A Reliable Method for Determining the Degree of Orientation of Fibrous Foods Using Laser Transmission and Computer Vision

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

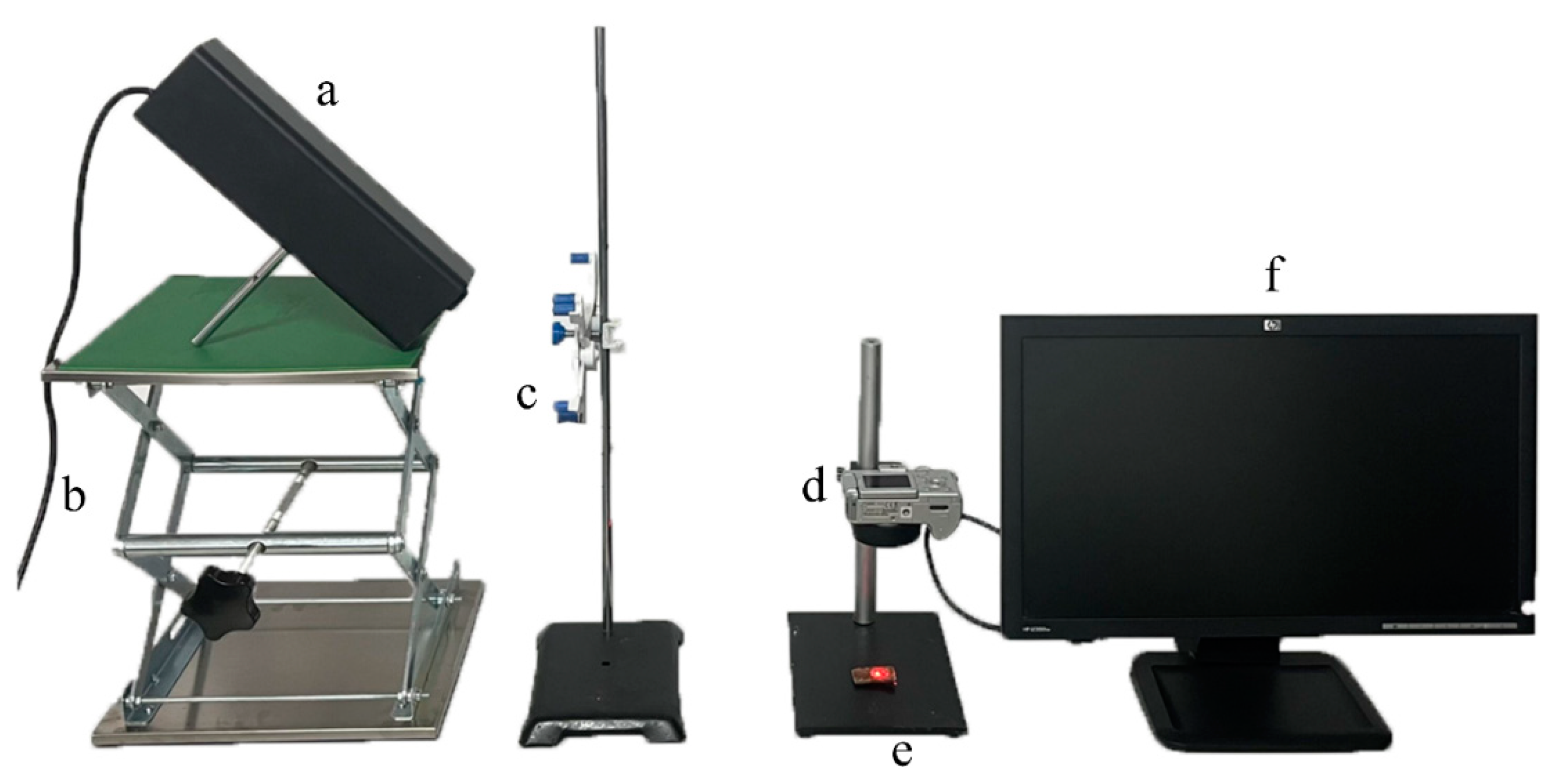

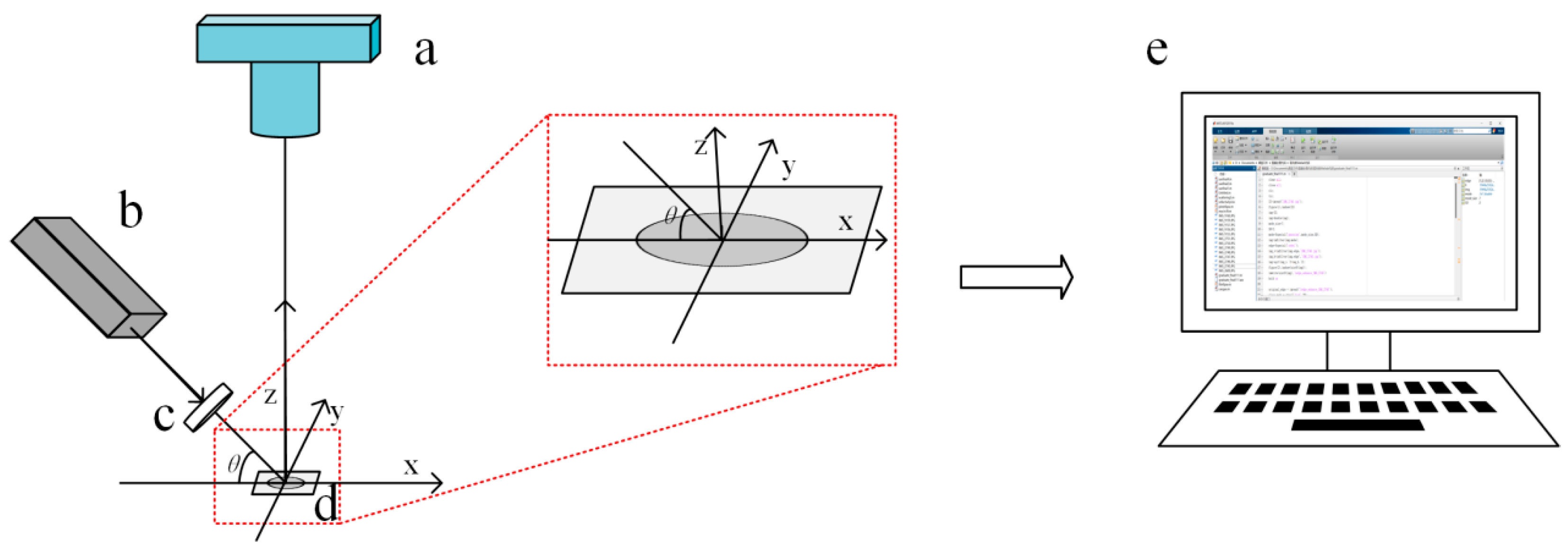

2.3. Construction of the Laser Transmission Imaging System

2.4. Laser Spot Image Acquisition Process

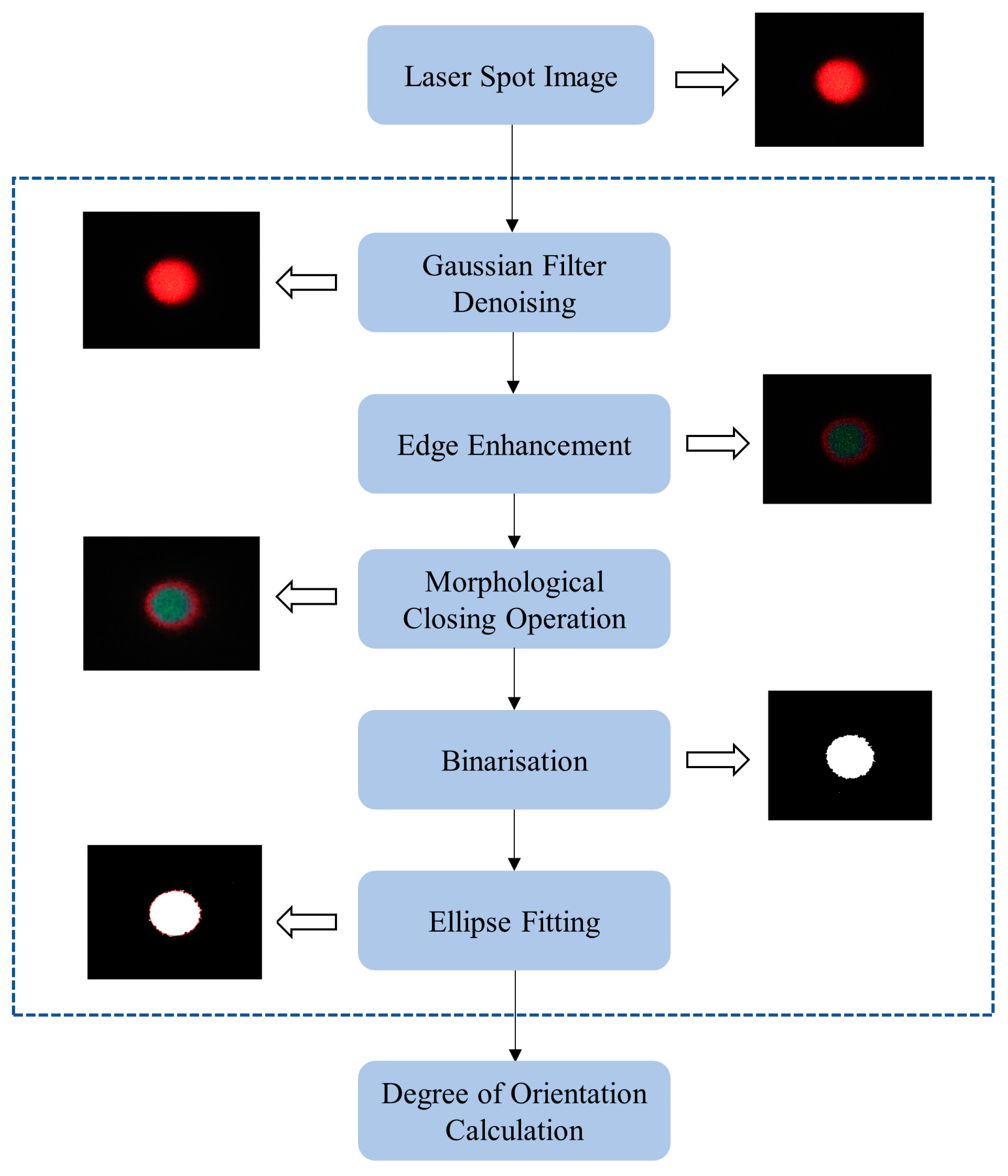

2.5. Processing Steps for Laser Spot Images

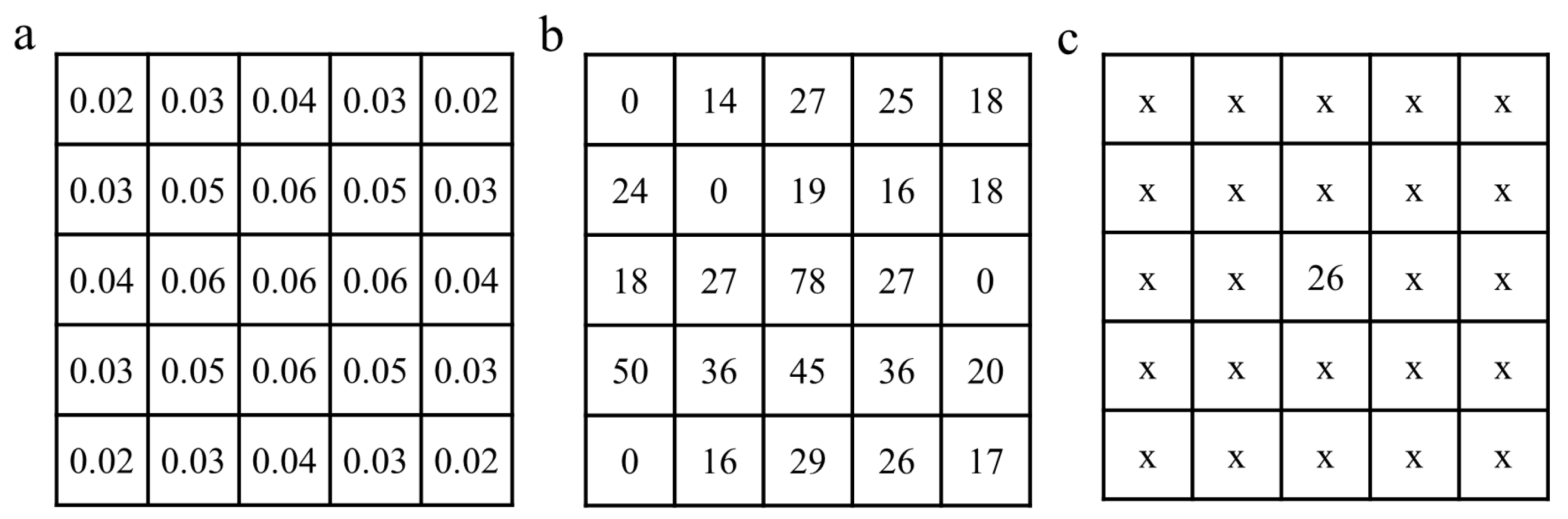

2.5.1. Gaussian Filters Denoising

2.5.2. Edge Enhancement

2.5.3. Morphological Smoothing

2.5.4. Binarisation Treatment

2.5.5. Ellipse Fitting

2.6. Method for Calculating the Degree of Orientation

2.7. Verification of the Determination Method

2.7.1. Degree of Orientation Determination

2.7.2. Pseudocolour Maps Acquisition

2.7.3. Microstructural Characteristics

2.7.4. Textural Properties

