Comprehensive Analyses of Breads Supplemented with Tannic Acids

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bread

2.3. Proximate Analysis

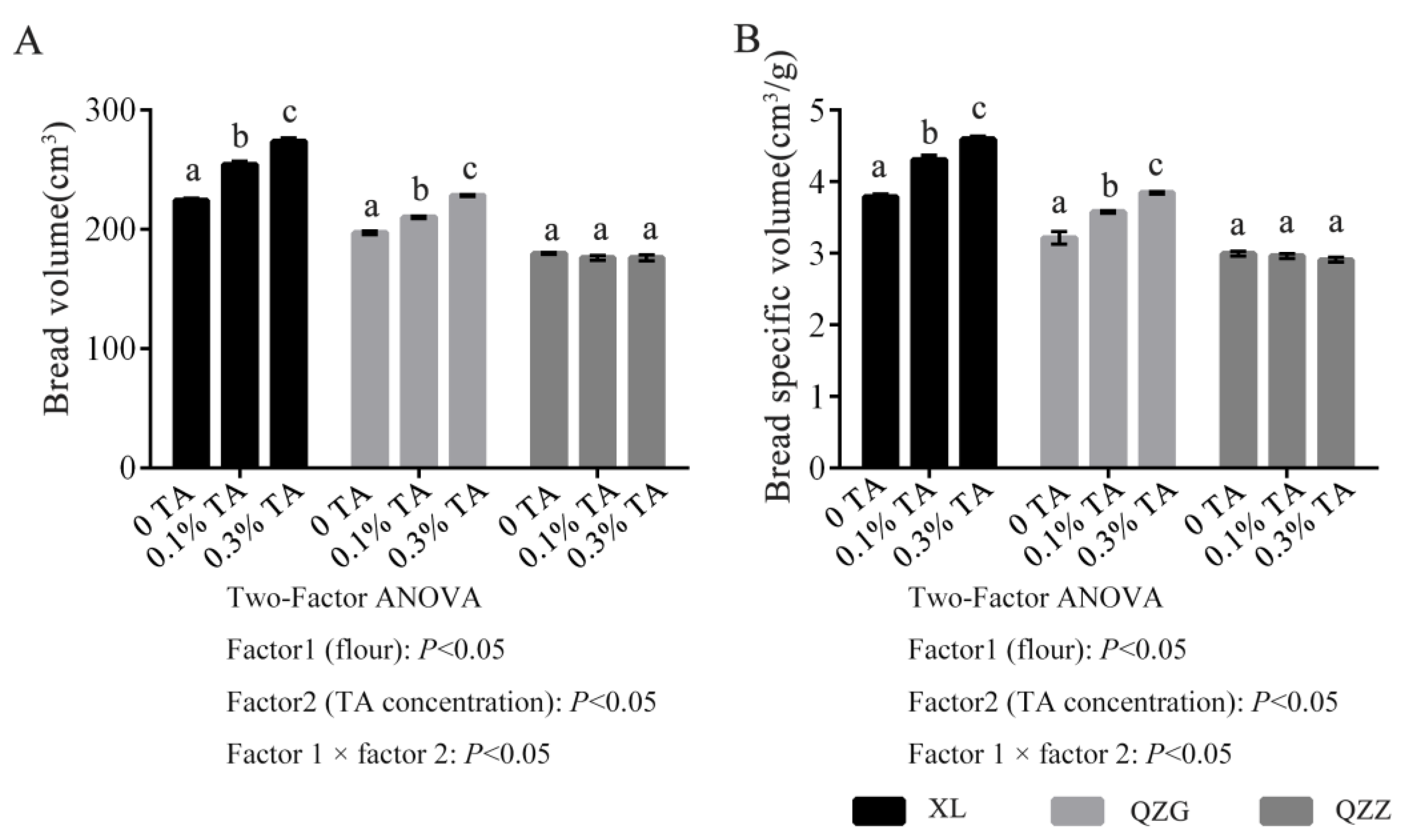

2.4. Volume and Specific Volume Measurement and Texture Profile

2.5. Antioxidant Capacity Assays

2.6. Determination of Crust and Crumb Color

2.7. Image Analysis

2.8. Sensory Evaluation of Bread

2.9. Statistical Analysis

3. Results

3.1. Proximate Analysis

3.2. Baking Parameters

3.3. Antioxidant Activity of the TA-Supplemented Breads

3.4. Texture Evaluation

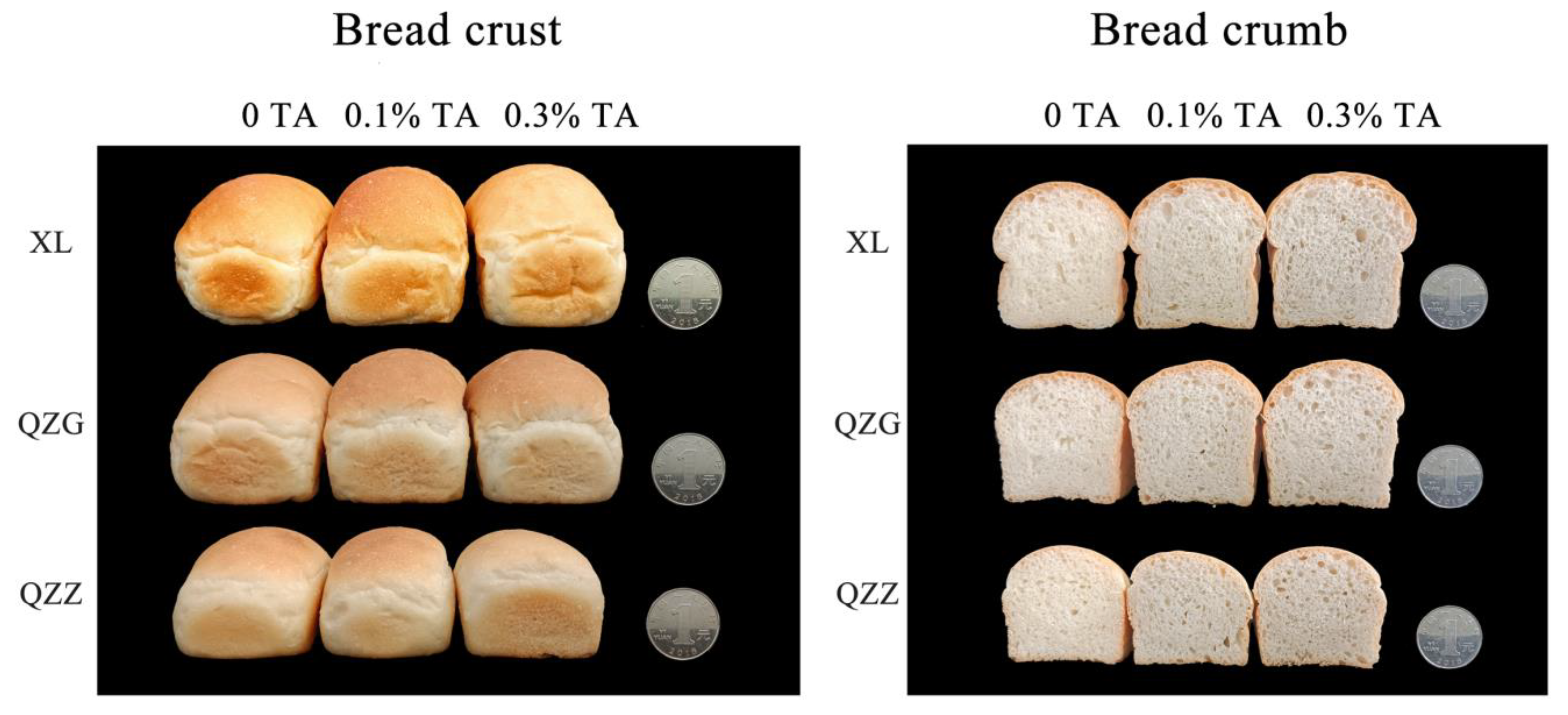

3.5. Visual Attributes of the TA-Supplemented Breads

3.5.1. Color Analysis

3.5.2. Crumb Image Analysis

3.6. Effect of TA Supplementation on the Bread Sensory Attributes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sestili, F.; Margiotta, B.; Vaccino, P.; Moscaritolo, S.; Giorgi, D.; Lucretti, S.; Palombieri, S.; Masci, S.; Lafiandra, D. A cross between bread wheat and a 2D(2R) disomic substitution triticale line leads to the formation of a novel disomic addition line and provides information of the role of rye secalins on breadmaking characteristics. Int. J. Mol. Sci. 2020, 21, 8450. [Google Scholar] [CrossRef]

- Shewry, P.R. What is gluten-Why is it special? Front. Nutr. 2019, 6, 101. [Google Scholar] [CrossRef] [PubMed]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum aestivum L.) bran in bread making: A critical review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef]

- Brouns, F.; van Buul, V.J.; Shewry, P.R. Does wheat make us fat and sick? J. Cereal Sci. 2013, 58, 209–215. [Google Scholar] [CrossRef]

