Techno-Functional and In Vitro Digestibility Properties of Gluten-Free Cookies Made from Raw, Pre-Cooked, and Germinated Chickpea Flours

Abstract

:1. Introduction

2. Materials and Methods

2.1. Flours

2.2. Flour Analyses

2.2.1. Proximate Analysis of Flours

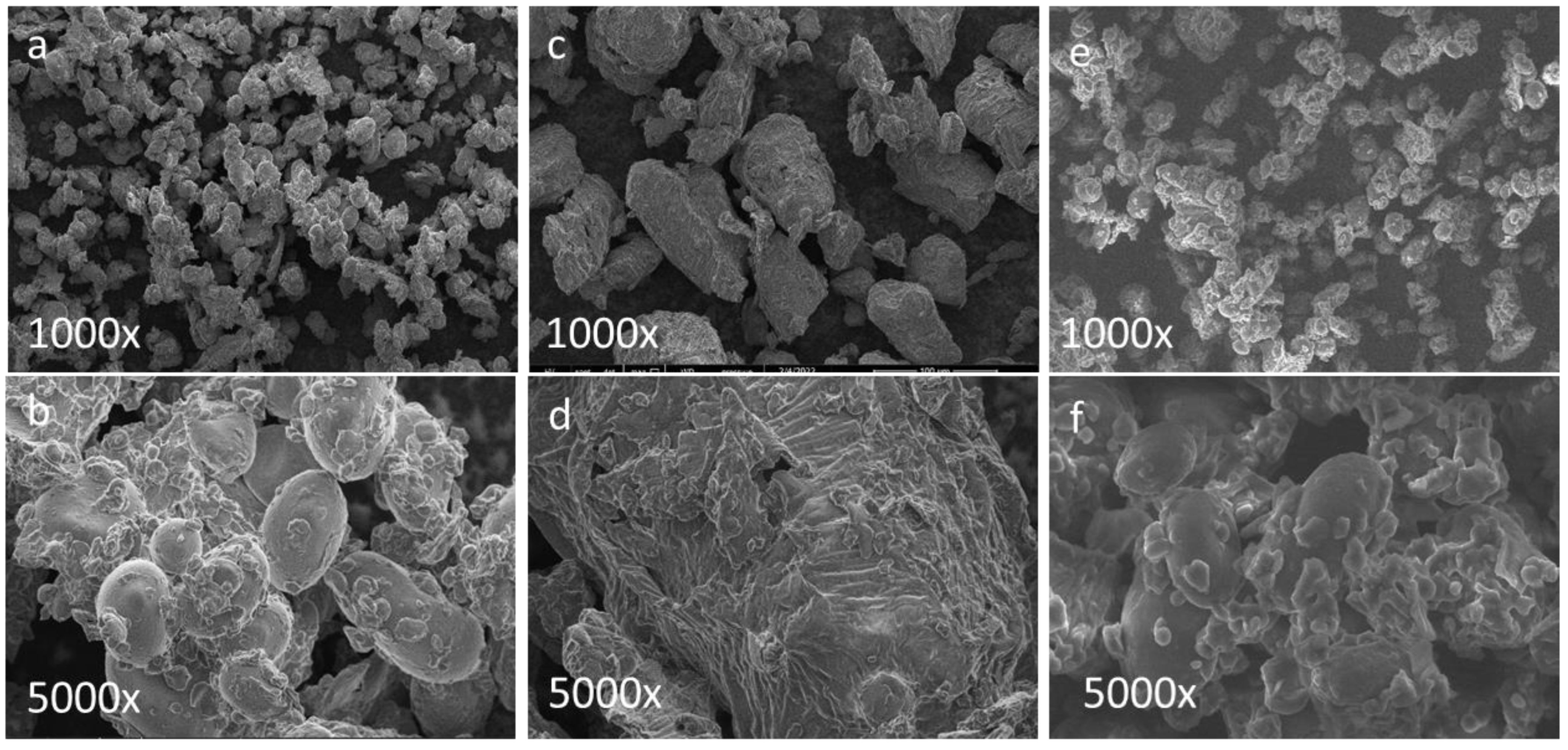

2.2.2. Physical Properties of Flours

2.3. Cookie Formulations

2.4. Dough Analyses

2.4.1. Rheological Analysis of Doughs

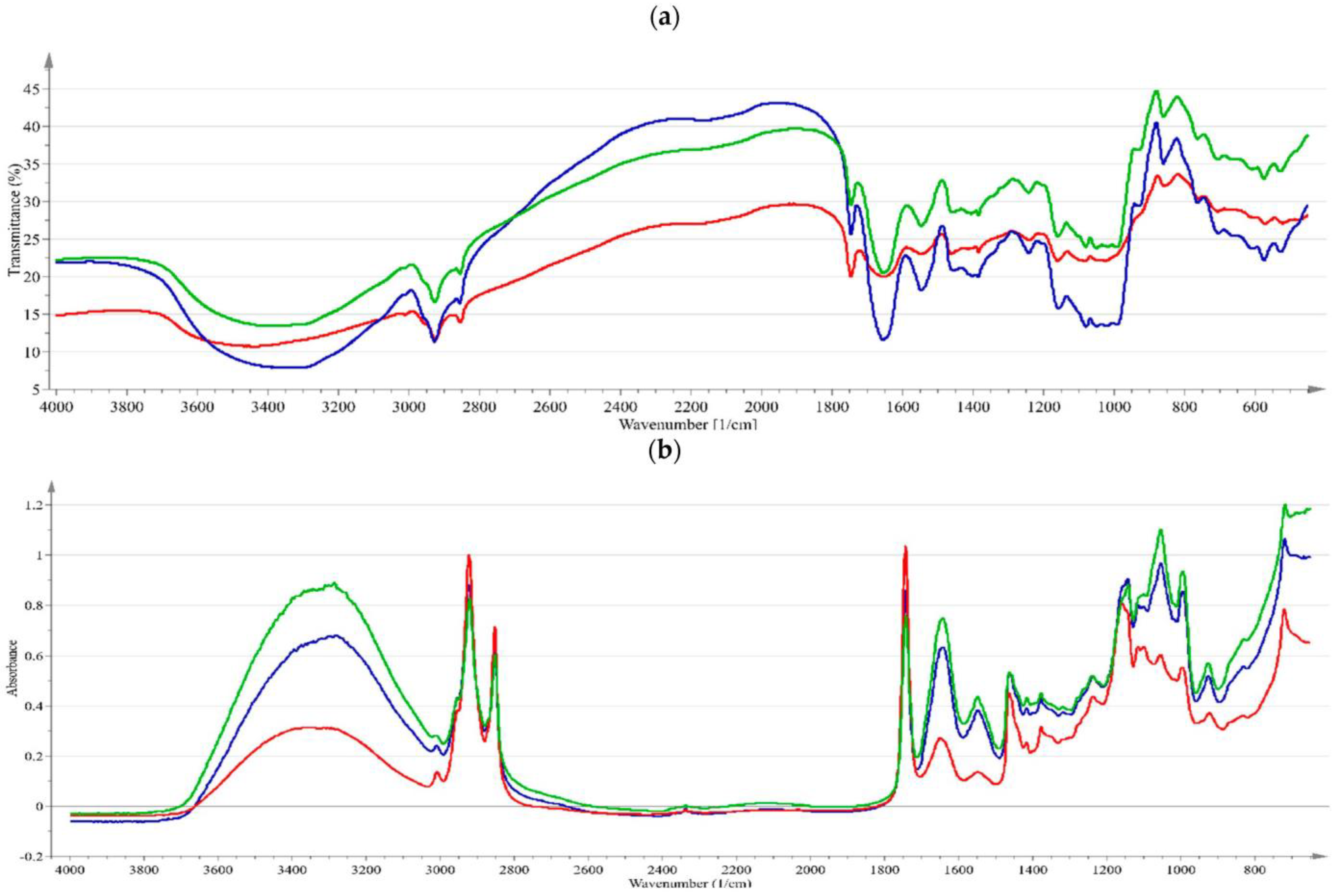

2.4.2. Fourier Transform Infrared Spectroscopy Analysis of Doughs

2.5. Cookie Analyses

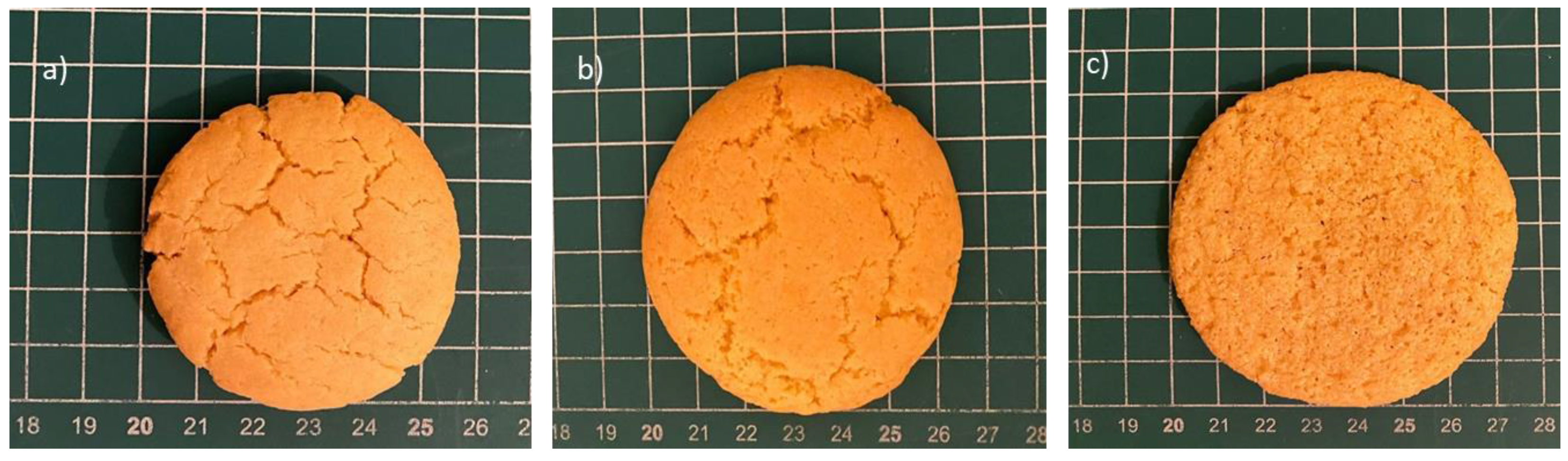

2.5.1. Quality Parameters of Cookies

2.5.2. Texture Measurement of Cookies

2.5.3. Nutritional Value Calculation and In Vitro Digestion Analysis of Cookies

2.5.4. Sensory Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Flour Properties

