The Impact of the Foliar Application of Amino Acid Aqueous Fertilizer on the Flavor of Potato Tubers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment Materials and Fertilizers

2.2. Reagents and Equipment

2.3. Experimental Method

2.4. Sampling and Index Measurement

2.5. Data Processing and Statistical Analysis

3. Results

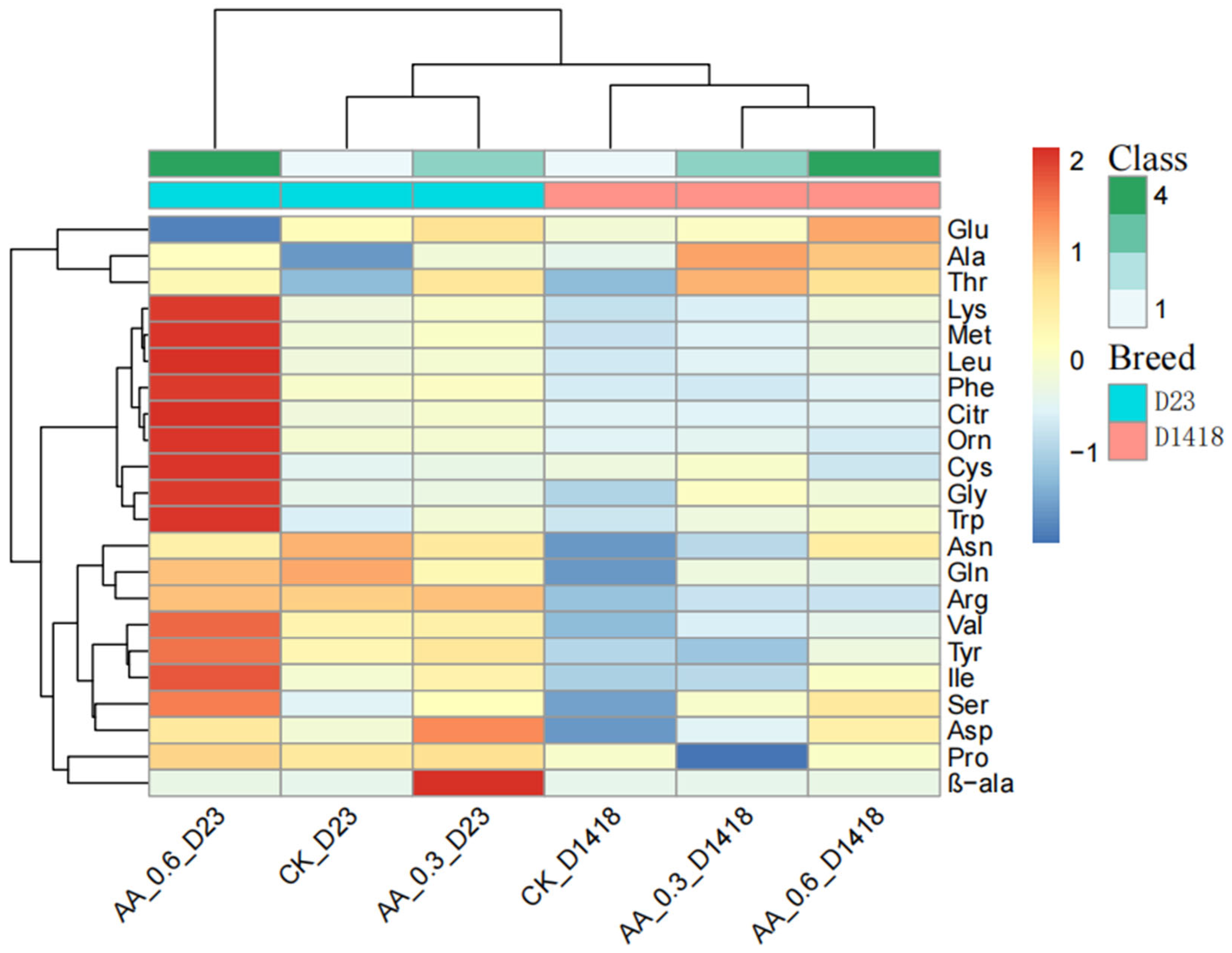

3.1. The Impact of Foliar Fertilizer Spraying on the Free Amino Acid Content in Potato Tubers

3.2. The Impact of Foliar Fertilizer Spraying on Volatile Flavor Compounds in Potato Tubers

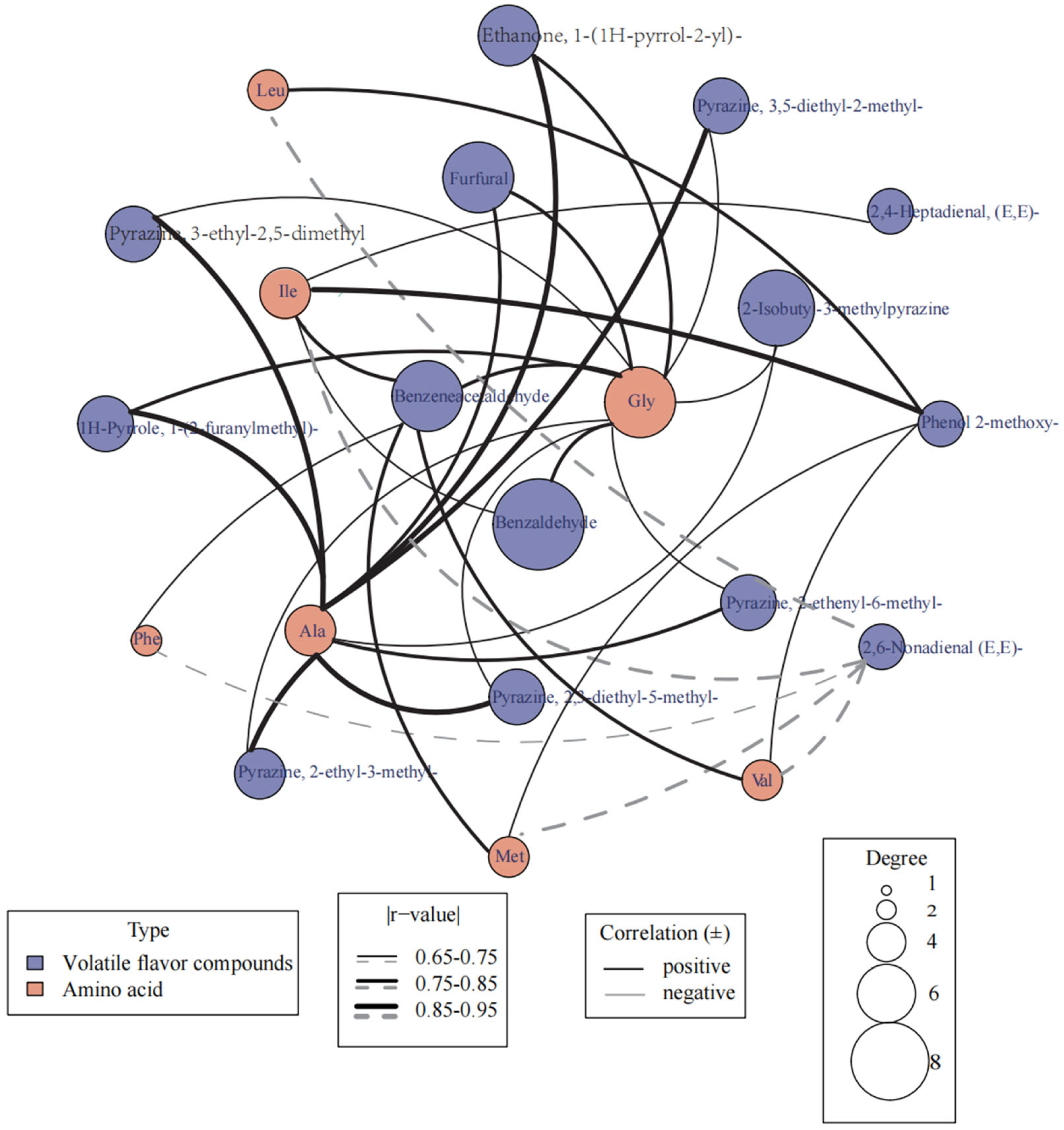

3.3. Analysis of the Correlation between Volatile Flavor Comp8onents and Free Amino Acids in Potato Tubers

3.4. Effects of Foliar Amino Acid Fertilizer Spraying on the Main Free Amino Acid Content in Potato Tubers

3.5. ROAV Analysis of Potato Volatile Flavor Substances after the Foliar Application of Amino Acid Aqueous Fertilizer

3.6. Analysis of Principal Components of Main Volatile Substances and Free Amino Acids under Amino Acid Water-Soluble Fertilizer Treatment

