Manag. 2022, 274, 116433. [Google Scholar] [CrossRef]

- Schwarz, A.; Lensen, S.; Langeveld, E.; Parker, L.; Urbanus, J. Plastics in the global environment assessed through material flow analysis, degradation and environmental transportation. Sci. Total Environ. 2023, 875, 162644. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, L.H.; Nguyen, B.-S.; Le, D.-T.; Alomar, T.S.; AlMasoud, N.; Ghotekar, S.; Oza, R.; Raizada, P.; Singh, P.; Nguyen, V.-H. A concept for the biotechnological minimizing of emerging plastics, micro- and nano-plastics pollutants from the environment: A review. Environ. Res. 2023, 216, 114342. [Google Scholar] [CrossRef]

- Zunita, M.; Winoto, H.P.; Fauzan, M.F.K.; Haikal, R. Recent advances in plastics waste degradation using ionic liquid-based process. Polym. Degrad. Stab. 2023, 211, 110320. [Google Scholar] [CrossRef]

- Nabi, I.; Bacha, A.-U.; Ahmad, F.; Zhang, L. Application of titanium dioxide for the photocatalytic degradation of macro- and micro-plastics: A review. J. Environ. Chem. Eng. 2021, 9, 105964. [Google Scholar] [CrossRef]

- Kontominas, M.G. Use of Alginates as Food Packaging Materials. Foods 2020, 9, 1440. [Google Scholar] [CrossRef]

- Tan, C.; Pang, D.; Wu, R.; Zou, F.; Zhang, B.; Shang, N.; Li, P. Development of a Multifunctional Edible Coating and Its Preservation Effect on Sturgeon (Acipenser baeri♀ × Acipenser schrenckii♂) Fillets during Refrigerated Storage at 4 °C. Foods 2022, 11, 3380. [Google Scholar] [CrossRef]

- Peng, N.; Gu, L.; Li, J.; Chang, C.; Li, X.; Su, Y.; Yang, Y. Films Based on Egg White Protein and Succinylated Casein Cross-Linked with Transglutaminase. Food Bioprocess Technol. 2017, 10, 1422–1430. [Google Scholar] [CrossRef]

- Razi, S.M.; Fahim, H.; Amirabadi, S.; Rashidinejad, A. An overview of the functional properties of egg white proteins and their application in the food industry. Food Hydrocoll. 2023, 135, 108183. [Google Scholar] [CrossRef]

- Huang, X.; Luo, X.; Liu, L.; Dong, K.; Yang, R.; Lin, C.; Song, H.; Li, S.; Huang, Q. Formation mechanism of egg white protein/κ-Carrageenan composite film and its application to oil packaging. Food Hydrocoll. 2020, 105, 105780. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, Y.; Kang, S.; Wang, K.; Xu, H. Development and evaluation of soy protein isolate-based antibacterial nanocomposite films containing cellulose nanocrystals and zinc oxide nanoparticles. Food Hydrocoll. 2020, 106, 105898. [Google Scholar] [CrossRef]

- Hu, J.; Li, D.; Huai, Q.; Geng, M.; Sun, Z.; Wang, M.; Wang, S.; Li, Y.; Zheng, H. Development and evaluation of soybean protein isolate–based antibacterial nanocomposite films containing nano-TiO2. Ind. Crops Prod. 2023, 197, 116620. [Google Scholar] [CrossRef]

- Chollakup, R.; Pongburoos, S.; Boonsong, W.; Khanoonkon, N.; Kongsin, K.; Sothornvit, R.; Sukyai, P.; Sukatta, U.; Harnkarnsujarit, N. Antioxidant and antibacterial activities of cassava starch and whey protein blend films containing rambutan peel extract and cinnamon oil for active packaging. LWT 2020, 130, 109573. [Google Scholar] [CrossRef]

- Zou, Z.; Ismail, B.B.; Zhang, X.; Yang, Z.; Liu, D.; Guo, M. Improving barrier and antibacterial properties of chitosan composite films by incorporating lignin nanoparticles and acylated soy protein isolate nanogel. Food Hydrocoll. 2023, 134, 108091. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Lee, H.; Min, S.C. Effects of in-package atmospheric dielectric barrier discharge cold plasma treatment on the antimicrobial efficacy of whey protein isolate-based edible films that incorporate malic acid against Salmonella in chicken breast processed meat. Innov. Food Sci. Emerg. Technol. 2023, 85, 103339. [Google Scholar] [CrossRef]