3.2. Cookie Dough Properties

3.3. Cookie Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Markets and Markets. Gluten Free Products Market. Available online: https://www.marketsandmarkets.com/Market-Reports/gluten-free-products-market-738.html (accessed on 24 June 2023).

- Caio, G.; Volta, U.; Sapone, A.; Leffler, D.A.; De Giorgio, R.; Catassi, C.; Fasano, A. Celiac disease: A comprehensive current review. BMC Med. 2019, 17, 142. [Google Scholar] [CrossRef] [Green Version]

- Lamacchia, C.; Camarca, A.; Picascia, S.; Di Luccia, A.; Gianfrani, C. Cereal-based gluten-free food: How to reconcile nutritional and technological properties of wheat proteins with safety for celiac disease patients. Nutrients 2014, 6, 575–590. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rachwa-Rosiak, D.; Nebesny, E.; Budryn, G. Chickpeas—Composition, nutritional value, health benefits, application to bread and snacks: A review. Crit. Rev. Food Sci. 2015, 55, 1137–1145. [Google Scholar] [CrossRef]

- Safonova, Y.A.; Ivliev, M.N.; Lemeshkin, A.V. Chickpea seeds germination rational parameters optimization. J. Phys. Conf. Ser. 2018, 1015, 032118. [Google Scholar] [CrossRef] [Green Version]

- Zia-Ul-Haq, M.; Iqbal, S.; Ahmad, S.; Imran, M.; Niaz, A.; Bhanger, M.I. Nutritional and compositional study of Desi chickpea (Cicer arietinum L.) cultivars grown in Punjab, Pakistan. Food Chem. 2007, 105, 1357–1363. [Google Scholar] [CrossRef]

- Berrios, J.D.J.; Morales, P.; Cámara, M.; Sánchez-Mata, M.C. Carbohydrate composition of raw and extruded pulse flours. Food Res. Int. 2010, 43, 531–536. [Google Scholar] [CrossRef]

