Storage Quality Changes in Craft and Industrial Blueberry, Strawberry, Raspberry and Passion Fruit-Mango Sorbets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Industrial Sorbets (S)

2.2. Raw Materials for Craft Sorbets (C)

2.3. Preparation of Sorbets

2.4. Physico-Chemical Parameters

- V = melting resistance [%],

- V1 = volume of melted sorbet [cm3], and

- V2 = volume of cylinder (24.73) [cm3].

2.5. Color Analysis

- ∆L = brightness difference,

- ∆a = redness difference, and

- ∆b = yellowness difference.

2.6. Sensory Evaluation

2.7. Statistical Analysis

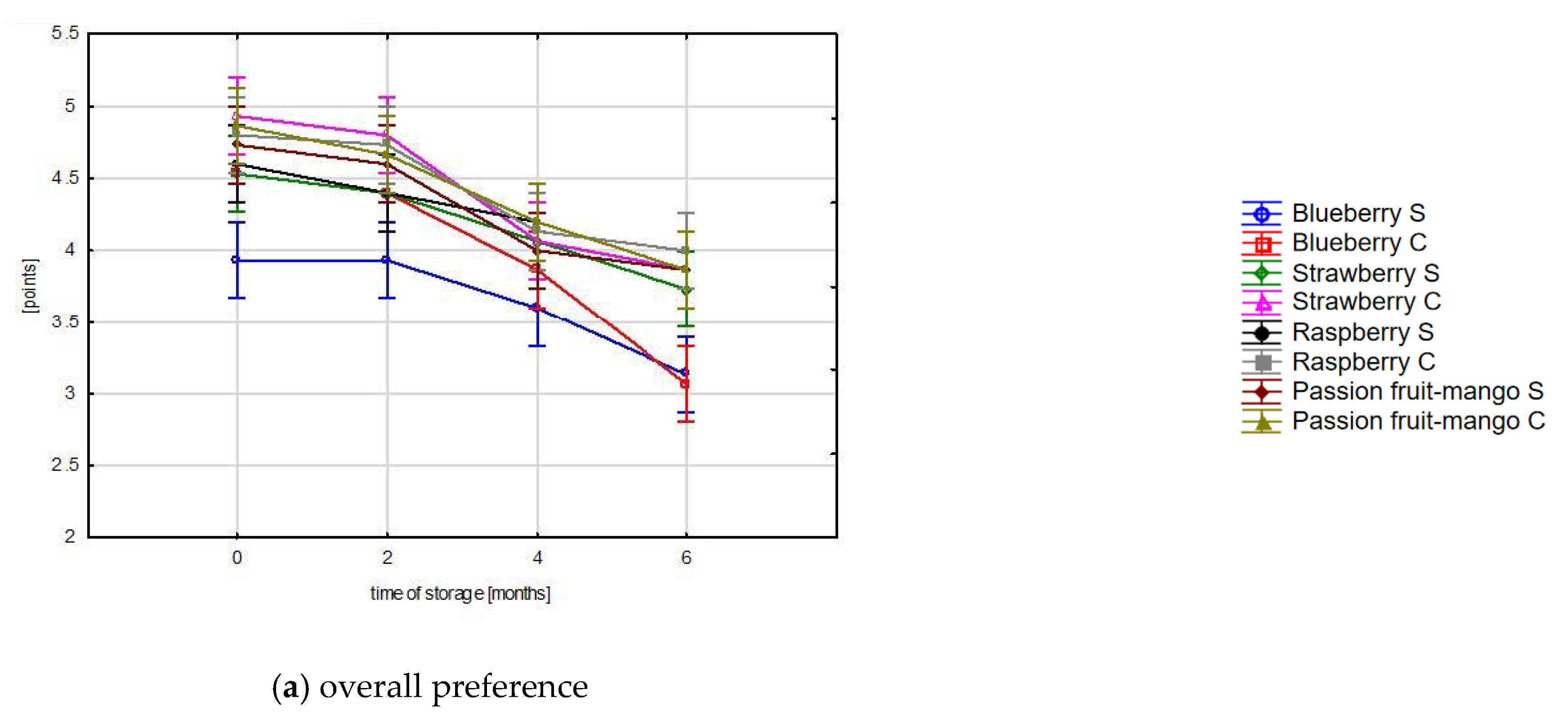

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Malgor, M.; Sabbione, A.C.; Scilingo, A. Amaranth Lemon Sorbet, Elaboration of a Potential Functional Food. Plant Foods Hum. Nutr. 2020, 75, 404–412. [Google Scholar] [CrossRef] [PubMed]

