Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality

Abstract

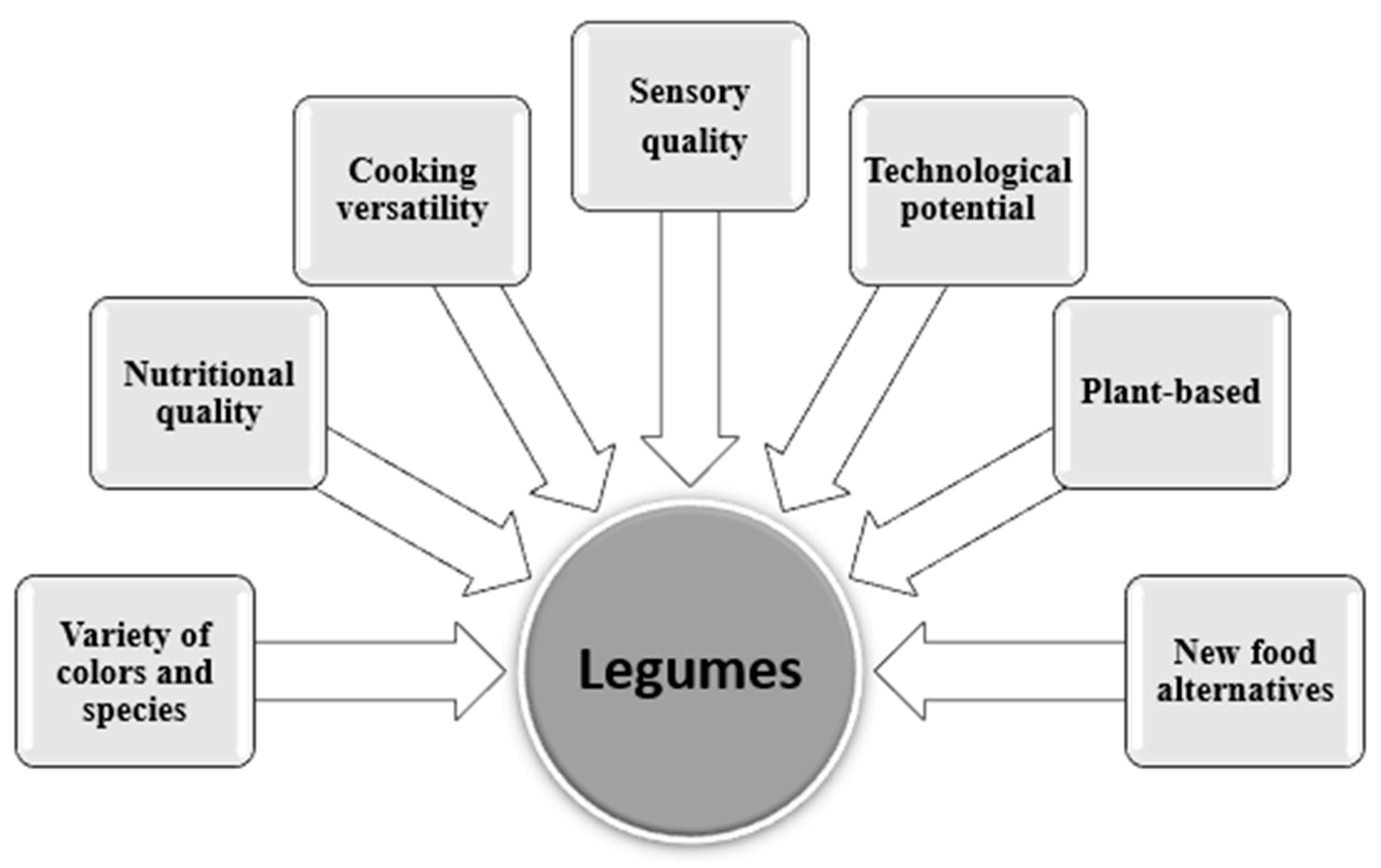

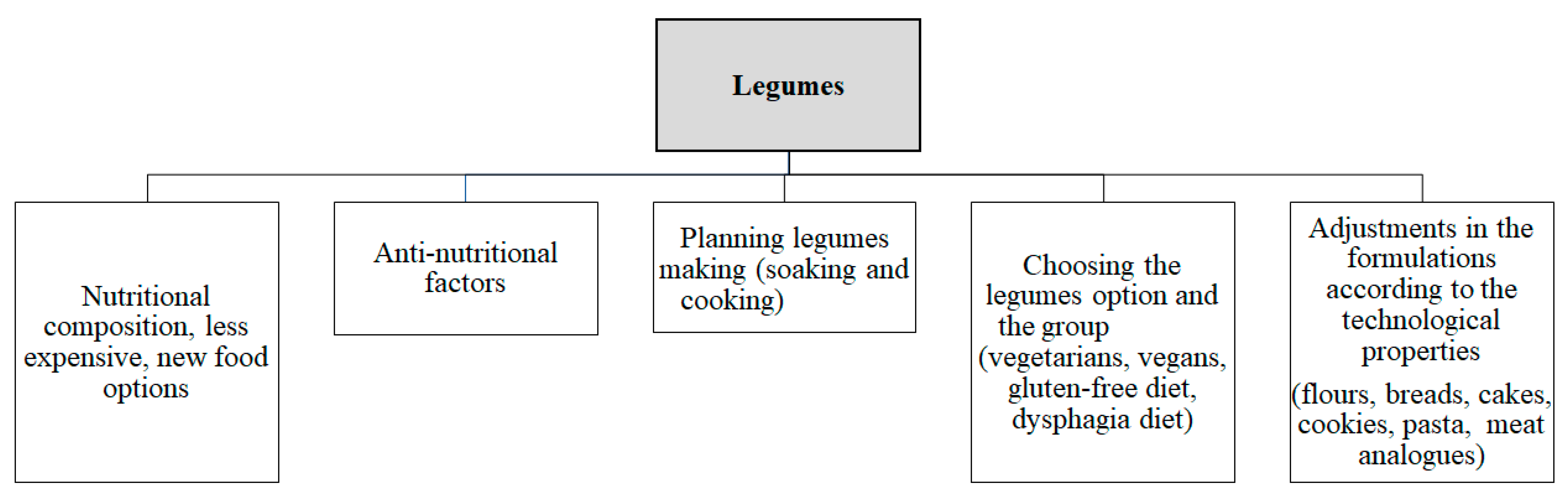

1. Introduction

2. Nutritional Quality of Legumes

3. Legumes’ Germination: Antinutritional Factors and New Products Options

4. Use of Legume Flours and Other Products

5. Using Other Products from Legumes

5.1. Aquafaba

5.2. Legumes as Substitutes for Animal Source Foods

5.3. Special-Purpose Legume Application

6. Technological and Functional Properties of Legume Proteins

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ministério da Agricultura, Pecuária e Abastecimento. Brasil—Plano Nacional de Desenvolvimento Da Cadeia Do Feijão e Pulses; Ministério da Agricultura, Pecuária e Abastecimento: Brasília, Brasil, 2018.

- Smýkal, P.; Aubert, G.; Burstin, J.; Coyne, C.J.; Ellis, N.T.H.; Flavell, A.J.; Ford, R.; Hýbl, M.; Macas, J.; Neumann, P.; et al. Pea (Pisum sativum L.) in the Genomic Era. Agronomy 2012, 2, 74–115. [Google Scholar] [CrossRef]