- Alajaji, S.A.; El-Adawy, T.A. Nutritional composition of chickpea (Cicer arietinum L.) as affected by microwave cooking and other traditional cooking methods. J. Food Compos. Anal. 2006, 19, 806–812. [Google Scholar] [CrossRef]

- Hernández-López, I.; Ortiz-Solà, J.; Alamprese, C.; Barros, L.; Shelef, O.; Basheer, L.; Rivera, A.; Abadias, M.; Aguiló-Aguayo, I. Valorization of local legumes and nuts as key components of the Mediterranean diet. Foods 2022, 11, 3858. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, C.D.; Bubolz, V.K.; da Silva, J.; Dittgen, C.L.; Ziegler, V.; de Oliveira Raphaelli, C.; de Oliveira, M. Changes in the chemical composition and bioactive compounds of chickpea (Cicer arietinum L.) fortified by germination. LWT 2019, 111, 363–369. [Google Scholar] [CrossRef]

- Fernandez-Orozco, R.; Frias, J.; Zielinski, H.; Muñoz, R.; Piskula, M.K.; Kozlowska, H.; Vidal-Valverde, C. Evaluation of bioprocesses to improve the antioxidant properties of chickpeas. LWT 2009, 42, 885–892. [Google Scholar] [CrossRef]

- Khattak, A.B.; Zeb, A.; Bibi, N.; Khalil, S.A.; Khattak, M.S. Influence of germination techniques on phytic acid and polyphenols content of chickpea (Cicer arietinum L.) sprouts. Food Chem. 2007, 104, 1074–1079. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Li, A.; Liu, R.H.; Gao, X.; Li, D.; Kou, X.; Xue, Z. Nutritional constituent and health benefits of chickpea (Cicer arietinum L.): A review. Food Res. Int. 2021, 150, 110790. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, M.L.; Berry, J.W. Nutritional evaluation of chickpea and germinated chickpea flours. Plant Foods Human. Nutr. 1988, 38, 127–134. [Google Scholar] [CrossRef]

- López-Martínez, L.X.; Leyva-López, N.; Gutiérrez-Grijalva, E.P.; Heredia, J.B. Effect of cooking and germination on bioactive compounds in pulses and their health benefits. J. Funct. Foods 2017, 38, 624–634. [Google Scholar] [CrossRef]

- Atudorei, D.; Codină, G.G. Perspectives on the use of germinated legumes in the bread making process, a review. Appl. Sci. 2020, 10, 6244. [Google Scholar] [CrossRef]

- Clemente, A.; Sánchez-Vioque, R.; Vioque, J.; Bautista, J.; Millán, F. Effect of processing on water absorption and softening kinetics in chickpea (Cicer arietinum L.) seeds. J. Sci. Food Agric. 1998, 78, 169–174. [Google Scholar] [CrossRef]

- Wang, N.; Hatcher, D.W.; Tyler, R.T.; Toews, R.; Gawalko, E.J. Effect of cooking on the composition of beans (Phaseolus vulgaris L.) and chickpeas (Cicer arietinum L.). Food Res. Int. 2010, 43, 589–594. [Google Scholar] [CrossRef]

- Hamdani, A.M.; Wani, I.A.; Bhat, N.A. Gluten free cookies from rice-chickpea composite flour using exudate gums from acacia, apricot and karaya. Food Biosci. 2020, 35, 100541. [Google Scholar] [CrossRef]

- Yaver, E. Nutritional and textural properties and antioxidant activity of breads prepared from immature, mature, germinated, fermented and black chickpea flours. J. Sci. Food Agr. 2022, 102, 7164–7171. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Herranz, B.; Fuentes, R.; Cuesta, F.J.; Canet, W. Replacement of wheat flour by chickpea flour in muffin batter: Effect on rheological properties. J. Food Process Eng. 2017, 40, e12372. [Google Scholar] [CrossRef] [Green Version]

- Gómez, M.; Oliete, B.; Rosell, C.M.; Pando, V.; Fernández, E. Studies on cake quality made of wheat–chickpea flour blends. LWT-Food Sci. Technol. 2008, 41, 1701–1709. [Google Scholar] [CrossRef] [Green Version]