- Nistor, O.; Pohrib, E.; Mocanu, G.; Constantin, O.; Ceclu, L. An overview on the earliest representative of today vegan and vegetarian ice cream. J. Agroaliment. Process. Technol. 2020, 26, 281–286. [Google Scholar]

- Petkova, T.; Doykina, P.; Alexieva, I.; Mihaylova, D.; Popova, A. Characterization of Fruit Sorbet Matrices with Added Value from Zizyphus jujuba and Stevia rebaudiana. Foods 2022, 11, 2748. [Google Scholar] [CrossRef] [PubMed]

- Giampieri, F.; Tulipani, S.; Alvarez-Suarez, J.M.; Quiles, J.L.; Mezzetti, B.; Battino, M. The strawberry: Composition, nutritional quality, and impact on human health. Nutrition 2012, 28, 9–19. [Google Scholar] [CrossRef] [PubMed]

- Neri, L.; Faieta, M.; Di Mattia, C.; Sacchetti, G.; Mastrocola, D.; Pittia, P. Antioxidant Activity in Frozen Plant Foods: Effect of Cryoprotectants, Freezing Process and Frozen Storage. Foods 2020, 9, 1886. [Google Scholar] [CrossRef]

- Robbins, R.J. Phenolic acids in foods: An overview of analytical methodology. J. Agric. Food Chem. 2003, 51, 2866–2887. [Google Scholar] [CrossRef]

- Ekici, L.; Kafadar, A.D.; Albayrak, S. Physicochemical, sensory, and bioactive properties of some traditional Turkish sorbets. J. Food Process Preserv. 2018, 42, e13664. [Google Scholar] [CrossRef]

- Paredes-Lopez, O.; Cervantes-Ceja, M.L.; Vigna-Perez, M.; Hernandez-Perez, T. Berries: Improving human health and healthy aging, and promoting quality life—A review. Plant Foods Hum. Nutr. 2010, 65, 299–308. [Google Scholar] [CrossRef]

- Jiang, Y.; Subbiah, V.; Wu, H.; Bk, A.; Sharifi-Rad, J.; Suleria, H. Phenolic Profiling of Berries Waste and Determination of Their Antioxidant Potential. J. Food Qual. 2022, 2022, 5605739. [Google Scholar] [CrossRef]

- Beattie, J.; Crozier, A.; Duthie, G.G. Potential health benefits of berries. Curr. Nutr. Food Sci. 2005, 1, 71–86. [Google Scholar] [CrossRef]

- Van Duyn, M.A.; Pivonka, E. Overview of the health benefits of fruit and vegetable consumption for the dietetics professional: Selected literature. J. Am. Diet. Assoc. 2000, 100, 1511–1521. [Google Scholar] [CrossRef] [PubMed]

- Žlabur, J.Š.; Mikulec, N.; Doždor, L.; Duralija, B.; Galić, A.; Voća, S. Preservation of Biologically Active Compounds and Nutritional Potential of Quick-Frozen Berry Fruits of the Genus Rubus. Processes 2021, 9, 1940. [Google Scholar] [CrossRef]

- Huang, W.Y.; Zhang, H.C.; Liu, W.X.; Li, C.Y. Survey of antioxidant capacity and phenolic composition of blueberry, blackberry, and strawberry in nanjing. J. Zhejiang Univ. Sci. B 2012, 13, 94–102. [Google Scholar] [CrossRef] [Green Version]

- Krenn, L.; Steitz, M.; Schlicht, C.; Kurth, H.; Gaedcke, F. Anthocyanin- and proanthocyanidin-rich extracts of berries in food supplements—Analysis with problems. Pharmazie 2007, 62, 803–812. [Google Scholar] [PubMed]

