Valorisation of Buckwheat By-Product as a Health-Promoting Ingredient Rich in Fibre for the Formulation of Gluten-Free Bread

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Dough Formulation and Breadmaking Procedure

2.3. Rheological Properties of Doughs

2.4. Proximal Composition of Bread Samples

2.5. Total Phenol Content (TPC) and Total Antioxidant Capacity (TAC)

2.6. Bread Microstructure

2.7. Bread Quality Evaluation

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Rheological Properties of Doughs

3.2. Proximal Composition of Bread Samples

3.3. Total Phenol Content (TPC) and Total Antioxidant Capacity (TAC)

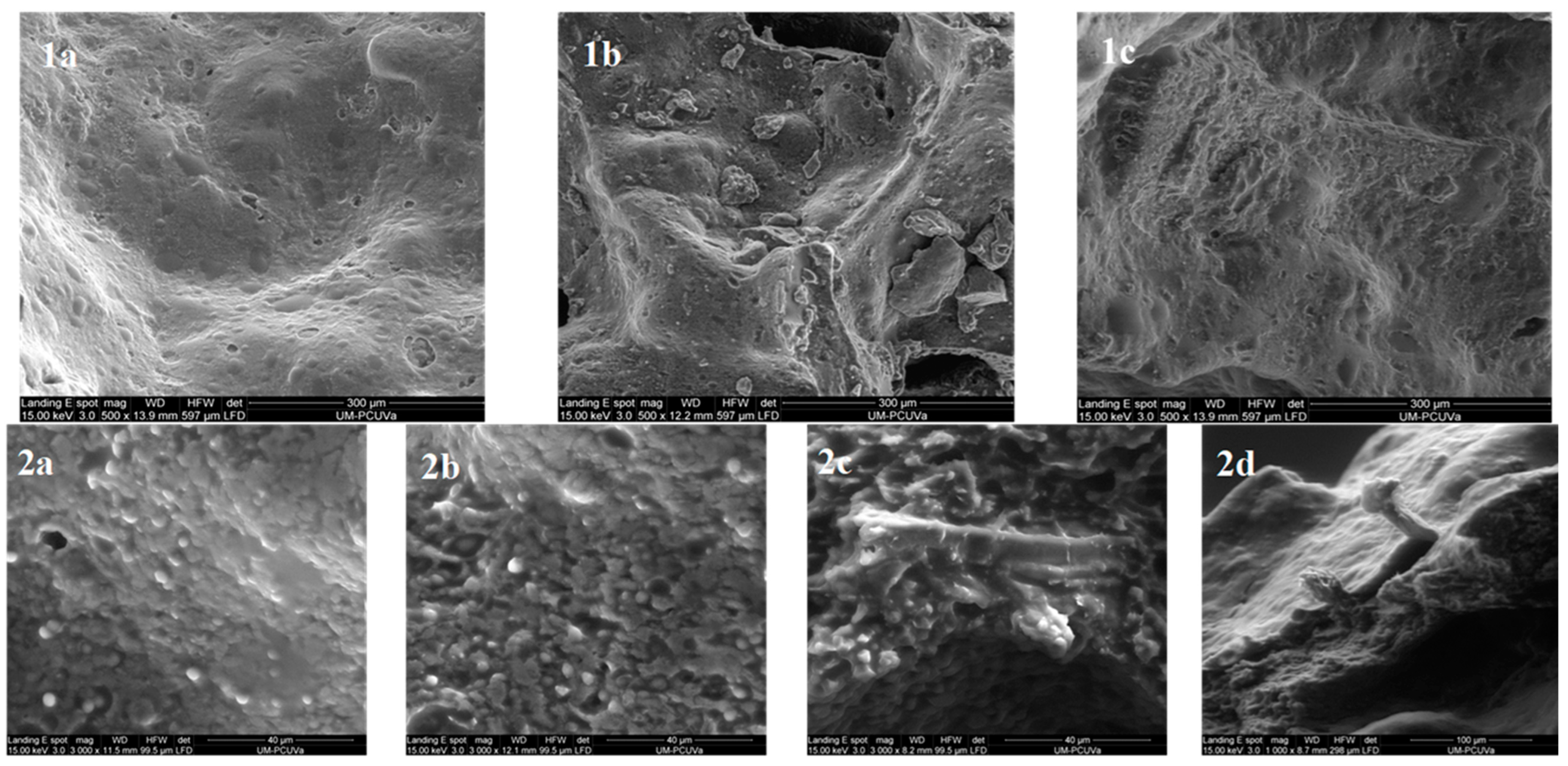

3.4. Bread Microstructure

3.5. Bread Quality Evaluation

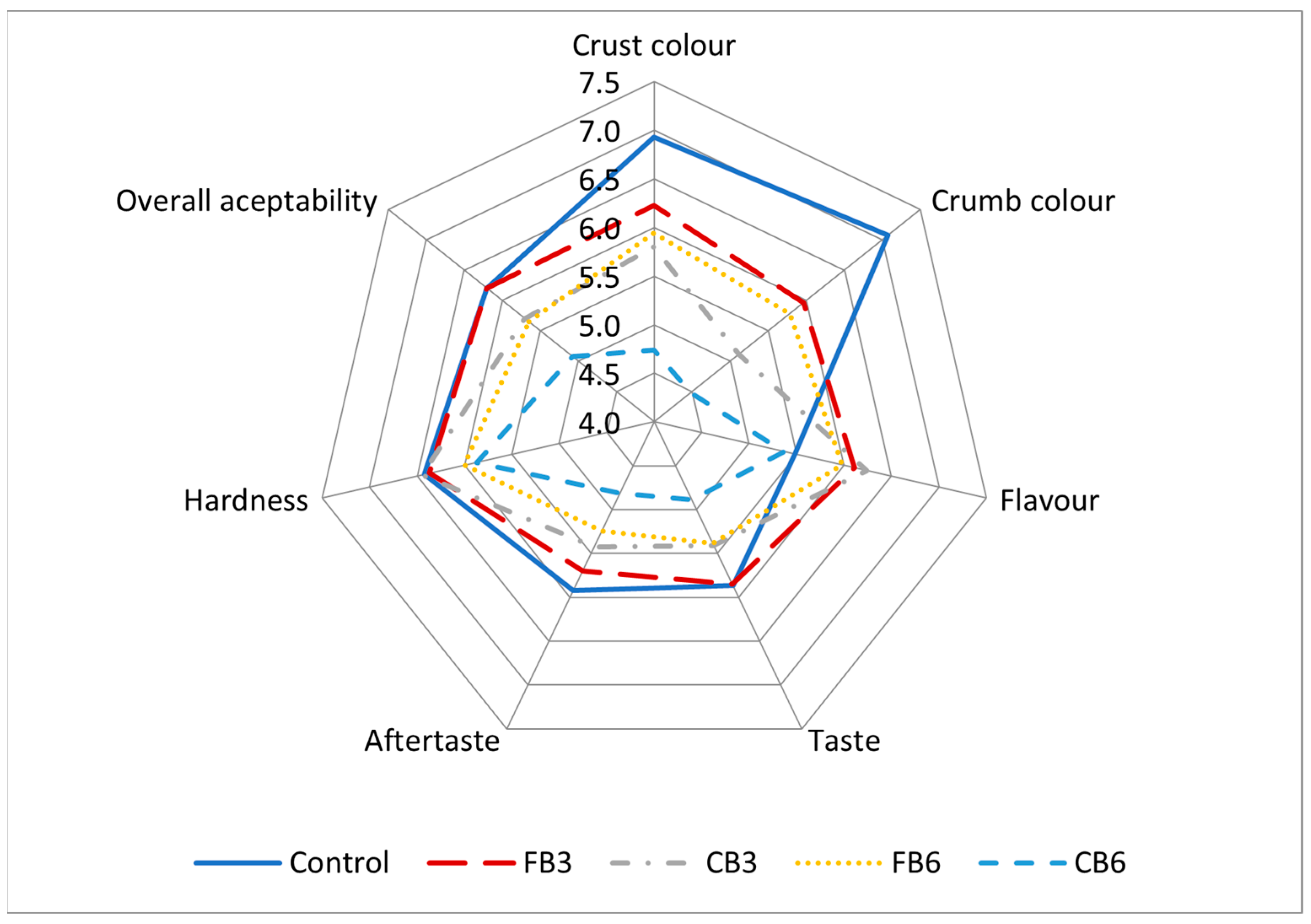

3.6. Sensory Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dahl, W.J.; Stewart, M.L. Position of the Academy of Nutrition and Dietetics: Health Implications of Dietary Fiber. J. Acad. Nutr. Diet. 2015, 115, 1861–1870. [Google Scholar] [CrossRef] [PubMed]