- Fardet, A. New hypotheses for the health-protective mechanisms of whole-grain cereals: What is beyond fibre? Nutr. Res. Rev. 2010, 23, 65–134. [Google Scholar] [CrossRef] [PubMed]

- Hazard, B.; Trafford, K.; Lovegrove, A.; Griffiths, S.; Shewry, P. Strategies to improve wheat for human health. Nat. Food 2020, 1, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Vishwakarma, S.; Genu Dalbhagat, C.; Mandliya, S.; Niwas Mishra, H. Investigation of natural food fortificants for improving various properties of fortified foods: A review. Food Res. Int. 2022, 156, 111186. [Google Scholar] [CrossRef]

- Butt, M.S.; Arshad, M.U.; Alam, M.S.; Nadeem, M.T. Bioavailability and storage stability of vitamin A fortificant (retinyl acetate) in fortified cookies. Food Res. Int. 2007, 40, 1212–1219. [Google Scholar] [CrossRef]

- Liguori, I.; Russo, G.; Curcio, F.; Bulli, G.; Aran, L.; Della-Morte, D.; Gargiulo, G.; Testa, G.; Cacciatore, F.; Bonaduce, D.; et al. Oxidative stress, aging, and diseases. Clin. Interv. Aging. 2018, 13, 757–772. [Google Scholar] [CrossRef]

- Paucean, A.; Muresan, V.; Maria-Man, S.; Chis, M.S.; Muresan, A.E.; Serban, L.R.; Pop, A.; Muste, S. Metabolomics as a tool to elucidate the sensory, nutritional and safety quality of wheat bread-A review. Int. J. Mol. Sci. 2021, 22, 8945. [Google Scholar] [CrossRef]

- Mitelut, A.C.; Popa, E.E.; Popescu, P.A.; Popa, M.E. Chapter 7—Trends of Innovation in Bread and Bakery Production, in Trends in Wheat and Bread Making; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 199–226. [Google Scholar]

- Melis, S.; Delcour, J.A. Impact of wheat endogenous lipids on the quality of fresh bread: Key terms, concepts, and underlying mechanisms. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3715–3754. [Google Scholar] [CrossRef] [PubMed]

- Mannuramath, M.; Yenagi, N.; Orsat, V. Quality evaluation of little millet (Panicum miliare) incorporated functional bread. J. Food Sci. Technol. 2015, 52, 8357–8363. [Google Scholar] [CrossRef] [PubMed]

- Nasir, S.; Allai, F.M.; Gani, M.; Ganaie, S.; Gul, K.; Jabeen, A.; Majeed, D. Physical, textural, rheological, and sensory characteristics of amaranth-based wheat flour bread. Int. J. Food Sci. 2020, 2020, 8874872. [Google Scholar] [CrossRef] [PubMed]

- Tolve, R.; Simonato, B.; Rainero, G.; Bianchi, F.; Rizzi, C.; Cervini, M.; Giuberti, G. Wheat bread fortification by grape pomace powder: Nutritional, technological, antioxidant, and sensory properties. Foods 2021, 10, 75. [Google Scholar] [CrossRef]

- Chlopicka, J.; Pasko, P.; Gorinstein, S.; Jedryas, A.; Zagrodzki, P. Total phenolic and total flavonoid content, antioxidant activity and sensory evaluation of pseudocereal breads. LWT-Food Sci. Technol. 2012, 46, 548–555. [Google Scholar] [CrossRef]

- Han, H.M.; Koh, B.K. Effect of phenolic acids on the rheological properties and proteins of hard wheat flour dough and bread. J. Sci. Food Agric. 2011, 91, 2495–2499. [Google Scholar] [CrossRef]

- Han, H.M.; Koh, B.K. Antioxidant activity of hard wheat flour, dough and bread prepared using various processes with the addition of different phenolic acids. J. Sci. Food Agric. 2011, 91, 604–608. [Google Scholar] [CrossRef]

- Girard, A.L.; Castell-Perez, M.E.; Bean, S.R.; Adrianos, S.L.; Awika, J.M. Effect of condensed tannin profile on wheat flour dough rheology. J. Agric. Food Chem. 2016, 64, 7348. [Google Scholar] [CrossRef]

- Zhang, L.; Cheng, L.; Jiang, L.; Wang, Y.; Yang, G.; He, G. Effects of tannic acid on gluten protein structure, dough properties and bread quality of Chinese wheat. J. Sci. Food Agric. 2010, 90, 2462–2468. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Sun, F.; Li, X.; Wang, P.; Sun, J.; Zeng, J.; Wang, C.; Hu, W.; Chang, J.; et al. Tannins improve dough mixing properties through affecting physicochemical and structural properties of wheat gluten proteins. Food Res. Int. 2015, 69, 64–71. [Google Scholar] [CrossRef]