2.8. Statistical Analysis

3. Results

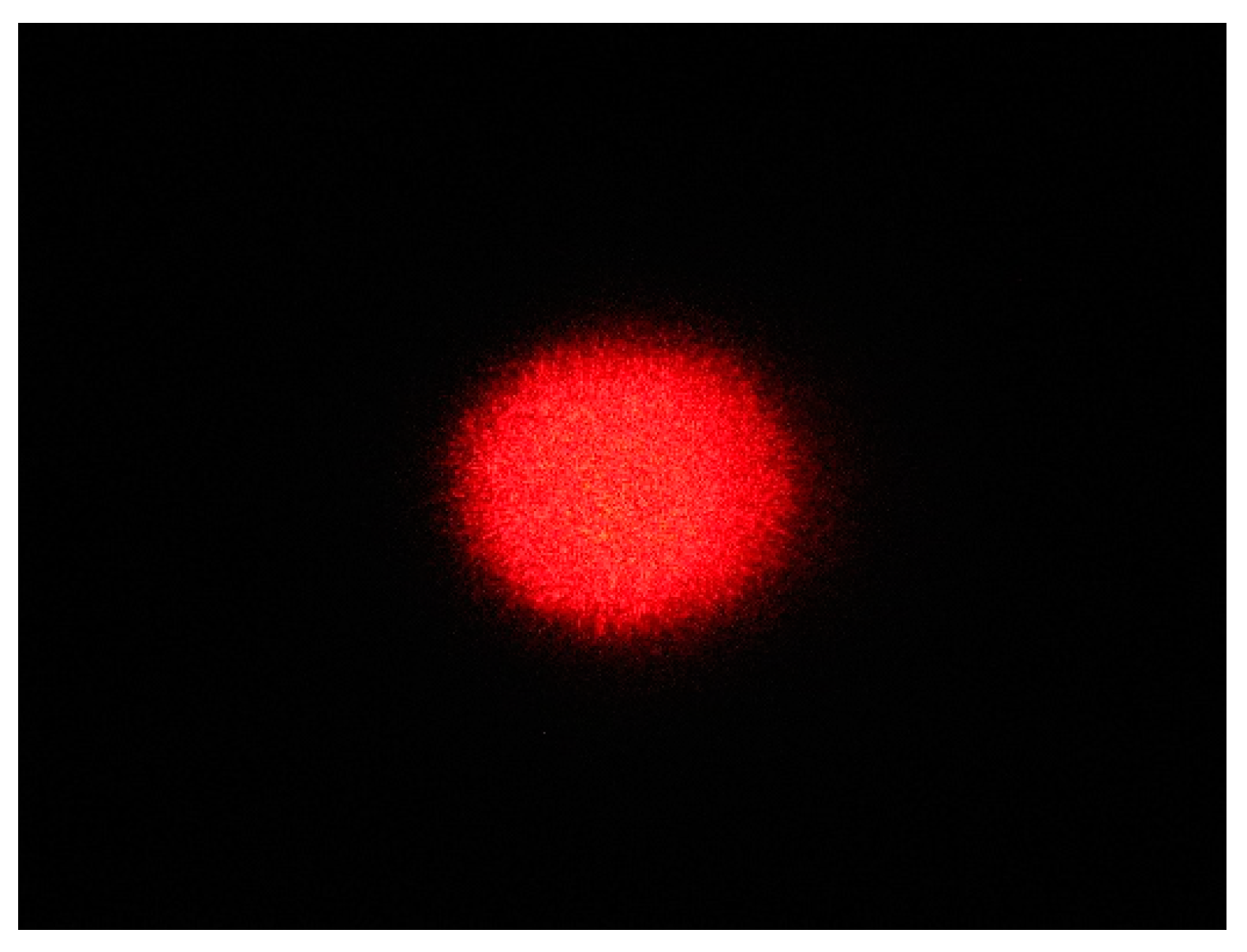

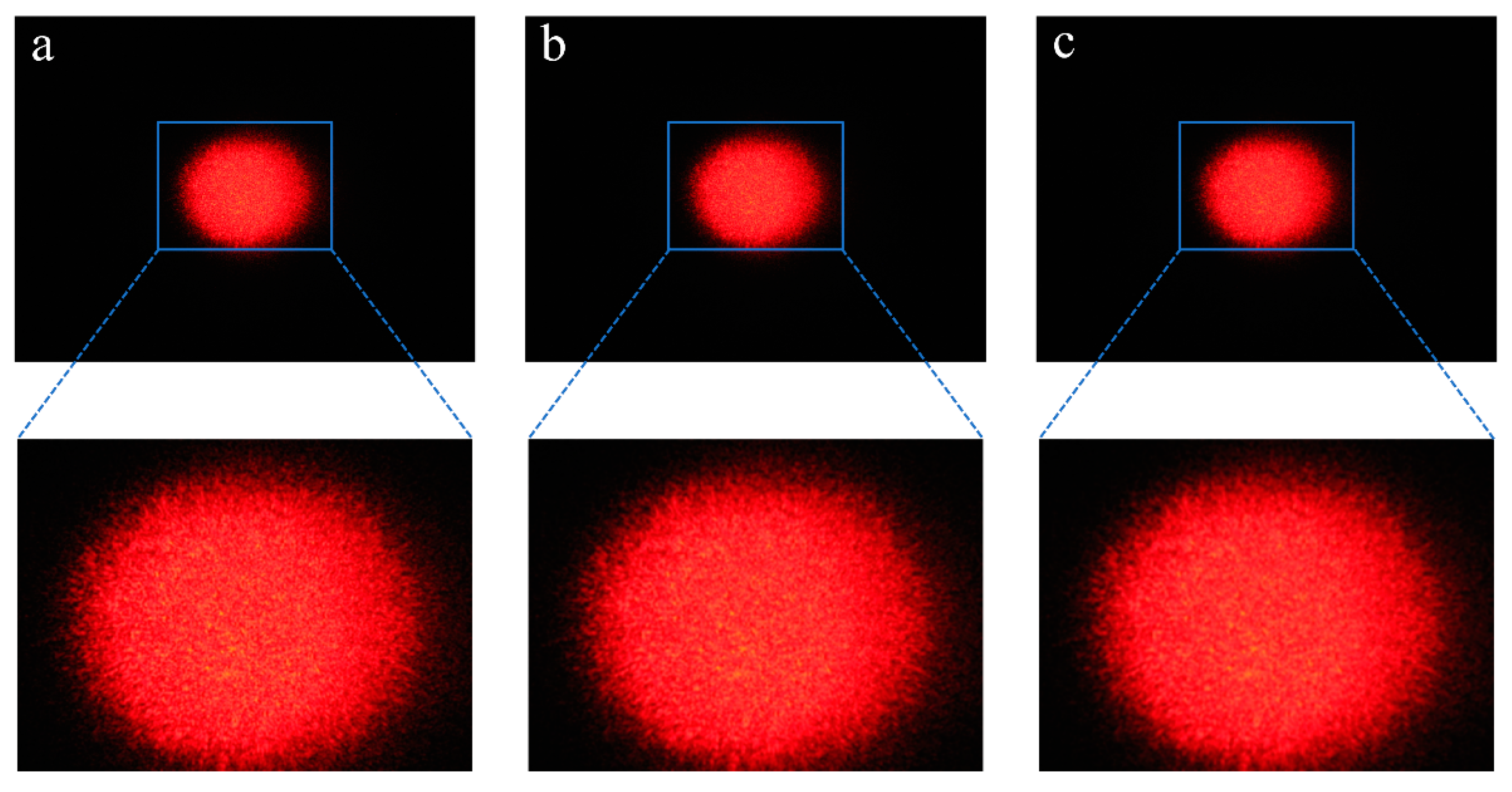

3.1. Acquired Laser Spot Images

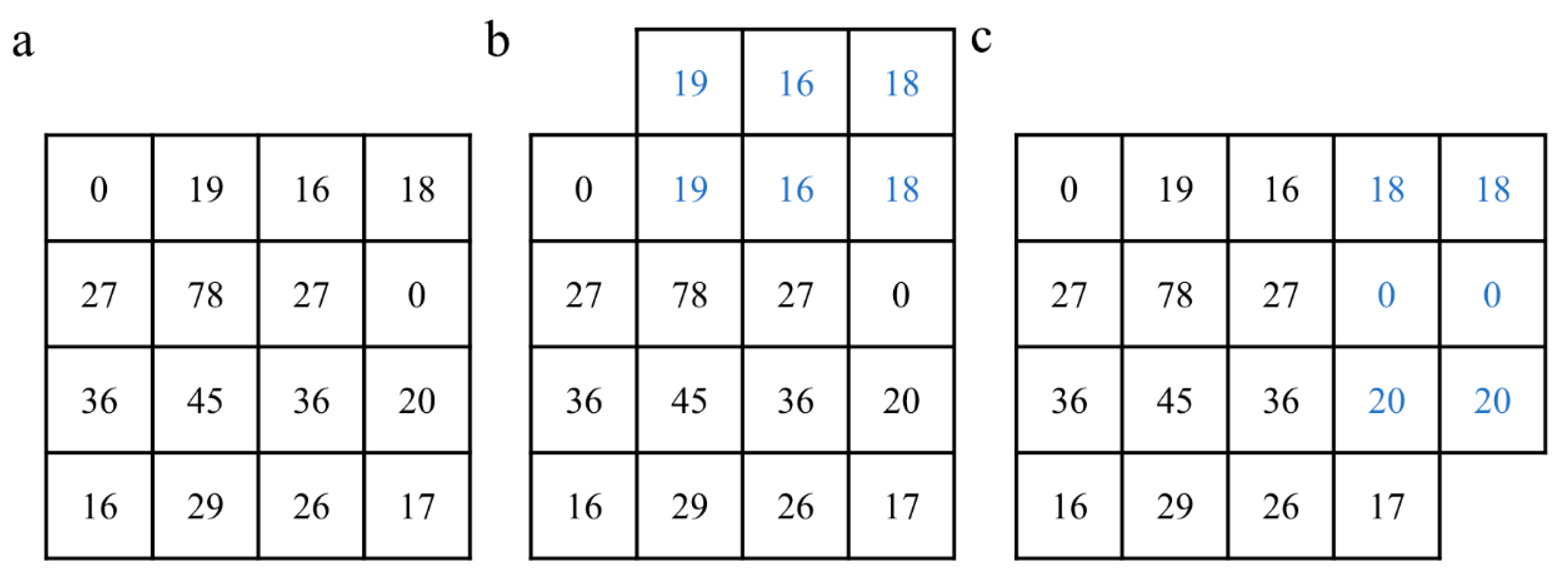

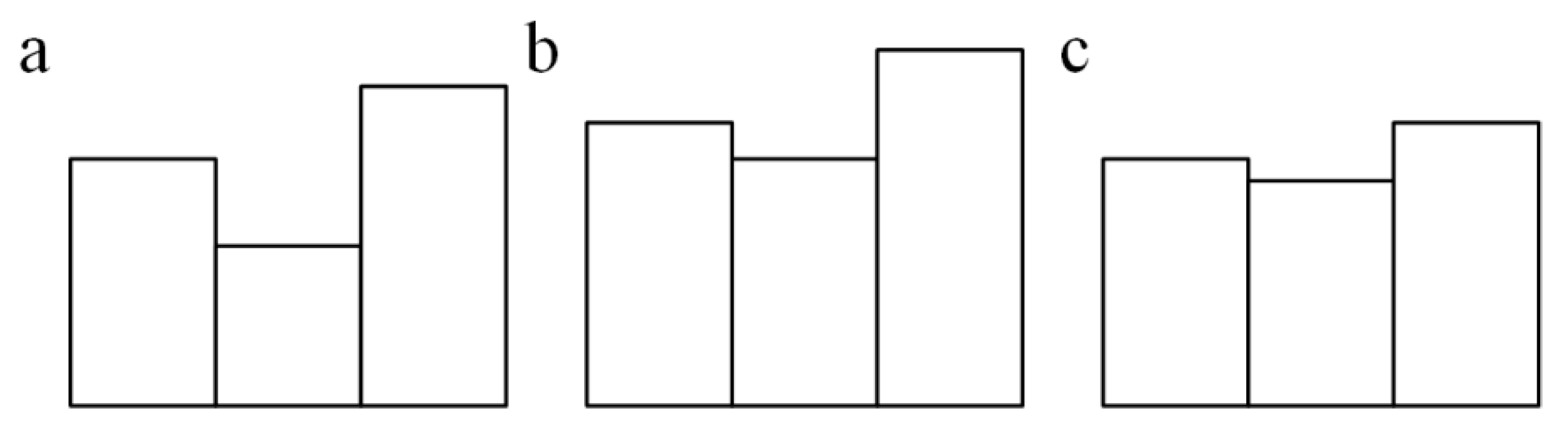

3.2. Results of Laser Spot Image Processing

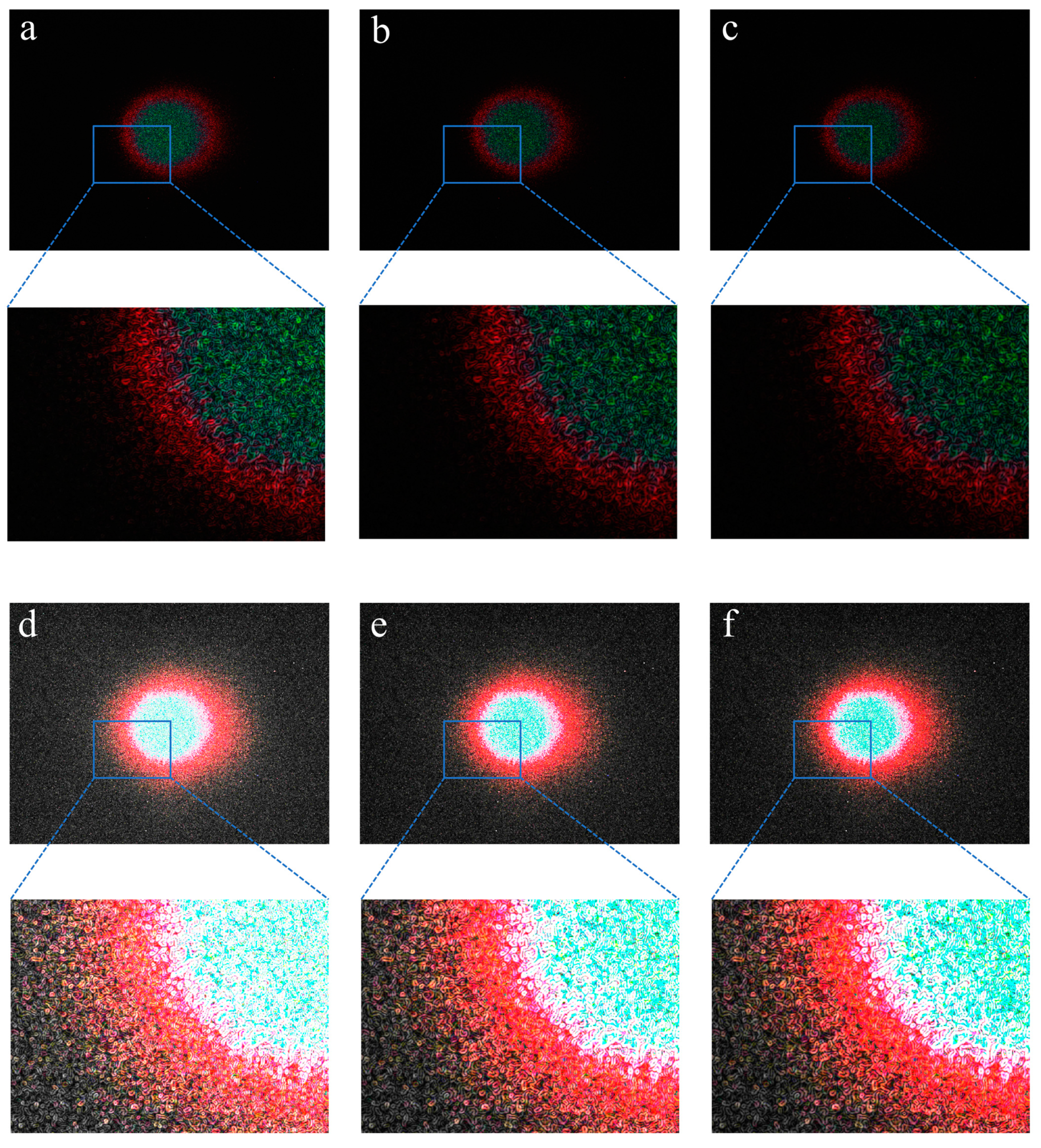

3.2.1. Gaussian Filter Denoising

3.2.2. Edge Enhancement

3.2.3. Morphological Smoothing

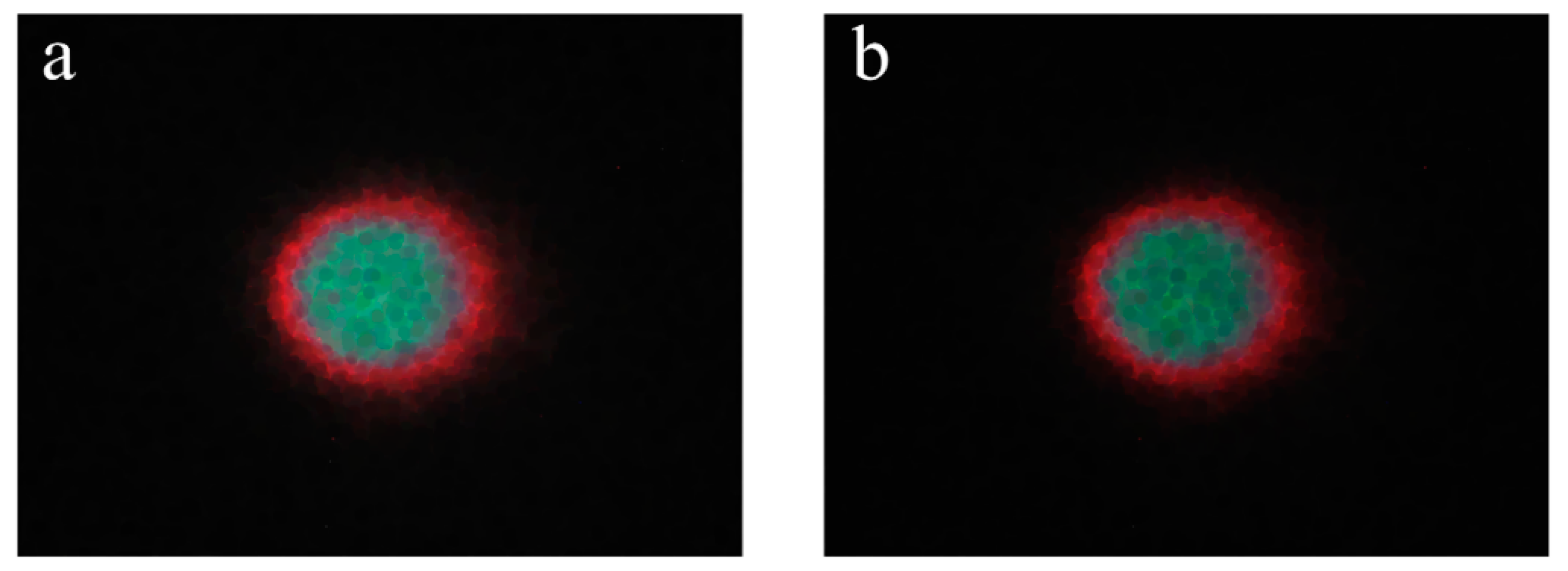

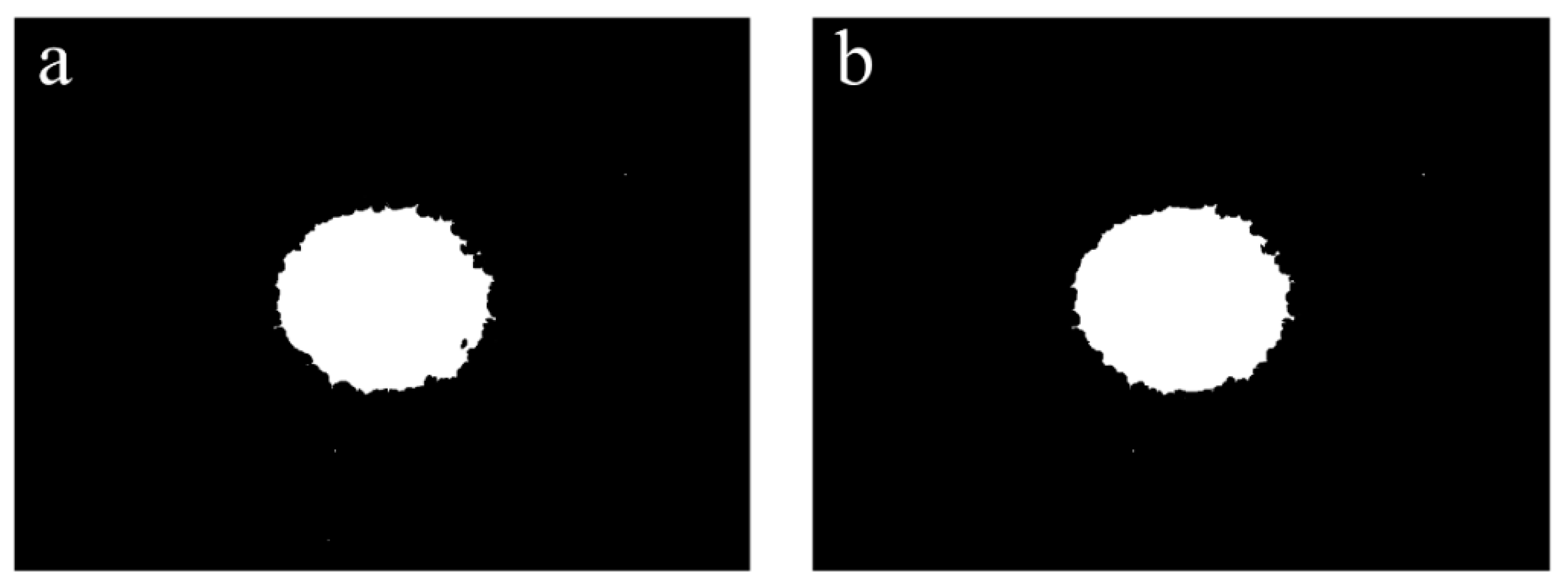

3.2.4. Binarisation Treatment

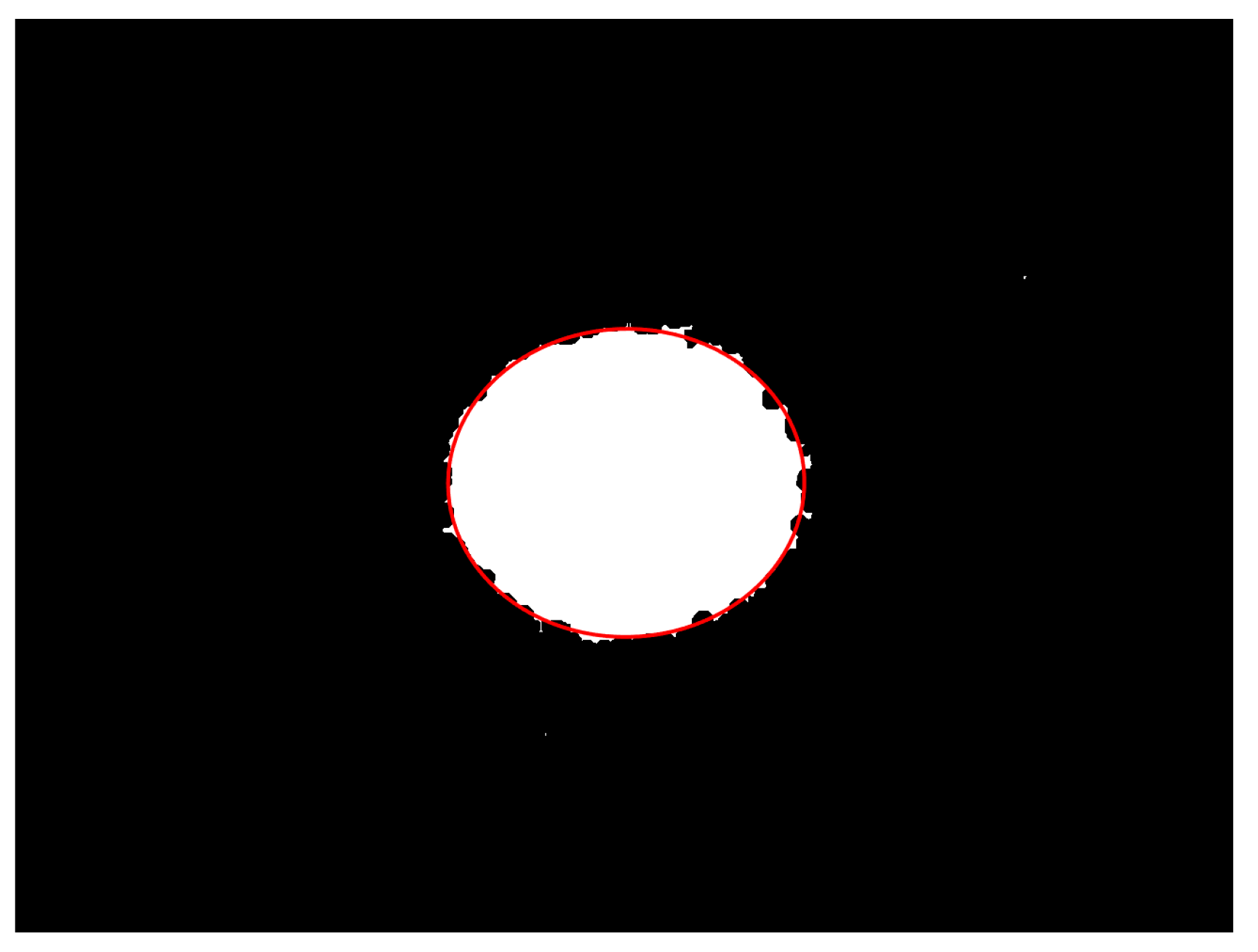

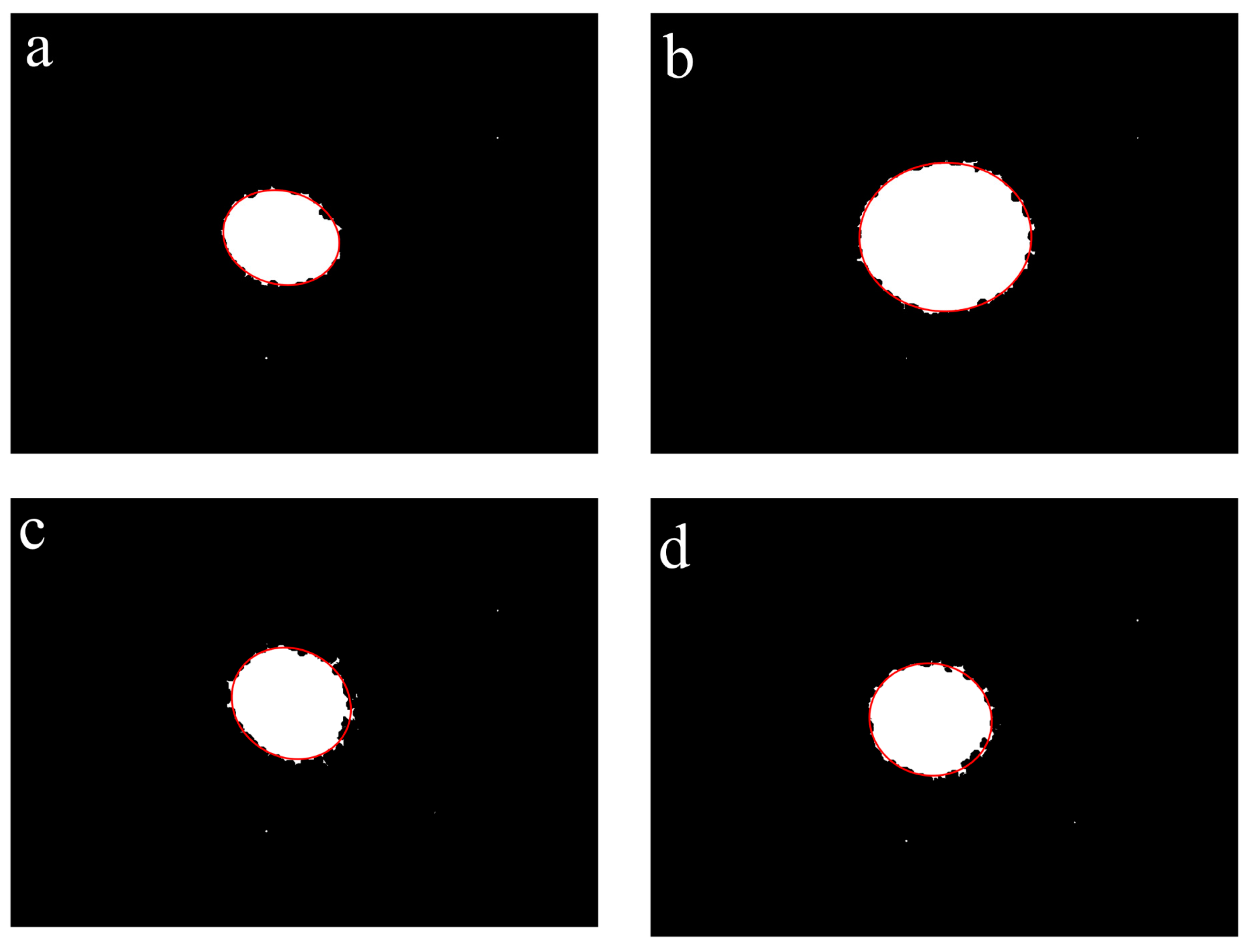

3.2.5. Ellipse Fitting

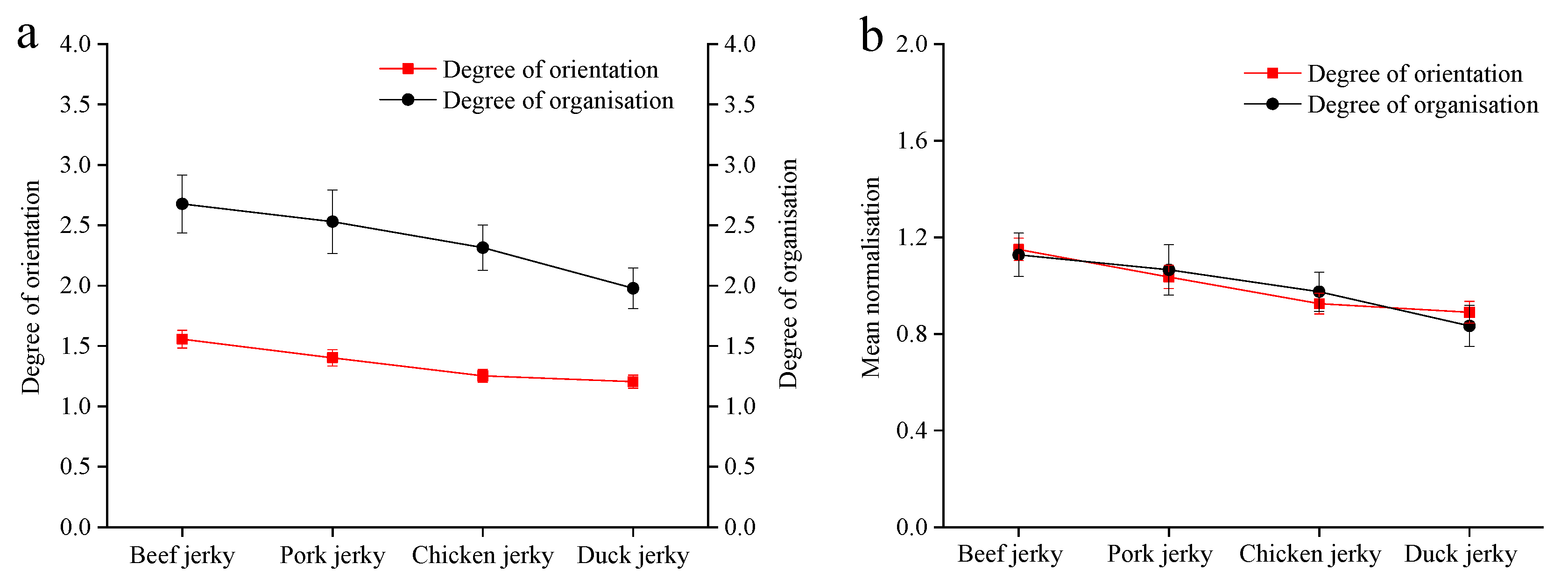

3.3. Results of the Degree of Orientation

3.4. Validation of the Orientation Determination Method

3.4.1. Orientation Results for Extruded Jerky

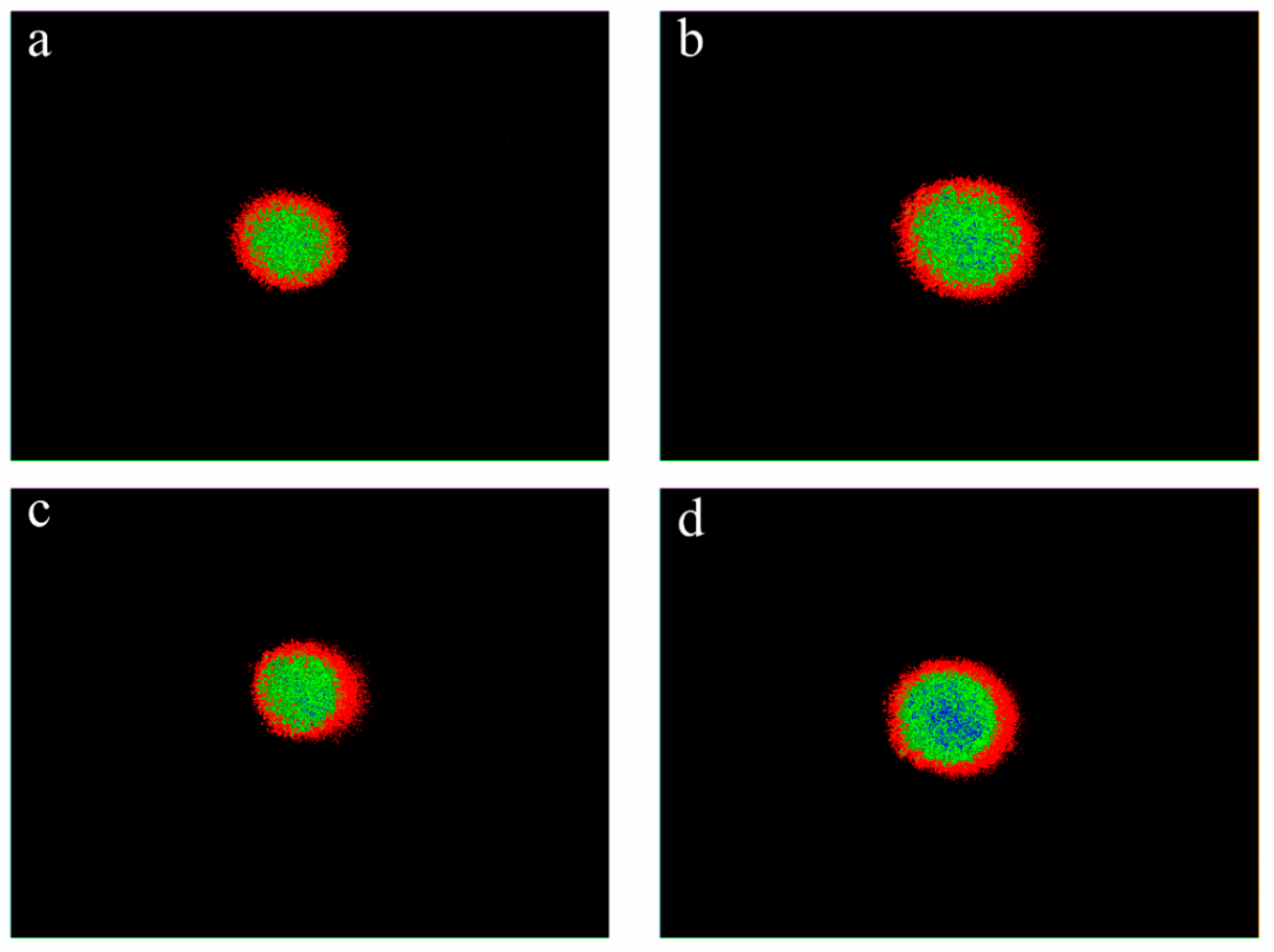

3.4.2. Comparison of Pseudocolour Map Differences