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Devaux, A.; Hareau, G.; Ordinola, M.; Andrade-Piedra, J.; Thiele, G. Native Potatoes. Choices 2020, 35, 1–7. [Google Scholar]

- Burlingame, B.; Mouillé, B.; Charrondiere, R. Nutrients, bioactive non-nutrients and anti-nutrients in potatoes. J. Food Compost. Anal. 2009, 22, 494–502. [Google Scholar] [CrossRef]

- Morris, W.L.; Taylor, M.A. Improving flavour to increase consumption. Am. J. Potato Res. 2019, 96, 195–200. [Google Scholar] [CrossRef]

- Auvray, M.; Spence, C. The multisensory perception of flavour. Conscious. Cogn. 2008, 17, 1016–1031. [Google Scholar] [CrossRef]

- Jansky, S.H. Potato flavor. Am. J. Potato Res. 2010, 87, 209–217. [Google Scholar] [CrossRef]

- Duckham, S.C.; Dodson, A.T.; Bakker, J.; Ames, J.M. Effect of cultivar and storage time on the volatile flavour components of baked potato. J. Agric. Food Chem. 2002, 50, 5640–5648. [Google Scholar] [CrossRef]

- Jansky, S.H. Genotypic and environmental contributions to baked potato flavour. Am. J. Potato Res. 2008, 85, 455–465. [Google Scholar] [CrossRef]