- Du, J.; Dang, M.; Khalifa, I.; Du, X.; Xu, Y.; Li, C. Persimmon tannin changes the properties and the morphology of wheat gluten by altering the cross-linking, and the secondary structure in a dose-dependent manner. Food Res. Int. 2020, 137, 109536. [Google Scholar] [CrossRef]

- Sanyal, R.; Darroudi, F.; Parzefall, W.; Nagao, M.; Knasmuller, S. Inhibition of the genotoxic effects of heterocyclic amines in human derived hepatoma cells by dietary bioantimutagens. Mutagenesis 1997, 12, 297–303. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Method of Analysis of AOAC Internation, 21st ed.; AOAC International: Arlington, VA, USA, 2019. [Google Scholar]

- International Association for Cereal Science and Technology. Standard Methods of the ICC; The Association: Vienna, Austria, 2003. [Google Scholar]

- Supasil, R.; Suttisansanee, U.; Santivarangkna, C.; Tangsuphoom, N.; Khemthong, C.; Chupeerach, C.; On-Nom, N. Improvement of sourdough and bread qualities by fermented water of asian pears and assam tea leaves with co-cultures of lactiplantibacillus plantarum and saccharomyces cerevisiae. Foods 2022, 11, 2071. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zeng, J.; Li, Y.; Hu, W.; Chen, L.; Miao, Y.; Deng, P.; Yuan, C.; Ma, C.; Chen, X.; et al. Enrichment of provitamin A content in wheat (Triticum aestivum L.) by introduction of the bacterial carotenoid biosynthetic genes CrtB and CrtI. J. Exp. Bot. 2014, 65, 2545–2556. [Google Scholar] [CrossRef] [PubMed]

- de Erive, M.O.; Wang, T.; He, F.; Chen, G. Development of high-fiber wheat bread using microfluidized corn bran. Food Chem. 2020, 310, 125921. [Google Scholar] [CrossRef]

- Atudorei, D.; Atudorei, O.; Codina, G.G. Dough rheological properties, microstructure and bread quality of wheat-germinated bean composite flour. Foods 2021, 10, 1542. [Google Scholar] [CrossRef]

- Atudorei, D.; Mironeasa, S.; Codina, G.G. Effects of germinated lentil flour on dough rheological behavior and bread quality. Foods 2022, 11, 2982. [Google Scholar] [CrossRef]

- Kazakos, S.; Mantzourani, I.; Plessas, S. Quality characteristics of novel sourdough breads made with functional Lacticaseibacillus paracasei SP5 and prebiotic food matrices. Foods 2022, 11, 3226. [Google Scholar] [CrossRef]

- Castellari, M.P.; Simsek, S.; Ohm, J.-B.; Perry, R.; Poffenbarger, H.J.; Phillips, T.D.; Jacobsen, K.L.; Van Sanford, D.A. Genetic variation and heritability of sensory and artisan bread traits in a set of SRW wheat breeding lines. Foods 2023, 12, 2617. [Google Scholar] [CrossRef]

- Pořízka, J.; Slavíková, Z.; Bidmonová, K.; Vymětalová, M.; Diviš, P. Physiochemical and sensory properties of bread fortified with wheat bran and whey protein isolates. Foods 2023, 12, 2635. [Google Scholar] [CrossRef]

- Guo, X.; Shi, L.; Yang, S.; Yang, R.; Dai, X.; Zhang, T.; Liu, R.; Chang, M.; Jin, Q.; Wang, X. Effect of sea-buckthorn pulp and flaxseed residues on quality and shelf life of bread. Food Funct. 2019, 10, 4220–4230. [Google Scholar] [CrossRef]

- Sivam, A.S.; Sun-Waterhouse, D.; Waterhouse, G.I.N.; Quek, S.; Perera, C.O. Physicochemical properties of bread dough and finished bread with added pectin fiber and phenolic antioxidants. J. Food Sci. 2011, 76, 97–107. [Google Scholar] [CrossRef] [PubMed]

- Czubaszek, A.; Czaja, A.; Sokół-Łętowska, A.; Kolniak-Ostek, J.; Kucharska, A.Z. Changes in antioxidant properties and amounts of bioactive compounds during simulated in vitro digestion of wheat bread enriched with plant extracts. Molecules 2021, 26, 6292. [Google Scholar] [CrossRef] [PubMed]