- Shea, Z.; Singer, W.M.; Zhang, B. Soybean Production, Versatility, and Improvement; Hasanuzzaman, M., Ed.; Intech Open: Rijeka, Croatia, 2020; ISBN 978-1-83968-274-2. [Google Scholar]

- Bitocchi, E.; Rau, D.; Bellucci, E.; Rodriguez, M.; Murgia, M.L.; Gioia, T.; Santo, D.; Nanni, L.; Attene, G.; Papa, R. Beans (Phaseolus Ssp.) as a Model for Understanding Crop Evolution. Front. Plant Sci. 2017, 8, 722. [Google Scholar] [CrossRef] [PubMed]

- Yegrem, L. Nutritional Composition, Antinutritional Factors, and Utilization Trends of Ethiopian Chickpea (Cicer arietinum L.). Int. J. Food Sci. 2021, 2021, 5570753. [Google Scholar] [CrossRef] [PubMed]

- Innamorato, V.; Longobardi, F.; Lippolis, V.; Cortese, M.; Logrieco, A.F.; Catucci, L.; Agostiano, A.; De Girolamo, A. Tracing the Geographical Origin of Lentils (Lens culinaris Medik.) by Infrared Spectroscopy and Chemometrics. Food Anal. Methods 2019, 12, 773–779. [Google Scholar] [CrossRef]

