The Possibility of Replacing Wet-Milling with Dry-Milling in the Production of Waxy Rice Flour for the Application in Waxy Rice Ball

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Waxy Rice Flour, Dough and Waxy Rice Ball

2.2. Particle Size and Damaged Starch Content of Waxy Rice Flour

2.3. Water Holding Capacity and Solubility of Waxy Rice Flour

2.4. Pasting Properties

2.5. Rheological Properties of Flour and Creep-Recovery Measurements of Dough

2.6. Observation on the Gelatinization Process of Waxy Rice Flour

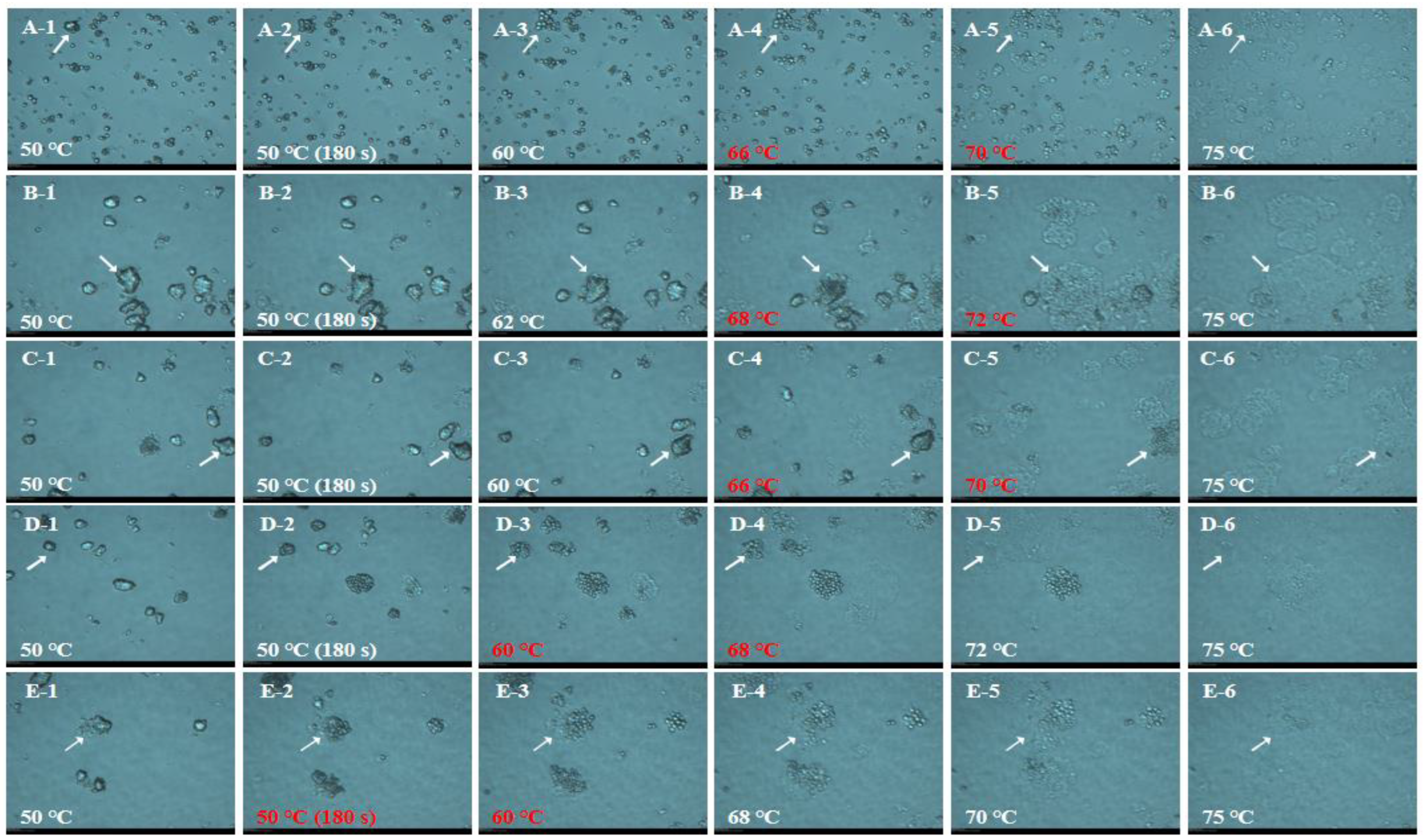

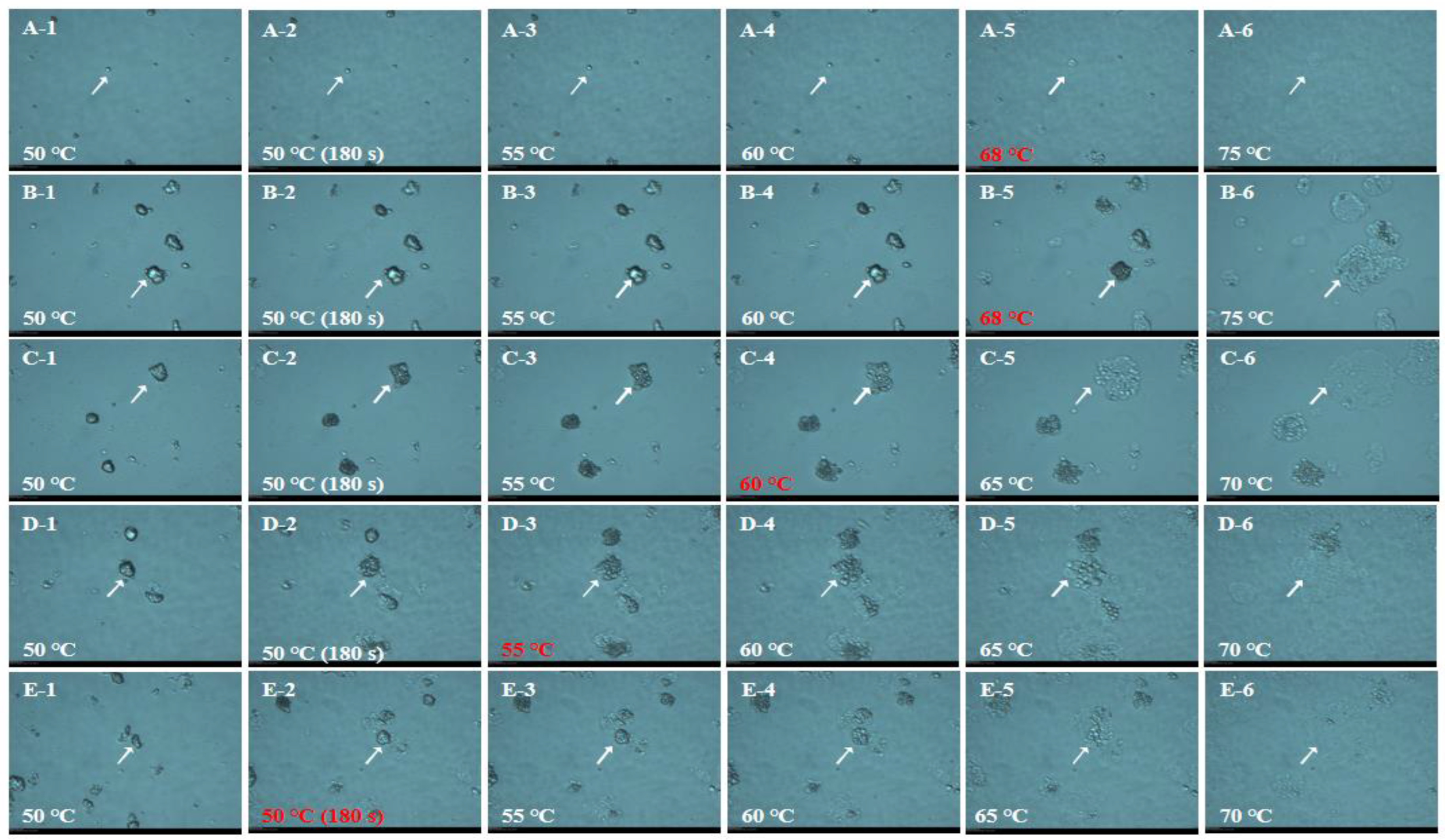

2.7. Analysis of SPME-GC-MS

2.8. Freeze Cracking Rate, Transparency and Appearance of Waxy Rice Ball

2.9. Sensory Evaluation and Consumer Test

2.10. Statistical Analysis

3. Results and Discussion

3.1. The Changes in Physical Characteristics of Dry-Milled Waxy Rice Flour with Decreased Particle Size