- Oloniyo, R.O.; Omoba, O.S.; Awolu, O.O.; Olagunju, A.I. Orange-fleshed sweet potatoes composite bread: A good carrier of beta (beta)-carotene and antioxidant properties. J. Food Biochem. 2021, 45, e13423. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, A.; Sharma, N.; Sharma, V.; Alam, T.; Sahu, J.K.; Hamid, H. Assessing the consumer acceptance and storability of chitosan and beeswax coated cellulose packaging for whole wheat bread. Food Control. 2022, 133, 108682. [Google Scholar] [CrossRef]

- Perri, G.; Coda, R.; Rizzello, C.G.; Celano, G.; Ampollini, M.; Gobbetti, M.; De Angelis, M.; Calasso, M. Sourdough fermentation of whole and sprouted lentil flours: In situ formation of dextran and effects on the nutritional, texture and sensory characteristics of white bread. Food Chem. 2021, 355, 129638. [Google Scholar] [CrossRef]

- Salmenkallio-Marttila, M.; Roininen, K.; Autio, K.; Lahteenmaki, L. Effects of gluten and transglutaminase on microstructure, sensory characteristics and instrumental texture of oat bread. Agric. Food Sci. 2004, 13, 138–150. [Google Scholar] [CrossRef][Green Version]

- Thiranusornkij, L.; Thamnarathip, P.; Chandrachai, A.; Kuakpetoon, D.; Adisakwattana, S. Comparative studies on physicochemical properties, starch hydrolysis, predicted glycemic index of Hom Mali rice and Riceberry rice flour and their applications in bread. Food Chem. 2019, 283, 224–231. [Google Scholar] [CrossRef]

- Crowley, P.; Grau, H.; Arendt, E. Influence of additives and mixing time on crumb grain characteristics of wheat bread. Cereal Chem. 2000, 77, 370–375. [Google Scholar] [CrossRef]

- Skendi, A.; Biliaderis, C.G.; Papageorgiou, M.; Izydorczyk, M.S. Effects of two barley β-glucan isolates on wheat flour dough and bread properties. Food Chem. 2010, 119, 1159–1167. [Google Scholar] [CrossRef]

- Dhen, N.; Ben Rejeb, I.; Boukhris, H.; Damergi, C.; Gargouri, M. Physicochemical and sensory properties of wheat- Apricot kernels composite bread. LWT-Food Sci. Technol. 2018, 95, 262–267. [Google Scholar] [CrossRef]

- de Erive, M.O.; He, F.; Wang, T.; Chen, G. Development of β-glucan enriched wheat bread using soluble oat fiber. J. Cereal Sci. 2020, 95, 103051. [Google Scholar] [CrossRef]

- Sullivan, P.; O’Flaherty, J.; Brunton, N.; Arendt, E.; Gallagher, E. The utilisation of barley middlings to add value and health benefits to white breads. J. Food Eng. 2011, 105, 493–502. [Google Scholar] [CrossRef]

- Parafati, L.; Restuccia, C.; Palmeri, R.; Fallico, B.; Arena, E. Characterization of prickly pear peel flour as a bioactive and functional ingredient in bread preparation. Foods 2020, 9, 1189. [Google Scholar] [CrossRef]

- Czaja, A.; Czubaszek, A.; Wyspiańska, D.; Sokół-Łętowska, A.; Kucharska, A.Z. Quality of wheat bread enriched with onion extract and polyphenols content and antioxidant activity changes during bread storage. Int. J. Food Sci. Technol. 2020, 55, 1725–1734. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Kalisz, S.; Sujka, K. Effect of the addition of dried dandelion roots (Taraxacum officinale F. H. Wigg.) on wheat dough and bread properties. Molecules 2021, 26, 7564. [Google Scholar] [CrossRef]

| Breads | Samples | Ash Content (g/100 g DM) | Protein Content (g/100 g DM) | Fat Content (g/100 g DM) | Fiber Content (g/100 g DM) | ABTS (µmol TE/g DM) | FRAP (µmol TE/g DM) |

|---|---|---|---|---|---|---|---|

| XL | 0 | 6.17 ± 0.14 a | 13.74 ± 0.09 a | 3.23 ± 0.10 a | 3.23 ± 0.10 a | 4.65 ± 0.75 a | 4.27 ± 0.34 a |

| 0.10% | 6.02 ± 0.05 a | 13.76 ± 0.07 a | 3.46 ± 0.09 a | 3.46 ± 0.09 a | 10.11 ± 0.88 b | 9.58 ± 0.05 b | |

| 0.30% | 6.10 ± 0.08 a | 13.44 ± 0.18 a | 3.52 ± 0.03 a | 3.59 ± 0.04 a | 15.03 ± 1.51 c | 21.97 ± 0.08 c | |

