Improving the Stability of Water-in-Oil Emulsions with Medium Internal Phase by the Introduction of Gelatin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Emulsions

2.3. Appearance Observation of Emulsions

2.4. Emulsions Type Test

2.5. WHC Test

2.6. Interfacial Tension Test

2.7. Microscopic and Droplet Size Test

2.8. Viscosity Test

2.9. Emulsions Stability Test

2.9.1. Storage Stability

2.9.2. Thermal Stability

2.9.3. Freeze–Thaw Stability

2.10. Statistical Analysis

3. Results and Discussion

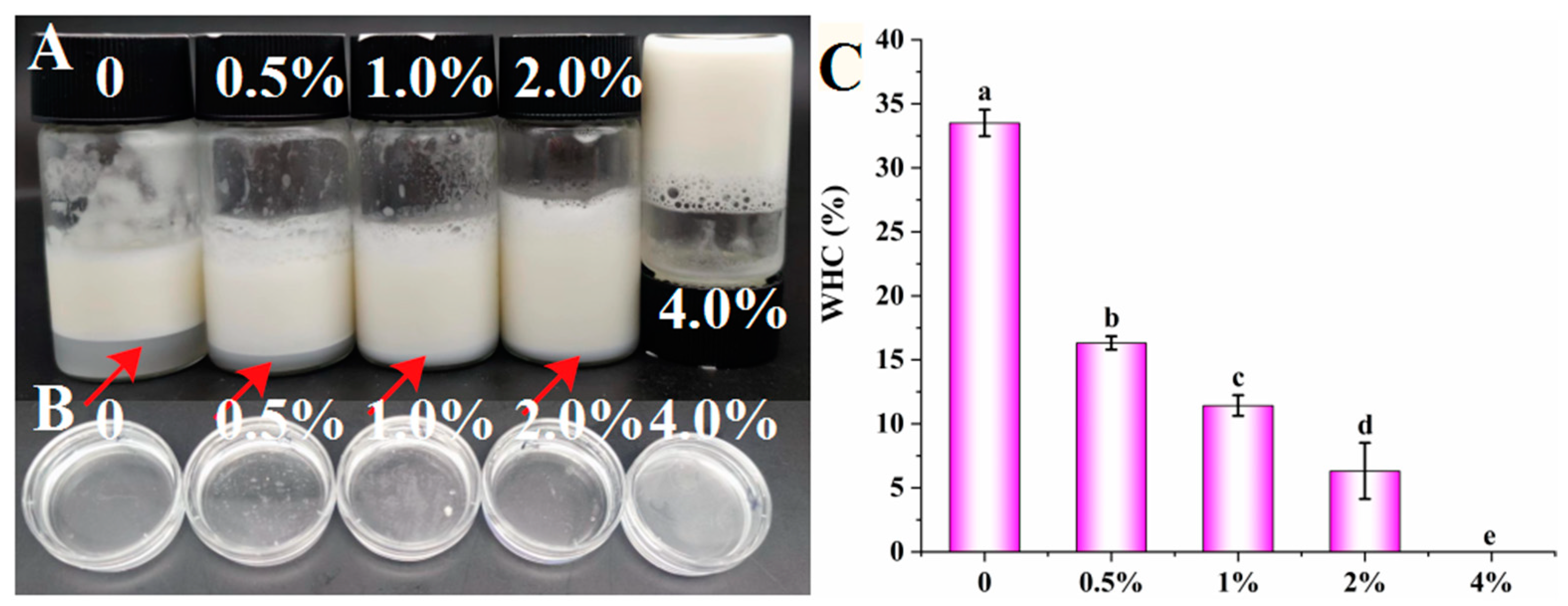

3.1. Analysis of Appearance and WHC

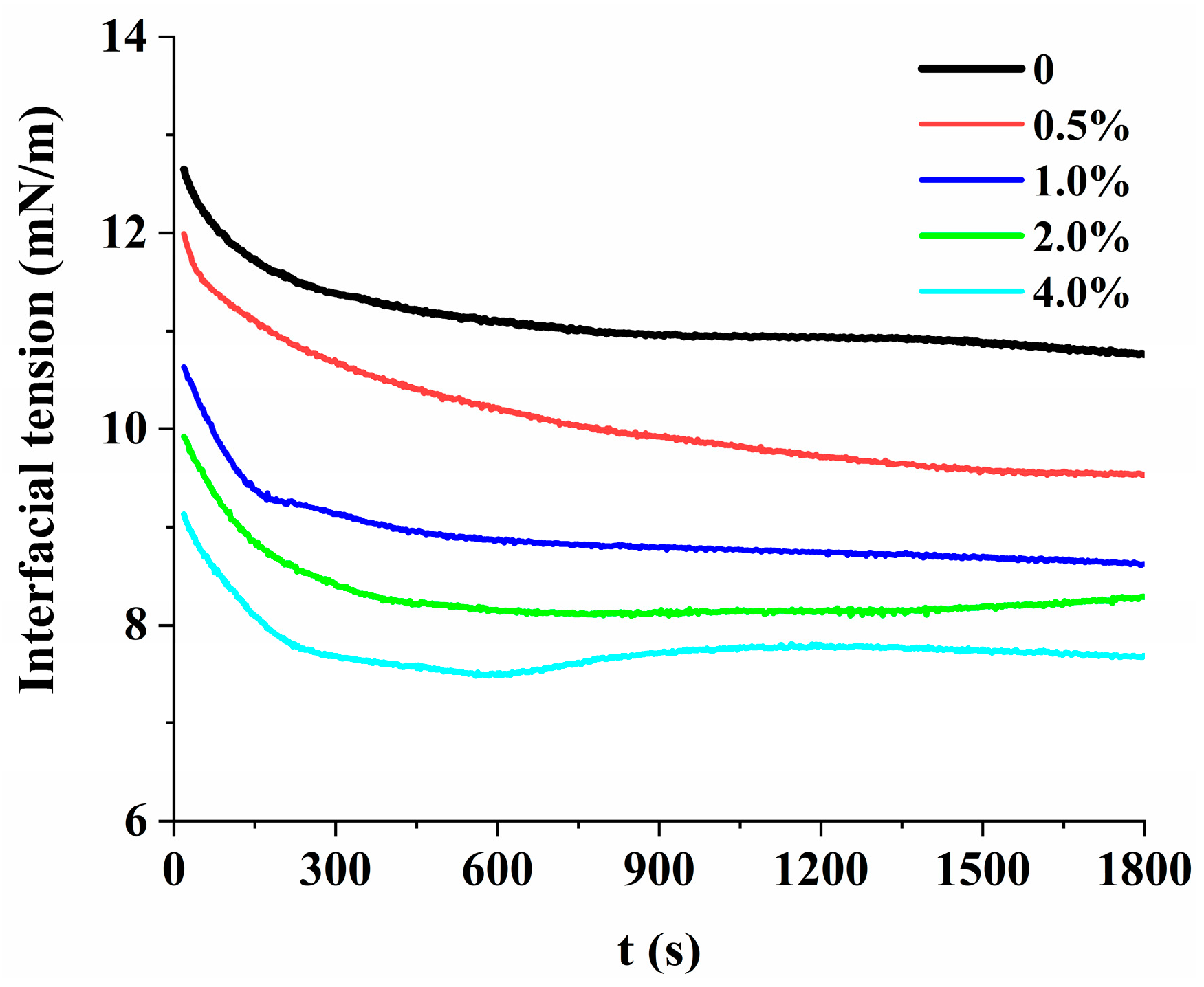

3.2. Analysis of Interfacial Tension

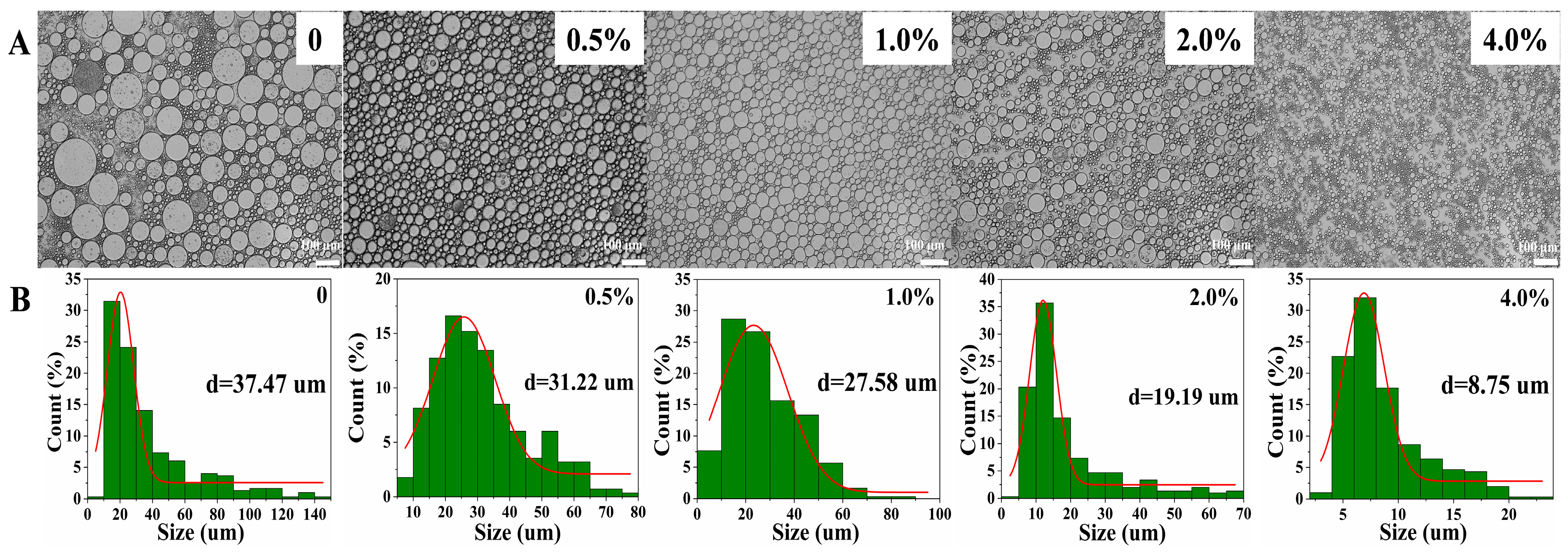