3.1.1. Damaged Starch Content, Solubility and Water Holding Capacity of Waxy Rice Flour

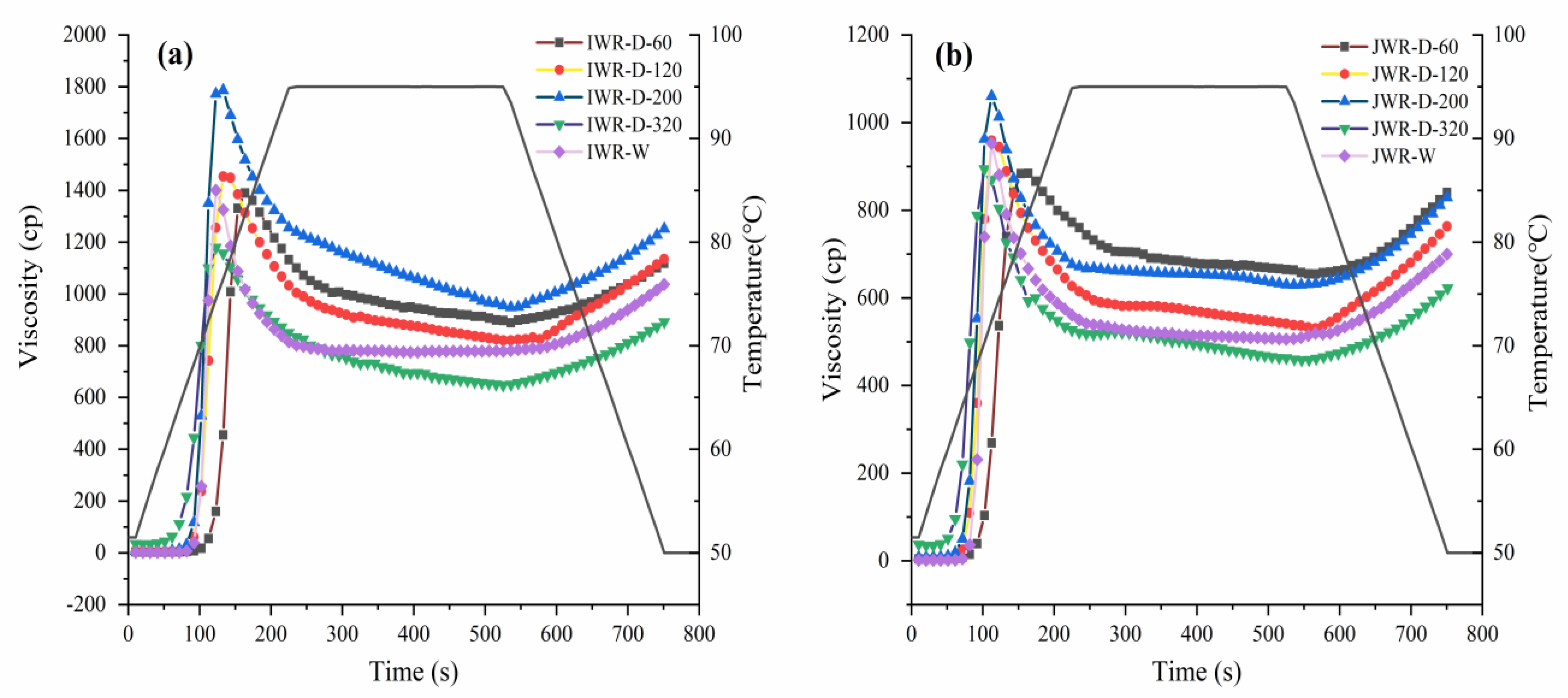

3.1.2. Pasting Properties of Waxy Rice Flour

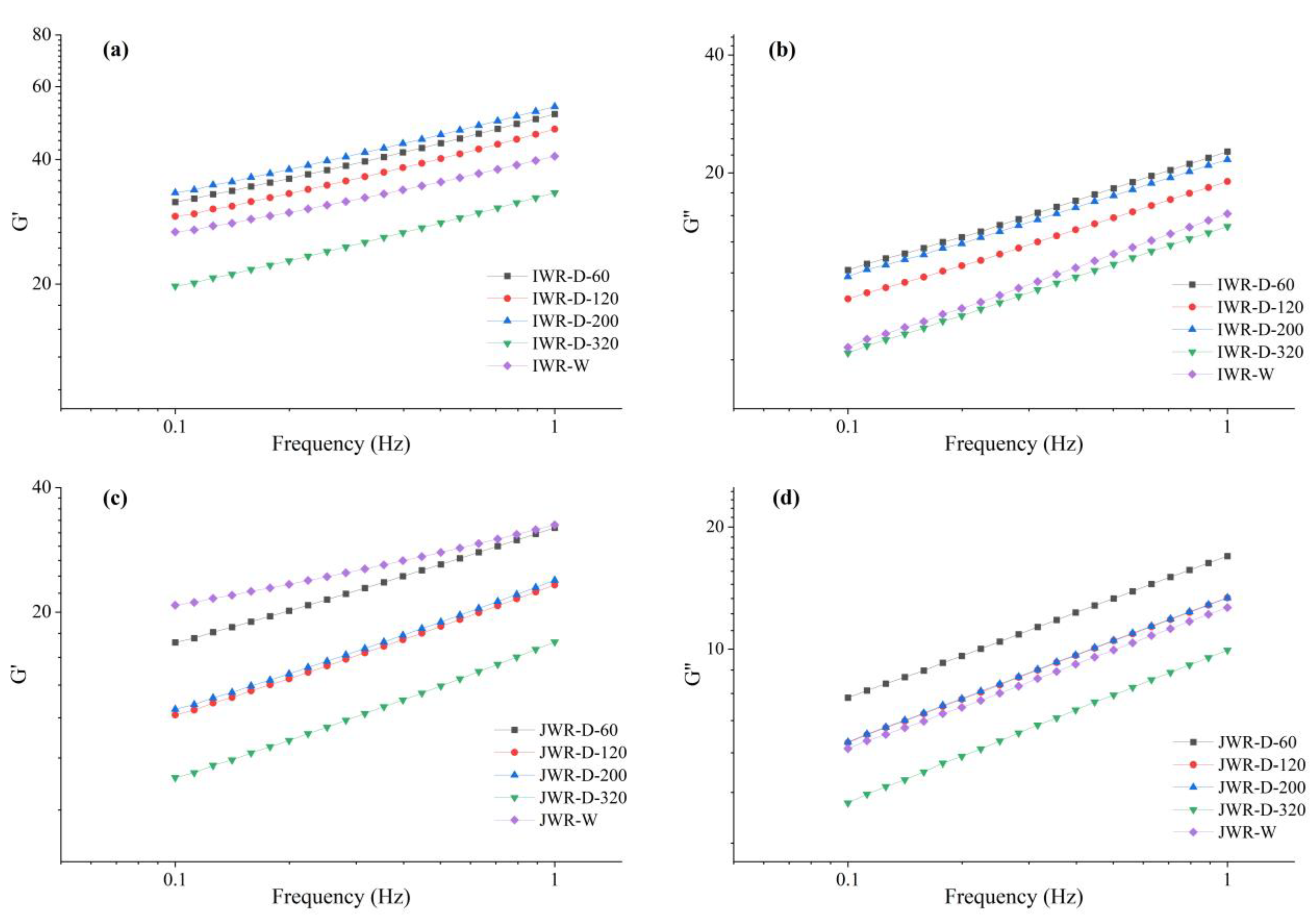

3.1.3. Rheological Properties of Waxy Rice Flour

3.2. The Changes in Physical Characteristics of Dry-Milled Waxy Rice Flour with Decreased Particle Size

3.2.1. Waxy Rice Dough Stretch Ability

3.2.2. Freeze Cracking Rate of Waxy Rice Balls

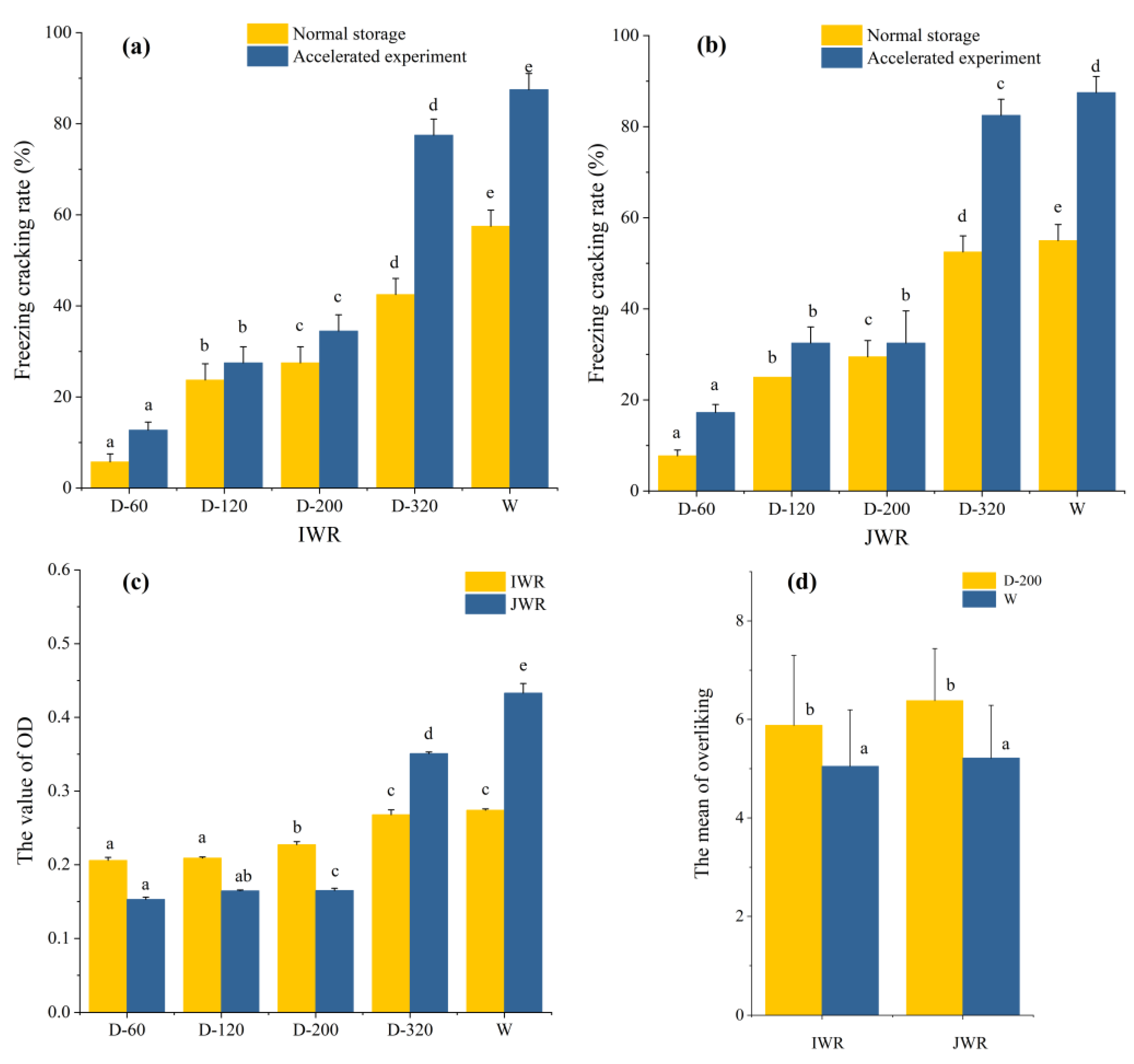

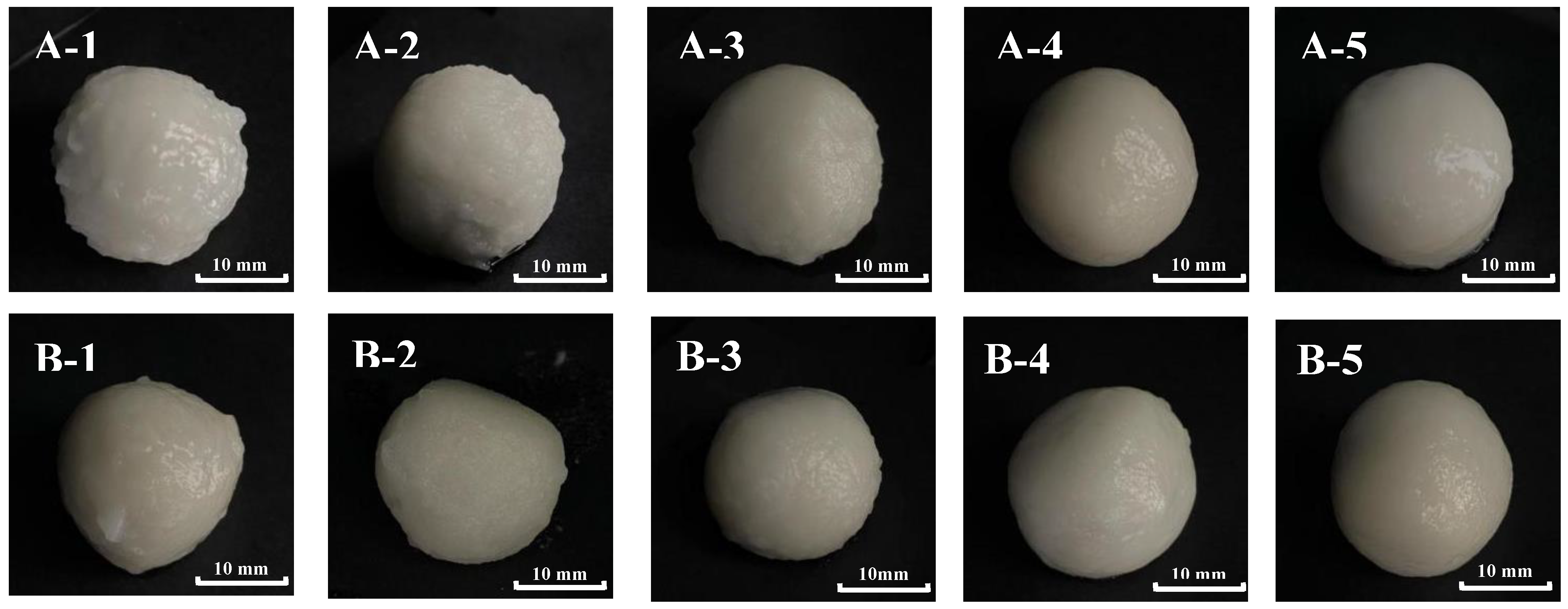

3.2.3. Appearance, Transparency of Soup and Texture Characteristics of Waxy Rice Balls

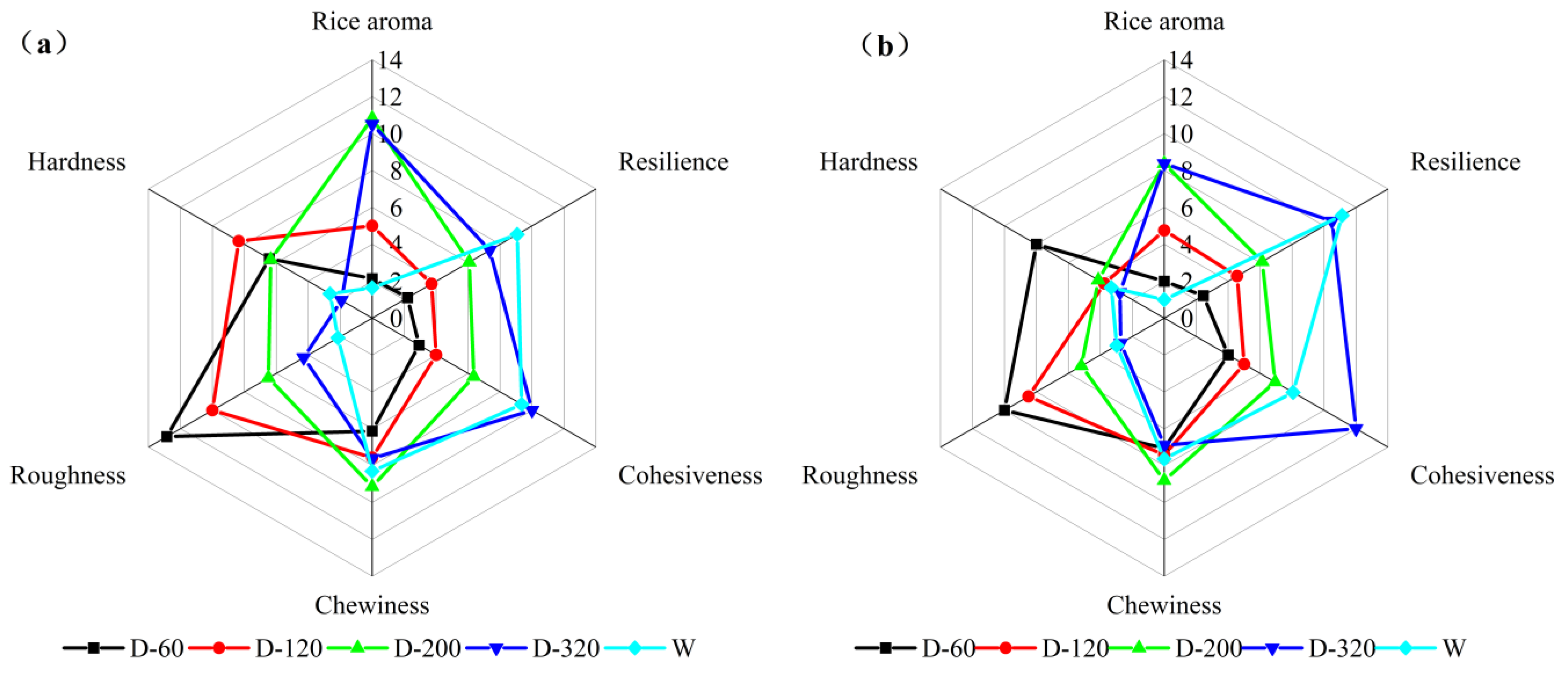

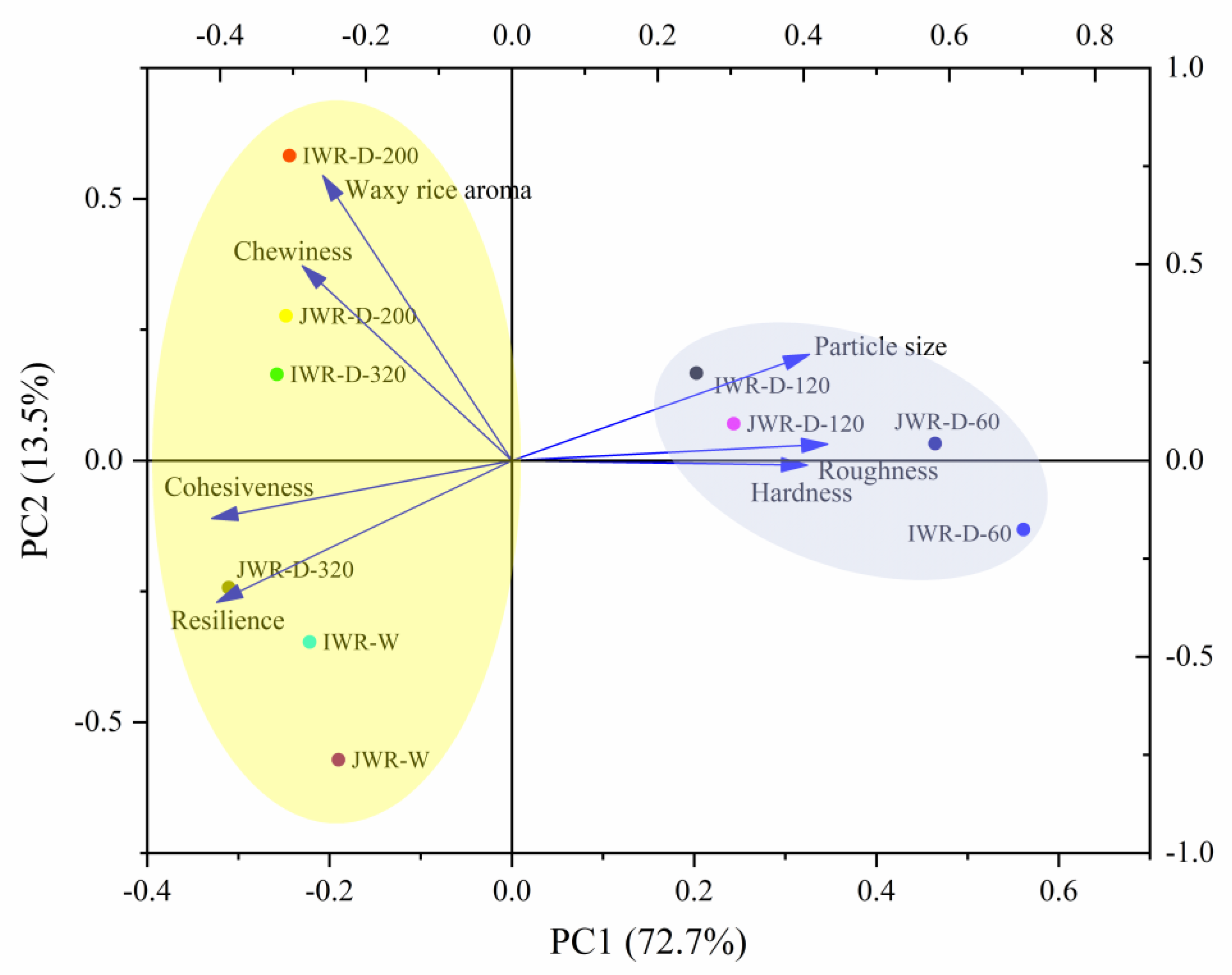

3.2.4. Sensory Evaluation, Volatile Component Analysis and Consumer Test of Waxy Rice Balls