- Ma, Y.; Ye, K.; Liu, P.; Yuan, A.; Chen, S.; He, Y. Effect of a Konjac glucomannan/chitosan antibacterial composite membrane microencapsulated with oregano essential oil on the quality of chilled pork. Appl. Food Res. 2023, 3, 100249. [Google Scholar] [CrossRef]

- Ma, W.; Yuan, F.; Feng, L.; Wang, J.; Sun, Y.; Cao, Y.; Huang, J. ε-Polylysine-mediated enhancement of the structural stability and gelling properties of myofibrillar protein under oxidative stress. Int. J. Biol. Macromol. 2022, 220, 1114–1123. [Google Scholar] [CrossRef]

- He, B.; Wang, Y.; Jiang, Z.; Liu, S.; Zhu, J. Physical properties and antibacterial activity of the composited films based on carboxymethyl cellulose and gelatin functionalized with ε-polylysine. Int. J. Biol. Macromol. 2021, 191, 1126–1136. [Google Scholar] [CrossRef]

- Li, X.; Liu, A.; Ye, R.; Wang, Y.; Wang, W. Fabrication of gelatin–laponite composite films: Effect of the concentration of laponite on physical properties and the freshness of meat during storage. Food Hydrocoll. 2015, 44, 390–398. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, A.; Ye, R.; Wang, W.; Li, X. Transglutaminase-induced crosslinking of gelatin–calcium carbonate composite films. Food Chem. 2015, 166, 414–422. [Google Scholar] [CrossRef]

- Gan, L.; Jiang, G.; Yang, Y.; Zheng, B.; Zhang, S.; Li, X.; Tian, Y.; Peng, B. Development and characterization of levan/pullulan/chitosan edible films enriched with ε-polylysine for active food packaging. Food Chem. 2022, 388, 132989. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Xu, H.; Zhou, Q.; Li, W.; Gao, J.; Liao, X.; Yu, Z.; Zheng, M.; Zhou, Y.; Sui, X.; et al. Influence mechanism of wheat bran cellulose and cellulose nanocrystals on the storage stability of soy protein isolate films: Conformation modification and molecular interaction perspective. Food Hydrocoll. 2023, 139, 108475. [Google Scholar] [CrossRef]

- Mousavi, Z.; Naseri, M.; Babaei, S.; Hosseini, S.; Shekarforoush, S. The effect of cross-linker type on structural, antimicrobial and controlled release properties of fish gelatin-chitosan composite films incorporated with epsilon-poly-l-lysine. Int. J. Biol. Macromol. 2021, 183, 1743–1752. [Google Scholar] [CrossRef] [PubMed]

- Sáez-Orviz, S.; Rendueles, M.; Díaz, M. Impact of adding prebiotics and probiotics on the characteristics of edible films and coatings—A review. Food Res. Int. 2023, 164, 112381. [Google Scholar] [CrossRef]

- He, Y.; Ye, H.-C.; You, T.-T.; Xu, F. Sustainable and multifunctional cellulose-lignin films with excellent antibacterial and UV-shielding for active food packaging. Food Hydrocoll. 2023, 137, 108355. [Google Scholar] [CrossRef]

- Kumar, A.; Hasan, M.; Mangaraj, S.; Pravitha, M.; Verma, D.K.; Srivastav, P.P. Trends in Edible Packaging Films and Its Prospective Future in Food: A Review. Appl. Food Res. 2022, 2, 100118. [Google Scholar]

- Zhang, W.; Zeng, Q.-M.; Tang, R.-C. Gallic acid functionalized polylysine for endowing cotton fiber with antibacterial, antioxidant, and drug delivery properties. Int. J. Biol. Macromol. 2022, 216, 65–74. [Google Scholar] [CrossRef]