- Tyler, R.; Wang, N.; Han, J. Composition, Nutritional Value, Functionality, Processing, and Novel Food Uses of Pulses and Pulse Ingredients. Cereal Chem. 2017, 94, 1. [Google Scholar] [CrossRef]

- Patto, M.C.V.; Amarowicz, R.; Aryee, A.N.A.; Boye, J.I.; Chung, H.-J.; Martín-Cabrejas, M.A.; Domoney, C. Achievements and Challenges in Improving the Nutritional Quality of Food Legumes. Crit. Rev. Plant Sci. 2015, 34, 105–143. [Google Scholar] [CrossRef]

- Iriti, M.; Varoni, E.M. Pulses, Healthy, and Sustainable Food Sources for Feeding the Planet. Int. J. Mol. Sci. 2017, 18, 255. [Google Scholar] [CrossRef]

- Bourré, L.; Frohlich, P.; Young, G.; Borsuk, Y.; Sopiwnyk, E.; Sarkar, A.; Nickerson, M.T.; Ai, Y.; Dyck, A.; Malcolmson, L. Influence of Particle Size on Flour and Baking Properties of Yellow Pea, Navy Bean, and Red Lentil Flours. Cereal Chem. 2019, 96, 655–667. [Google Scholar] [CrossRef]

- Kaale, L.D.; Siddiq, M.; Hooper, S. Lentil (Lens culinaris Medik) as Nutrient-Rich and Versatile Food Legume: A Review. Legum. Sci. 2022, 5, 169. [Google Scholar] [CrossRef]

- Binou, P.; Yanni, A.E.; Karathanos, V.T. Physical Properties, Sensory Acceptance, Postprandial Glycemic Response, and Satiety of Cereal Based Foods Enriched with Legume Flours: A Review. Crit. Rev. Food Sci. Nutr. 2022, 62, 2722–2740. [Google Scholar] [CrossRef]

- Wen, C.; Liu, G.; Ren, J.; Deng, Q.; Xu, X.; Zhang, J. Current Progress in the Extraction, Functional Properties, Interaction with Polyphenols, and Application of Legume Protein. J. Agric. Food Chem. 2022, 70, 992–1002. [Google Scholar] [CrossRef] [PubMed]

- Keskin, S.O.; Ali, T.M.; Ahmed, J.; Shaikh, M.; Siddiq, M.; Uebersax, M.A. Physico-Chemical and Functional Properties of Legume Protein, Starch, and Dietary Fiber—A Review. Legume Sci. 2022, 4, e117. [Google Scholar] [CrossRef]

- Sagratini, G.; Zuo, Y.; Caprioli, G.; Cristalli, G.; Giardinà, D.; Maggi, F.; Molin, L.; Ricciutelli, M.; Traldi, P.; Vittori, S. Quantification of Soyasaponins I and Βg in Italian Lentil Seeds by Solid-Phase Extraction (SPE) and High-Performance Liquid Chromatography−Mass Spectrometry (HPLC-MS). J. Agric. Food Chem. 2009, 57, 11226–11233. [Google Scholar] [CrossRef] [PubMed]

- Hall, C.; Hillen, C.; Garden Robinson, J. Composition, Nutritional Value, and Health Benefits of Pulses. Cereal Chem. J. 2017, 94, 11–31. [Google Scholar] [CrossRef]

- Ramírez-Ojeda, A.M.; Moreno-Rojas, R.; Cámara-Martos, F. Mineral and Trace Element Content in Legumes (Lentils, Chickpeas and Beans): Bioaccesibility and Probabilistic Assessment of the Dietary Intake. J. Food Compos. Anal. 2018, 73, 17–28. [Google Scholar] [CrossRef]

- Caprioli, G.; Iannarelli, R.; Cianfaglione, K.; Fiorini, D.; Giuliani, C.; Lucarini, D.; Papa, F.; Sagratini, G.; Vittori, S.; Maggi, F. Volatile Profile, Nutritional Value and Secretory Structures of the Berry-like Fruits of Hypericum androsaemum L. Food Res. Int. 2016, 79, 1–10. [Google Scholar] [CrossRef]

- NEPA. Tabela Brasileira de Composição de Alimentos; NEPA: Campinas Brazil, 2011; p. 161.