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Chiang, P.Y.; Yeh, A.I. Effect of soaking on wet-milling of rice. J. Cereal Sci. 2002, 35, 85–94. [Google Scholar] [CrossRef]

- Lin, Z.; Geng, D.H.; Qin, W.; Huang, J.; Tong, L.T. Effects of damaged starch on glutinous rice flour properties and sweet dumpling qualities. Int. J. Biol. Macromol. 2021, 181, 390–397. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.; Lin, Z.; Wang, A.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.T. Influence of particle size on the properties of rice flour and quality of gluten-free rice bread. LWT 2021, 151, 112236. [Google Scholar] [CrossRef]

- Murakami, S.; Kuramochi, M.; Koda, T.; Nishio, T.; Nishioka, A. Relationship between rice flour particle sizes and expansion ratio of pure rice bread. J. Appl. Glycosci. 2016, 63, 19–22. [Google Scholar] [CrossRef]

- Qin, W.; Lin, Z.; Wang, A.; Xiao, T.; He, Y.; Chen, Z.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of damaged starch on the properties of rice flour and quality attributes of gluten-free rice bread. J. Cereal Sci. 2021, 101, 103296. [Google Scholar] [CrossRef]

- Leewatchararongjaroen, J.; Anuntagool, J. Effects of dry-milling and wet-milling on chemical, physical and gelatinization properties of rice flour. Rice Sci. 2016, 23, 274–281. [Google Scholar] [CrossRef]

- Kumar, C.S.; Malleshi, N.G.; Bhattacharya, S. A comparison of selected quality attributes of flours: Effects of dry and wet grinding methods. Int. J. Food Prop. 2008, 11, 845–857. [Google Scholar] [CrossRef]

- Sharma, P.; Chakkaravarthi, A.; Singh, V.; Subramanian, R. Grinding characteristics and batter quality of rice in different wet grinding systems. J. Food Eng. 2008, 88, 499–506. [Google Scholar] [CrossRef]