- Johnson, S.K.; Thomas, S.J.; Hall, R.S. Palatability and glucose, insulin and satiety responses of chickpea flour and extruded chickpea flour bread eaten as part of a breakfast. Eur. J. Clin. Nutr. 2005, 59, 169–176. [Google Scholar] [CrossRef] [PubMed]

- Torra, M.; Belorio, M.; Ayuso, M.; Carocho, M.; Ferreira, I.C.F.R.; Barros, L.; Gómez, M. Chickpea and chestnut flours as non-gluten alternatives in cookies. Foods 2021, 10, 911. [Google Scholar] [CrossRef] [PubMed]

- Aziah, A.A.; Noor, A.Y.; Ho, L.H. Physicochemical and organoleptic properties of cookies incorporated with legume flour. Int. Food Res. J. 2012, 19, 1539–1543. [Google Scholar]

- Byanju, B.; Hojilla-Evangelista, M.P.; Lamsal, B.P. Fermentation performance and nutritional assessment of physically processed lentil and green pea flour. J. Sci. Food Agric. 2021, 101, 5792–5806. [Google Scholar] [CrossRef]

- Narayana, K.; Rao, M.N. Effect of partial proteolysis on the functional properties of winged bean (Psophocarpus tetragonolobus) flour. J. Food Sci. 1984, 49, 944–947. [Google Scholar] [CrossRef]

- Turan, D.; Capanoglu, E.; Altay, F. Investigating the effect of roasting on functional properties of defatted hazelnut flour by response surface methodology (RSM). LWT 2015, 63, 758–765. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Monteiro, F.; Teixeira, J.A.; Gonzales-Barron, U. Combined effect of xanthan gum and water content on physicochemical and textural properties of gluten-free batter and bread. Food Res. Int. 2018, 111, 544–555. [Google Scholar] [CrossRef] [Green Version]

- Yamsaengsung, R.; Berghofer, E.; Schoenlechner, R. Physical properties and sensory acceptability of cookies made from chickpea addition to white wheat or whole wheat flour compared to gluten-free amaranth or buckwheat flour. Int. J. Food Sci. Technol. 2012, 47, 2221–2227. [Google Scholar] [CrossRef]

- Inglett, G.; Chen, D.; Liu, S. Physical properties of gluten-free sugar cookies made from amaranth–oat composites. LWT 2015, 63, 214–220. [Google Scholar] [CrossRef]

- Chakraborty, S.K.; Singh, D.S.; Kumbhar, B.K.; Singh, D. Process parameter optimization for textural properties of ready-to-eat extruded snack food from millet and legume pieces blends. J. Texture Stud. 2009, 40, 710–726. [Google Scholar] [CrossRef]

- Englyst, K.N.; Hudson, G.J.; Englyst, H.N. Starch analysis in food. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; Wiley: Hoboken, NJ, USA, 2000; pp. 4246–4262. [Google Scholar]

- Bashir, K.; Aggarwal, M. Effects of gamma irradiation on the physicochemical, thermal and functional properties of chickpea flour. LWT 2016, 69, 614–622. [Google Scholar] [CrossRef]

- Sofi, S.A.; Singh, J.; Muzaffar, K.; Mir, S.A.; Dar, B.N. Effect of germination time on physico-chemical, functional, pasting, rheology and electrophoretic characteristics of chickpea flour. J. Food Meas. Charact. 2020, 14, 2380–2392. [Google Scholar] [CrossRef]

- Simons, C.W.; Hall, C., III. Consumer acceptability of gluten-free cookies containing raw cooked and germinated pinto bean flours. Food Sci. Nutr. 2018, 6, 77–84. [Google Scholar] [CrossRef]

- Jan, R.; Saxena, D.C.; Singh, S. Physico-chemical, textural, sensory and antioxidant characteristics of gluten–Free cookies made from raw and germinated Chenopodium (Chenopodium album) flour. LWT 2016, 71, 281–287. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, N. Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem. 2005, 91, 403–411. [Google Scholar] [CrossRef]

- Ma, Z.; Boye, J.I.; Simpson, B.K.; Prasher, S.O.; Monpetit, D.; Malcolmson, L. Thermal processing effects on the functional properties and microstructure of lentil, chickpea, and pea flours. Food Res. Int. 2011, 44, 2534–2544. [Google Scholar] [CrossRef]