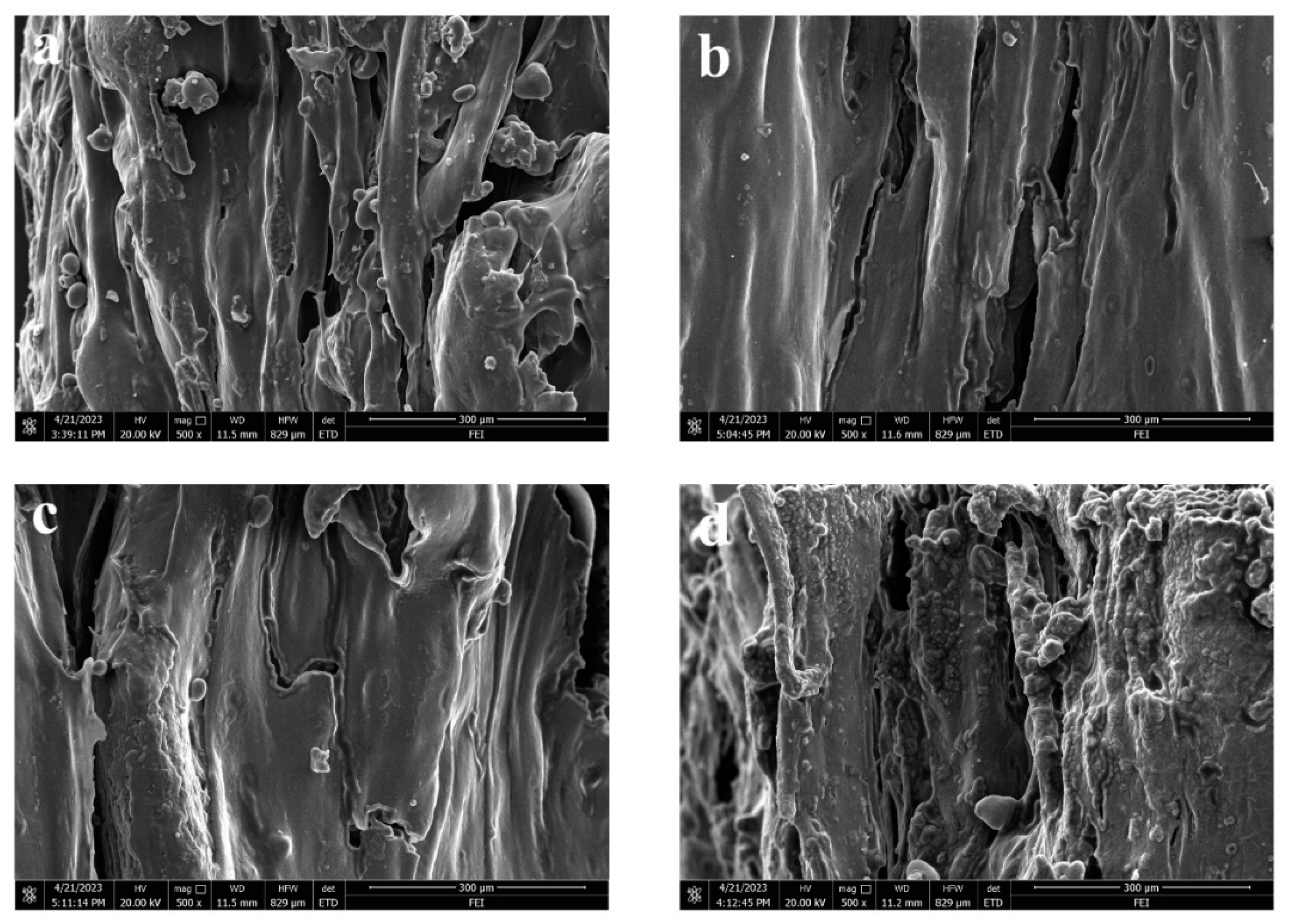

3.4.3. Comparison of Structural Characteristics

3.4.4. Comparison and Analysis of Textural Properties

4. Discussion

4.1. Comparing Findings with Similar Studies

4.2. Comparing Orientation Determination Methods

4.3. Advantages and Limitations of Our Method

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, T.; Yong, H.; Cha, J.; Park, S.; Jung, S.; Choi, Y. Drying-induced restructured jerky analog developed using a combination of edible insect protein and textured vegetable protein. Food Chem. 2021, 373, 31519. [Google Scholar] [CrossRef] [PubMed]

- Hoi, L.W.S.; Martincigh, B.S. Sugar cane plant fibres: Separation and characterisation. Ind. Crops Prod. 2013, 47, 1–12. [Google Scholar] [CrossRef]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T.; Vandenberghe, L.P.S.; Mohan, R. Biotechnological potential of agro-industrial residues. II: Cassava bagasse. Bioresour. Technol. 