- Ngamnikom, P.; Songsermpong, S. The effects of freeze, dry, and wet grinding processes on rice flour properties and their energy consumption. J. Food Eng. 2011, 104, 632–638. [Google Scholar] [CrossRef]

- Tong, L.-T.; Zhu, R.; Zhou, X.; Zhong, K.; Wang, L.; Liu, L.; Hu, X.; Zhou, S. Soaking time of rice in semidry flour milling was shortened by increasing the grains cracks. J. Cereal Sci. 2017, 74, 121–126. [Google Scholar] [CrossRef]

- Yu, S.; Ma, Y.; Menager, L.; Sun, D.-W. Physicochemical properties of starch and flour from different rice cultivars. Food Bioprocess Technol. 2010, 5, 626–637. [Google Scholar] [CrossRef]

- Saito, S. Rice starch and rice powder as materials for food industry. J. Jpn. Soc. Starch Sci. 1980, 27, 295–313. [Google Scholar] [CrossRef]

- Suksomboon, A.; Naivikul, O. Effect of dry-and wet-milling processes on chemical, physicochemical properties and starch molecular structures of rice starches. Kasetsart J. Nat. Sci. 2006, 40, 125–134. [Google Scholar]

- Maldaner, V.; Coradi, P.C.; Nunes, M.T.; Müller, A.; Carneiro, L.O.; Teodoro, P.E.; Ribeiro Teodoro, L.P.; Bressiani, J.; Anschau, K.F.; Müller, E.I. Effects of intermittent drying on physicochemical and morphological quality of rice and endosperm of milled brown rice. LWT 2021, 152, 112334. [Google Scholar] [CrossRef]

- Park, I.-M.; Ibáñez, A.M.; Zhong, F.; Shoemaker, C.F. Gelatinization and pasting properties of waxy and non-waxy rice starches. Starch Stärke 2007, 59, 388–396. [Google Scholar] [CrossRef]

- Fang, S.; Chen, C.; Yao, Y.; Nsor-Atindana, J.; Liu, F.; Chen, M.; Zhong, F. Study on the pasting properties of indica and japonica waxy rice. Foods 2022, 11, 1132. [Google Scholar] [CrossRef]