- Stephen, A.M.; Champ, M.M.; Cloran, S.J.; Fleith, M.; Van Lieshout, L.; Mejborn, H.; Burley, V.J. Dietary fibre in Europe: Current state of knowledge on definitions, sources, recommendations, intakes and relationships to health. Nutr. Res. Rev. 2017, 30, 149–190. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- EFSA Panel on Dietetic Products, Nutrition, and Allergies (NDA). Scientific Opinion on Dietary Reference Values for carbohydrates and dietary fibre. EFSA J. 2010, 8, 1462. [Google Scholar] [CrossRef] [Green Version]

- McRorie, J.W.; McKeown, N.M. Understanding the Physics of Functional Fibers in the Gastrointestinal Tract: An Evidence-Based Approach to Resolving Enduring Misconceptions about Insoluble and Soluble Fiber. J. Acad. Nutr. Diet. 2017, 117, 251–264. [Google Scholar] [CrossRef] [Green Version]

- Barber, T.M.; Kabisch, S.; Pfei, A.F.H.; Weickert, M.O. The Health Benefits of Dietary Fibre. Nutrients 2020, 12, 3209. [Google Scholar] [CrossRef]

- Cardo, A.; Churruca, I.; Lasa, A.; Navarro, V.; Vázquez-Polo, M.; Perez-Junkera, G.; Larretxi, I. Nutritional Imbalances in Adult Celiac Patients Following a Gluten-Free Diet. Nutrients 2021, 13, 2877. [Google Scholar] [CrossRef]

- Babio, N.; Alcázar, M.; Castillejo, G.; Recasens, M.; Martínez-Cerezo, F.; Gutiérrez-Pensado, V.; Masip, G.; Vaqué, C.; Vila-Martí, A.; Torres-Moreno, M.; et al. Patients with celiac disease reported higher consumption of added sugar and total fat than healthy individuals. J. Pediatr. Gastroenterol. Nutr. 2017, 64, 63–69. [Google Scholar] [CrossRef]

- Torres, M.D.; Arufe, S.; Chenlo, F.; Moreira, R. Coeliacs cannot live by gluten-free bread alone—Every once in awhile they need antioxidants. Int. J. Food Sci. Technol. 2016, 52, 81–90. [Google Scholar] [CrossRef]

- Mobley, A.R.; Jones, J.M.; Rodriguez, J.; Slavin, J.; Zelman, K.M. Identifying Practical Solutions to Meet America’s Fiber Needs: Proceedings from the Food & Fiber Summit. Nutrients 2014, 6, 2540–2551. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.H. Whole grain phytochemicals and health. J. Cereal Sci. 2007, 46, 207–219. [Google Scholar] [CrossRef]