- Slatnar, A.; Jakopic, J.; Stampar, F.; Veberic, R.; Jamnik, P. The effect of bioactive compounds on in vitro and in vivo antioxidant activity of different berry juices. PLoS ONE 2012, 7, e47880. [Google Scholar] [CrossRef] [Green Version]

- Zorzi, M.; Gai, F.; Medana, C.; Aigotti, R.; Morello, S.; Peiretti, P.G. Bioactive Compounds and Antioxidant Capacity of Small Berries. Foods 2020, 9, 623. [Google Scholar] [CrossRef]

- Skrovankova, S.; Sumczynski, D.; Mlcek, J.; Jurikova, T.; Sochor, J. Bioactive Compounds and Antioxidant Activity in Different Types of Berries. Int. J. Mol. Sci. 2015, 16, 24673–24706. [Google Scholar] [CrossRef] [Green Version]

- Ganhão, R.; Pinheiro, J.; Tino, C.; Faria, H.; Gil, M.M. Characterization of Nutritional, Physicochemical, and Phytochemical Composition and Antioxidant Capacity of Three Strawberry “Fragaria × ananassa Duch”. Cultivars (“Primoris”, “Endurance”, and “Portola”) from Western Region of Portugal. Foods 2019, 8, 682. [Google Scholar] [CrossRef] [Green Version]

- Devareddy, L.; Hooshmand, S.; Collins, J.K.; Lucas, E.A.; Chai, S.C.; Arjmandi, B.H. Blueberryprevents bone loss in ovariectomized rat model of postmenopausal osteoporosis. J. Nutr. Biochem. 2008, 19, 694–699. [Google Scholar] [CrossRef] [PubMed]

- Georgescu, C.; Frum, A.; Virchea, L.-I.; Sumacheva, A.; Shamtsyan, M.; Gligor, F.-G.; Olah, N.K.; Mathe, E.; Mironescu, M. Geographic Variability of Berry Phytochemicals with Antioxidant and Antimicrobial Properties. Molecules 2022, 27, 4986. [Google Scholar] [CrossRef]

- Hubert, P.A.; Lee, S.G.; Lee, S.-K.; Chun, O.K. Dietary Polyphenols, Berries, and Age-Related Bone Loss: A Review Based on Human, Animal and Cell Studies. Antioxidants. 2014, 3, 144–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonçalves, G.A.S.; Resende, N.S.; Carvalho, E.E.N.; Resende, J.V.; Vilas Boas, E.V.B. Effect of pasteurisation and freezing method on bioactive compounds and antioxidant activity of strawberry pulp. Int. J. Food Sci. Nutr. 2017, 68, 682–694. [Google Scholar] [CrossRef] [PubMed]

- Luís, Â.; Duarte, A.P.; Pereira, L.; Domingues, F. Interactions between the major bioactive polyphenols of berries: Effects on antioxidant properties. Eur. Food Res. Technol. 2017, 244, 175–185. [Google Scholar] [CrossRef]

- Tang, J.; Dunshea, F.R.; Suleria, H.A. LC-ESI-QTOF/MS characterization of phenolic compounds from medicinal plants (hops and juniper berries) and their antioxidant activity. Foods 2020, 9, 7. [Google Scholar] [CrossRef] [Green Version]

- Del Rio, D.; Borges, G.; Crozier, A. Berry flavonoids and phenolics: Bioavailability and evidence of protective effects. Br. J. Nutr. 2010, 104 (Suppl. 3), 67–90. [Google Scholar] [CrossRef] [Green Version]

- Basu, A.; Nguyen, A.; Betts, M.N.; Lyons, J.T. Strawberry As a Functional Food: An Evidence-Based Review. Crit. Rev. Food Sci. Nutr. 2014, 54, 790–806. [Google Scholar] [CrossRef]

- Jahurul, M.H.A.; Zaidul, I.; Ghafoor, K.; Al-Juhaimi, F.Y.; Nyam, K.-L.; Norulaini, N.; Sahena, F.; Omar, A.M. Mango (Mangifera indica L.) by-Products and Their Valuable Components: A Review. Food Chem. 2015, 183, 173–180. [Google Scholar] [CrossRef]