2020, 74, 81–87. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- Murillo, J.L.S.; Osen, R.; Hiermaier, S.; Ganzenmueller, G. Towards understanding the mechanism of fibrous texture formation during high-moisture extrusion of meat substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Oppen, D.; Young, A.K.; Piepho, H.-P.; Weiss, J. Fibrous food and particle size influence electromyography and the kinematics of oral processing. Food Res. Int. 2023, 165, 112564. [Google Scholar] [CrossRef]

- Oppen, D.; Grossmann, L.; Weiss, J. Insights into characterizing and producing anisotropic food structures. Crit. Rev. Food Sci. Nutr. 2022, 1–19. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Jiang, Y.; Faisal, S.; Wang, Q. A new insight into the high-moisture extrusion process of peanut protein: From the aspect of the orders and amount of energy input. J. Food Eng. 2020, 264, 109668. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.-H. A comparison of physicochemical characteristics, texture, and structure of meat analogue and meats. J. Sci. Food Agric. 2019, 99, 2708–2715. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Hamoen, R.; Boom, R.M.; van der Goot, A.J. Understanding fiber formation in a concentrated soy protein isolate—Pectin blend. J. Food Eng. 2018, 222, 84–92. [Google Scholar] [CrossRef]

- Krintiras, G.A.; Gobel, J.; Bouwman, W.G.; van der Goot, A.J.; Stefanidis, G.D. On characterization of anisotropic plant protein structures. Food Funct. 2014, 5, 3233–3240. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Liu, J.; Chen, J.; Li, X.; Zhao, Z.; Wang, X. New insights into orientation differences between skin and core regions of polyacrylonitrile fibers during pre-stabilization with the stretching process. Polymer 2020, 210, 123043. [Google Scholar] [CrossRef]