- Boye, J.I.; Aksay, S.; Roufik, S.; Ribéreau, S.; Mondor, M.; Farnworth, E.; Rajamohamed, S.H. Comparison of the Functional Properties of Pea, Chickpea and Lentil Protein Concentrates Processed Using Ultrafiltration and Isoelectric Precipitation Techniques. Food Res. Int. 2010, 43, 537–546. [Google Scholar] [CrossRef]

- Rumiyati; James, A.P.; Jayasena, V. Effect of Germination on the Nutritional and Protein Profile of Australian Sweet Lupin (Lupinus angustifolius L.). Food Nutr. Sci. 2012, 3, 621–626. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N.; Chen, Y.; Kaur, A.; Yu, L. Pulse Proteins: Secondary Structure, Functionality and Applications. J. Food Sci. Technol. 2019, 56, 2787–2798. [Google Scholar] [CrossRef]

- Boye, J.; Wijesinha-Bettoni, R.; Burlingame, B. Protein Quality Evaluation Twenty Years after the Introduction of the Protein Digestibility Corrected Amino Acid Score Method. Br. J. Nutr. 2012, 108, S183–S211. [Google Scholar] [CrossRef]

- Gilani, G.S.; Xiao, C.W.; Cockell, K.A. Impact of Antinutritional Factors in Food Proteins on the Digestibility of Protein and the Bioavailability of Amino Acids and on Protein Quality. Br. J. Nutr. 2012, 108, S315–S332. [Google Scholar] [CrossRef] [PubMed]

- Dahl, W.J.; Foster, L.M.; Tyler, R.T. Review of the Health Benefits of Peas (Pisum sativum L.). Br. J. Nutr. 2012, 108, S3–S10. [Google Scholar] [CrossRef] [PubMed]

- Maphosa, Y.; Jideani, V.A. The Role of Legumes in Human Nutrition. In Functional Food—Improve Health through Adequate Food; Intech Open: Rijeka, Croatia, 2017; p. 103. [Google Scholar]

- Levy-Costa, R.B.; Sichieri, R.; Pontes, N.d.S.; Monteiro, C.A. Disponibilidade Domiciliar de Alimentos no Brasil: Distribuição e Evolução (1974–2003). Rev. Saude Publica 2005, 39, 530–540. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ragaee, S.; Marcone, M.F.; Abdel-Aal, E.-S.M. Effect of Different Cooking Methods and Heating Solutions on Nutritionally-Important Starch Fractions and Flatus Oligosaccharides in Selected Pulses. Cereal Chem. 2020, 97, 1216–1226. [Google Scholar] [CrossRef]

- Shi, L.; Arntfield, S.D.; Nickerson, M. Changes in Levels of Phytic Acid, Lectins and Oxalates during Soaking and Cooking of Canadian Pulses. Food Res. Int. 2018, 107, 660–668. [Google Scholar] [CrossRef]

- Valdelvira, R.; Garcia-Medina, G.; Crespo, J.F.; Cabanillas, B. Allergenic Content of New Alimentary Pasta Made of Lentils Compared with Lentil Seeds and Analysis of the Impact of Boiling Processing. Plant Foods Hum. Nutr. 2022, 77, 443–446. [Google Scholar] [CrossRef]

- Valdelvira, R.; Garcia-Medina, G.; Crespo, J.F.; Cabanillas, B. Novel Alimentary Pasta Made of Chickpeas Has an Important Allergenic Content That Is Altered by Boiling in a Different Manner than Chickpea Seeds. Food Chem. 2022, 395, 133586. [Google Scholar] [CrossRef]

- Brandolini, A.; Glorio-Paulet, P.; Estivi, L.; Locatelli, N.; Cordova-Ramos, J.S.; Hidalgo, A. Tocopherols, Carotenoids and Phenolics Changes during Andean Lupin (Lupinus mutabilis Sweet) Seeds Processing. J. Food Compos. Anal. 2022, 106, 104335. [Google Scholar] [CrossRef]

- Córdova-Ramos, J.S.; Glorio-Paulet, P.; Camarena, F.; Brandolini, A.; Hidalgo, A. Andean Lupin (Lupinus Mutabilis Sweet): Processing Effects on Chemical Composition, Heat Damage, and in Vitro Protein Digestibility. Cereal Chem. 2020, 97, 827–835. [Google Scholar] [CrossRef]