- Lauricella, M.; Emanuele, S.; Calvaruso, G.; Giuliano, M.; D’Anneo, A. Multifaceted Health Benefits of Mangifera indica L. (Mango): The Inestimable Value of Orchards Recently Planted in Sicilian Rural Areas. Nutrients 2017, 9, 525. [Google Scholar] [CrossRef]

- Lebaka, V.R.; Wee, Y.-J.; Ye, W.; Korivi, M. Nutritional Composition and Bioactive Compounds in Three Different Parts of Mango Fruit. Int. J. Environ. Res. Public Health 2021, 18, 741. [Google Scholar] [CrossRef]

- Ledeker, C.N.; Chambers, D.H.; Chambers, I.E.; Adhikari, K. Changes in the Sensory Characteristics of Mango Cultivars during the Production of Mango Purée and Sorbet. J. Food Sci. 2012, 77, S348–S355. [Google Scholar] [CrossRef]

- Janzantti, N.S.; Macoris, M.S.; Garruti, D.S.; Monteiro, M. Influence of the cultivation system in the aroma of the volatile compounds and total antioxidant activity of passion fruit. LWT Food Sci. Technol. 2012, 46, 511–518. [Google Scholar] [CrossRef]

- Zeraik, M.L.; Serteyn, D.; Dupont, G.D.; Wauters, J.N.; Tits, M.; Yariwake, J.H.; Angenot, L.; Franck, T. Evaluation of antioxidant activity of passion fruit (Passiflora edulis and Passiflora alata) extracts on stimulated neutrophils and myeloperoxidase activity assays. Food Chem. 2011, 128, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Macoris, M.S.; De Marchi, R.; Janzantti, N.S.; Monteiro, M. The influence of ripening stage and cultivation system on the total antioxidant activity and total phenolic compounds of yellow passion fruit pulp. J. Sci. Food Agric. 2012, 92, 1886–1891. [Google Scholar] [CrossRef]

- Devi Ramaiya, S.; Bujang, J.S.; Zakaria, M.H.; King, W.S.; Shaffiq Sahrir, M.A. Sugars, ascorbic acid, total phenolic content and total antioxidant activity in passion fruit (Passiflora) cultivars. J. Sci. Food Agric. 2013, 93, 1198–1205. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wei, X.; Ali, M.M.; Rizwan, H.M.; Li, B.; Li, H.; Jia, K.; Yang, X.; Ma, S.; Li, S.; et al. Changes in the Content of Organic Acids and Expression Analysis of Citric Acid Accumulation-Related Genes during Fruit Development of Yellow (Passiflora edulis f. flavicarpa) and Purple (Passiflora edulis f. edulis) Passion Fruits. Int. J. Mol. Sci. 2021, 22, 5765. [Google Scholar] [CrossRef]

- Williams, J.; D’Cunha, N.M.; Kellett, J.; Georgousopoulou, E.N.; McKune, A.J.; Mellor, D.D.; Naumovski, N. Physicochemical, antioxidant and sensory properties of Mango Sorbet containing L theanine as a potential functional food product. J. Food Sci. Technol. 2022, 59, 4833–4843. [Google Scholar] [CrossRef]

- Ekici, L. Effects of concentration methods on bioactivity and color properties of poppy (Papaver rhoeas L.) sorbet, a traditional Turkish beverage. LWT Food Sci. Technol. 2014, 56, 40–48. [Google Scholar] [CrossRef]

- Celli, G.B.; Ghanem, A.; Brooks, M.S.-L. Influence of Freezing Process and Frozen Storage on the Quality of Fruits and Fruit Products. Food Rev. Int. 2016, 32, 280–304. [Google Scholar] [CrossRef]

- Wu, R.; Frei, B.; Kennedy, J.A.; Zhao, Y. Effects of refrigerated storage and processing technologies on the bioactive com-pounds and antioxidant capacities of ‘Marion’ and ‘Evergreen’ blackberries. LWT–Food Sci. Technol. 2010, 43, 1253–1264. [Google Scholar] [CrossRef]

