Stability and Rheological Behavior of Mayonnaise-like Emulsion Co-Emulsified by Konjac Glucomannan and Whey Protein

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mayonnaise-like Emulsion

2.3. Droplet Size Distribution and Mean Droplet Size Measurements

2.4. Microstructure Analysis

2.5. Appearance Texture and Stackability

2.6. Rheological Properties

2.7. Statistical Analysis

3. Results and Discussion

3.1. Stabilization of Emulsion

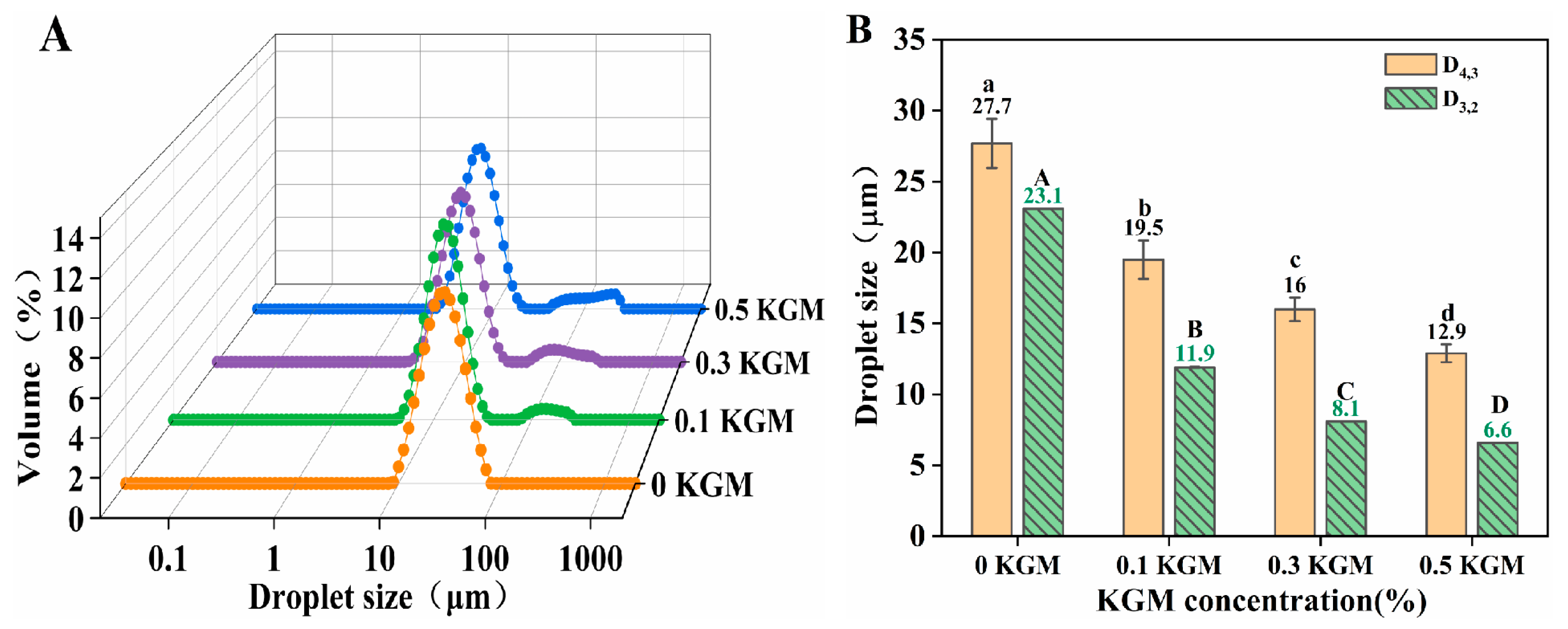

3.1.1. Impact of KGM Concentration

