2.1. Materials

An experimental refrigerated cold room, with programmable temperatures, was used to simulate a refrigerated condition during the produce cold chain. This has a polyurethane sandwich panel as isolation material, and the room measured 2 × 1.50 × 1.50 m. The refrigerated unit functions by internal evaporation with an external condensation unit of hermetic alternative compressor of 5 kW with R-134a as a refrigerant. Air speed is a constant, and it flows around 2.5 m/s. The room has its own temperature sensor to show the temperature in the control display. This sensor is placed on the wall of the door, 150 cm above the ground.

Data loggers were utilized to measure the ambient parameters. U12-013 HOBO measured temperature (range of −20° to 70 °C) and RH (5% to 95%). Each logger had two external ports where two temperature probes were connected, TMC6-HD and an air, water, or soil temperature sensor. The measurement range was −40° to 50 °C (−40° to 122 °F) in the water or soil and −40° to 100 °C (−40° to 212 °F) in the air.

The thermal camera utilized was Flir brand, E6 model. IR resolution was 160 × 120, with a thermal sensitivity of <0.006 °C, temperature range of –20° to 250 °C, and accuracy between ±2% or 2 °C.

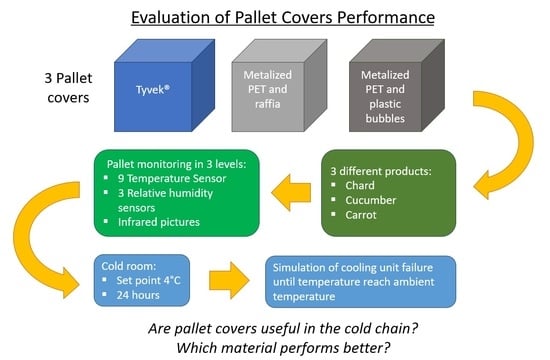

Three different types of pallet covers were used as coverage for the pallets (see

Figure 1). The first was a DuPont™ Tyvek

® Air Cargo Cover, breathable, lightweight and made of Tyvek

®, and 1200 × 1000 × 1700 mm in size. The second cover was made of Metalized PET and raffia and was not breathable; therefore, it accumulated condensation inside. The third was a cover composed of three layers, the inside and outside made of Metalized PET with the middle layer made of plastic bubbles. The size of the last two covers was 1200 × 1000 × 1700 mm. The pallet used was 1200 × 1000 mm in size, and the plastic grid boxes were 500 × 380 × 280 mm.

The products used were fresh vegetables, and in all cases, the experiment did not start more than 24 h after harvest. Products included 400 kg of chard for the first experiment, 400 kg of cucumbers for the second, and 500 kg of carrots for the last experiment.

The optimum storage conditions for these products are presented in

Table 1. As can be seen, carrots can be stored for a longer period of time than chard or cucumbers due to their lower water content.

2.2. Methods

IR camera cannot give a surface temperature with precision, and thus calibration is necessary. Prior to the experiment, calibration of the thermal camera was carried out due to the emissivity of the materials in the covers tested. That calibration was made by preparing a flat surface of the covers, attaching a TMC6-HD probe to it and measuring the temperature. Then, a thermal picture was taken in the probe area, the temperature from the probe and the IR image were compared, and the emissivity was adjusted in the camera settings.

The following method descriptions are separated according to the three different products used. The three products combined with the different covers have different experimentation times but share the same procedure.

Each product was distributed into 18 boxes—about 15 kilos per box for chard and 20 kilos for cucumbers and carrots.

The pallet was built in three layers, with a data logger installed in the center of each layer of the boxes and two probes also installed inside the boxes at the end of a cable in opposite boxes diagonally, as shown in

Figure 2. In total, there were 3 humidity sensors in the middle of the three layers and 9 temperature sensors, conforming to a diagonal mesh of sensors in the pallet. The sensors were set to record temperature and humidity every 5 min. The position of the sensors covers the three highs of the pallet and one diagonal, which represents the maximum, minimum and average temperatures among the pallet, as observed in previous studies [

21,

22,

23].

In the following step, three pictures from the surface on top of the pallet were taken using the thermal camera, one picture from the top-right corner, one in the middle and one in the bottom-left corner, as indicated in

Figure 2. On top of the pallet representation, the three pictures taken are represented—one in the upper-left part of the image, the other in the middle and the other in the bottom-right. These pictures are intended to be used as a complement to the study; the pictures provide the produce surface temperature, which is the temperature over the entire pallet since the product was not exposed to any heat/cold source. The pallet was then covered with one of the types of covers.

At this moment, the product was at room temperature and the cold room was set to cool down to a temperature of 4 °C; five pictures were taken with the IR camera, specifically the four top corners and the middle of the pallet’s upper face center. After 24 h, the refrigerating unit was switched off to simulate a failure in the cooling system. The temperature increased until it reached the ambient temperature (23 °C), and the surface of the pallet was recorded with pictures from the thermal camera and the corresponding temperature data that was registered in the image; those pictures were taken at the same points as in the beginning, the four top corners and the pallet’s top face center. The aim of taking those pictures was to have a record of the critical moments, such as the extreme temperatures at the beginning and at the end of the dynamic temperature curves. The temperature from the IR image was extracted and used in the results (

Figure 3).

The temperature ramp from 4 °C to 10 °C represents an important gap that could affect the quality of the vegetables. This leap is common when there is a break in the cold chain, such as refrigeration failure or when the freight is exposed to ambient temperatures; the product temperature might not reach the ambient temperature, but it increases. In addition, the authors wanted to have identical temperature ranges in all the scenarios, which makes the experiments replicable.

Thus, the temperature ramp was replicated twelve times, with three different real fresh vegetables—it is important to remark that real produce is a difficult-to-find good in research experiments due to their perishable characteristics—and with each vegetable type, it was repeated using three different covers and no cover.

When the process was finished, the data were analyzed with ad hoc software developed in MATLAB 2022a. The correlation between the thermal images and sensor temperatures was studied by conducting a statistical analysis. RMSE (Root Mean Squared Error) was used to obtain an error with the same unit as the outcome variable for easier interpretation purposes. The closer the point is to the regression, the lower the metric value and the higher the accuracy of the regression model. When a model is 100% perfect, this metric value will be equal to zero. The RMSE formula is

where

N is the number of samples;

Yi are the observed values;

ŷi are the estimated values.