- Rodríguez, R.; Jimenez, A.; Fernández-Bolaños, J.; Guillén, R.; Heredia, A. Dietary fibre from vegetable products as source of functional ingredients. Trends Food Sci. Technol. 2006, 17, 3–15. [Google Scholar] [CrossRef]

- Gómez, M.; Ronda, F.; Blanco, C.A.; Caballero, P.A.; Apesteguía, A. Effect of dietary fibre on dough rheology and bread quality. Eur. Food Res. Technol. 2003, 216, 51–56. [Google Scholar] [CrossRef]

- Anil, M. Using of hazelnut testa as a source of dietary fiber in breadmaking. J. Food Eng. 2007, 80, 61–67. [Google Scholar] [CrossRef]

- Pérez-Quirce, S.; Collar, C.; Ronda, F. Significance of healthy viscous dietary fibres on the performance of gluten-free rice-based formulated breads. Int. J. Food Sci. Technol. 2014, 49, 1375–1382. [Google Scholar] [CrossRef] [Green Version]

- Chatterjee, B.; Modi, K.; Patel, T. Food as vector for nutraceutical ingredients. Int. J. Med. Res. Health Sci. 2016, 5, 92. [Google Scholar] [CrossRef]

- Li, S.Q.; Howard Zhang, Q. Advances in the development of functional foods from buckwheat. Crit. Rev. Food Sci. Nutr. 2001, 41, 451–464. [Google Scholar] [CrossRef]

- Steadman, K.J.; Burgoon, M.S.; Lewis, B.A.; Edwardson, S.E.; Obendorf, R.L. Buckwheat seed milling fractions: Description, macronutrient composition and dietary fibre. J. Cereal Sci. 2001, 33, 271–278. [Google Scholar] [CrossRef]

- Heś, M.; Górecka, D.; Dziedzic, K. Antioxidant properties of extracts from buckwheat by-products. Acta Sci. Pol. Technol. Aliment. 2012, 11, 167–174. [Google Scholar]

- Dziedzic, K.; Górecka, D.; Kucharska, M.; Przybylska, B. Influence of technological process during buckwheat groats production on dietary fibre content and sorption of bile acids. Food Res. Int. 2012, 47, 279–283. [Google Scholar] [CrossRef]

- Taranenko, L.K.; Yatsyshen, O.L.; Taranenko, P.P.; Taranenko, T.P. The Unique Value of Buckwheat as a Most Important Traditional Cereal Crop in Ukraine. In Molecular Breeding and Nutritional Aspects of Buckwheat, 1st ed.; Zhou, M., Kreft, I., Woo, S., Chrungoo, N., Wieslander, G., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 81–85. ISBN 9780128036921. [Google Scholar]

- Sharma, S.K.; Bansal, S.; Mangal, M.; Dixit, A.K.; Gupta, R.K.; Mangal, A.K. Utilization of food processing by-products as dietary, functional, and novel fiber: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1647–1661. [Google Scholar] [CrossRef] [PubMed]

- Nobili, C.; De Acutis, A.; Reverberi, M.; Bello, C.; Leone, G.P.; Palumbo, D.; Natella, F.; Procacci, S.; Zjalic, S.; Brunori, A. Buckwheat Hull Extracts Inhibit Aspergillus flavus Growth and AFB 1 Biosynthesis. Front. Microbiol. 2019, 10, 1997. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, L.; Li, Y.; Guo, Z.; Wang, H.; Wang, A.; Li, Z.; Chen, Y.; Qiu, J. Effect of buckwheat hull particle-size on bread staling quality. Food Chem. 2023, 405, 134851. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Du, B.; Li, R.; Li, J. Effect of micronization technology on physicochemical and antioxidant properties of dietary fiber from buckwheat hulls. Biocatal. Agric. Biotechnol. 2014, 3, 30–34. [Google Scholar] [CrossRef]

- Villanueva, M.; Harasym, J.; María, J.; Ronda, F. Rice flour physically modified by microwave radiation improves viscoelastic behavior of doughs and its bread-making performance. Food Hydrocoll. 2019, 90, 472–481. [Google Scholar] [CrossRef] [Green Version]