- Kaur, R.; Prasad, K. Technological, Processing and Nutritional Aspects of Chickpea (Cicer arietinum)—A Review. Trends Food Sci. Technol. 2021, 109, 448–463. [Google Scholar] [CrossRef]

- Ghavidel, R.A.; Prakash, J. The Impact of Germination and Dehulling on Nutrients, Antinutrients, in vitro Iron and Calcium Bioavailability and in vitro Starch and Protein Digestibility of Some Legume Seeds. LWT Food Sci. Technol. 2007, 40, 1292–1299. [Google Scholar] [CrossRef]

- Shohag, M.J.I.; Wei, Y.; Yang, X. Changes of Folate and Other Potential Health-Promoting Phytochemicals in Legume Seeds as Affected by Germination. J. Agric. Food Chem. 2012, 60, 9137–9143. [Google Scholar] [CrossRef] [PubMed]

- Malunga, L.N.; Dadon, S.B.-E.; Zinal, E.; Berkovich, Z.; Abbo, S.; Reifen, R. The Potential Use of Chickpeas in Development of Infant Follow-on Formula. Nutr. J. 2014, 13, 8. [Google Scholar] [CrossRef] [PubMed]

- Ohanenye, I.C.; Tsopmo, A.; Ejike, C.E.C.C.; Udenigwe, C.C. Germination as a Bioprocess for Enhancing the Quality and Nutritional Prospects of Legume Proteins. Trends Food Sci. Technol. 2020, 101, 213–222. [Google Scholar] [CrossRef]

- Bresciani, A.; Marti, A. Using Pulses in Baked Products: Lights, Shadows, and Potential Solutions. Foods 2019, 8, 451. [Google Scholar] [CrossRef] [PubMed]

- Guardado-Félix, D.; Lazo-Vélez, M.A.; Pérez-Carrillo, E.; Panata-Saquicili, D.E.; Serna-Saldívar, S.O. Effect of Partial Replacement of Wheat Flour with Sprouted Chickpea Flours with or without Selenium on Physicochemical, Sensory, Antioxidant and Protein Quality of Yeast-Leavened Breads. LWT 2020, 129, 109517. [Google Scholar] [CrossRef]

- Idowu, A.T.; Olatunde, O.O.; Adekoya, A.E.; Idowu, S. Germination: An Alternative Source to Promote Phytonutrients in Edible Seeds. Food Qual. Saf. 2020, 4, 129–133. [Google Scholar] [CrossRef]

- Perri, G.; Coda, R.; Rizzello, C.G.; Celano, G.; Ampollini, M.; Gobbetti, M.; De Angelis, M.; Calasso, M. Sourdough Fermentation of Whole and Sprouted Lentil Flours: In Situ Formation of Dextran and Effects on the Nutritional, Texture and Sensory Characteristics of White Bread. Food Chem. 2021, 355, 129638. [Google Scholar] [CrossRef]

- Ahure, D.; Ejoha, P.O. Quality Evaluation of Cookies from Malted Sorghum (Sorghum bicolor), Sprouted Soybean (Glycine max) and Carrot (Daucus carota) Flour Blends. Asian J. Biotechnol. Bioresour. Technol. 2020, 6, 14–27. [Google Scholar] [CrossRef]

- Coda, R.; Varis, J.; Verni, M.; Rizzello, C.G.; Katina, K. Improvement of the Protein Quality of Wheat Bread through Faba Bean Sourdough Addition. LWT Food Sci. Technol. 2017, 82, 296–302. [Google Scholar] [CrossRef]

- Simons, C.W.; Hall, C. Consumer Acceptability of Gluten-Free Cookies Containing Raw Cooked and Germinated Pinto Bean Flours. Food Sci. Nutr. 2018, 6, 77–84. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N. Influence of Kidney Bean, Field Pea and Amaranth Protein Isolates on the Characteristics of Starch-Based Gluten-Free Muffins. Int. J. Food Sci. Technol. 2014, 49, 2237–2244. [Google Scholar] [CrossRef]