| QZG | 0 | 5.85 ± 0.06 b | 11.05 ± 0.06 a | 2.94 ± 0.04 a | 2.94 ± 0.04 a | 4.14 ± 0.07 a | 4.24 ± 0.08 a |

| 0.10% | 5.97 ± 0.09 b | 11.07 ± 0.02 a | 2.97 ± 0.08 a | 2.97 ± 0.08 a | 7.34 ± 0.21 b | 10.09 ± 0.16 b | |

| 0.30% | 5.37 ± 0.16 a | 11.21 ± 0.08 a | 2.91 ± 0.10 a | 2.91 ± 0.10 a | 16.71 ± 0.54 c | 22.30 ± 0.11 c | |

| QZZ | 0 | 5.36 ± 0.08 a | 10.28 ± 0.10 a | 3.02 ± 0.14 a | 3.02 ± 0.14 a | 4.43 ± 0.74 a | 3.97 ± 0.13 a |

| 0.10% | 5.19 ± 0.08 a | 10.41 ± 0.09 a | 2.88 ± 0.03 a | 2.88 ± 0.03 a | 6.68 ± 0.22 a | 10.15 ± 0.20 b | |

| 0.30% | 5.52 ± 0.09 a | 10.46 ± 0.07 a | 2.68 ± 0.08 a | 2.68 ± 0.08 a | 15.52 ± 1.49 b | 22.57 ± 0.17 c | |

| Two-Factor ANOVA—p | |||||||

| Factor 1 (flour) | <0.05 | <0.05 | <0.05 | >0.05 | >0.05 | >0.05 | |

| Factor 2 (TA concentration) | >0.05 | >0.05 | >0.05 | <0.05 | <0.05 | <0.05 | |

| Factor 1 × factor 2 | <0.05 | >0.05 | <0.05 | >0.05 | >0.05 | >0.05 | |

| Breads | Samples | Hardness (N) | Springiness (−) | Cohesiveness (−) | Gumminess (−) | Chewiness (−) | Resilience (−) |

|---|---|---|---|---|---|---|---|

| XL | 0 TA | 950.75 ± 9.11 c | 0.95 ± 0.01 a | 0.74 ± 0.01 a | 705.87 ± 9.32 b | 672.74 ± 9.79 b | 0.43 ± 0.01 a |

| 0.1% TA | 858.99 ± 14.28 b | 0.97 ± 0.02 a | 0.78 ± 0.03 a | 667.46 ± 16.42 b | 645.86 ± 25.17 b | 0.47 ± 0.03 a | |

| 0.3% TA | 595.73 ± 7.14 a | 0.96 ± 0.01 a | 0.78 ± 0.02 a | 464.50 ± 8.30 a | 447.60 ± 11.50 a | 0.47 ± 0.01 a | |

| QZG | 0 TA | 1243.19 ± 32.00 ab | 0.97 ± 0.01 a | 0.68 ± 0.01 a | 840.05 ± 15.14 a | 814.07 ± 16.15 a | 0.40 ± 0.01 a |

| 0.1% TA | 1272.64 ± 9.04 b | 0.96 ± 0.01 a | 0.74 ± 0.03 a | 934.70 ± 31.12 a | 896.29 ± 22.03 b | 0.43 ± 0.02 a | |

| 0.3% TA | 1143.08 ± 38.36 a | 0.97 ± 0.01 a | 0.74 ± 0.01 a | 840.94 ± 16.66 a | 812.32 ± 15.91 a | 0.45 ± 0.01 a | |

| QZZ | 0 TA | 2359.12 ± 88.59 a | 0.97 ± 0.01 a | 0.71 ± 0.06 a | 1653.40 ± 77.11 a | 1610.66 ± 75.72 a | 0.45 ± 0.06 a |

| 0.1% TA | 2221.69 ± 95.21 a | 0.98 ± 0.01 a | 0.67 ± 0.01 a | 1495.30 ± 60.60 a | 1459.18 ± 61.83 a | 0.42 ± 0.01 a | |

| 0.3% TA | 2167.52 ± 107.32 a | 0.97 ± 0.01 a | 0.66 ± 0.03 a | 1414.10 ± 21.97 a | 1371.37 ± 10.89 a | 0.40 ± 0.03 a | |

| Two-Factor ANOVA—p | |||||||

| Factor 1 (flour) | <0.05 | >0.05 | <0.05 | <0.05 | <0.05 | >0.05 | |

| Factor 2 (TA concentration) | <0.05 | >0.05 | >0.05 | <0.05 | <0.05 | >0.05 | |