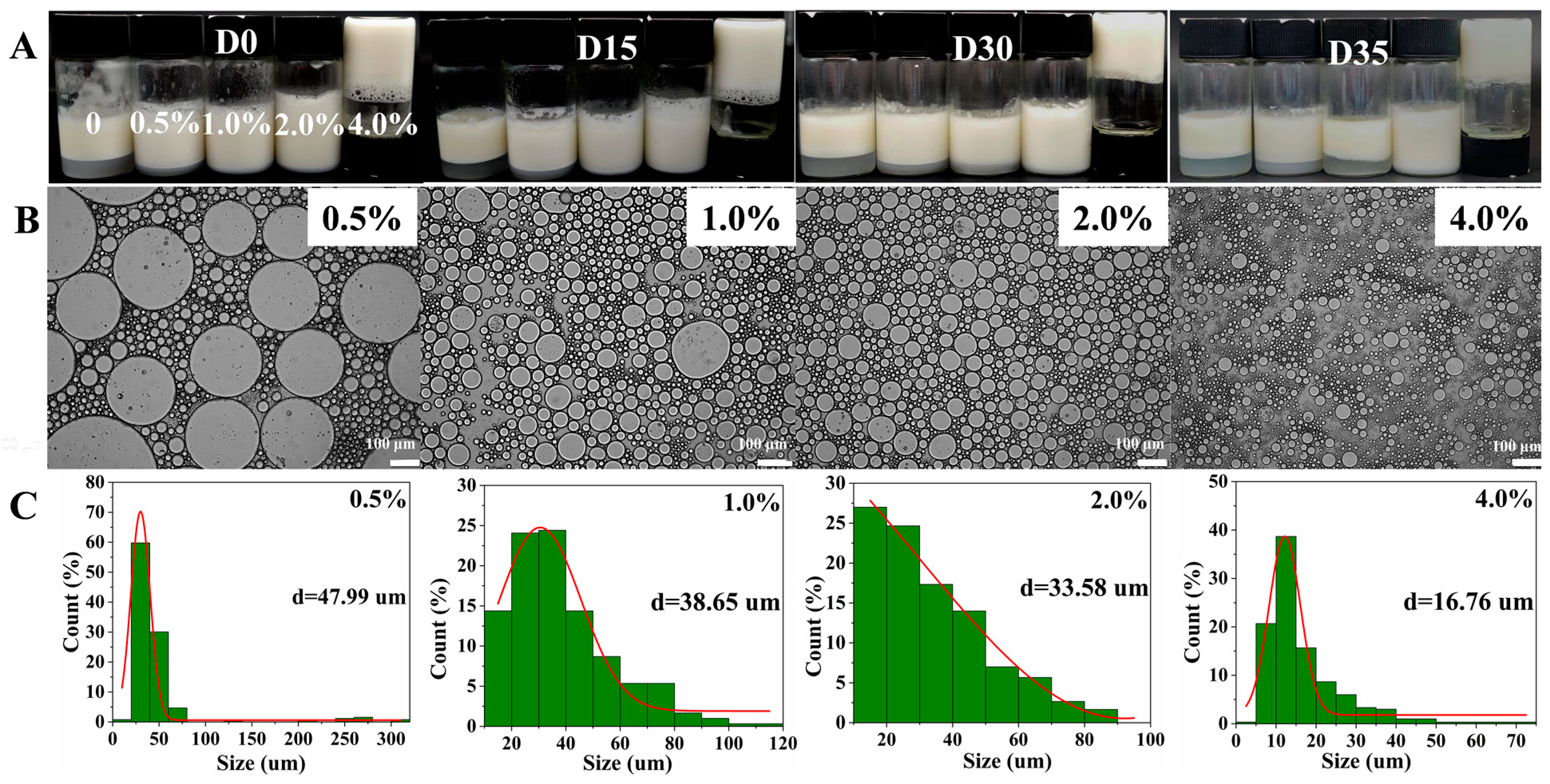

3.3. Analysis of Microscopic and Droplet Size

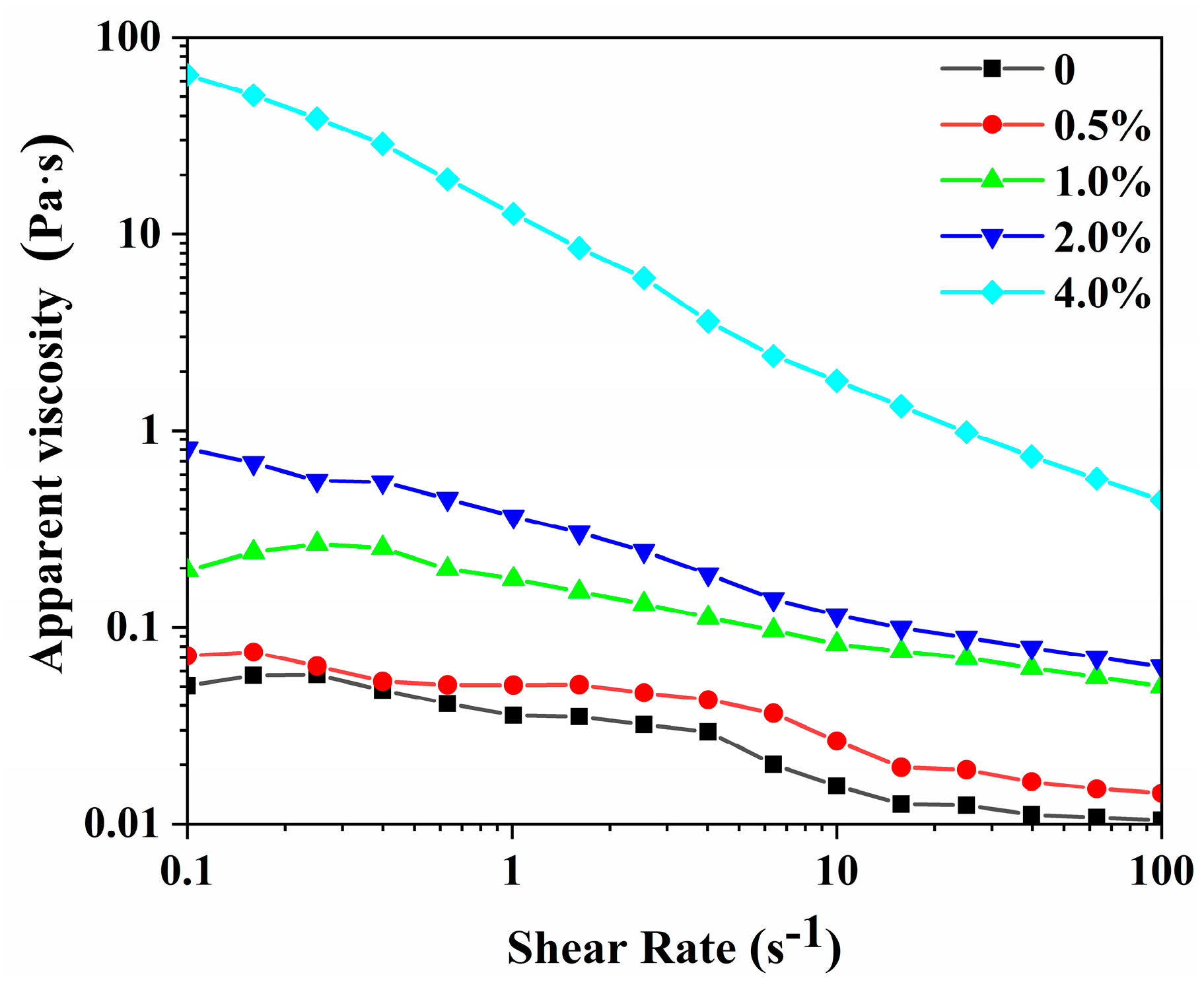

3.4. Analysis of Viscosity

3.5. Analysis of Storage Stability

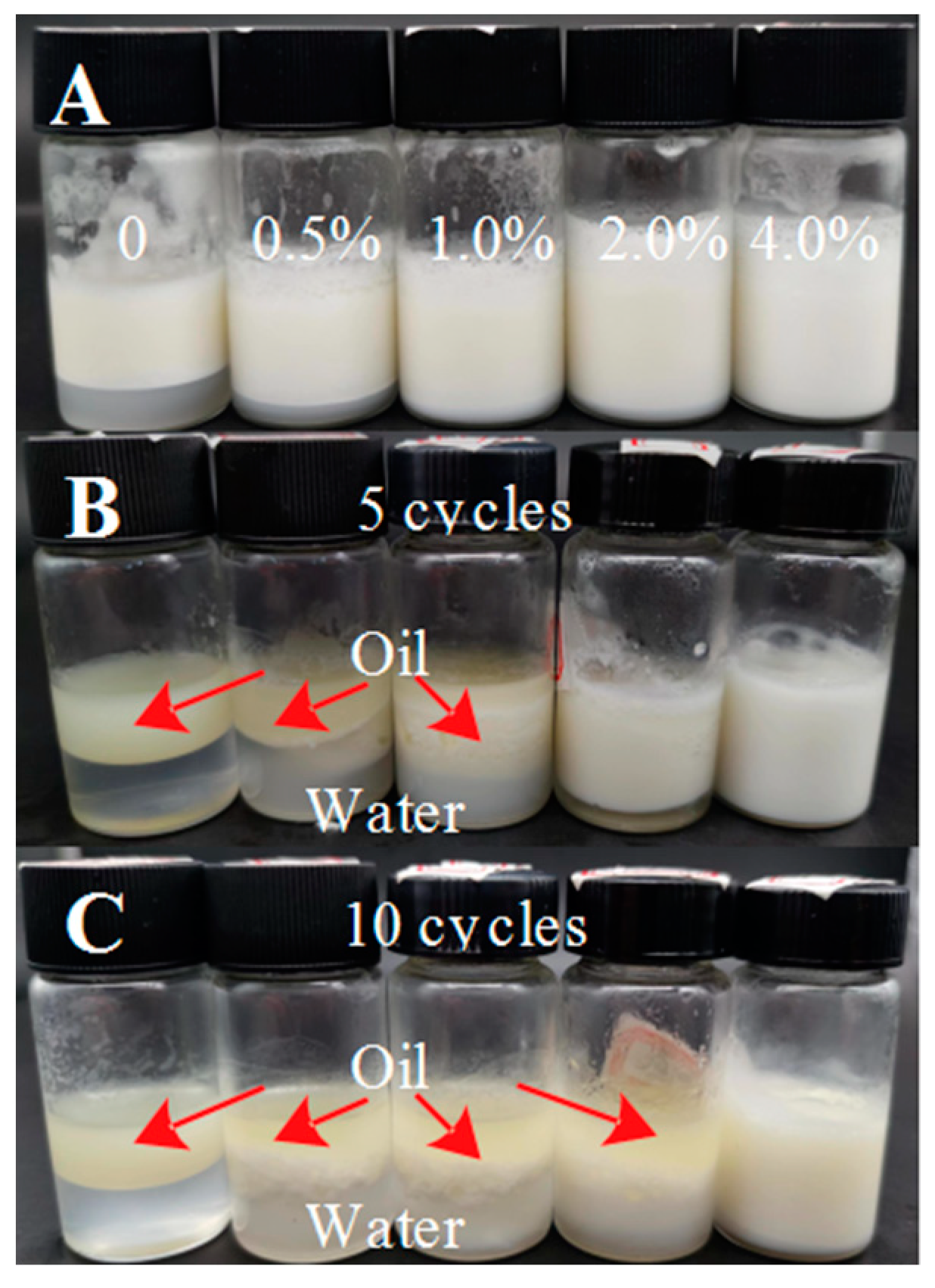

3.6. Analysis of Thermal Stability

3.7. Analysis of Freeze–Thaw Stability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, F.G.; Liang, X.P.; Yan, J.; Zhao, S.L.; Li, S.Q.; Liu, X.B.; Ngai, T.; McClements, D.J. Tailoring the properties of double-crosslinked emulsion gels using structural design principles: Physical characteristics, stability, and delivery of lycopene. Biomaterials 2022, 280, 121265. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Sun, X.; Jia, P.; Li, L.; Xu, K.; Cao, Y.; Lü, X.; Wang, L. Multifunctional sustainable films of bacterial cellulose nanocrystal-based, three-phase pickering nanoemulsions: A promising active food packaging for cheese. Chem. Eng. J. 2023, 466, 143295. [Google Scholar] [CrossRef]

- He, X.; Liu, J.; Li, Z.; Samchek, M.; Gates, I.; Hu, J.; Lu, Q. Aqueous condition-tolerated high internal phase oil-in-water Pickering emulsion as building block for engineering 3D functional materials. Chem. Eng. J. 2022, 446, 137162. [Google Scholar] [CrossRef]

- Liu, Q.; Zhai, W. Hierarchical Porous Ceramics with Distinctive Microstructures by Emulsion-Based Direct Ink Writing. ACS Appl. Mater. Interface 2022, 14, 32196–32205. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, Y.; Wu, Y.; Zheng, Z.; Xie, Y.; Li, Y.; Li, B.; Pei, Y.; Liu, S. Construction of stable O/W/O multiple emulsions using beeswax to control the melting point of the continuous oil phase. Food Hydrocoll. 2023, 136, 108219. [Google Scholar] [CrossRef]

- Tenorio-Garcia, E.; Araiza-Calahorra, A.; Simone, E.; Sarkar, A. Recent advances in design and stability of double emulsions: Trends in Pickering stabilization. Food Hydrocoll. 2022, 128, 107601. [Google Scholar] [CrossRef]

- Gu, X.; Du, L.; Meng, Z. Comparative study of natural wax-based W/O emulsion gels: Microstructure and macroscopic properties. Food Res. Int. 2023, 165, 112509. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Meng, R.; Xu, B.; Zhang, B.; Cui, B.; Wu, Z. Function emulsion gels prepared with carrageenan and zein/carboxymethyl dextrin stabilized emulsion as a new fat replacer in sausages. Food Chem. 2022, 389, 133005. [Google Scholar] [CrossRef]

- Song, J.; Sun, Y.; Wang, H.; Tan, M. Preparation of high internal phase Pickering emulsion by centrifugation for 3D printing and astaxanthin delivery. Food Hydrocoll. 2023, 142, 108840. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y.; Wang, Y.; Zhong, J.; Li, S.; Zhu, B.; Dong, X. Application of cod protein-stabilized and casein-stabilized high internal phase emulsions as novel fat substitutes in fish cake. LWT 2023, 173, 114267. [Google Scholar] [CrossRef]

- Zhang, L.; Zaky, A.A.; Zhou, C.; Chen, Y.; Su, W.; Wang, H.; Abd El-Aty, A.M.; Tan, M. High internal phase Pickering emulsion stabilized by sea bass protein microgel particles: Food 3D printing application. Food Hydrocoll. 2022, 131, 107744. [Google Scholar] [CrossRef]

- Gao, Y.; Lei, Y.; Wu, Y.; Liang, H.; Li, J.; Pei, Y.; Li, Y.; Li, B.; Luo, X.; Liu, S. Beeswax: A potential self-emulsifying agent for the construction of thermal-sensitive food W/O emulsion. Food Chem. 2021, 349, 129203. [Google Scholar] [CrossRef]

- Li, J.; Guo, C.; Cai, S.; Yi, J.; Zhou, L. Fabrication of anthocyanin-rich W1/O/W2 emulsion gels based on pectin–GDL complexes: 3D printing performance. Food Res. Int. 2023, 168, 112782. [Google Scholar] [CrossRef]