- Cremer, D.R.; Eichner, K. The reaction kinetics for the formation of Strecker aldehydes in low moisture model systems and in plant powders. Food Chem. 2000, 71, 37–43. [Google Scholar] [CrossRef]

- Maga, J.; Holm, D. Subjective and Objective Comparison of Baked Potato Aroma as Influenced by Variety/Clone; Elsevier: Amsterdam, The Netherlands, 1992; pp. 537–541. [Google Scholar]

- Oruna-Concha, M.J.; Duckham, S.C.; Ames, J.M. Comparison of volatile compounds isolated from the skin and flesh of four potato cultivars after baking. J. Agric. Food Chem. 2001, 49, 2414–2421. [Google Scholar] [CrossRef]

- Muttucumaru, N.; Powers, S.; Elmore, J.; Briddon, A.; Mottram, D.; Halford, N. Evidence for the complex relationship between free amino acid and sugar concentrations and acrylamide-forming potential in potato. Ann. Appl. Biol. 2014, 164, 286–300. [Google Scholar] [CrossRef]

- Di, R.; Kim, J.; Martin, M.N.; Leustek, T.; Jhoo, J.; Ho, C.-T.; Tumer, N.E. Enhancement of the primary flavour compound methional in potato by increasing the level of soluble methionine. J. Agric. Food Chem. 2003, 51, 5695–5702. [Google Scholar] [CrossRef] [PubMed]