- Cai, L.; Cao, A.; Bai, F.; Li, J. Effect of ε-polylysine in combination with alginate coating treatment on physicochemical and microbial characteristics of Japanese sea bass (Lateolabrax japonicas) during refrigerated storage. LWT Food Sci. Technol. 2015, 62, 1053–1059. [Google Scholar] [CrossRef]

- Chen, H.; Wu, C.; Feng, X.; He, M.; Zhu, X.; Li, Y.; Teng, F. Effects of two fatty acids on soy protein isolate/sodium alginate edible films: Structures and properties. LWT 2022, 159, 113221. [Google Scholar] [CrossRef]

- Azeredo, H.M.; Waldron, K.W. Crosslinking in polysaccharide and protein films and coatings for food contact—A review. Trends Food Sci. Technol. 2016, 52, 109–122. [Google Scholar] [CrossRef]

- Abeykoon, A.H.; Noinaj, N.; Choi, B.-E.; Wise, L.; He, Y.; Chao, C.-C.; Wang, G.; Gucek, M.; Ching, W.-M.; Chock, P.B.; et al. Structural Insights into Substrate Recognition and Catalysis in Outer Membrane Protein B (OmpB) by Protein-lysine Methyltransferases from Rickettsia. J. Biol. Chem. 2016, 291, 19962–19974. [Google Scholar] [CrossRef] [Green Version]

- Lvov, Y.; Ariga, K.; Ichinose, I.; Kunitake, T. Assembly of Multicomponent Protein Films by Means of Electrostatic Layer-by-Layer Adsorption. J. Am. Chem. Soc. 1995, 117, 6117–6123. [Google Scholar] [CrossRef]

- Cheng, J.; Li, Z.; Wang, J.; Zhu, Z.; Yi, J.; Chen, B.; Cui, L. Structural characteristics of pea protein isolate (PPI) modified by high-pressure homogenization and its relation to the packaging properties of PPI edible film. Food Chem. 2022, 388, 132974. [Google Scholar] [CrossRef] [PubMed]

- Lan, X.; Liu, Y.; Wang, Y.; Tian, F.; Miao, X.; Wang, H.; Tang, Y. Coaxial electrospun PVA/PCL nanofibers with dual release of tea polyphenols and epsilon-poly (L-lysine) as antioxidant and antibacterial wound dressing materials. Int. J. Pharm. 2021, 601, 120525. [Google Scholar] [CrossRef]

- Meng, Y.; Xue, Q.; Chen, J.; Li, Y.; Shao, Z. Structure, stability, rheology, and texture properties of epsilon-polylysine-whey protein complexes. J. Dairy Sci. 2022, 105, 3746–3757. [Google Scholar] [CrossRef] [PubMed]

- Salma-Ancane, K.; Sceglovs, A.; Tracuma, E.; Wychowaniec, J.; Aunina, K.; Ramata-Stunda, A.; Nikolajeva, V.; Loca, D. Effect of crosslinking strategy on the biological, antibacterial and physicochemical performance of hyaluronic acid and ɛ-polylysine based hydrogels. Int. J. Biol. Macromol. 2022, 208, 995–1008. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Watowita, P.; Chen, R.; Shi, Y.; Geng, J.-T.; Takahashi, K.; Li, L.; Osako, K. Multilayer gelatin/myofibrillar films containing clove essential oil: Properties, protein-phenolic interactions, and migration of active compounds. Food Packag. Shelf Life 2022, 32, 100842. [Google Scholar] [CrossRef]

- Celebioglu, A.; Uyar, T. Electrohydrodynamic encapsulation of eugenol-cyclodextrin complexes in pullulan nanofibers. Food Hydrocoll. 2020, 111, 106264. [Google Scholar] [CrossRef]

- Zheng, T.; Tang, P.; Yang, C.; Ran, R.; Li, G. Development of active packaging films based on collagen/gallic acid-grafted chitosan incorporating with ε-polylysine for pork preservation. Food Hydrocoll. 2023, 140, 108590. [Google Scholar] [CrossRef]