- Foschia, M.; Horstmann, S.W.; Arendt, E.K.; Zannini, E. Legumes as Functional Ingredients in Gluten-Free Bakery and Pasta Products. Annu. Rev. Food Sci. Technol. 2017, 8, 75–96. [Google Scholar] [CrossRef] [PubMed]

- Oyeyinka, S.A.; Singh, S.; Amonsou, E.O. A Review on Structural, Digestibility and Physicochemical Properties of Legume Starch-Lipid Complexes. Food Chem. 2021, 349, 129165. [Google Scholar] [CrossRef] [PubMed]

- Talens, P.; Castells, M.L.; Verdú, S.; Barat, J.M.; Grau, R. Flow, Viscoelastic and Masticatory Properties of Tailor Made Thickened Pea Cream for People with Swallowing Problems. J. Food Eng. 2021, 292, 110265. [Google Scholar] [CrossRef]

- Thakur, S.; Scanlon, M.G.; Tyler, R.T.; Milani, A.; Paliwal, J. Pulse Flour Characteristics from a Wheat Flour Miller’s Perspective: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 775–797. [Google Scholar] [CrossRef] [PubMed]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Fortunati, P.; Masoero, F. Cooking Quality and Starch Digestibility of Gluten Free Pasta Using New Bean Flour. Food Chem. 2015, 175, 43–49. [Google Scholar] [CrossRef]

- Angioloni, A.; Collar, C. High Legume-Wheat Matrices: An Alternative to Promote Bread Nutritional Value Meeting Dough Viscoelastic Restrictions. Eur. Food Res. Technol. 2012, 234, 273–284. [Google Scholar] [CrossRef]

- Hoehnel, A.; Bez, J.; Petersen, I.L.; Amarowicz, R.; Juśkiewicz, J.; Zannini, E.; Arendt, E.K. Combining High-Protein Ingredients from Pseudocereals and Legumes for the Development of Fresh High-Protein Hybrid Pasta: Enhanced Nutritional Profile. J. Sci. Food Agric. 2022, 102, 5000–5010. [Google Scholar] [CrossRef] [PubMed]

- Betrouche, A.; Estivi, L.; Colombo, D.; Pasini, G.; Benatallah, L.; Brandolini, A.; Hidalgo, A. Antioxidant Properties of Gluten-Free Pasta Enriched with Vegetable By-Products. Molecules 2022, 27, 8993. [Google Scholar] [CrossRef] [PubMed]

- Komeroski, M.R.; Homem, R.V.; Schmidt, H.d.O.; Rockett, F.C.; de Lira, L.; Vitória da Farias, D.; Kist, T.L.; Doneda, D.; Rios, A.d.O.; Ruffo de Oliveira, V. Effect of Whey Protein and Mixed Flours on the Quality Parameters of Gluten-Free Breads. Int. J. Gastron. Food Sci. 2021, 24, 100361. [Google Scholar] [CrossRef]

- Guimarães, R.M.; Pimentel, T.C.; de Rezende, T.A.M.; Silva, J.d.S.; Falcão, H.G.; Ida, E.I.; Egea, M.B. Gluten-Free Bread: Effect of Soy and Corn Co-Products on the Quality Parameters. Eur. Food Res. Technol. 2019, 245, 1365–1376. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Labarbuta, R.; Summo, C. Production of Extruded-Cooked Lentil Flours at Industrial Level: Effect of Processing Conditions on Starch Gelatinization, Dough Rheological Properties and Techno-Functional Parameters. LWT 2021, 147, 111580. [Google Scholar] [CrossRef]

- Joehnke, M.S.; Jeske, S.; Ispiryan, L.; Zannini, E.; Arendt, E.K.; Bez, J.; Sørensen, J.C.; Petersen, I.L. Nutritional and Anti-Nutritional Properties of Lentil (Lens culinaris) Protein Isolates Prepared by Pilot-Scale Processing. Food Chem. X 2021, 9, 100112. [Google Scholar] [CrossRef] [PubMed]

- Du, S.-K.; Jiang, H.; Yu, X.; Jane, J.L. Physicochemical and Functional Properties of Whole Legume Flour. LWT Food Sci. Technol. 2014, 55, 308–313. [Google Scholar] [CrossRef]