- Kandi, M.A.S.; Tobeh, A.; Golipouri, A.; Godehkahriz, S.J.; Rastgar, Z. Concentration changes of lysine and methionine amino acids in potatoes varieties affected by different levels of Nitrogen fertilizer. Tech. J. Eng. Appl. Sci. 2012, 2, 93–96. [Google Scholar]

- Pourali, S.; Roozbahani, A. Evaluation of quantitative and qualitative traits of potato (Solanum tuberosum L.) under amino acids and iron application. Crop Res. 2015, 50, 101–106. [Google Scholar]

- Bakpa, E.P.; Xie, J.; Zhang, J.; Han, K.; Ma, Y.; Liu, T. Influence of soil amendment of different concentrations of amino acid water-soluble fertilizer on physiological characteristics, yield and quality of “Hangjiao No. 2” Chili Pepper. PeerJ 2021, 9, e12472. [Google Scholar] [CrossRef] [PubMed]

- Cieślik, E.; Gębusia, A.; Florkiewicz, A.; Mickowska, B. The content of protein and of amino acids in Jerusalem artichoke tubers (Helianthus tuberosus L.) of red variety Rote Zonenkugel. ACTA Sci. Pol. Technol. Aliment. 2011, 10, 433–441. [Google Scholar] [PubMed]

- Li, K.; Yin, Y.; Wang, Q.; Lin, T.; Guo, H. Correlation analysis of volatile flavor components and metabolites among potato varieties. Sci. Agric. Sin. 2021, 54, 792–803. [Google Scholar]

- Van Gemert, L. Compilations of Odour Threshold Values in Air, Water and Other Media; Elsevier: Amsterdam, The Netherlands, 2003; pp. 245–384. [Google Scholar]

- Wang, Y.; He, Y.; Liu, Y.; Wang, D. Analyzing Volatile Compounds of Young and Mature Docynia delavayi Fruit by HS-SPME-GC-MS and rOAV. Foods 2020, 12, 59. [Google Scholar] [CrossRef] [PubMed]

- Angeloni, S.; Mustafa, A.M.; Abouelenein, D.; Alessandroni, L.; Acquaticci, L.; Nzekoue, F.K.; Petrelli, R.; Sagratini, G.; Vittori, S.; Torregiani, E. Characterization of the aroma profile and main key odorants of espresso coffee. Molecules 2021, 26, 3856. [Google Scholar] [CrossRef]

- Chen, Q.; Song, J.; Bi, J.; Meng, X.; Wu, X. Characterization of volatile profile from ten different varieties of Chinese jujubes by HS-SPME/GC-MS coupled with E-nose. Food Res. Int. 2018, 105, 605–615. [Google Scholar] [CrossRef]

- Li, H.; Kang, X.; Wang, S.; Mo, H.; Xu, D.; Zhou, W.; Hu, L. Early detection and monitoring for Aspergillus flavus contamination in maize kernels. Food Control 2021, 121, 107636. [Google Scholar] [CrossRef]

- Xiang, Q.; Feng, T.; Su, Q.; Yao, L. Response surface methodology for optimization of L-arabinose/glycine Maillard reaction through microwave heating. J. Food Qual. 2022, 2022, 1535296. [Google Scholar] [CrossRef]

- Pareles, S.R.; Chang, S.S. Identification of compounds responsible for baked potato flavor. J. Agric. Food Chem. 1974, 22, 339–340. [Google Scholar] [CrossRef]

- Buttery, R.; Guadagni, D.; Ling, L. Volatile components of baked potatoes. J. Sci. Food Agric. 1973, 24, 1125–1131. [Google Scholar] [CrossRef]

- Fageria, N.; Filho, M.B.; Moreira, A.; Guimarães, C. Foliar fertilization of crop plants. J. Plant Nutr. 2009, 32, 1044–1064. [Google Scholar] [CrossRef]

- Gaj, R.; Chudzinska, E.; Borowski-Beszta, J.; Spychalski, W. Effect of potassium and micronutrient foliar fertilisation on the content and accumulation of macroelements, yield and quality parameters of potato tubers. J. Elem. 2020, 25, 1213–1231. [Google Scholar]