- Yu, H.; Wang, H.; Su, W.; Song, Y.; Zaky, A.A.; Abd El-Aty, A.M.; Tan, M. Co-delivery of hydrophobic astaxanthin and hydrophilic phycocyanin by a pH-sensitive water-in-oil-in-water double emulsion-filled gellan gum hydrogel. Food Hydrocoll. 2022, 131, 107810. [Google Scholar] [CrossRef]

- Wang, F.; Guo, L.; Liu, H.; Tao, H.; Yu, B.; Zhao, H.; Li, J.; Tao, H.; Cui, B.; Wang, Y. Water-in-oil oleogel with biphasic stabilization for fabrication of low-fat salad dressing. Food Hydrocoll. 2023, 142, 108805. [Google Scholar] [CrossRef]

- Zhu, Q.; Qiu, S.; Zhang, H.; Cheng, Y.; Yin, L. Physical stability, microstructure and micro-rheological properties of water-in-oil-in-water (W/O/W) emulsions stabilized by porcine gelatin. Food Chem. 2018, 253, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Li, W.; Wang, W.; Cao, Y.; Lan, Y.; Huang, Q.; Xiao, J. Effects of gelation on the stability, tribological properties and time-delayed release profile of double emulsions. Food Hydrocoll. 2022, 131, 107753. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, L.; Liu, Y.; Li, J. A mechanistic investigation of the effect of dispersion phase protein type on the physicochemical stability of water–in–oil emulsions. Food Res. Int. 2022, 157, 111293. [Google Scholar] [CrossRef]

- Huang, H.; Belwal, T.; Aalim, H.; Li, L.; Lin, X.; Liu, S.; Ma, C.; Li, Q.; Zou, Y.; Luo, Z. Protein-polysaccharide complex coated W/O/W emulsion as secondary microcapsule for hydrophilic arbutin and hydrophobic coumaric acid. Food Chem. 2019, 300, 125171. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, J.; Zhang, Y.; Wang, X.; Lorenzo, J.M.; Zhong, J. Gelatins as emulsifiers for oil-in-water emulsions: Extraction, chemical composition, molecular structure, and molecular modification. Trends Food Sci. Technol. 2020, 106, 113–131. [Google Scholar] [CrossRef]

- Tang, C.; Zhou, K.; Zhu, Y.; Zhang, W.; Xie, Y.; Wang, Z.; Zhou, H.; Yang, T.; Zhang, Q.; Xu, B. Collagen and its derivatives: From structure and properties to their applications in food industry. Food Hydrocoll. 2022, 131, 107748. [Google Scholar] [CrossRef]

- Feng, X.; Dai, H.; Yu, Y.; Wei, Y.; Tan, H.; Tang, M.; Ma, L.; Zhang, Y. Adjusting the interfacial property and emulsifying property of cellulose nanofibrils by ultrasonic treatment combined with gelatin addition. Food Hydrocoll. 2022, 133, 107905. [Google Scholar] [CrossRef]

- Feng, X.; Dai, H.; Ma, L.; Yu, Y.; Tang, M.; Li, Y.; Hu, W.; Liu, T.; Zhang, Y. Food-Grade Gelatin Nanoparticles: Preparation, Characterization, and Preliminary Application for Stabilizing Pickering Emulsions. Foods 2019, 8, 479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Lee, W.J.; Tan, C.P.; Lai, O.M.; Wang, Y.; Qiu, C. W/O high internal phase emulsion featuring by interfacial crystallization of diacylglycerol and different internal compositions. Food Chem. 2022, 372, 131305. [Google Scholar] [CrossRef]

- Balcaen, M.; Steyls, J.; Schoeppe, A.; Nelis, V.; Van der Meeren, P. Phosphatidylcholine-depleted lecithin: A clean-label low-HLB emulsifier to replace PGPR in w/o and w/o/w emulsions. J. Colloid Interface Sci. 2021, 581, 836–846. [Google Scholar] [CrossRef]

- Cheng, C.; Gao, H.; McClements, D.J.; Zeng, H.; Ma, L.; Zou, L.; Miao, J.; Wu, X.; Tan, J.; Liang, R.; et al. Impact of polysaccharide mixtures on the formation, stability and EGCG loading of water-in-oil high internal phase emulsions. Food Chem. 2022, 372, 131225. [Google Scholar] [CrossRef]

- García-González, D.O.; Yánez-Soto, B.; Dibildox-Alvarado, E.; Ornelas-Paz, J.D.J.; Pérez-Martínez, J.D. The effect of interfacial interactions on the rheology of water in oil emulsions oleogelled by candelilla wax and saturated triacylglycerols. LWT 2021, 146, 111405. [Google Scholar] [CrossRef]