- Cui, Y.; Hua, X.; Liu, L.-Z.; Li, S.; Shi, Y. Evaluating polyacrylonitrile precursor structure effects on carbon fiber production. Polym. Bull. 2023, 80, 8321–8338. [Google Scholar] [CrossRef]

- Gindl, W.; Reifferscheid, M.; Adusumalli, R.B.; Weber, H.; Roeder, T.; Sixta, H.; Schoeberl, T. Anisotropy of the modulus of elasticity in regenerated cellulose fibres related to molecular orientation. Polymer 2008, 49, 792–799. [Google Scholar] [CrossRef]

- Martens, A.; Kersemans, M.; Daemen, J.; Verboven, E.; Van Paepegem, W.; Delrue, S.; Van den Abeele, K. Characterization of the orthotropic viscoelastic tensor of composites using the Ultrasonic Polar Scan. Compos. Struct. 2019, 230, 111499. [Google Scholar] [CrossRef]

- Cho, M.; Ko, F.K.; Renneckar, S. Molecular Orientation and Organization of Technical Lignin-Based Composite Nanofibers and Films. Biomacromolecules 2019, 20, 4485–4493. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Zi, Z.; Minghui, H. The art of laser ablation in aeroengine: The crown jewel of modern industry. J. Appl. Phys. 2020, 127, 080902. [Google Scholar] [CrossRef]

- Alerstam, E. Anisotropic diffusive transport: Connecting microscopic scattering and macroscopic transport properties. Phys. Rev. E 2014, 89, 063202. [Google Scholar] [CrossRef]

- Elzerman, J.E.; Hoek, A.C.; van Boekel, M.A.J.S.; Luning, P.A. Consumer acceptance and appropriateness of meat substitutes in a meal context. Food Qual. Prefer. 2011, 22, 233–240. [Google Scholar] [CrossRef]

- Ranasinghesagara, J.; Nath, T.M.; Wells, S.J.; Weaver, A.D.; Gerrard, D.E.; Yao, G. Imaging optical diffuse reflectance in beef muscles for tenderness prediction. Meat Sci. 2010, 84, 413–421. [Google Scholar] [CrossRef]