- Sai, F.; Zhang, H.; Qu, J.; Wang, J.; Zhu, X.; Ye, P.; Zhang, Z. Thermal-driven self-healing and green recyclable waterborne polyurethane films based on double reversible covalent bonds. Prog. Org. Coat. 2023, 178, 107460. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Jiao, Y.; Wang, Z.; Tang, X.; Du, Z.; Zhang, Z.; Lu, S.; Qiao, C.; Cui, J. Biodegradable packaging films with ε-polylysine/ZIF-L composites. LWT 2022, 166, 113776. [Google Scholar] [CrossRef]

- He, S.; Liu, A.; Zhang, J.; Liu, J.; Shao, W. Preparation of ε-polylysine and hyaluronic acid self-assembled microspheres loaded bacterial cellulose aerogels with excellent antibacterial activity. Colloids Surf. A Physicochem. Eng. Asp. 2022, 654, 130114. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Mujumdar, A.S.; Yu, D.; Wang, H. Potential nano bacteriostatic agents to be used in meat-based foods processing and storage: A critical review. Trends Food Sci. Technol. 2023, 131, 77–90. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, W.; Zhang, J.; Zhu, J.; Sun, T.; Li, J.; Cheng, L. Synergistic effects of ε-polylysine hydrochloride and gallic acid on Shewanella putrefaciens and quality of refrigerated sea bass fillets. Food Control 2022, 139, 109070. [Google Scholar] [CrossRef]

- Wang, X.; Xie, Y.; Li, Z.; Chen, Q.; Sun, J.; Han, X.; Liu, R.; Hu, Z.; Liang, C.; Zhang, C.; et al. Honokiol inhibits growth and improves control efficiency against Phytophthora nicotianae through disrupting redox homeostasis and energy metabolism. Ind. Crop. Prod. 2022, 178, 114656. [Google Scholar] [CrossRef]

- Bhattacharjee, R.; Negi, A.; Bhattacharya, B.; Dey, T.; Mitra, P.; Preetam, S.; Kumar, L.; Kar, S.; Das, S.S.; Iqbal, D.; et al. Nanotheranostics to target antibiotic-resistant bacteria: Strategies and applications. Open Nano 2023, 11, 100138. [Google Scholar] [CrossRef]

- Wu, Y.; He, Q.; Che, X.; Liu, F.; Lu, J.; Kong, X. Effect of number of lysine motifs on the bactericidal and hemolytic activity of short cationic antimicrobial peptides. Biochem. Biophys. Res. Commun. 2023, 648, 66–71. [Google Scholar] [CrossRef]

- Nabi, L.; Nourani, M. Biodegradable form stable phase change material for cold storage packaging of meat. Meat Sci. 2023, 201, 109188. [Google Scholar] [CrossRef]

- Tan, C.; Hu, J.; Gao, B.; Zhang, B.; Li, P.; Shang, N. Effects of the interaction between Aeromonas sobria and Macrococcus caseolyticus on protein degradation of refrigerated sturgeon fillets: Novel perspective on fish spoilage. LWT 2023, 183, 114908. [Google Scholar] [CrossRef]

- Yun, X.; Chen, W.; Zhang, J.; Dong, T. Colorimetric porous microspheres of natural sodium alginate for chilled pork visual monitoring. Int. J. Biol. Macromol. 2023, 230, 123198. [Google Scholar] [CrossRef]

- Lian, F.; Jøstensen, O.; Siikavuopio, S.I.; Lorentzen, G. Live holding of red king crab (Paralithodes camtschaticus) and snow crab (Chionoecetes opilio)—Effect on microbial growth in processed leg meat during refrigerated storage. Food Microbiol. 2021, 104, 103973. [Google Scholar] [CrossRef] [PubMed]