- Tian, H.; Xiang, D.; Wang, B.; Zhang, W.; Li, C. Using hydrogels in dispersed phase of water-in-oil emulsion for encapsulating tea polyphenols to sustain their release. Colloids Surf. A 2021, 612, 125999. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, L.; Liu, Y.; Li, J. Effects of alkali treatment on structural and functional properties of chickpea protein isolate and its interaction with gallic acid: To improve the physicochemical stability of water–in–oil emulsions. Food Hydrocoll. 2023, 140, 108601. [Google Scholar] [CrossRef]

- Perez-Moral, N.; Watt, S.; Wilde, P. Comparative study of the stability of multiple emulsions containing a gelled or aqueous internal phase. Food Hydrocoll. 2014, 42, 215–222. [Google Scholar] [CrossRef]

- Su, J.; Flanagan, J.; Hemar, Y.; Singh, H. Synergistic effects of polyglycerol ester of polyricinoleic acid and sodium caseinate on the stabilisation of water–oil–water emulsions. Food Hydrocoll. 2006, 20, 261–268. [Google Scholar] [CrossRef]

- Gülseren, İ.; Corredig, M. Interactions between polyglycerol polyricinoleate (PGPR) and pectins at the oil–water interface and their influence on the stability of water-in-oil emulsions. Food Hydrocoll. 2014, 34, 154–160. [Google Scholar] [CrossRef]

- Gomes, A.; Costa, A.L.R.; de Assis Perrechil, F.; Da Cunha, R.L. Role of the phases composition on the incorporation of gallic acid in O/W and W/O emulsions. J. Food Eng. 2016, 168, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Yu, J.J.; Liu, N.; Gao, Y.; Mao, L. W/O emulsions featuring ethylcellulose structuring in the water phase, interface and oil phase for multiple delivery. Carbohyd Polym. 2022, 283, 119158. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Pan, Y.; Jia, X.; Li, J.; Zhang, M.; Yin, L. Review on the Stability Mechanism and Application of Water-in-Oil Emulsions Encapsulating Various Additives. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1660–1675. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, R.C.; Gomes, A.; Cunha, R.L. Tailoring W/O emulsions for application as inner phase of W/O/W emulsions: Modulation of the aqueous phase composition. J. Food Eng. 2021, 297, 110482. [Google Scholar] [CrossRef]

- Chevalier, R.C.; Gomes, A.; Cunha, R.L. Role of aqueous phase composition and hydrophilic emulsifier type on the stability of W/O/W emulsions. Food Res. Int. 2022, 156, 111123. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Mao, J.; Meng, Z. Tracing distribution and interface behavior of water droplets in W/O emulsions with fat crystals. Food Res. Int. 2023, 163, 112215. [Google Scholar] [CrossRef]

- Thanasukarn, P.; Pongsawatmanit, R.; McClements, D.J. Influence of emulsifier type on freeze–thaw stability of hydrogenated palm oil-in-water emulsions. Food Hydrocoll. 2004, 18, 1033–1043. [Google Scholar] [CrossRef]

- Luo, S.; Hu, X.; Pan, L.; Zheng, Z.; Zhao, Y.; Cao, L.; Pang, M.; Hou, Z.; Jiang, S. Preparation of camellia oil-based W/O emulsions stabilized by tea polyphenol palmitate: Structuring camellia oil as a potential solid fat replacer. Food Chem. 2019, 276, 209–217. [Google Scholar] [CrossRef]

- Ghosh, S.; Rousseau, D. Freeze–thaw stability of water-in-oil emulsions. J. Colloid Interface Sci. 2009, 339, 91–102. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yu, Y. Improving the Stability of Water-in-Oil Emulsions with Medium Internal Phase by the Introduction of Gelatin. Foods 2023, 12, 2863. https://doi.org/10.3390/foods12152863

Zhang L, Yu Y. Improving the Stability of Water-in-Oil Emulsions with Medium Internal Phase by the Introduction of Gelatin. Foods. 2023; 12(15):2863. https://doi.org/10.3390/foods12152863

Chicago/Turabian StyleZhang, Lei, and Yong Yu. 2023. "Improving the Stability of Water-in-Oil Emulsions with Medium Internal Phase by the Introduction of Gelatin" Foods 12, no. 15: 2863. https://doi.org/10.3390/foods12152863