- Oliveira, A.; Coelho, M.; Alexandre, E.M.C.; Almeida, D.P.F.; Pintado, M. Long-term frozen storage and pasteurization effects on strawberry polyphenols content. Food Bioprocess Technol. 2015, 8, 1838–1844. [Google Scholar] [CrossRef]

- Tharanathan, R.N.; Yashoda, H.M.; Prabha, T.N. Mango (Mangifera indica L.), “The King of Fruits”—An Overview. Food Rev. Int. 2006, 22, 95–123. [Google Scholar] [CrossRef]

- Palka, A.; Skotnicka, M. The Health-Promoting and Sensory Properties of Tropical Fruit Sorbets with Inulin. Molecules 2022, 27, 4239. [Google Scholar] [CrossRef]

- Huang, D.; Boxin, O.U.; Prior, R.L. The Chemistry behind Antioxidant Capacity Assays. J. Agric. Food Chem. 2005, 53, 1841–1856. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.K.; Shibamoto, T. Antioxidant Assays for Plant and Food Components. J. Agric. Food Chem. 2009, 57, 1655–1666. [Google Scholar] [CrossRef] [PubMed]

- Cheftel, H.; Pigeaud, M.L. Estimation of Ascorbic Acid (Vitamin C) by Titration. Nature 1936, 138, 42. [Google Scholar] [CrossRef]

- Buck, R.; Rondinini, S.; Covington, A.; Baucke, F.; Brett, C.; Camões, M.; Milton, M.; Mussini, T.; Naumann, R.; Pratt, K.W.; et al. Measurement of pH. Definition, standards, and procedures. Pure Appl. Chem. 2002, 74, 2169–2200. [Google Scholar] [CrossRef] [Green Version]

- ISO/CIE 11664-4:2019; Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space. International Commission on Illumination: Vienna, Austria, 2019.

- Zhao, R.; Huang, D.; Zhang, Z.; Leng, Y. Effect of defrost heat leakage on freezer temperature rise during periodical defrost cycles in a frost-free refrigerator–freezer with an electric defrost heater. Sci. Technol. Built Environ. 2017, 23, 211–217. [Google Scholar] [CrossRef]

- Motyl, W.; Dziugan, P.; Motyl, I.; Jóźwiak, A.; Nowak, S. Functional ice cream with a “clean label” Biotechnol. Food Sci. 2019, 83, 121–134. [Google Scholar] [CrossRef]

- Poiana, M.-A.; Moigradean, D.; Raba, D.; Alda, L.-M. The effect of long-term frozen storage on the nutraceutical compounds, antioxidant properties and color indices of different kinds of berries. J. Food Agric. Environ. 2010, 8, 54–58. [Google Scholar]

- King, E.S.; Noll, A.; Glenn, S.; Bolling, B.W. Refrigerated and frozen storage impact aronia berry quality. Food Prod. Process. Nutr. 2022, 4, 3. [Google Scholar] [CrossRef]

- Mullen, W.; Stewart, A.J.; Lean, M.E.; Gardner, P.; Duthie, G.G.; Crozier, A. Effect of freezing and storage on the phenolics, ellagitannins, flavonoids, and antioxidant capacity of red raspberries. J. Agric. Food Chem. 2002, 50, 5197–5201. [Google Scholar] [CrossRef] [PubMed]

- Kiani, H.; Sun, D.-W. Water crystallization and its importance to freezing of foods: A review. Trends Food Sci. Technol. 2011, 22, 407–426. [Google Scholar] [CrossRef]

- Palka, A.; Palich, P. Changes in water content and its influence on sensory features of ice cream during storage. Acta Agrophysica 2009, 14, 701–713. (In Polish) [Google Scholar]