Droplet Size

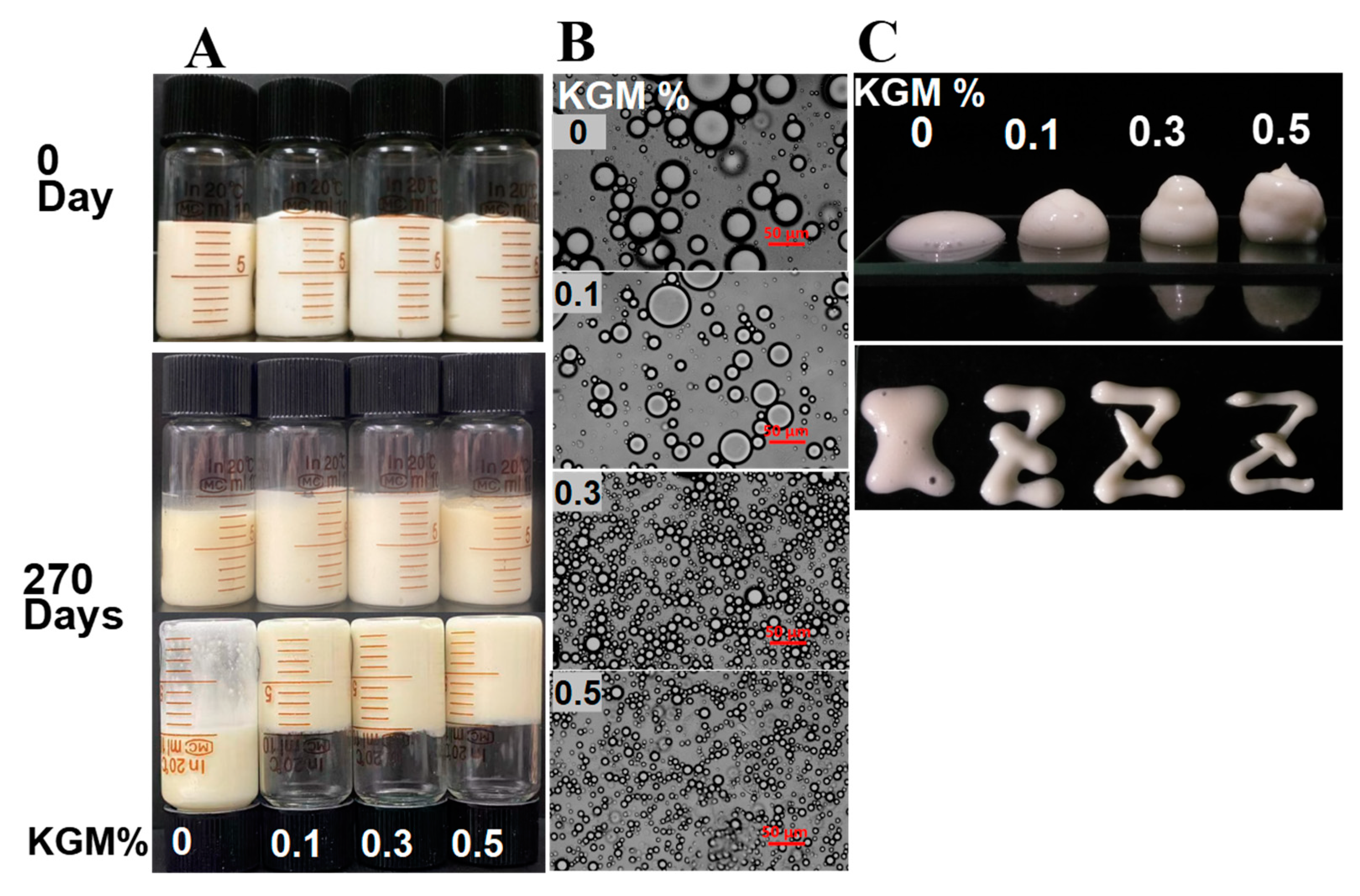

Visual Appearance, Texture, and Microstructure

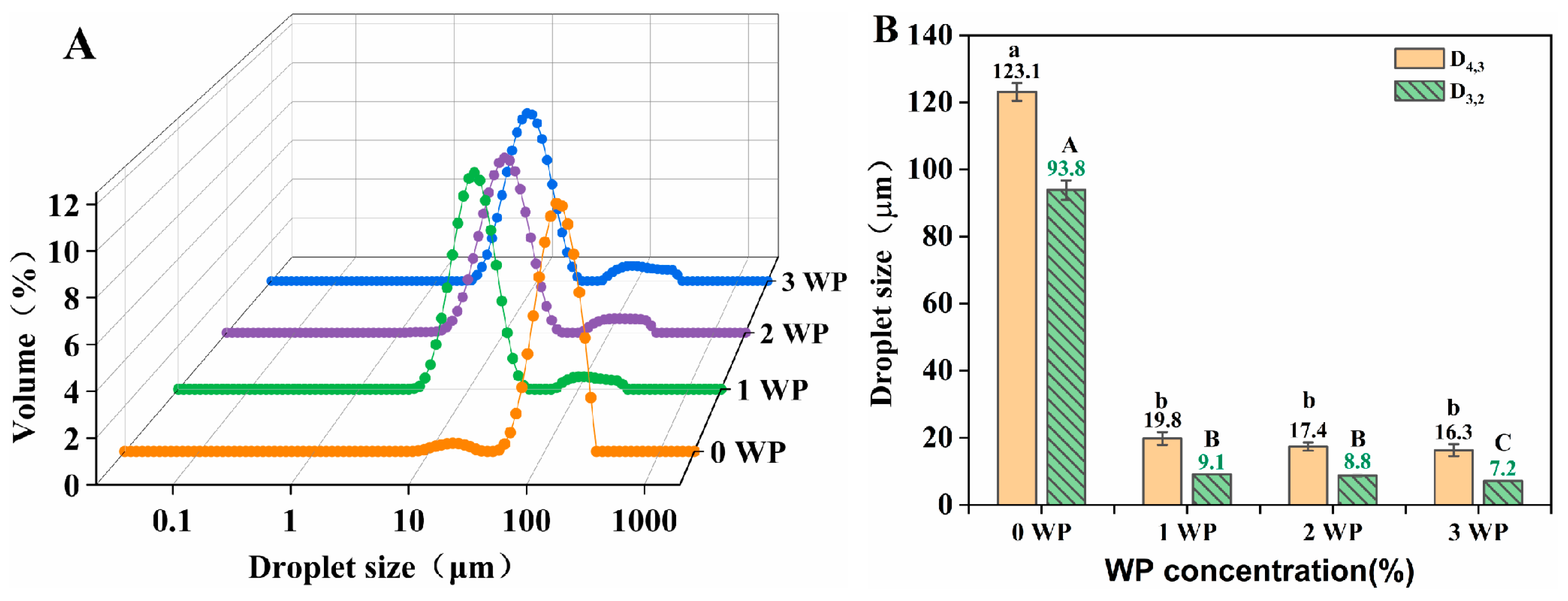

3.1.2. Impact of WP Concentration

Droplet Size

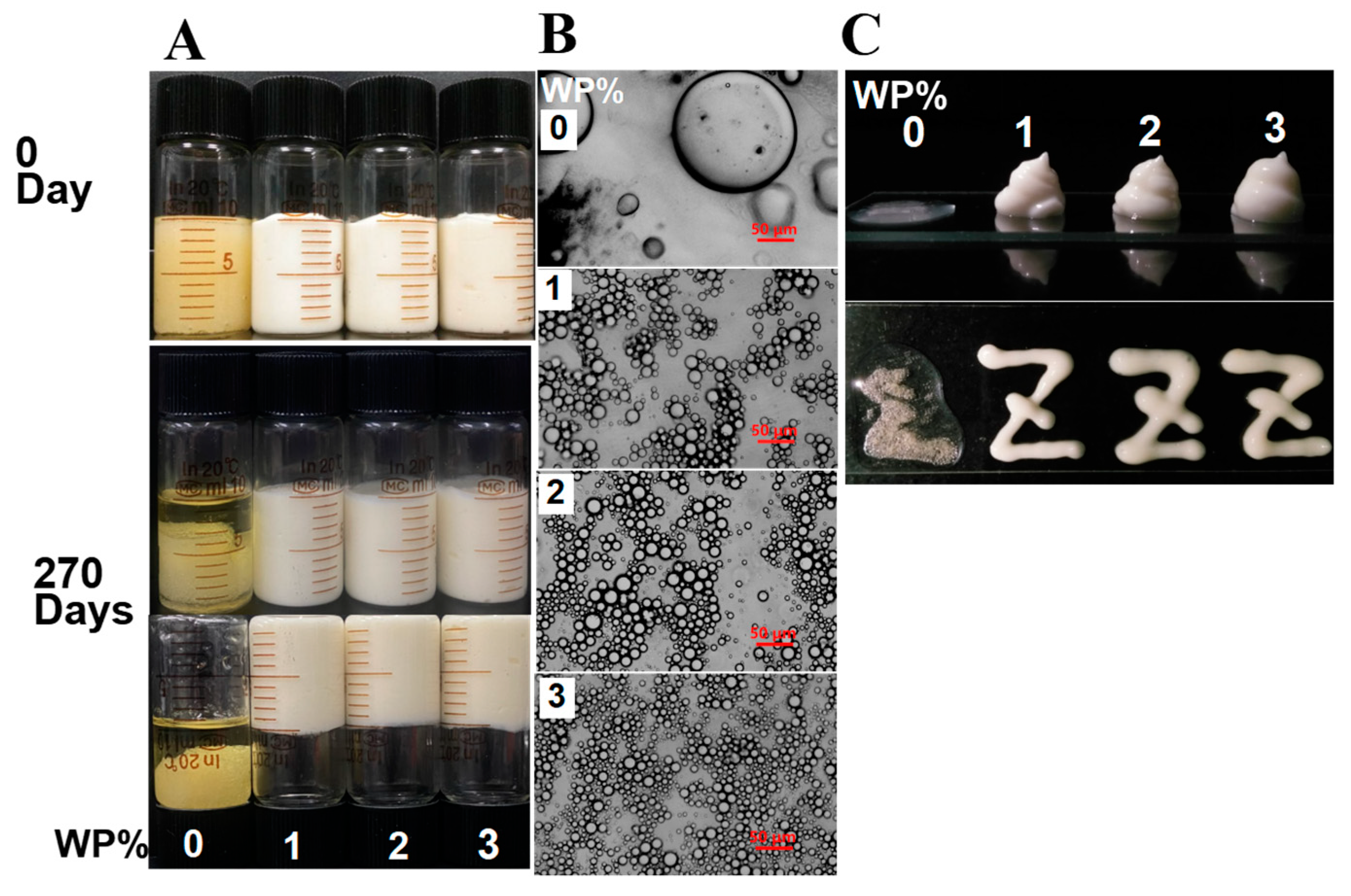

Visual Appearance, Texture, and Microstructure

3.2. Rheological Behavior of Mayonnaise-like Emulsion

3.2.1. Flow Behavior

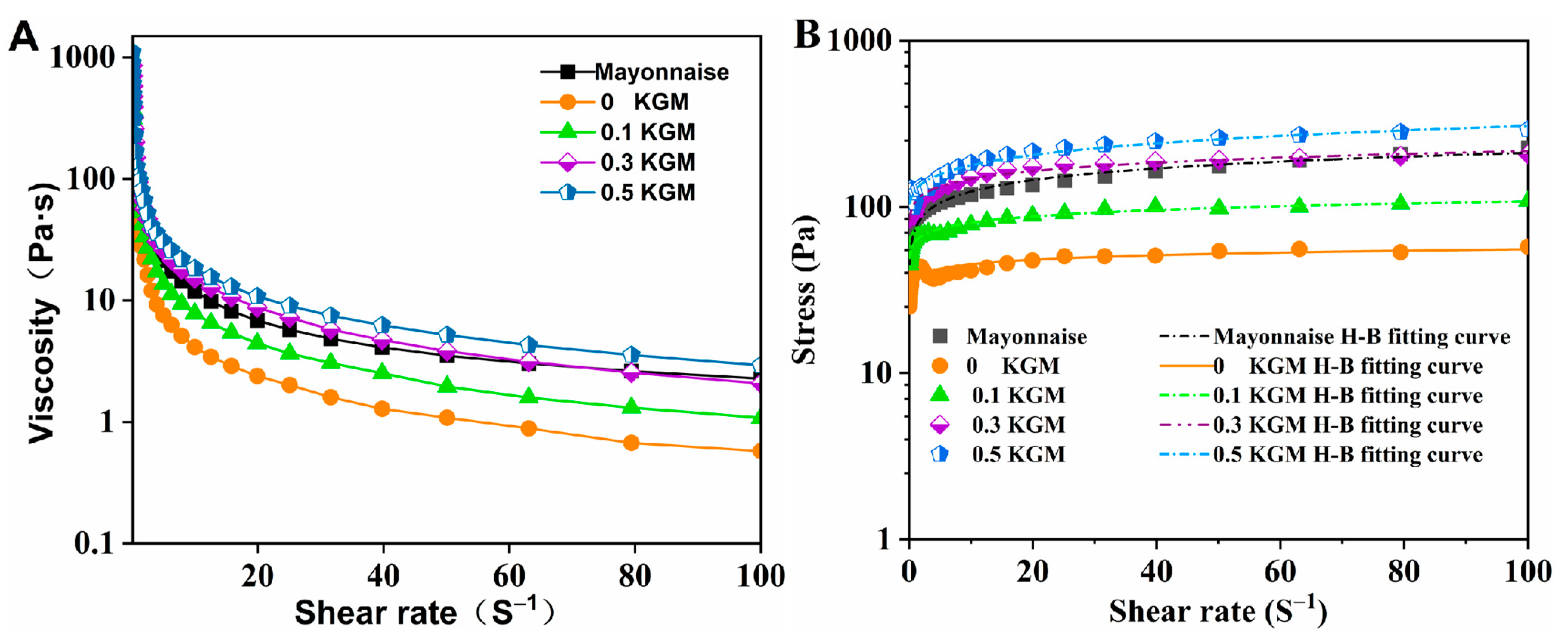

Impact of KGM Concentration

3.2.2. Viscoelastic Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Depree, J.; Savage, G. Physical and flavour stability of mayonnaise. Trends Food Sci. Technol 2001, 12, 157–163. [Google Scholar] [CrossRef]

- Moros, J.; Franco, J.; Gallegos, C. Rheological properties of cholesterol-reduced, yolk-stabilized mayonnaise. J. Am. Oil Chem. Soc. 2002, 79, 837–843. [Google Scholar] [CrossRef]

- Xiong, R.; Xie, G.; Edmondson, A. The fate of Salmonella enteritidis PT4 in home-made mayonnaise prepared with citric acid. Lett. Appl. Microbiol. 1999, 28, 36–40. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Zhou, S.; Ye, F.; Zhou, G.; Gao, R.; Qin, D.; Zhao, G. A novel cholesterol-free mayonnaise made from Pickering emulsion stabilized by apple pomace particles. Food Chem. 2021, 353, 129418. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Gong, T.; Lu, Y.H.; Li, A.; Sun, L.; Guo, Y. Compatibility of sodium alginate and konjac glucomannan and their applications in fabricating low-fat mayonnaise-like emulsion gels. Carbohydr. Polym. 2020, 229, 115468. [Google Scholar] [CrossRef]