- Artyszak, A. Effect of silicon fertilization on crop yield quantity and quality—A literature review in Europe. Plants 2018, 7, 54. [Google Scholar] [CrossRef]

- Horvat, T.; Poljak, M.; Lazarevic, B.; Svečnjak, Z.; Hanaček, K. Effect of foliar fertilizers on physiological characteristics of potato. Rom. Agric. Res. 2014, 31, 159–165. [Google Scholar]

- Xu, Y.; Meng, D.; Liu, H.-J.; Chen, L.; Shi, C.-Y. Effect of potassium fertilizer on nutritional components of sweet potato storage roots and its relationship with roasting flavor. J. Plant Nutr. Fertil. 2020, 26, 1758–1767. [Google Scholar]

- Nooshkam, M.; Varidi, M.; Bashash, M. The Maillard reaction products as food-born antioxidant and antibrowning agents in model and real food systems. Food Chem. 2019, 275, 644–660. [Google Scholar] [CrossRef]

- Wagner, R.K.; Grosch, W. Key odorants of French fries. J. Am. Oil Chem. Soc. 1998, 75, 1385–1392. [Google Scholar] [CrossRef]

- Low, M.Y.; Koutsidis, G.; Parker, J.K.; Elmore, J.S.; Dodson, A.T.; Mottram, D.S. Effect of citric acid and glycine addition on acrylamide and flavor in a potato model system. J. Agric. Food Chem. 2006, 54, 5976–5983. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, J.; Ho, C.T. Dicarbonyl Intermediates a Control Factor in the Maillard Reaction; American Chemical Society: Washington, DC, USA, 2009; p. 127. [Google Scholar]

- Cheng, K.-W.; Wong, C.C.; Cho, C.K.; Chu, I.K.; Sze, K.H.; Lo, C.; Chen, F.; Wang, M. Trapping of phenylacetaldehyde as a key mechanism responsible for naringenin’s inhibitory activity in mutagenic 2-amino-1-methyl-6-phenylimidazo[4,5-b]pyridine formation. Chem. Res. Toxicol. 2008, 21, 2026–2034. [Google Scholar] [CrossRef]

- Romano, R.; Filosa, G.; Pizzolongo, F.; Durazzo, A.; Lucarini, M.; Severino, P.; Souto, E.B.; Santini, A. Oxidative stability of high oleic sunflower oil during deep-frying process of purple potato Purple Majesty. Heliyon 2021, 7, e06294. [Google Scholar] [CrossRef]

- Thybo, A.; Christiansen, J.; Kaack, K.; Petersen, M. Effect of cultivars, wound healing and storage on sensory quality and chemical components in pre-peeled potatoes. LWT 2006, 39, 166–176. [Google Scholar] [CrossRef]

- Comandini, P.; Cerretani, L.; Blanda, G.; Bendini, A.; Toschi, T.G. Characterization of potato flavours: An overview of volatile profiles and analytical procedures. Potato V. Food 2011, 5, 1–14. [Google Scholar]

- Taylor, M.A.; McDougall, G.J.; Stewart, D. Potato flavour and texture. In Potato Biology and Biotechnology; Elsevier: Amsterdam, The Netherlands, 2007; pp. 525–540. [Google Scholar]