- Van Bockstaele, F.; De Leyn, I.; Eeckhout, M.; Dewettinck, K. Rheological properties of wheat flour dough and the relationship with bread volume. I. Creep-recovery measurements. Cereal Chem. J. 2008, 85, 753–761. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, B.; Dong, J.; Tian, Y.; Lin, Y.; Fang, G.; Wang, S. Identification of mouldy rice using an electronic nose combined with spme-gc/ms. J. Stored Prod. Res. 2022, 95, 101921. [Google Scholar] [CrossRef]

- Zhu, J.; Xiao, Z. Characterization of the Major Odor-Active Compounds in Dry Jujube Cultivars by Application of Gas Chromatography-Olfactometry and Odor Activity Value. J. Agric. Food Chem. 2018, 66, 7722–7734. [Google Scholar] [CrossRef]

- Stone, H.; Bleibaum, R.; Thomas, H.; Stone, H.; Bleibaum, R.; Thomas, H. Sensory evaluation practices. Sens. Eval. Pract. 1992, 296–304. [Google Scholar]

- Wang, Q.; Li, L.; Zheng, X. A review of milling damaged starch: Generation, measurement, functionality and its effect on starch-based food systems. Food Chem. 2020, 315, 126267. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.J.; Lii, C.Y.; Lu, S. Physicochemical and morphological analyses on damaged rice starches. J. Food Drug Anal. 2003, 11, 283–289. [Google Scholar] [CrossRef]

- Hossen, M.S.; Sotome, I.; Takenaka, M.; Isobe, S.; Nakajima, M.; Okadome, H. Starch damage and pasting properties of rice flours produced by dry jet grinding. Cereal Chem. J. 2011, 88, 6–11. [Google Scholar] [CrossRef]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled mr263 rice flour. Food Chem. 2015, 191, 45–51. [Google Scholar] [CrossRef]

- Juszczak, L.; Witczak, T.; Ziobro, R.; Korus, J.; CieśLik, E.; Witczak, M. Effect of inulin on rheological and thermal properties of gluten-free dough. Carbohydr. Polym. 2012, 90, 353–360. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. The impact of resistant starch on characteristics of gluten-free dough and bread. Food Hydrocoll. 2009, 23, 988–995. [Google Scholar] [CrossRef]

- Hu, W.X.; Chen, J.; Xu, F.; Chen, L.; Zhao, J.W. Study on crystalline, gelatinization and rheological properties of japonica rice flour as affected by starch fine structure. Int. J. Biol. Macromol. 2019, 148, 1232–1241. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J. Effect of barley β-glucan concentrate on oscillatory and creep behavior of composite wheat flour dough. J. Food Eng. 2015, 152, 85–94. [Google Scholar] [CrossRef]

- Craig, S.; Maningat, C.; Seib, P.A.; Hoseney, R.C. Starch paste clarity. Cereal Chem. 1989, 66, 173–182. [Google Scholar]

- Dias, L.G.; Hacke, A.; Bergara, S.F.; Villela, O.V.; Bragagnolo, N. Identification of volatiles and odor-active compounds of aromatic rice by osme analysis and spme/gc-ms. Food Res. Int. 2021, 142, 110206. [Google Scholar] [CrossRef] [PubMed]

- Dias, L.G.; Duarte, G.; Mariutti, L.; Bragagnolo, N. Aroma profile of rice varieties by a novel spme method able to maximize 2-acetyl-1-pyrroline and minimize hexanal extraction. Food Res. Int. 2019, 123, 550–558. [Google Scholar] [CrossRef]

- Hu, X.; Lu, L.; Guo, Z.; Zhu, Z. Volatile compounds, affecting factors and evaluation methods for rice aroma: A review. Trends Food Sci. Technol. 2020, 97, 136–146. [Google Scholar] [CrossRef]

- Mathure, S.V.; Jawali, N.; Thengane, R.J.; Nadaf, A.B. Comparative quantitative analysis of headspace volatiles and their association with badh2 marker in non-basmati scented, basmati and non-scented rice (oryza sativa l.) cultivars of india. Food Chem. 2014, 142, 383–391. [Google Scholar] [CrossRef] [PubMed]

| Sample | Particle Size (μm) | Damaged Starch Content (%) | Solubility (%) | Water Holding Capacity (%) |