- AOAC. Methods 990.03, 2003.05, 985.29 & 923.03. In Official Methods of Analysis of AOAC International, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Gutiérrez, Á.L.; Rico, D.; Ronda, F.; Martín-Diana, A.B.; Caballero, P.A. Development of a gluten-free whole grain flour by combining soaking and high hydrostatic pressure treatments for enhancing functional, nutritional and bioactive properties. J. Cereal Sci. 2022, 105, 103458. [Google Scholar] [CrossRef]

- Rico, D.; Villaverde, A.; Martinez-Villaluenga, C.; Gutierrez, A.L.; Caballero, P.A.; Ronda, F.; Peñas, E.; Frias, J.; Diana, A.B.M. Application of autoclave treatment for development of a natural wheat bran antioxidant ingredient. Foods 2020, 9, 781. [Google Scholar] [CrossRef]

- Rico, D.; Cano, A.B.; Martín-diana, A.B. Pulse-Cereal Blend Extrusion for Improving the Antioxidant Properties of a Pulse-Cereal Blend Extrusion for Improving the Antioxidant Properties of a Gluten-Free Flour. Molecules 2021, 26, 5578. [Google Scholar] [CrossRef]

- Villanueva, M.; Abebe, W.; Pérez-Quirce, S.; Ronda, F. Impact of the Variety of Tef [Eragrostis tef (Zucc.) Trotter] on Physical, Sensorial and Nutritional Properties of Gluten-Free Breads. Foods 2022, 11, 1017. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Bustos, M.C.; Vignola, M.B.; Paesani, C.; Salinas, C.N.; Pérez, G.T. A study on fibre addition to gluten free bread: Its effects on bread quality and in vitro digestibility. J. Food Sci. Technol. 2017, 54, 244–252. [Google Scholar] [CrossRef] [Green Version]

- Sabanis, D.; Lebesi, D.; Tzia, C. Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT—Food Sci. Technol. 2009, 42, 1380–1389. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Villanueva, M. Rheological Properties of Gluten-Free Bread Doughs: Relationship With Bread Quality. In Advances in Food Rheology and Its Applications; Ahmed, J., Ptaszek, P., Basu, S., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 297–334. ISBN 9780081004319. [Google Scholar]

- Wang, C.; Yang, Z.; Xing, J.; Guo, X.; Zhu, K. Food Hydrocolloids Effects of insoluble dietary fiber and ferulic acid on the rheological properties of dough. Food Hydrocoll. 2021, 121, 107008. [Google Scholar] [CrossRef]

- Phimolsiripol, Y.; Mukprasirt, A.; Schoenlechner, R. Quality improvement of rice-based gluten-free bread using different dietary fibre fractions of rice bran. J. Cereal Sci. 2012, 56, 389–395. [Google Scholar] [CrossRef]

- Li, F.-H.; Yuan, Y.; Yang, X.-L.; Tao, S.-Y.; Ming, J. Phenolic Profiles and Antioxidant Activity of Buckwheat (Fagopyrum esculentum Möench and Fagopyrum tartaricum L. Gaerth) Hulls, Brans and Flours. J. Integr. Agric. 2013, 12, 1684–1693. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Zhu, Y.; Liu, Q.; Bao, J.; Liu, Q. Identification and quantification of polyphenols in hull, bran and endosperm of common buckwheat (Fagopyrum esculentum) seeds. J. Funct. Foods 2017, 38, 363–369. [Google Scholar] [CrossRef]

- Sedej, I.; Sakač, M.; Mandić, A.; Mišan, A.; Tumbas, V.; Čanadanović-Brunet, J. Buckwheat (Fagopyrum esculentum Moench) Grain and Fractions: Antioxidant Compounds and Activities. J. Food Sci. 2012, 77, C954–C959. [Google Scholar] [CrossRef] [PubMed]