- Liu, X.; Guo, J.; Wan, Z.L.; Liu, Y.Y.; Ruan, Q.J.; Yang, X.Q. Wheat gluten-stabilized high internal phase emulsions as mayonnaise replacers. Food Hydrocoll. 2018, 77, 168–175. [Google Scholar] [CrossRef]

- Biller, E.; Waszkiewicz-Robak, B.; Longo, E.; Boselli, E.; Obiedziński, M.; Siwek, A.; Stachelska, M.A. Effects of the addition of spray-dried whey on the stability of fat-reduced mayonnaise-type emulsions during storage. J. Am. Oil Chem. Soc. 2018, 95, 337–348. [Google Scholar] [CrossRef]

- Huang, Z.X.; Lin, W.F.; Zhang, Y.; Tang, C.H. Freeze-thaw-stable high internal phase emulsions stabilized by soy protein isolate and chitosan complexes at pH 3.0 as promising mayonnaise replacers. Food Res. Int. 2022, 156, 111309. [Google Scholar] [CrossRef]

- Jolayemi, O.S.; Stranges, N.; Flamminii, F.; Casiraghi, E.; Alamprese, C. Influence of Free and Encapsulated Olive Leaf Phenolic Extract on the Storage Stability of Single and Double Emulsion Salad Dressings. Food Bioprocess Technol. 2021, 14, 93–105. [Google Scholar] [CrossRef]

- Nikzade, V.; Tehrani, M.M.; Saadatmand-Tarzjan, M. Optimization of low-cholesterol–low-fat mayonnaise formulation: Effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocoll. 2012, 28, 344–352. [Google Scholar] [CrossRef]

- Mozafari, H.R.; Hosseini, E.; Hojjatoleslamy, M.; Mohebbi, G.H.; Jannati, N. Optimization low-fat and low cholesterol mayonnaise production by central composite design. J. Food Sci. Technol. 2017, 54, 591–600. [Google Scholar] [CrossRef] [Green Version]

- Puligundla, P.; Cho, Y.; Lee, Y. Physicochemical and sensory properties of reduced-fat mayonnaise formulations prepared with rice starch and starch-gum mixtures. Emir. J. Food. Agric. 2015, 27, 463–468. [Google Scholar] [CrossRef] [Green Version]

- Heggset, E.B.; Aaen, R.; Veslum, T.; Henriksson, M.; Simon, S.; Syverud, K. Cellulose nanofibrils as rheology modifier in mayonnaise—A pilot scale demonstration. Food Hydrocoll. 2020, 108, 106084. [Google Scholar] [CrossRef]

- Chetana, R.; Bhavana, K.P.; Babylatha, R.; Geetha, V.; Suresh Kumar, G. Studies on eggless mayonnaise from rice bran and sesame oils. J. Food Sci. Technol. 2019, 56, 3117–3125. [Google Scholar] [CrossRef]

- Hijazi, T.; Karasu, S.; Tekin-Cakmak, Z.H.; Bozkurt, F. Extraction of natural gum from cold-pressed chia seed, flaxseed, and rocket seed oil by-product and application in low fat vegan mayonnaise. Foods 2022, 11, 363. [Google Scholar] [CrossRef]

- Park, J.J.; Olawuyi, I.F.; Lee, W.Y. Characteristics of low-fat mayonnaise using different modified arrowroot starches as fat replacer. Int. J. Biol. Macromol. 2020, 153, 215–223. [Google Scholar] [CrossRef]

- El-Waseif, M.; Saed, B.; Fahmy, H.; Sabry, A.; Shaaban, H.; Abdelgawad, M.; Amin, A.; Farouk, A. Mayonnaise Enriched with Flaxseed Oil: Omega-3 Fatty Acids Content, Sensory Quality and Stability during the Storage. Foods 2022, 11, 2282. [Google Scholar] [CrossRef]

- Miguel, G.A.; Jacobsen, C.; Prieto, C.; Kempen, P.J.; Lagaron, J.M.; Chronakis, I.S.; García-Moreno, P.J. Oxidative stability and physical properties of mayonnaise fortified with zein electrosprayed capsules loaded with fish oil. J. Food Eng. 2019, 263, 348–358. [Google Scholar] [CrossRef]

- Di Mattia, C.; Balestra, F.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and structural properties of extra-virgin olive oil based mayonnaise. LWT—Food Sci. Technol. 2015, 62, 764–770. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, Z.; Pei, Y.; Li, J.; Li, B. Gelation behaviors of the konjac gum from different origins: A. guripingensis and A. rivirei. Food Hydrocoll. 2021, 111, 106152. [Google Scholar] [CrossRef]