- Hong, T.; Yin, J.Y.; Nie, S.P.; Xie, M.Y. Applications of infrared spectroscopy in polysaccharide structural analysis: Progress, challenge and perspective. Food Chem. X 2021, 12, 100168. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Lim, S.T. Digestibility of legume starches as influenced by their physical and structural properties. Carbohyd. Polym. 2008, 71, 245–252. [Google Scholar] [CrossRef]

- Ells, L.J.; Seal, C.J.; Kettlitz, B.; Bal, W.; Mathers, J.C. Postprandial glycaemic, lipaemic and haemostatic responses to ingestion of rapidly and slowly digested starches in healthy young women. Brit. J. Nutr. 2005, 94, 948–955. [Google Scholar] [CrossRef] [Green Version]

- Butterworth, P.J.; Warren, F.J.; Ellis, P.R. Human α-amylase and starch digestion: An interesting marriage. Starch Stärke 2011, 63, 395–405. [Google Scholar] [CrossRef]

| Properties | Raw (RCF) | Cooked (CCF) | Germinated (GCF) |

|---|---|---|---|

| Moisture (g/100 g) | 4.69 ± 0.12 b | 3.30 ± 0.20 c | 9.16 ± 0.04 a |

| Protein (g/100 g) | 22.29 ± 1.57 a | 22.44 ± 1.68 a | 20.76 ± 0.28 a |

| Fat (g/100 g) | 6.38 ± 1.19 ab | 10.06 ± 1.27 a | 4.66 ± 0.41 b |

| Carbohydrate (g/100 g) | 63.41 | 63.59 | 62.61 |

| Total Ash (g/100 g) | 3.23 ± 0.05 a | 1.95 ± 0.11 c | 2.82 ± 0.08 b |

| Crude Fiber (g/100 g) | 3.48 ± 0.19 a | 1.96 ± 0.07 b | 3.24 ± 0.55 ab |

| Total Phenol Content (mg GAE/g flour) | 0.59 ± 0.20 ab | 0.46 ± 0.08 b | 0.66 ± 0.04 a |

| Bulk Density (g/mL) | 0.61 ± 0.00 c | 0.70 ± 0.00 b | 0.74 ± 0.01 a |

| Water Retention Capacity (%) | 137.26 ± 5.24 b | 300.76 ± 12.84 a | 174.12 ± 12.78 b |

| Oil Absorption Capacity (g/g) | 0.90 ± 0.02 b | 1.38 ± 0.13 a | 1.01 ± 0.09 ab |

| Emulsion Activity (%) | 46.99 ± 2.81 a | 51.00 ± 1.41 a | 53.53 ± 0.66 a |

| Emulsion Stability (%) | 96.81 ± 1.37 a | 95.15 ± 4.03 a | 90.52 ± 2.92 a |

| Foaming Capacity (%) | 17.28 ± 1.41 a | 17.29 ± 3.83 a | 19.29 ± 4.14 a |

| Foaming Stability (%) | 11.02 ± 1.15 a | 8.17 ± 0.24 b | 1.84 ± 0.02 c |

| L* | 90.60 ± 1.01 a | 88.95 ± 0.91 a | 85.80 ± 1.15 b |

| a* | −5.52 ± 0.60 c | 0.91 ± 0.04 a | −3.87 ± 0.20 b |

| b* | 25.20 ± 0.70 b | 31.86 ± 0.45 a | 24.20 ± 1.57 b |

| Properties | Raw (RCF) | Cooked (CCF) | Germinated (GCF) |

|---|---|---|---|

| Firmness (N) | 4.66 ± 0.63 b | 40.23 ± 7.26 a | 7.43 ± 1.18 b |

| Consistency (N × s) | 10.885 ± 0.74 b | 119.02 ± 8.06 a | 18.12 ± 3.70 b |

| Viscosity Index (N × s) | −4.18 ± 0.62 a | −15.26 ± 4.5 b | −5.40 ± 0.87 a |

| Cohesiveness (N) | −3.60 ± 0.53 a | −15.19 ± 1.91 b | −4.77 ± 0.81 a |

| Properties | Raw (RCF) | Cooked (CCF) | Germinated (GCF) |

|---|---|---|---|

| Moisture (%) | 11.52 ± 0.29 a | 9.94 ± 0.71 b | 7.46 ± 0.94 c |

| Baking Weight Loss (%) (BWL) | 13.40 ± 0.81 b | 11.78 ± 0.73 c | 15.90 ± 1.01 a |