- Sakac, M.; Torbica, A.; Sedej, I.; Hadnadev, M. Influence of breadmaking on antioxidant capacity of gluten free breads based on rice and buckwheat flours. Food Res. Int. 2011, 44, 2806–2813. [Google Scholar] [CrossRef]

- Żmijewski, M.; Sokół-Łętowska, A.; Pejcz, E.; Orzeł, D. Antioxidant activity of rye bread enriched with milled buckwheat groats fractions. Rocz. Państwowego Zakładu Hig. 2015, 66, 115–121. [Google Scholar]

- Hromádková, Z.; Stavová, A.; Ebringerová, A.; Hirsch, J.Á.N. Effect of buckwheat hull hemicelluloses addition on the bread-making quality of wheat flour. J. Food Nutr. Res. 2007, 46, 158–166. [Google Scholar]

- Martínez, M.M.; Díaz, Á.; Gómez, M. Effect of different microstructural features of soluble and insoluble fibres on gluten-free dough rheology and bread-making. J. Food Eng. 2014, 142, 49–56. [Google Scholar] [CrossRef]

- Wronkowska, M.; Haros, M.; Soral-Śmietana, M. Effect of Starch Substitution by Buckwheat Flour on Gluten-Free Bread Quality. Food Bioprocess Technol. 2013, 6, 1820–1827. [Google Scholar] [CrossRef] [Green Version]

- Zanoletti, M.; Marti, A.; Marengo, M.; Iametti, S.; Pagani, M.A.; Renzetti, S. Understanding the influence of buckwheat bran on wheat dough baking performance: Mechanistic insights from molecular and material science approaches. Food Res. Int. 2017, 102, 728–737. [Google Scholar] [CrossRef] [PubMed]

- Ktenioudaki, A.; Gallagher, E. Recent advances in the development of high-fibre baked products. Trends Food Sci. Technol. 2012, 28, 4–14. [Google Scholar] [CrossRef]

- Torbica, A.; Hadnadev, M.; Dapčević, T. Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocoll. 2010, 24, 626–632. [Google Scholar] [CrossRef]

| Sample | G′1 (Pa) | a | G″1 (Pa) | b | (tan δ) 1 | c | G*1 (Pa) | Crosspoint (G′ = G″) (Pa) | τmax (Pa) |

|---|---|---|---|---|---|---|---|---|---|

| C | 712 a | 0.326 d | 400 a | 0.384 c | 0.561 d | 0.058 a | 817 a | 24 a | 1.67 a |

| FB3 | 1480 c | 0.274 b | 682 c | 0.364 b | 0.462 b | 0.090 b | 1629 c | 42 c | 2.07 a |

| CB3 | 1027 b | 0.299 c | 509 b | 0.384 c | 0.495 c | 0.086 b | 1147 b | 35 b | 1.85 a |

| FB6 | 3738 e | 0.211 a | 1385 e | 0.307 a | 0.37 a | 0.096 b | 3985 e | 83 e | 3.25 b |

| CB6 | 1973 d | 0.272 b | 896 d | 0.359 b | 0.454 b | 0.087 b | 2166 d | 50 d | 2.19 ab |

| SE | 76 | 0.003 | 28 | 0.004 | 0.004 | 0.003 | 57 | 1 | 0.86 |

| Analysis of variance and significance of factors (p-values) | |||||||||

| BH particle size | ** | ** | ** | ** | ** | ns | ** | ** | ns |

| BH addition level | ** | ** | ** | ** | ** | ns | ** | ** | ns |

| Particle size × Addition level | ** | ** | ** | ** | ** | ns | ** | ** | ns |

| Sample | Carbohydrates (dw) | T.D.F. (dw) | Protein (dw) | Ash (dw) | Fats (dw) |