- Liu, L.; Islam, M.Z.; Liu, X.; Gupta, M.; Rozmus, W.; Mandal, M.; Tsui, Y.Y. Multi-wavelength multi-direction laser light scattering for cell characterization using machine learning-based methods. Cytom. Part A 2023, 1–11. [Google Scholar] [CrossRef]

- Heeman, W.; Steenbergen, W.; van Dam, G.M.; Boerma, E.C. Clinical applications of laser speckle contrast imaging: A review. J. Biomed. Opt. 2019, 24, 080901. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.H.; Ma, Q.; Ge, J.; Peng, Q.Y.; Riley, W.W.; Tang, S.Z. Prediction of texture characteristics from extrusion food surface images using a computer vision system and artificial neural networks. J. Food Eng. 2013, 118, 426–433. [Google Scholar] [CrossRef]

- Kurade, C.; Meenu, M.; Kalra, S.; Miglani, A.; Neelapu, B.C.; Yu, Y.; Ramaswamy, H.S. An Automated Image Processing Module for Quality Evaluation of Milled Rice. Foods 2023, 12, 1273. [Google Scholar] [CrossRef] [PubMed]

- Martynenko, A. Computer Vision for Real-Time Control in Drying. Food Eng. Rev. 2017, 9, 91–111. [Google Scholar] [CrossRef]

- Meenu, M.; Kurade, C.; Neelapu, B.C.; Kalra, S.; Ramaswamy, H.S.; Yu, Y. A concise review on food quality assessment using digital image processing. Trends Food Sci. Technol. 2021, 118, 106–124. [Google Scholar] [CrossRef]

- Udomkun, P.; Nagle, M.; Argyropoulos, D.; Wiredu, A.N.; Mahayothee, B.; Mueller, J. Computer vision coupled with laser backscattering for non-destructive colour evaluation of papaya during drying. J. Food Meas. Charact. 2017, 11, 2142–2150. [Google Scholar] [CrossRef]

- Ranasinghesagara, J.; Hsieh, F.H.; Huff, H.; Yao, G. Laser Scanning System for Real-Time Mapping of Fiber Formations in Meat Analogues. J. Food Sci. 2009, 74, E39–E45. [Google Scholar] [CrossRef]

- Lin, Q.; Pan, L.; Deng, N.; Sang, M.; Cai, K.; Chen, C.; Han, J.; Ye, A. Protein digestibility of textured-wheat-protein (TWP)-based meat analogues: (I) Effects of fibrous structure. Food Hydrocoll. 2022, 130, 107694. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Jiang, Y.; Shah, F.; Xu, Y.; Wang, Q. High-moisture extrusion of peanut protein-/carrageenan/sodium alginate/wheat starch mixtures: Effect of different exogenous polysaccharides on the process forming a fibrous structure. Food Hydrocoll. 2020, 99, 105311. [Google Scholar] [CrossRef]

- Jin, X.; Deng, L.; Chen, X. Storage property of extruded pork jerky and the anti-mildew effect of β-CD controlled releasing cinnamaldehyde. Food Sci. Technol. 2016, 41, 144–148. [Google Scholar] [CrossRef]

- Akram, M.N.; Chen, X. Speckle reduction methods in laser-based picture projectors. Opt. Rev. 2016, 23, 108–120. [Google Scholar] [CrossRef]

- Aum, J.; Kim, J.-h.; Jeong, J. Effective speckle noise suppression in optical coherence tomography images using nonlocal means denoising filter with double Gaussian anisotropic kernels. Appl. Opt. 2015, 54, D43–D50. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Cui, X.; Zhao, Y.; Peng, Z. An improved algorithm of laser spot center detection in strong noise background. In Proceedings of the 2017 International Conference on Optical Instruments and Technology: Optical Systems and Modern Optoelectronic Instruments, Beijing, China, 28–30 October 2017; Volume 10616, pp. 203–209. [Google Scholar] [CrossRef]

- Jalobeanu, A.; Blanc-Feraud, L.; Zerubia, J. An adaptive Gaussian model for satellite image deblurring. IEEE Trans. Image Process. 2004, 13, 613–621. [Google Scholar] [CrossRef] [PubMed]

- Azimirad, E. Design of an optimized fuzzy system for edge detection in images. J. Intell. Fuzzy Syst. 2022, 43, 2363–2373. [Google Scholar] [CrossRef]

- Lopez-Molina, C.; De Baets, B.; Bustince, H.; Sanz, J.; Barrenechea, E. Multiscale edge detection based on Gaussian smoothing and edge tracking. Knowl.-Based Syst. 2013, 44, 101–111. [Google Scholar] [CrossRef]

- Verdu-Monedero, R.; Angulo, J.; Serra, J. Anisotropic Morphological Filters With Spatially-Variant Structuring Elements Based on Image-Dependent Gradient Fields. IEEE Trans. Image Process. 2011, 20, 200–212. [Google Scholar] [CrossRef]

- Abid Hasan, S.M.; Ko, K. Depth edge detection by image-based smoothing and morphological operations. J. Comput. Des. Eng. 2016, 3, 191–197. [Google Scholar] [CrossRef]

- Lin, Y.; Wu, L. Improved abrasive image segmentation method based on bit-plane and morphological reconstruction. Multimed. Tools Appl. 2019, 78, 29197–29210. [Google Scholar] [CrossRef]

- Kang, D.; Milster, T.D. Effect of optical aberration on Gaussian speckle in a partially coherent imaging system. J. Opt. Soc. Am. A 2009, 26, 2577–2585. [Google Scholar] [CrossRef]

- Gedde, U.W.; Hedenqvist, M.S. Fundamental Polymer Science; Springer: Cham, Switzerland, 2019; pp. 387–418. [Google Scholar]

| Extruded Samples | Descriptive Indicators | Transverse Shear Force (N) | Longitudinal Shear Force (N) | Degree of Organisation | Degree of Orientation |

|---|---|---|---|---|---|

| Beef jerky | Variable amplitude | 91.20–113.17 | 30.30–43.91 | 2.43–3.32 | 1.42–1.64 |

| Average value | 100.53 ± 6.62 a | 37.81 ± 3.69 bc | 2.68 ± 0.24 a | 1.56 ± 0.07 a | |

| Coefficient of variation (%) | 6.59 | 9.76 | 8.99 | 4.66 | |

| Pork jerky | Variable amplitude | 93.91–119.19 | 32.70–51.62 | 2.23–3.08 | 1.30–1.51 |

| Average value | 102.60 ± 7.49 a | 41.02 ± 5.40 b | 2.53 ± 0.26 ab | 1.40 ± 0.07 b | |

| Coefficient of variation (%) | 7.30 | 13.17 | 10.39 | 4.82 | |

| Chicken jerky | Variable amplitude | 61.55–88.44 | 23.78–41.60 | 2.06–2.63 | 1.16–1.32 |

| Average value | 78.42 ± 8.10 b | 34.22 ± 5.16 c | 2.31 ± 0.19 b | 1.25 ± 0.05 c | |

| Coefficient of variation (%) | 10.34 | 15.07 | 8.08 | 4.20 | |

| Duck jerky | Variable amplitude | 83.22–110.16 | 40.42–58.40 | 1.74–2.37 | 1.12–1.29 |

| Average value | 100.28 ± 7.64 a | 50.99 ± 5.26 a | 1.98 ± 0.17 c | 1.20 ± 0.05 c | |

| Coefficient of variation (%) | 7.62 | 10.32 | 8.5 | 4.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Xia, X.; Shi, C.; Chen, X.; Tang, H.; Deng, L. A Reliable Method for Determining the Degree of Orientation of Fibrous Foods Using Laser Transmission and Computer Vision. Foods 2023, 12, 3541. https://doi.org/10.3390/foods12193541

Li J, Xia X, Shi C, Chen X, Tang H, Deng L. A Reliable Method for Determining the Degree of Orientation of Fibrous Foods Using Laser Transmission and Computer Vision. Foods. 2023; 12(19):3541. https://doi.org/10.3390/foods12193541

Chicago/Turabian StyleLi, Jingpeng, Xu Xia, Cuizhu Shi, Xiaoqing Chen, Hao Tang, and Li Deng. 2023. "A Reliable Method for Determining the Degree of Orientation of Fibrous Foods Using Laser Transmission and Computer Vision" Foods 12, no. 19: 3541. https://doi.org/10.3390/foods12193541

APA StyleLi, J., Xia, X., Shi, C., Chen, X., Tang, H., & Deng, L. (2023). A Reliable Method for Determining the Degree of Orientation of Fibrous Foods Using Laser Transmission and Computer Vision. Foods, 12(19), 3541. https://doi.org/10.3390/foods12193541