| Lys (%) | WS (%) | MC (%) | SC (%) | WVP (gPa−1s−1m−1·10−10) |

|---|---|---|---|---|

| 0 | 36.68 ± 2.78 a | 16.34 ± 2.13 a | 4.23 ± 0.36 a | 14.87 ± 1.78 a |

| 0.4 | 35.78 ± 1.51 a | 13.22 ± 1.39 ab | 4.15 ± 0.10 ab | 14.73 ± 0.40 a |

| 0.8 | 33.99 ± 1.19 ab | 14.39 ± 1.21 ab | 3.72 ± 0.19 bc | 14.37 ± 0.93 a |

| 1.2 | 33.03 ± 3.62 ab | 12.94 ± 2.29 ab | 3.63 ± 0.26 c | 13.53 ± 0.06 a |

| 1.6 | 29.77 ± 0.33 bc | 15.21 ± 1.34 a | 3.19 ± 0.08 d | 11.60 ± 0.66 b |

| 2.0 | 26.45 ± 3.15 c | 10.27 ± 1.29 b | 2.84 ± 0.16 d | 9.30 ± 0.66 c |

| Chromatic Aberration | Storage Time (d) | Control Group | Lys Group |

|---|---|---|---|

| L* | 1 | 55.69 ± 1.11 c | 42.16 ± 0.79 b |

| 3 | 59.35 ± 0.54 b | 41.03 ± 1.89 b | |

| 5 | 61.71 ± 1.06 a | 46.37 ± 0.50 a | |

| 7 | 61.12 ± 0.06 a | 46.54 ± 2.92 a | |

| a* | 1 | 3.07 ± 0.40 a | 2.07 ± 0.34 b |

| 3 | 2.05 ± 0.30 b | 3.47 ± 0.41 a | |

| 5 | 0.89 ± 0.08 c | 1.87 ± 0.03 b | |

| 7 | 0.48 ± 0.04 d | 1.46 ± 0.06 c | |

| b* | 1 | 12.82 ± 0.45 a | 10.57 ± 0.85 a |

| 3 | 8.06 ± 0.82 c | 9.86 ± 1.32 a | |

| 5 | 11.58 ± 0.61 b | 8.39 ± 0.09 b | |

| 7 | 10.90 ± 0.04 b | 10.33 ± 0.44 a | |

| Δ E | 1 | 34.68 ± 1.03 a | 47.38 ± 0.65 a |

| 3 | 30.49 ± 0.54 b | 48.95 ± 1.80 a | |

| 5 | 29.46 ± 0.86 b | 43.79 ± 0.17 b | |

| 7 | 27.48 ± 1.89 c | 41.04 ± 3.95 b |

| Group | 1 d (CFU) | 3 d (CFU) | 5 d (CFU) | 7 d (CFU) |

|---|---|---|---|---|

| Control | (1.00 ± 0.28) × 10−4 | (8.15 ± 1.63) × 10−4 | (1.82 ± 0.37) × 10−5 | (3.85 ± 0.27) × 10−5 |

| Lys | (2.85 ± 0.35) × 10−4 | (4.90 ± 0.56) × 10−4 | (9.85 ± 0.92) × 10−4 | (1.57 ± 0.30) × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Lv, J.; Niu, M.; Liu, S.; Wu, Y.; Liu, J.; Xie, J.; Sun, C.; Wang, Y.-M. Characterization and Antibacterial Properties of Egg White Protein Films Loaded with ε-Polylysine: Evaluation of Their Degradability and Application. Foods 2023, 12, 2431. https://doi.org/10.3390/foods12122431

Li X, Lv J, Niu M, Liu S, Wu Y, Liu J, Xie J, Sun C, Wang Y-M. Characterization and Antibacterial Properties of Egg White Protein Films Loaded with ε-Polylysine: Evaluation of Their Degradability and Application. Foods. 2023; 12(12):2431. https://doi.org/10.3390/foods12122431

Chicago/Turabian StyleLi, Xin, Jianhao Lv, Minghao Niu, Siqi Liu, Yue Wu, Jiahan Liu, Jingwen Xie, Chengfeng Sun, and Yue-Meng Wang. 2023. "Characterization and Antibacterial Properties of Egg White Protein Films Loaded with ε-Polylysine: Evaluation of Their Degradability and Application" Foods 12, no. 12: 2431. https://doi.org/10.3390/foods12122431

APA StyleLi, X., Lv, J., Niu, M., Liu, S., Wu, Y., Liu, J., Xie, J., Sun, C., & Wang, Y.-M. (2023). Characterization and Antibacterial Properties of Egg White Protein Films Loaded with ε-Polylysine: Evaluation of Their Degradability and Application. Foods, 12(12), 2431. https://doi.org/10.3390/foods12122431