| Name | D23 (ug·g−1) | D1418 (ug·g−1) | ||||

|---|---|---|---|---|---|---|

| CK | AA_0.3 | AA_0.6 | CK | AA_0.3 | AA_0.6 | |

| Ala | 21.115 | 31.63 | 33.801 | 29.995 | 42.639 | 40.544 |

| Glu | 28.093 | 35.974 | 0.253 | 23.778 | 26.698 | 43.501 |

| Gln | 660.725 | 594.785 | 648.53 | 472.735 | 559.055 | 553.67 |

| Tyr | 37.847 | 44.372 | 64.462 | 13.641 | 9.937 | 26.319 |

| Arg | 121.083 | 125.461 | 125.512 | 44.709 | 60.074 | 60.532 |

| Val | 81.479 | 83.763 | 116.249 | 43.038 | 58.853 | 63.854 |

| Phe | 47.764 | 52.596 | 143.385 | 21.087 | 19.243 | 27.005 |

| Ile | 29.651 | 35.947 | 53.781 | 19.142 | 20.508 | 31.371 |

| Thr | 15.074 | 23.565 | 21.844 | 15.021 | 26.02 | 23.875 |

| Met | 32.723 | 37.512 | 83.406 | 20.518 | 24.828 | 30.077 |

| Asn | 263.491 | 234.975 | 226.144 | 124.503 | 160.128 | 229.772 |

| Ser | 15.738 | 18.101 | 23.223 | 12.216 | 17.583 | 19.748 |

| Asp | 29 | 38.192 | 33.144 | 20.929 | 26.944 | 32.303 |

| Citr | 2.455 | 3.316 | 14.812 | 0.923 | 0.668 | 0.909 |

| Pro | 77.795 | 81.099 | 83.889 | 63.277 | 20.879 | 65.078 |

| Gly | 6.566 | 6.825 | 12.598 | 5.248 | 7.736 | 7.139 |

| Leu | 13.069 | 14.655 | 40.839 | 7.988 | 9.849 | 12.427 |

| Trp | 24.09 | 40.875 | 129.448 | 18.912 | 36.165 | 44.818 |

| Orn | 16.895 | 17.254 | 59.693 | 9.689 | 9.806 | 7.32 |

| Lys | 35.014 | 38.67 | 76.811 | 24.096 | 28.181 | 35.831 |

| β-ala | 0.179 | 6.143 | 0.288 | 0.14 | 0.212 | 0.314 |

| Cys | 5.676 | 6.332 | 22.486 | 7.089 | 8.567 | 4.049 |

| Name | Relvtive Peak Area × 102 (%) | |||||

|---|---|---|---|---|---|---|

| D1418 | D23 | |||||

| 0.3_AA | 0.6_AA | CK | 0.3_AA | 0.6_AA | CK | |

| 1-Hexanol 2-ethyl- | 512,459.5 | 437,399.5 | 72,187.5 | 527,603 | 345,730 | 88,660 |

| 1-Octanol | 199,450 | 129,537 | 10,675 | 185,247 | 108,486.3 | 6084 |

| 1H-Pyrrole, 1-(2-furanylmethyl)- | 2,085,267.5 | 1,235,397 | 2650.5 | 981,915.5 | 739,987.7 | 2155 |

| 2-(2-Methylpropyl)-3-(1-methylethyl)pyra | 16,971,213.5 | 10,679,824 | 168,642 | 15,017,781.5 | 8,622,082.5 | 230,322 |

| 2-Decenal (E)- | 18,663 | 2777 | 0 | 476.5 | 1084.5 | 344 |

| 2-Dodecenal (E)- | 8675.5 | 18,181 | 3482.5 | 47,588 | 23,083.8 | 2573 |

| 2-Heptanone | 54,388 | 31,966 | 10,519.5 | 35,454 | 25,979.8 | 7470.5 |

| 2-Heptenal (E) | 399 | 106,655 | 44,725.5 | 9578.5 | 53,653 | 16,703.5 |

| 2-Hexenal (E)- | 4348 | 5240 | 4526.5 | 16,959 | 8908.5 | 0 |

| 2-Isoamyl-6-methylpyrazine | 405,664.5 | 347,880 | 25,621.5 | 509,848 | 294,449.8 | 32,323.5 |

| 2-Isobutyl-3-methylpyrazine | 10,960,588 | 7,320,303.5 | 81,422.5 | 886,6978 | 5,422,901.3 | 86,452 |

| 2-n-Butyl furan | 8080.5 | 3095 | 206.5 | 7959 | 3753.5 | 0 |

| 2-Nonenal (E)- | 630,186.5 | 540,706 | 84,725 | 444,203 | 356,544.7 | 87,146.5 |