- Jian, W.; Wu, H.; Wu, L.; Wu, Y.; Jia, L.; Pang, J.; Sun, Y.M. Effect of molecular characteristics of Konjac glucomannan on gelling and rheological properties of Tilapia myofibrillar protein. Carbohydr. Polym. 2016, 150, 21–31. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Liu, R.; Liang, B.; Wu, T.; Sui, W.; Zhang, M. Microparticulated whey protein-pectin complex: A texture-controllable gel for low-fat mayonnaise. Food Res. Int. 2018, 108, 151–160. [Google Scholar] [CrossRef] [PubMed]

- Trujillo-Ramírez, D.; Lobato-Calleros, C.; Román-Guerrero, A.; Hernández-Rodríguez, L.; Alvarez-Ramirez, J.; Vernon-Carter, E.J. Complexation with whey protein hydrolysate improves cacao pods husk pectin surface active and emulsifying properties. React. Funct. Polym. 2018, 123, 61–69. [Google Scholar] [CrossRef]

- Patel, S. Functional food relevance of whey protein: A review of recent findings and scopes ahead. J. Funct. Foods 2015, 19, 308–319. [Google Scholar] [CrossRef]

- Nourbehesht, N.; Shekarchizadeh, H.; Soltanizadeh, N. Investigation of stability, consistency, and oil oxidation of emulsion filled gel prepared by inulin and rice bran oil using ultrasonic radiation. Ultrason. Sonochem. 2018, 42, 585–593. [Google Scholar] [CrossRef] [PubMed]

- Taslikh, M.; Mollakhalili-Meybodi, N.; Alizadeh, A.M.; Mousavi, M.M.; Nayebzadeh, K.; Mortazavian, A.M. Mayonnaise main ingredients influence on its structure as an emulsion. J. Food Sci. Technol. 2022, 59, 2108–2116. [Google Scholar] [CrossRef]

- Zhu, Y.; Gao, H.; Liu, W.; Zou, L.; McClements, D.J. A review of the rheological properties of dilute and concentrated food emulsions. J. Texture Stud. 2020, 51, 45–55. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, C.; Pei, Y. Impact of flaxseed oil concentration on stabilization of mayonnaise-like emulsion co-stabilized by WP and KGM. Sci. Technol. Cereals Oils Foods 2023, 31, 41–47. [Google Scholar]

- Su, H.P.; Lien, C.P.; Lee, T.A.; Ho, J.H. Development of low-fat mayonnaise containing polysaccharide gums as functional ingredients. J. Sci. Food Agric. 2010, 90, 806–812. [Google Scholar] [CrossRef]

- Whitby, C.P.; McVicker, R.; Connor, J.N.; Sedev, R. Yielding and fracturing of concentrated emulsions in narrow gaps. Soft Matter 2013, 9, 5975–5981. [Google Scholar] [CrossRef]

- Dapčević Hadnađev, T.; Dokić, P.; Krstonošić, V.; Hadnađev, M. Influence of oil phase concentration on droplet size distribution and stability of oil-in-water emulsions. Eur. J. Lipid Sci. Technol. 2013, 115, 313–321. [Google Scholar] [CrossRef]

- Katsaros, G.; Tsoukala, M.; Giannoglou, M.; Taoukis, P. Effect of storage on the rheological and viscoelastic properties of mayonnaise emulsions of different oil droplet size. Heliyon 2020, 6, e05788. [Google Scholar] [CrossRef]

- Unnikrishnan, P.; Puthenveetil Kizhakkethil, B.; Anant Jadhav, M.; Sivam, V.; Ashraf, P.M.; Ninan, G.; Aliyamveetil Abubacker, Z. Protein hydrolysate from yellowfin tuna red meat as fortifying and stabilizing agent in mayonnaise. J. Food Sci. Technol. 2020, 57, 413–425. [Google Scholar] [CrossRef]

- Franco, J.; Partal, P.; Ruiz-Márquez, D.; Conde, B.; Gallegos, C. Influence of pH and protei thermal treatment on the rheology of pea protein-stabilized oil-in-water emulsions. J. Am. Oil Chem. Soc. 2000, 77, 975–984. [Google Scholar] [CrossRef]

- Borderías, A.J.; Tovar, C.A.; Domínguez-Timón, F.; Díaz, M.T.; Pedrosa, M.M.; Pedrosa, M.M.; Moreno, H.M. Characterization of healthier mixed surimi gels obtained through partial substitution of myofibrillar proteins by pea protein isolates. Food Hydrocoll. 2020, 107, 105976. [Google Scholar] [CrossRef]