| Spread Ratio | 4.53 ± 0.14 b | 3.89 ± 0.33 c | 7.88 ± 0.65 a |

| Hardness (N) | 7.91 ± 1.05 a | 5.03 ± 1.67 b | 4.72 ± 1.31 b |

| L* | 68.02 ± 1.75 b | 72.71 ± 0.84 a | 61.95 ± 2.16 c |

| a* | 2.07 ± 0.45 a | −1.45 ± 0.42 b | 1.83 ± 0.95 a |

| b* | 46.27 ± 0.85 a | 40.48 ± 0.84 b | 39.18 ± 0.99 c |

| Raw (RCF) | Cooked (CCF) | Germinated (GCF) | |

|---|---|---|---|

| Starch fractions * | |||

| Rapidly digestible starch (RDS) | 2.58 ± 0.31 c | 24.63 ± 0.15 a | 7.09 ± 0.52 b |

| Slowly digestible starch (SDS) | 3.45 ± 0.29 c | 7.46 ± 1.34 a | 5.96 ± 0.16 b |

| Resistant starch (RS) | 38.59 ± 0.25 a | 13.10 ± 1.37 c | 29.69 ± 0.66 b |

| Nutritional Values ** | |||

| Protein/100 g | 12.00 | 11.48 | 11.52 |

| Fiber/100 g | 1.32 | 0.73 | 1.27 |

| Fat/100 g | 25.09 | 26.02 | 25.16 |

| Carbohydrate/100 g | 56.90 | 58.29 | 52.43 |

| kcal/100 g | 504.05 | 514.72 | 484.78 |

| Protein/100 kcal | 2.38 | 2.23 | 2.38 |

| Fiber/100 kcal | 0.26 | 0.14 | 0.26 |

| Energy % from protein | 9.52 | 8.92 | 9.51 |

| Sensory Properties * | Raw (RCF) | Cooked (CCF) | Germinated (GCF) |

|---|---|---|---|

| Color | 5.68 ± 1.09 a | 5.32 ± 1.24 a | 5.45 ± 1.33 a |

| Flavor | 4.82 ± 1.54 a | 4.18 ± 1.52 a | 4.76 ± 1.58 a |

| Texture | 5.18 ± 1.54 a | 5.16 ± 1.38 a | 4.55 ± 1.64 a |

| Taste | 5.08 ± 1.55 a | 4.42 ± 1.57 a | 4.34 ± 1.46 a |

| Overall acceptability | 5.18 ± 1.29 a | 4.72 ± 1.17 a | 4.66 ± 1.34 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dogruer, I.; Coban, B.; Baser, F.; Gulec, S.; Ozen, B. Techno-Functional and In Vitro Digestibility Properties of Gluten-Free Cookies Made from Raw, Pre-Cooked, and Germinated Chickpea Flours. Foods 2023, 12, 2829. https://doi.org/10.3390/foods12152829

Dogruer I, Coban B, Baser F, Gulec S, Ozen B. Techno-Functional and In Vitro Digestibility Properties of Gluten-Free Cookies Made from Raw, Pre-Cooked, and Germinated Chickpea Flours. Foods. 2023; 12(15):2829. https://doi.org/10.3390/foods12152829

Chicago/Turabian StyleDogruer, Ilgin, Basak Coban, Filiz Baser, Sukru Gulec, and Banu Ozen. 2023. "Techno-Functional and In Vitro Digestibility Properties of Gluten-Free Cookies Made from Raw, Pre-Cooked, and Germinated Chickpea Flours" Foods 12, no. 15: 2829. https://doi.org/10.3390/foods12152829

APA StyleDogruer, I., Coban, B., Baser, F., Gulec, S., & Ozen, B. (2023). Techno-Functional and In Vitro Digestibility Properties of Gluten-Free Cookies Made from Raw, Pre-Cooked, and Germinated Chickpea Flours. Foods, 12(15), 2829. https://doi.org/10.3390/foods12152829