| Factor 1 × factor 2 | >0.05 | >0.05 | >0.05 | <0.05 | <0.05 | >0.05 | |

| Breads | Samples | Crust Color | Crumb Color | ||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ||

| XL | 0 TA | 68.31 ± 0.75 a | 16.98 ± 0.53 ab | 29.91 ± 0.98 a | 90.64 ± 0.24 a | 0.71 ± 0.03 a | 10.58 ± 0.18 a |

| 0.1% TA | 70.77 ± 0.54 b | 17.85 ± 0.35 b | 34.21 ± 0.49 b | 83.55 ± 0.27 b | 2.05 ± 0.01 b | 4.98 ± 0.15 b | |

| 0.3% TA | 72.99 ± 0.22 c | 15.71 ± 0.24 a | 34.40 ± 0.42 b | 82.17 ± 0.19 c | 3.03 ± 0.01 c | 5.32 ± 0.09 b | |

| QZG | 0 TA | 79.91 ± 0.80 a | 18.68 ± 0.27 a | 39.87 ± 0.50 a | 90.90 ± 0.21 a | 0.98 ± 0.02 a | 10.09 ± 0.24 a |

| 0.1% TA | 78.79 ± 0.18 a | 17.37 ± 0.87 ab | 37.77 ± 0.61 a | 85.41 ± 0.15 b | 1.95 ± 0.02 b | 7.13 ± 0.11 b | |

| 0.3% TA | 74.57 ± 0.89 b | 16.40 ± 0.38 b | 34.54 ± 0.78 b | 84.01 ± 0.25 c | 2.79 ± 0.01 c | 6.84 ± 0.21 b | |

| QZZ | 0 TA | 83.75 ± 0.89 ab | 16.78 ± 0.41 ab | 42.10 ± 1.02 a | 85.94 ± 0.17 a | 0.97 ± 0.02 a | 11.00 ± 0.24 a |

| 0.1% TA | 82.36 ± 1.50 b | 19.01 ± 1.30 a | 42.11 ± 0.34 a | 81.71 ± 0.26 b | 1.75 ± 0.03 b | 7.68 ± 0.24 b | |

| 0.3% TA | 86.36 ± 0.77 a | 13.99 ± 0.66 b | 39.47 ± 0.37 b | 78.75 ± 0.19 c | 2.74 ± 0.02 c | 8.63 ± 0.17 c | |

| Two-Factor ANOVA—p | |||||||

| Factor1 (flour) | <0.05 | >0.05 | <0.05 | <0.05 | <0.05 | <0.05 | |

| Factor 2 (TA concentration) | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | |

| Factor 1 × factor 2 | >0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | |

| Breads | Samples | Total Number of Cells | Total Area of Cells (mm2) | Average Area of Cells (mm2) | Porosity (%) | Percentage of Number of Cells < 4 mm2 (%) |

|---|---|---|---|---|---|---|

| XL | 0 TA | 1419.33 ± 43.43 a | 323.07 ± 16.04 a | 0.23 ± 0.02 a | 35.23 ± 1.57 a | 99.00 ± 0.15 a |

| 0.1% TA | 1242.33 ± 65.58 a | 353.30 ± 10.23 a | 0.29 ± 0.02 ab | 37.77 ± 1.14 a | 98.43 ± 0.16 ab | |

| 0.3% TA | 1322.33 ± 18.17 a | 411.43 ± 2.91 b | 0.31 ± 0.00 b | 43.38 ± 0.70 b | 98.33 ± 0.12 b | |

| QZG | 0 TA | 1223.00 ± 39.51 a | 262.60 ± 14.88 a | 0.22 ± 0.02 a | 28.54 ± 1.52 a | 99.10 ±0.13 a |

| 0.1% TA | 1290.33 ± 52.60 a | 278.55 ± 2.01 ab | 0.22 ± 0.01 a | 30.32 ± 0.49 ab | 99.10 ± 0.01 a | |

| 0.3% TA | 1184.33 ± 20.76 a | 313.25 ± 4.44 b | 0.26 ± 0.01 a | 33.87 ± 0.59 b | 98.42 ± 0.23 b | |

| QZZ | 0 TA | 1492.33 ± 6.39 a | 253.38 ± 14.45 a | 0.17 ± 0.01 a | 27.22 ± 1.41 a | 99.35 ± 0.18 a |

| 0.1% TA | 1412.67 ± 28.90 a | 308.20 ± 10.97 b | 0.22 ± 0.01 b | 33.60 ± 1.31 b | 99.05 ± 0.04 a | |

| 0.3% TA | 1498.67 ± 37.68 a | 309.83 ± 5.51 b | 0.21 ± 0.01 b | 33.32 ± 0.64 b | 99.09 ± 0.13 a | |