- do Evangelho, J.A.; Vanier, N.L.; Pinto, V.Z.; Berrios, J.J.D.; Dias, A.R.G.; Zavareze, E.d.R. Black Bean (Phaseolus vulgaris L.) Protein Hydrolysates: Physicochemical and Functional Properties. Food Chem. 2017, 214, 460–467. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Boye, J.I.; Simpson, B.K. Preparation of Salad Dressing Emulsions Using Lentil, Chickpea and Pea Protein Isolates: A Response Surface Methodology Study. J. Food Qual. 2016, 39, 274–291. [Google Scholar] [CrossRef]

- Serventi, L.; Wang, S.; Zhu, J.; Liu, S.; Fei, F. Cooking Water of Yellow Soybeans as Emulsifier in Gluten-Free Crackers. Eur. Food Res. Technol. 2018, 244, 2141–2148. [Google Scholar] [CrossRef]

- Stantiall, S.E.; Dale, K.J.; Calizo, F.S.; Serventi, L. Application of Pulses Cooking Water as Functional Ingredients: The Foaming and Gelling Abilities. Eur. Food Res. Technol. 2018, 244, 97–104. [Google Scholar] [CrossRef]

- Mustafa, R.; Reaney, M.J.T. Aquafaba, from Food Waste to a Value-Added Product. In Food Wastes and By-Products; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 93–126. [Google Scholar]

- Shim, Y.Y.; Mustafa, R.; Shen, J.; Ratanapariyanuch, K.; Reaney, M.J.T. Composition and Properties of Aquafaba: Water Recovered from Commercially Canned Chickpeas. J. Vis. Exp. 2018, 132, e56305. [Google Scholar] [CrossRef]

- Lafarga, T.; Álvarez, C.; Bobo, G.; Aguiló-Aguayo, I. Characterization of Functional Properties of Proteins from Ganxet Beans (Phaseolus vulgaris L. Var. ganxet) Isolated Using an Ultrasound-Assisted Methodology. LWT 2018, 98, 106–112. [Google Scholar] [CrossRef]

- Pedrosa, M.M.; Cuadrado, C.; Burbano, C.; Allaf, K.; Haddad, J.; Gelencsér, E.; Takács, K.; Guillamón, E.; Muzquiz, M. Effect of Instant Controlled Pressure Drop on the Oligosaccharides, Inositol Phosphates, Trypsin Inhibitors and Lectins Contents of Different Legumes. Food Chem. 2012, 131, 862–868. [Google Scholar] [CrossRef]

- El-Hady, E.A.A.; Habiba, R.A. Effect of Soaking and Extrusion Conditions on Antinutrients and Protein Digestibility of Legume Seeds. LWT Food Sci. Technol. 2003, 36, 285–293. [Google Scholar] [CrossRef]

- He, Y.; Meda, V.; Reaney, M.J.T.; Mustafa, R. Aquafaba, a New Plant-Based Rheological Additive for Food Applications. Trends Food Sci. Technol. 2021, 111, 27–42. [Google Scholar] [CrossRef]

- Lemken, D.; Spiller, A.; Schulze-Ehlers, B. More Room for Legume—Consumer Acceptance of Meat Substitution with Classic, Processed and Meat-Resembling Legume Products. Appetite 2019, 143, 104412. [Google Scholar] [CrossRef] [PubMed]

- Hashempour-Baltork, F.; Khosravi-Darani, K.; Hosseini, H.; Farshi, P.; Reihani, S.F.S. Mycoproteins as Safe Meat Substitutes. J. Clean. Prod. 2020, 253, 119958. [Google Scholar] [CrossRef]

- Kim, T.; Miller, R.; Laird, H.; Riaz, M.N. Beef Flavor Vegetable Hamburger Patties with High Moisture Meat Analogs (HMMA) with Pulse Proteins-Peas, Lentils, and Faba Beans. Food Sci. Nutr. 2021, 4048–4056. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef]

- Argel, N.S.; Ranalli, N.; Califano, A.N.; Andrés, S.C. Influence of Partial Pork Meat Replacement by Pulse Flour on Physicochemical and Sensory Characteristics of Low-Fat Burgers. J. Sci. Food Agric. 2020, 100, 3932–3941. [Google Scholar] [CrossRef]

- Cichero, J.A.Y.; Steele, C.; Duivestein, J.; Clavé, P.; Chen, J.; Kayashita, J.; Dantas, R.; Lecko, C.; Speyer, R.; Lam, P.; et al. The Need for International Terminology and Definitions for Texture-Modified Foods and Thickened Liquids Used in Dysphagia Management: Foundations of a Global Initiative. Curr. Phys. Med. Rehabil. Rep. 2013, 1, 280–291. [Google Scholar] [CrossRef]