|---|---|---|---|---|

| IWR-W | 15.45 ± 0.11 a | 6.03 ± 0.21 a | 9.28 ± 0.05 a | 18.13 ± 0.30 e |

| IWR-D-60 | 164.33 ± 0.88 e | 9.40 ± 0.11 b | 34.89 ± 0.72 b | 8.79 ± 0.20 d |

| IWR-D-120 | 84.07 ± 2.63 d | 16.16 ± 0.23 c | 36.45 ± 0.12 c | 8.54 ± 0.14 c |

| IWR-D-200 | 67.00 ± 0.10 c | 19.58 ± 0.45 d | 39.45 ± 0.64 d | 8.38 ± 0.21 b |

| IWR-D-320 | 27.10 ± 0.20 b | 26.22 ± 0.31 e | 42.03 ± 0.84 e | 7.92 ± 0.31 a |

| JWR-W | 11.70 ± 0.05 a | 5.70 ± 0.12 a | 16.51 ± 0.04 a | 16.14 ± 0.29 e |

| JWR-D-60 | 158.47 ± 1.94 e | 12.03 ± 0.14 b | 51.02 ± 1.05 b | 6.90 ± 0.01 d |

| JWR-D-120 | 87.83 ± 3.98 d | 17.29 ± 0.18 c | 53.21 ± 2.13 c | 6.78 ± 0.21 c |

| JWR-D-200 | 55.40 ± 0.31 c | 20.36 ± 0.09 d | 53.45 ± 1.26 d | 6.65 ± 0.13 b |

| JWR-D-320 | 34.00 ± 0.52 b | 24.64 ± 0.54 e | 56.16 ± 2.54 e | 6.48 ± 0.21 a |

| Sample | G′ | G″ | |

|---|---|---|---|

| IWR-W | 17.79 | 6.61 | 0.368 ± 0.01 a |

| IWR-D-60 | 43.80 | 17.15 | 0.372 ± 0.00 a |

| IWR-D-120 | 44.92 | 16.98 | 0.378 ± 0.00 b |

| IWR-D-200 | 43.15 | 16.54 | 0.382 ± 0.00 c |

| IWR-D-320 | 28.11 | 11.68 | 0.415 ± 0.00 d |

| JWR-W | 29.26 | 10.50 | 0.358 ± 0.00 a |

| JWR-D-60 | 27.19 | 13.79 | 0.509 ± 0.00 b |

| JWR-D-120 | 18.93 | 10.51 | 0.538 ± 0.03 c |

| JWR-D-200 | 18.49 | 10.49 | 0.564 ± 0.01 d |

| JWR-D-320 | 13.27 | 7.71 | 0.610 ± 0.04 e |

| Sample | MCS (%) | MRS (%) | Recovery (%) |

|---|---|---|---|

| IWR-W | 0.36 ± 0.02 c | 0.14 ± 0.01 b | 38.89 a |

| IWR-D-60 | 0.51 ± 0.01 d | 0.21 ± 0.00 c | 41.18 c |

| IWR-D-120 | 0.54 ± 0.01 e | 0.22 ± 0.00 d | 40.74 b |

| IWR-D-200 | 0.19 ± 0.04 b | 0.15 ± 0.04 b | 76.68 d |

| IWR-D-320 | 0.12 ± 0.00 a | 0.11 ± 0.00 a | 95.66 e |

| JWR-W | 0.18 ± 0.01 a | 0.07 ± 0.00 a | 38.89 b |

| JWR-D-60 | 0.53 ± 0.04 d | 0.20 ± 0.01 b | 37.74 a |

| JWR-D-120 | 0.98 ± 0.01 e | 0.40 ± 0.03 e | 40.82 c |

| JWR-D-200 | 0.46 ± 0.02 c | 0.33 ± 0.01 d | 74.03 d |

| JWR-D-320 | 0.23 ± 0.02 b | 0.21 ± 0.02 c | 93.25 e |

| Sample | Hardness/g | Chewiness | Springiness | Resilience |

|---|---|---|---|---|

| IWR-W | 92.14 ± 5.17 a | 50.03 ± 2.74 a | 0.85 ± 0.00 b | 0.25 ± 0.02 c |

| IWR-D-60 | 194.06 ± 10.13 e | 107.50 ± 4.68 e | 0.95 ± 0.01 e | 0.20 ± 0.02 a |

| IWR-D-120 | 178.15 ± 1.03 d | 87.43 ± 1.86 b | 0.84 ± 0.02 a | 0.20 ± 0.01 a |

| IWR-D-200 | 158.81 ± 8.02 c | 92.13 ± 2.25 c | 0.90 ± 0.00 d | 0.21 ± 0.02 b |

| IWR-D-320 | 151.93 ± 2.81 b | 99.65 ± 2.59 d | 0.87 ± 0.02 c | 0.21 ± 0.02 b |

| JWR-W | 83.38 ± 5.23 a | 86.22 ± 2.06 c | 0.87 ± 0.01 a | 0.31 ± 0.01 d |

| JWR-D-60 | 158.48 ± 6.24 e | 96.16 ± 3.58 e | 0.90 ± 0.00 b | 0.18 ± 0.01 a |

| JWR-D-120 | 152.84 ± 5.70 d | 72.39 ± 2.06 a | 0.90 ± 0.01 b | 0.19 ± 0.00 b |

| JWR-D-200 | 149.32 ± 3.13 c | 73.10 ± 0.23 b | 0.90 ± 0.03 b | 0.19 ± 0.02 b |

| JWR-D-320 | 142.88 ± 4.32 b | 87.45 ± 0.23 d | 0.90 ± 0.02 b | 0.21 ± 0.02 c |

| Sample | Consumer Likes/Dislikes Reasons (Word Frequency) |

|---|---|

| IWR-D-200 | Soft texture (13), Moderate elasticity (6), Softer (4), Less chewy (5); |

| IWR-W | Harder (6), Good chewiness (8), Too elasticity (5), Strong stickiness (10), More delicate (3); |

| JWR-D-200 | Softer texture and less hardness (10), more waxy (6), Moderate stickiness (11), Easy Chew (3), Moderate elasticity (4), Moderate hardness (1); |

| JWR-W | Chewable (11), good elasticity (7), smooth and delicate (3), Too sticky (5), Too chewy (4); |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, S.; Chen, M.; Xu, F.; Liu, F.; Zhong, F. The Possibility of Replacing Wet-Milling with Dry-Milling in the Production of Waxy Rice Flour for the Application in Waxy Rice Ball. Foods 2023, 12, 280. https://doi.org/10.3390/foods12020280

Fang S, Chen M, Xu F, Liu F, Zhong F. The Possibility of Replacing Wet-Milling with Dry-Milling in the Production of Waxy Rice Flour for the Application in Waxy Rice Ball. Foods. 2023; 12(2):280. https://doi.org/10.3390/foods12020280

Chicago/Turabian StyleFang, Sicong, Maoshen Chen, Feifei Xu, Fei Liu, and Fang Zhong. 2023. "The Possibility of Replacing Wet-Milling with Dry-Milling in the Production of Waxy Rice Flour for the Application in Waxy Rice Ball" Foods 12, no. 2: 280. https://doi.org/10.3390/foods12020280

APA StyleFang, S., Chen, M., Xu, F., Liu, F., & Zhong, F. (2023). The Possibility of Replacing Wet-Milling with Dry-Milling in the Production of Waxy Rice Flour for the Application in Waxy Rice Ball. Foods, 12(2), 280. https://doi.org/10.3390/foods12020280