|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | |

| C | 85 b | 2.8 a | 9 a | 1.9 a | 4.4 a |

| FB3 | 84 ab | 8.0 b | 9 a | 1.9 a | 5.7 a |

| CB3 | 84 ab | 8.5 b | 9 a | 1.9 a | 5.7 a |

| FB6 | 83 ab | 13.1 c | 11 a | 1.9 a | 4.7 a |

| CB6 | 81 a | 12.5 c | 13 a | 2.1 a | 4.5 a |

| SE | 1 | 0.4 | 1 | 0.1 | 0.5 |

| Analysis of variance and significance of factors (p-values) | |||||

| BH particle size | ns | ns | ns | ns | ns |

| BH addition level | ns | ** | ns | ns | ns |

| Particle size × Addition level | ns | ns | ns | ns | ns |

| Sample | TPC (mg GAE/ 100 g dw) | DPPH (mg TE/ 100 g dw) | ABTS (mg TE/ 100 g dw) | ORAC (mg TE/ 100 g dw) | FRAP (mmol Fe2+/ 100 g dw) | Q-DPPH (mg TE/ 100 g dw) | Q-ABTS (mg TE/ 100 g dw) |

|---|---|---|---|---|---|---|---|

| C | n.d. | 19 a | 162 a | 78 a | 13.3 a | 2 a | 287 a |

| FB3 | 0.6 a | 40 b | 191 ab | 135 b | 13.5 ab | 24 bc | 966 cd |

| CB3 | 0.3 a | 38 b | 235 bc | 135 b | 13.8 b | 17 b | 878 bc |

| FB6 | 2.1 b | 54 c | 279 c | 290 d | 15.1 d | 52 d | 1058 d |

| CB6 | 1.8 b | 60 c | 261 c | 222 c | 14.6 c | 30 c | 799 b |

| SE | 0.3 | 3 | 20 | 4 | 0.2 | 3 | 43 |

| Analysis of variance and significance of factors (p-values) | |||||||

| BH particle size | ns | ns | ns | ** | ns | ** | ** |

| BH addition level | ** | ** | * | ** | ** | ** | ns |

| Particle size × Addition level | ns | ns | ns | ** | ** | * | ns |

| Sample | Volume (mL) | Specific Volume (mL/g) | Weight Loss (%) | Hardness | Hardness (Day 7) | Chewiness | Resilience | Cohesiveness | Springiness |

|---|---|---|---|---|---|---|---|---|---|

| C | 457 c | 3.0 b | 22.8 d | 1.8 a | 4.63 ab | 0.7 ab | 0.19 b | 0.45 bc | 0.85 a |

| FB3 | 470 c | 2.8 b | 17.1 a | 2.2 a | 3.88 a | 0.8 ab | 0.21 c | 0.47 c | 0.80 a |

| CB3 | 396 a | 2.5 a | 19.1 bc | 3.2 b | 6.81 d | 1.1 b | 0.17 a | 0.41 a | 0.81 a |

| FB6 | 460 c | 2.8 b | 18.6 b | 3.0 b | 5.65 bc | 1.1 b | 0.18 ab | 0.43 ab | 0.82 a |

| CB6 | 418 b | 2.6 a | 19.8 b | 3.1 b | 6.53 cd | 1.1 b | 0.17 ab | 0.41 a | 0.81 a |

| SE | 6 | 0.2 | 1.8 | 0.7 | 0.31 | 0.2 | 0.02 | 0.03 | 0.04 |

| Analysis of variance and significance of factors (p-values) | |||||||||

| BH particle size | ** | ** | * | ns | ** | ns | ** | ** | ns |

| BH addition level | ns | ns | ** | ** | ** | ** | ns | * | * |

| Particle size × Addition level | * | ns | ns | ns | ** | ns | ** | * | ns |

| Sample | Mean Cell Area | Crumb Grain Uniformity | Cell Density | Void Fraction |