- Moreno, H.M.; Dominguez-Timon, F.; Díaz, M.T.; Pedrosa, M.M.; Borderías, A.J.; Tovar, C.A. Evaluation of gels made with different commercial pea protein isolate: Rheological, structural and functional properties. Food Hydrocoll. 2020, 99, 105375. [Google Scholar] [CrossRef]

- Niknam, R.; Ghanbarzadeh, B.; Ayaseh, A.; Rezagholi, F. The effects of Plantago major seed gum on steady and dynamic oscillatory shear rheology of sunflower oil-in-water emulsions. J. Texture Stud. 2018, 49, 536–547. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Wang, K.; Bao, Y.; Regenstein, J.M.; Zhou, P. Fabrication of gel-like emulsions with whey protein isolate using microfluidization: Rheological properties and 3D printing performance. Food Bioprocess Technol. 2019, 12, 1967–1979. [Google Scholar] [CrossRef]

| Samples | Aqueous Phase Ingredients (%) | ||||

|---|---|---|---|---|---|

| 30% WP Stock Solution | 5% KGM Stock Solution | Double-Distilled Water | Condiments | ||

| WP% | 0 WP | 0 | 6.0 | 16.0 | The proportion of total condiments was 8.0%: 4.0% vinegar; 2.0% sugar; 2.0% salt |