- Regand, A.; Goff, H.D. Ice Recrystallization Inhibition in Ice Cream as Affected by Ice Structuring Proteins from Winter Wheat Grass. J. Dairy Sci. 2006, 89, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Varanyanond, W.; Naohara, J.; Wongkrajang, K.; Manabe, M. Changes in Pectin Content and Average Molecular Weight of Pectin during Maturation of the Mango “Kaew”. Food Sci. Technol. Res. 1999, 5, 362–364. [Google Scholar] [CrossRef] [Green Version]

| No. of Product | Fruits | Composition |

|---|---|---|

| 1 | Blueberry | Water, blueberries (25%), sugar, glucose, glucose syrup, concentrated lemon juice, stabilizers (guar gum, locust bean gum) |

| 3 | Strawberry | Water, strawberries (25%), sugar, glucose, glucose syrup, concentrated lemon juice, stabilizers (guar gum, locust bean gum) |

| 5 | Raspberry | Water, raspberries (25%), sugar, glucose, glucose syrup, concentrated lemon juice, stabilizers (guar gum, locust bean gum) |

| 7 | Mango + Passion fruit | Water, sugar, mango puree (13%), passion fruit juice from concentrated passion fruit juice (12%) (water, concentrated passion fruit juice), glucose syrup, stabilizers (locust bean gum, guar gum), emulsifier (mono- and diglycerides of fatty acids, thickeners (pectin)) |

| No. of Product | Fruits | Amount of Fruits [%] | Water [%] | Sucrose [%] |

|---|---|---|---|---|

| 2 | Blueberry | 50.0 | 40.0 | 10.0 |

| 4 | Strawberry | 50.0 | 40.0 | 10.0 |

| 6 | Raspberry | 50.0 | 40.0 | 10.0 |

| 8 | Mango + Passion fruit | 35.0 + 15.0 | 40.0 | 10.0 |

| Score | Organoleptic Quality | ||||

|---|---|---|---|---|---|

| Overall Preference | Color | Odor | Taste | Consistency | |

| 1 | Dislike | Dark | Dislike | Very poor | Very poor |

| 2 | Neither like nor dislike | Slightly dark | Neither like nor dislike | Poor | Poor |

| 3 | Like slightly | Moderate | Like slightly | Fair | Fair |

| 4 | Like moderately | Pale | Like moderately | Good | Good |

| 5 | Like very much | Very pale | Like very much | Very good | Very good |

| Type of Sorbet | Overall Preference | Color | Odor | Taste | Consistency |

|---|---|---|---|---|---|

| Blueberry S | 3.86 ± 0.864 d | 4.21 ± 0.579 a | 3.57 ± 1.222 a | 3.50 ± 1.160 a | 4.00 ± 1.038 a |

| Blueberry C | 4.64 ± 0.497 a | 4.14 ± 0.535 a | 4.14 ± 0.663 b | 4.29 ± 0.611 b | 4.43 ± 0.756 b |

| Strawberry S | 4.50 ± 0.519 a | 4.50 ± 0.519 b | 4.57 ± 0.756 c | 4.57 ± 0.756 c,d | 4.36 ± 0.745 b |

| Strawberry C | 4.93 ± 0.267 c | 4.50 ± 0.519 b | 4.64 ± 0.497 c | 4.79 ± 0.426 d | 4.71 ± 0.469 d |

| Raspberry S | 4.57 ± 0.514 a | 4.50 ± 0.519 b | 4.57 ± 0.514 c | 4.86 ± 0.363 d | 4.64 ± 0.497 d |

| Raspberry C | 4.79 ± 0.426 b | 4.50 ± 0.519 b | 4.71 ± 0.469 c | 4.64 ± 0.497 c,d | 4.57 ± 0.514 c |

| Passion fruit-mango S | 4.71 ± 0.469 b | 4.64 ± 0.497 b | 4.71 ± 0.469 c | 5.00 ± 0.000 d | 4.86 ± 0.363 e |

| Passion fruit-mango C | 4.86 ± 0.363 b,c | 4.50 ± 0.519 b | 4.79 ± 0.426 c | 5.00 ± 0.000 d | 4.86 ± 0.363 e |

| ΔE | |||

|---|---|---|---|

| Difference between 0 and 6 months | Difference between S and C after 0 months | Difference between S and C after 6 months | |