- Brishti, F.H.; Zarei, M.; Muhammad, S.K.S.; Ismail-Fitry, M.R.; Shukri, R.; Saari, N. Evaluation of the Functional Properties of Mung Bean Protein Isolate for Development of Textured Vegetable Protein. Int. Food Res. J. 2017, 24, 1595–1605. [Google Scholar]

- Soria-Hernández, C.; Serna-Saldívar, S.; Chuck-Hernández, C. Physicochemical and Functional Properties of Vegetable and Cereal Proteins as Potential Sources of Novel Food Ingredients. Food Technol. Biotechnol. 2015, 53, 269–277. [Google Scholar] [CrossRef]

- Gundogan, R.; Can Karaca, A. Physicochemical and Functional Properties of Proteins Isolated from Local Beans of Turkey. LWT 2020, 130, 109609. [Google Scholar] [CrossRef]

- Mulla, M.Z.; Subramanian, P.; Dar, B.N. Functionalization of Legume Proteins Using High Pressure Processing: Effect on Technofunctional Properties and Digestibility of Legume Proteins. LWT 2022, 158, 113106. [Google Scholar] [CrossRef]

- Damian, J.J.; Huo, S.; Serventi, L. Phytochemical Content and Emulsifying Ability of Pulses Cooking Water. Eur. Food Res. Technol. 2018, 244, 1647–1655. [Google Scholar] [CrossRef]

- Chigwedere, C.M.; Njoroge, D.M.; Van Loey, A.M.; Hendrickx, M.E. Understanding the Relations Among the Storage, Soaking, and Cooking Behavior of Pulses: A Scientific Basis for Innovations in Sustainable Foods for the Future. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1135–1165. [Google Scholar] [CrossRef]

- Joshi, M.; Timilsena, Y.; Adhikari, B. Global Production, Processing and Utilization of Lentil: A Review. J. Integr. Agric. 2017, 16, 2898–2913. [Google Scholar] [CrossRef]

- Carbonaro, M.; Maselli, P.; Nucara, A. Structural Aspects of Legume Proteins and Nutraceutical Properties. Food Res. Int. 2015, 76, 19–30. [Google Scholar] [CrossRef]

- Carrasco-Castilla, J.; Hernández-Álvarez, A.J.; Jiménez-Martínez, C.; Jacinto-Hernández, C.; Alaiz, M.; Girón-Calle, J.; Vioque, J.; Dávila-Ortiz, G. Antioxidant and Metal Chelating Activities of Phaseolus vulgaris L. Var. Jamapa Protein Isolates, Phaseolin and Lectin Hydrolysates. Food Chem. 2012, 131, 1157–1164. [Google Scholar] [CrossRef]

- Xu, M.; Jin, Z.; Gu, Z.; Rao, J.; Chen, B. Changes in Odor Characteristics of Pulse Protein Isolates from Germinated Chickpea, Lentil, and Yellow Pea: Role of Lipoxygenase and Free Radicals. Food Chem. 2020, 314, 126184. [Google Scholar] [CrossRef]

- Teferra, T.F. Advanced and Feasible Pulses Processing Technologies for Ethiopia to Achieve Better Economic and Nutritional Goals: A Review. Heliyon 2021, 7, e07459. [Google Scholar] [CrossRef] [PubMed]

- Drulyte, D.; Orlien, V. The Effect of Processing on Digestion of Legume Proteins. Foods 2019, 8, 224. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmidt, H.d.O.; Oliveira, V.R.d. Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality. Foods 2023, 12, 2586. https://doi.org/10.3390/foods12132586

Schmidt HdO, Oliveira VRd. Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality. Foods. 2023; 12(13):2586. https://doi.org/10.3390/foods12132586

Chicago/Turabian StyleSchmidt, Helena de Oliveira, and Viviani Ruffo de Oliveira. 2023. "Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality" Foods 12, no. 13: 2586. https://doi.org/10.3390/foods12132586

APA StyleSchmidt, H. d. O., & Oliveira, V. R. d. (2023). Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality. Foods, 12(13), 2586. https://doi.org/10.3390/foods12132586