|---|---|---|---|---|

| (mm2) | (cells/cm2) | (%) | ||

| C | 0.30 b | 7 a | 44 a | 13.7 d |

| FB3 | 0.19 a | 19 ab | 52 c | 10.0 b |

| CB3 | 0.17 a | 35 b | 48 b | 8.3 a |

| FB6 | 0.29 b | 8 a | 50 b | 15.7 e |

| CB6 | 0.20 a | 14 a | 56 d | 11.6 c |

| SE | 0.01 | 5 | 1 | 0.4 |

| Analysis of variance and significance of factors (p-values) | ||||

| BH particle size | ** | ns | ns | ** |

| BH addition level | ** | * | ** | ** |

| Particle size × Addition level | ** | ns | ** | ** |

| Sample | Crust Colour | Crumb Colour | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | C* | h | ΔE | L* | a* | b* | C* | h | ΔE | |

| C | 61 c | 13.3 e | 23 d | 27 e | 60 e | 74 e | −0.5 a | 5.4 b | 5 a | 95 c | ||

| FB3 | 49 b | 10.8 d | 11 c | 15 d | 45 c | 17.0 a | 50 c | 8.3 d | 10 d | 13 d | 50 b | 26 b |

| CB3 | 49 b | 7.8 bc | 10 b | 12 c | 51 d | 18.9 b | 53 d | 4.5 b | 5.8 b | 7 b | 52 b | 22 a |

| FB6 | 44. a | 9.8 c | 5 a | 11 b | 26 a | 24.7 c | 42 a | 8.9 e | 6.6 c | 11 c | 35 a | 33 d |

| CB6 | 45 a | 7.1 a | 5 a | 8 a | 33 b | 25.3 c | 45 b | 5.8 c | 4.0 a | 7 b | 37 a | 29 c |

| SE | 1 | 0.2 | 1 | 1 | 1 | 0.3 | 1 | 0.1 | 0.3 | 1 | 2 | 1 |

| Analysis of variance and significance of factors (p-values) | ||||||||||||

| BH particle size | ns | ** | * | ** | ** | * | ** | ** | ** | ** | ns | ** |

| BH addition level | ** | ** | ** | ** | ** | ** | ** | ** | ** | ** | ** | ** |

| Particle size × Addition level | ns | ns | * | ns | ns | ns | ns | ** | ** | ** | ns | ns |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutiérrez, Á.L.; Villanueva, M.; Rico, D.; Harasym, J.; Ronda, F.; Martín-Diana, A.B.; Caballero, P.A. Valorisation of Buckwheat By-Product as a Health-Promoting Ingredient Rich in Fibre for the Formulation of Gluten-Free Bread. Foods 2023, 12, 2781. https://doi.org/10.3390/foods12142781

Gutiérrez ÁL, Villanueva M, Rico D, Harasym J, Ronda F, Martín-Diana AB, Caballero PA. Valorisation of Buckwheat By-Product as a Health-Promoting Ingredient Rich in Fibre for the Formulation of Gluten-Free Bread. Foods. 2023; 12(14):2781. https://doi.org/10.3390/foods12142781

Chicago/Turabian StyleGutiérrez, Ángel L., Marina Villanueva, Daniel Rico, Joanna Harasym, Felicidad Ronda, Ana Belén Martín-Diana, and Pedro A. Caballero. 2023. "Valorisation of Buckwheat By-Product as a Health-Promoting Ingredient Rich in Fibre for the Formulation of Gluten-Free Bread" Foods 12, no. 14: 2781. https://doi.org/10.3390/foods12142781

APA StyleGutiérrez, Á. L., Villanueva, M., Rico, D., Harasym, J., Ronda, F., Martín-Diana, A. B., & Caballero, P. A. (2023). Valorisation of Buckwheat By-Product as a Health-Promoting Ingredient Rich in Fibre for the Formulation of Gluten-Free Bread. Foods, 12(14), 2781. https://doi.org/10.3390/foods12142781