| Blueberry S | 14.9 | 5.0 | 6.5 |

| Blueberry C | 15.0 | ||

| Strawberry S | 5.5 | 8.0 | 2.8 |

| Strawberry C | 14.8 | ||

| Raspberry S | 5.5 | 4.2 | 8.3 |

| Raspberry C | 0.9 | ||

| Passion fruit-mango S | 3.3 | 1.4 | 1.3 |

| Passion fruit-mango C | 4.4 | ||

| Type of Sorbet | Overrun | Melting Resistance | Color Parameters | Antiradical Activity (AA) [%] | Total Polyphenols (TP) [mg GAE/g] | Vitamin C Content [mg/100 g] | pH | ||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | |||||||

| Blueberry S | 60.71 ± 0.576 d | 25.41 ± 1.358 c | 28.39 ± 0.504 a | 9.53 ± 0.280 a | 3.28 ± 0.329 a | 64.97 ± 0.503 c | 2.37 ± 0.177 a | 14.48 ± 0.334 c | 3.45 ± 0.095 c |

| Blueberry C | 19.32 ± 0.310 a | 20.94 ± 0.254 a | 25.63 ± 0.138 a | 13.65 ± 0.377 b | 3.40 ± 0.181 a | 93.70 ± 0.200 d | 6.46 ± 0.162 c | 51.72 ± 0.010 e | 3.13 ± 0.021 b |

| Strawberry S | 55.06 ± 0.705 c | 44.06 ± 0.949 d | 40.99 ± 0.200 b | 33.46 ± 0.410 d | 22.75 ± 0.115 c | 47.63 ± 1.115 b | 2.46 ± 0.459 a | 17.86 ± 0.092 c | 3.61 ± 0.012 c |

| Strawberry C | 21.99 ± 0.350 b | 16.87 ± 0.433 b | 44.43 ± 0.362 b | 28.57 ± 0.232 c | 17.45 ± 0.280 b | 77.87 ± 0.945 e | 5.21 ± 0.159 d | 42.82 ± 0.012 d | 3.86 ± 0.012 d |

| Raspberry S | 66.71 ± 0.837 d | 43.27 ± 1.513 d | 39.70 ± 0.266 b | 37.50 ± 0.410 e | 17.70 ± 0.389 b | 57.63 ± 1.115 c | 3.19 ± 0.254 b | 7.48 ± 0.085 a | 2.88 ± 0.040 a |

| Raspberry C | 19.52 ± 0.469 a | 15.33 ± 0.577 b | 41.54 ± 0.332 b | 33.74 ± 0.236 d | 16.71 ± 0.059 b | 92.37 ± 0.252 d | 7.55 ± 0.251 e | 16.07 ± 0.010 c | 2.88 ± 0.015 a |

| Passion fruit-mango S | 71.24 ± 0.350 e | 32.89 ± 0.912 c,d | 53.31 ± 0.434 c | 16.51 ± 0.416 b | 30.31 ± 0.401 d | 32.03 ± 0.603 f | 3.28 ± 0.180 b | 7.27 ± 0.167 a | 3.36 ± 0.081 c |

| Passion fruit-mango C | 24.99 ± 0.837 b | 20.80 ± 0.254 a | 54.46 ± 0.516 c | 15.69 ± 0.104 b | 30.18 ± 0.080 d | 70.23 ± 0.306 a | 6.46 ± 0.162 c | 9.24 ± 0.127 b | 3.42 ± 0.023 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palka, A.; Wilczyńska, A. Storage Quality Changes in Craft and Industrial Blueberry, Strawberry, Raspberry and Passion Fruit-Mango Sorbets. Foods 2023, 12, 2733. https://doi.org/10.3390/foods12142733

Palka A, Wilczyńska A. Storage Quality Changes in Craft and Industrial Blueberry, Strawberry, Raspberry and Passion Fruit-Mango Sorbets. Foods. 2023; 12(14):2733. https://doi.org/10.3390/foods12142733

Chicago/Turabian StylePalka, Agnieszka, and Aleksandra Wilczyńska. 2023. "Storage Quality Changes in Craft and Industrial Blueberry, Strawberry, Raspberry and Passion Fruit-Mango Sorbets" Foods 12, no. 14: 2733. https://doi.org/10.3390/foods12142733