| 1 WP | 3.3 | 6.0 | 12.7 | ||

| 2 WP | 6.7 | 6.0 | 9.3 | ||

| 3 WP | 10.0 | 6.0 | 6.0 | ||

| KGM% | 0 KGM | 6.7 | 0 | 15.3 | |

| 0.1 KGM | 6.7 | 2.0 | 13.3 | ||

| 0.3 KGM | 6.7 | 6.0 | 9.3 | ||

| 0.5 KGM | 6.7 | 10.0 | 5.3 | ||

| Samples | K/Pa sn | n | R2 |

|---|---|---|---|

| 0 KGM | 36.70 ± 6.34 c | 0.49 ± 0.08 a | 0.90 |

| 0.1 KGM | 37.79 ± 5.48 c | 0.40 ± 0.03 a | 0.98 |

| 0.3 KGM | 68.35 ± 3.68 b | 0.24 ± 0.04 b | 0.97 |

| 0.5 KGM | 84.65 ± 3.69 a | 0.17 ± 0.05 c | 0.96 |

| Mayonnaise | 65.69 ± 5.59 b | 0.25 ± 0.04 b | 0.98 |

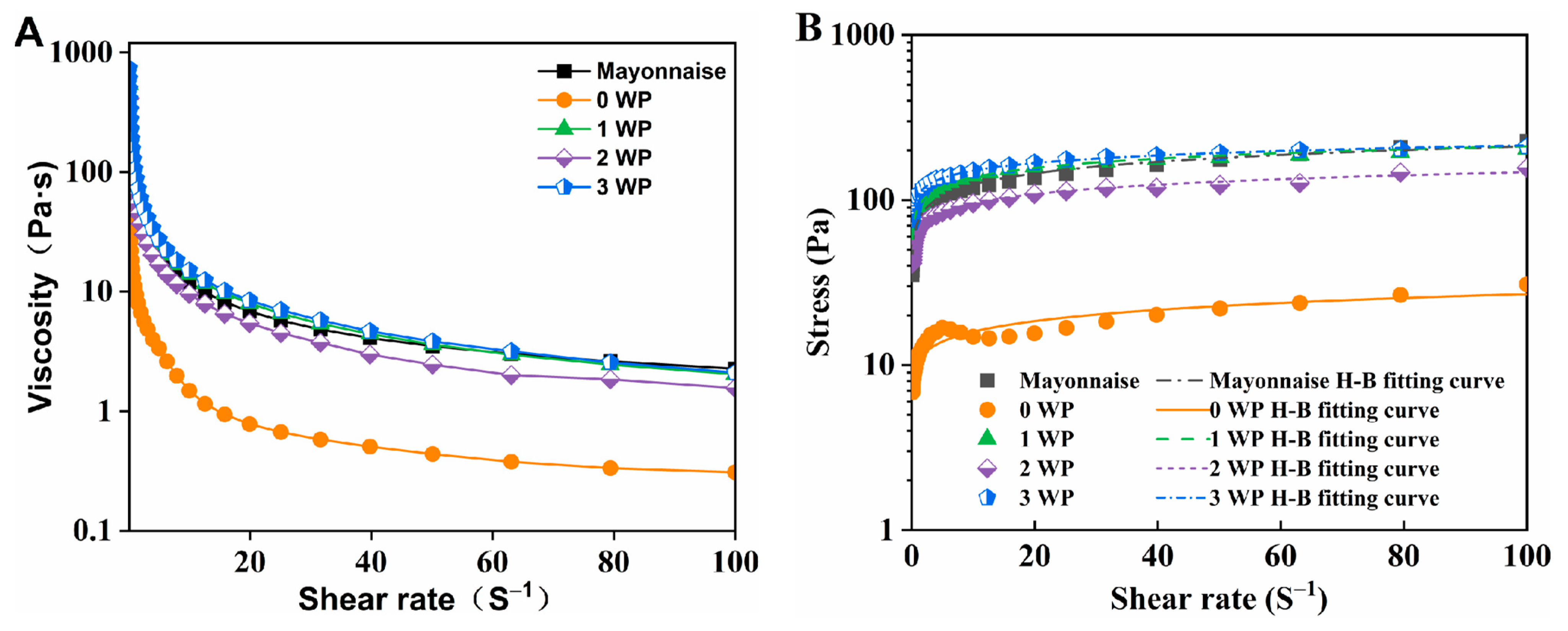

| Sample | K/Pa sn | n | R2 |

|---|---|---|---|

| 0 WP | 5.29 ± 2.06 d | 0.31 ± 0.07 a | 0.84 |

| 1 WP | 89.14 ± 8.21 b | 0.18 ± 0.01 c | 0.99 |

| 2 WP | 61.51 ± 7.32 c | 0.24 ± 0.02 b | 0.99 |

| 3 WP | 95.87 ± 7.85 a | 0.15 ± 0.01 d | 0.99 |

| Mayonnaise | 63.23 ± 6.57 c | 0.25 ± 0.03 b | 0.98 |

| Sample | G0′ (Pa) | n′ | R2 | G0″ (Pa) | n″ | R2 |

|---|---|---|---|---|---|---|

| 0 KGM | 147.4 ± 0.9 e | 0.14 ± 0.01 ab | 0.99 | 34.1 ± 0.3 e | 0.21 ± 0.01 b | 0.99 |

| 0.1 KGM | 555.6 ± 2.8 c | 0.12 ± 0.01 bc | 0.99 | 114.2 ± 5.8 c | 0.16 ± 0.02 c | 0.90 |

| 0.3 KGM | 681.0 ± 7.6 b | 0.11 ± 0.01 bc | 0.98 | 183.5 ± 8.0 b | 0.17 ± 0.02 c | 0.91 |

| 0.5 KGM | 815.9 ± 10 a | 0.10 ± 0.01 c | 0.97 | 238.7 ± 6.2 a | 0.16 ± 0.01 c | 0.94 |

| Mayonnaise | 336.1 ± 5.5 d | 0.16 ± 0.01 a | 0.97 | 48.4 ± 2.7.2 d | 0.29 ± 0.02 a | 0.91 |

| 0 WP | 11.8 ± 0.2 E | 0.22 ± 0.01 A | 0.98 | 4.9 ± 0.04 D | 0.18 ± 0.01 C | 0.99 |

| 1 WP | 769.6 ± 5.4 B | 0.12 ± 0.01 C | 0.99 | 147.9 ± 2.8 B | 0.17 ± 0.01 C | 0.97 |

| 2 WP | 615.9 ± 5.8 C | 0.11 ± 0.02 C | 0.99 | 106.4 ± 2.1 A | 0.18 ± 0.01 C | 0.98 |

| 3 WP | 787.1 ± 6.3 A | 0.10 ± 0.01 C | 0.99 | 154.1 ± 4.2 B | 0.17 ± 0.01 C | 0.95 |

| Mayonnaise | 336.1 ± 5.5 D | 0.16 ± 0.01 B | 0.97 | 48.4 ± 2.7.2 C | 0.29 ± 0.02 A | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, Y.; Zhang, Y.; Ding, H.; Li, B.; Yang, J. Stability and Rheological Behavior of Mayonnaise-like Emulsion Co-Emulsified by Konjac Glucomannan and Whey Protein. Foods 2023, 12, 2907. https://doi.org/10.3390/foods12152907

Pei Y, Zhang Y, Ding H, Li B, Yang J. Stability and Rheological Behavior of Mayonnaise-like Emulsion Co-Emulsified by Konjac Glucomannan and Whey Protein. Foods. 2023; 12(15):2907. https://doi.org/10.3390/foods12152907

Chicago/Turabian StylePei, Yaqiong, Yanqiu Zhang, Hui Ding, Bin Li, and Jun Yang. 2023. "Stability and Rheological Behavior of Mayonnaise-like Emulsion Co-Emulsified by Konjac Glucomannan and Whey Protein" Foods 12, no. 15: 2907. https://doi.org/10.3390/foods12152907

APA StylePei, Y., Zhang, Y., Ding, H., Li, B., & Yang, J. (2023). Stability and Rheological Behavior of Mayonnaise-like Emulsion Co-Emulsified by Konjac Glucomannan and Whey Protein. Foods, 12(15), 2907. https://doi.org/10.3390/foods12152907