| Two-Factor ANOVA—p | ||||||

| Factor1 (flour) | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | |

| Factor2 (TA concentration) | >0.05 | <0.05 | <0.05 | <0.05 | <0.05 | |

| Factor 1 × factor 2 | <0.05 | >0.05 | >0.05 | >0.05 | >0.05 | |

| Breads | Samples | Appearance | Crumb Characteristics | Crust Color | Crumb Color | Aroma | Taste |

|---|---|---|---|---|---|---|---|

| XL | 0 TA | 7.07 ± 0.18 a | 7.27 ± 0.40 a | 7.00 ± 0.26 a | 7.47 ± 0.24 a | 7.60 ± 0.27 a | 7.53 ± 0.26 a |

| 0.1% TA | 7.20 ± 0.24 a | 8.13 ± 0.19 b | 7.47 ± 0.22 a | 7.67 ± 0.21 a | 7.80 ± 0.22 a | 8.13 ± 0.19 a | |

| 0.3% TA | 7.80 ± 0.22 b | 8.60 ± 0.19 c | 7.67 ± 0.21 b | 7.80 ± 0.35 a | 7.73 ± 0.25 a | 8.40 ± 0.34 b | |

| QZG | 0 TA | 7.27 ± 0.21 a | 7.13 ± 0.24 a | 7.00 ± 0.24 a | 7.33 ± 0.27 a | 7.27 ± 0.32 a | 6.33 ± 0.37 a |

| 0.1% TA | 7.73 ± 0.21 a | 7.40 ± 0.25 a | 7.33 ± 0.23 a | 7.47 ± 0.24 a | 7.67 ± 0.23 a | 6.63 ± 0.41 a | |

| 0.3% TA | 7.60 ± 0.16 a | 7.60 ± 0.21 a | 7.73 ± 0.23 b | 7.33 ± 0.23 a | 7.40 ± 0.31 a | 7.03 ± 0.23 a | |

| QZZ | 0 TA | 7.27 ± 0.28 a | 6.53 ± 0.32 a | 7.27 ± 0.28 a | 7.27 ± 0.18 a | 7.60 ± 0.16 a | 6.27 ± 0.33 a |

| 0.1% TA | 7.40 ± 0.31 a | 7.13 ± 0.17 a | 7.40 ± 0.24 a | 7.07 ± 0.30 a | 7.13 ± 0.35 a | 6.93 ± 0.28 a | |

| 0.3% TA | 7.53 ± 0.31 a | 7.07 ± 0.27 a | 7.67 ± 0.21 a | 7.20 ± 0.24 a | 6.93 ± 0.45 a | 7.00 ± 0.26 a | |

| Two-Factor ANOVA—p | |||||||

| Factor1 (flour) | >0.05 | <0.05 | >0.05 | >0.05 | >0.05 | <0.05 | |

| Factor2 (TA concentration) | >0.05 | <0.05 | <0.05 | >0.05 | >0.05 | <0.05 | |

| Factor 1 × factor 2 | >0.05 | >0.05 | >0.05 | >0.05 | >0.05 | >0.05 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, Y.; Yang, X.; Pan, C.; Kong, J.; Wu, R.; Liu, X.; Wang, Y.; Chen, M.; Li, M.; Wang, Q.; et al. Comprehensive Analyses of Breads Supplemented with Tannic Acids. Foods 2023, 12, 3756. https://doi.org/10.3390/foods12203756

Guan Y, Yang X, Pan C, Kong J, Wu R, Liu X, Wang Y, Chen M, Li M, Wang Q, et al. Comprehensive Analyses of Breads Supplemented with Tannic Acids. Foods. 2023; 12(20):3756. https://doi.org/10.3390/foods12203756

Chicago/Turabian StyleGuan, Yanbin, Xun Yang, Chuang Pan, Jie Kong, Ruizhe Wu, Xueli Liu, Yuesheng Wang, Mingjie Chen, Miao Li, Qiong Wang, and et al. 2023. "Comprehensive Analyses of Breads Supplemented with Tannic Acids" Foods 12, no. 20: 3756. https://doi.org/10.3390/foods12203756

APA StyleGuan, Y., Yang, X., Pan, C., Kong, J., Wu, R., Liu, X., Wang, Y., Chen, M., Li, M., Wang, Q., He, G., Yang, G., Chang, J., Li, Y., & Wang, Y. (2023). Comprehensive Analyses of Breads Supplemented with Tannic Acids. Foods, 12(20), 3756. https://doi.org/10.3390/foods12203756