| 2-Octenal (E)- | 1132.5 | 1325.5 | 5930 | 525.5 | 2593.7 | 2692.5 |

| 2-Undecenal | 63,375.5 | 50,024.5 | 27,003.5 | 69,184 | 48,737.3 | 2105 |

| 2,3-Dimethyl-5-ethylpyrazine | 1,796,376 | 1,255,266.5 | 72,448.5 | 1,502,808 | 943,507.7 | 55,435.5 |

| 2,3-Octanedione | 27,686 | 112,349 | 114,718.5 | 716 | 75,927.8 | 2871.5 |

| 2,3,5-Trimethyl-6-(2-methylbutyl)pyrazin | 1,451,749.5 | 1,094,330 | 15,482 | 1,911,333.5 | 1,007,048.5 | 23,032.5 |

| 2,4-Decadienal, (E,E)- | 782,613 | 686,539 | 425,574.5 | 480,687.5 | 530,933.7 | 19,410.5 |

| 2,4-Heptadienal, (E,E)- | 22,916 | 15,054 | 1824.5 | 57,702.5 | 24,860.3 | 566.5 |

| 2,4-Nonadienal, (E,E)- | 23,089.5 | 15,059.5 | 31,206 | 30,868 | 25,711.2 | 0 |

| 2,4-Undecadienal | 4847 | 6102 | 5284.5 | 5348 | 5578.2 | 226.5 |

| 2,6-Nonadienal (E,E)- | 23,708.5 | 18,828 | 34,025.5 | 12,392 | 21,748.5 | 27,418 |

| 3-Heptanone,2-methyl- | 5,3048,701.5 | 54,602,032.5 | 11,231,486 | 40,713,983.5 | 35,515,834 | 15,115,644.5 |

| 3-Octen-2-one | 24,003.5 | 18,637 | 25,384.5 | 15,405.5 | 19,809 | 469.5 |

| 3,5-Dimethyl-2-isobutylpyrazine | 667,238.5 | 427,661 | 8776 | 460,271 | 298,902.7 | 13,802 |

| 3,5-Octadien-2-ol | 32,544.5 | 28,844.5 | 1160.5 | 20,113.5 | 16,706.2 | 0 |

| 4,5-Dimethyl-2-isopropyloxazole | 687,367.5 | 467,580.5 | 2361.5 | 676,230.5 | 382,057.5 | 1032.5 |

| 5-Hepten-2-one 6-methyl- | 246,326 | 491,362 | 23,806 | 374,973.5 | 296,713.8 | 45,391 |

| 5H-5-Methyl-6,7-dihydrocyclopentapyrazin | 1,663,741.5 | 1,063,249 | 6034 | 1,446,688 | 838,657 | 9155.5 |

| Benzaldehyde | 4,484,489.5 | 3,147,999.5 | 738,544 | 6,176,531 | 3,354,358.2 | 1,127,359.5 |

| Benzeneacetaldehyde | 6,364,881 | 6,172,831 | 905,105 | 13,624,411 | 6,900,782.3 | 1,609,060 |

| Butanal 2-methyl | 567,638.5 | 617,784 | 49,920 | 1,550,692.5 | 739,465.5 | 38,968 |

| Butanal 3-methyl | 10,959 | 20,286 | 8595 | 20,454 | 16,445 | 4486.5 |

| Decanal | 472,853 | 408,414.5 | 168,911.5 | 496,179.5 | 357,835.2 | 122,289 |

| Dibutyl phthalate | 14,082.5 | 17,288.5 | 10,530.5 | 14,232.5 | 14,017.2 | 9605.5 |

| Dimethyl trisulfide | 1,479,351 | 134,992.5 | 588,334.5 | 188,881.5 | 304,069.5 | 168,748.5 |

| Disulfide, dimethyl | 3,591,356 | 568,467 | 191,960 | 1,808,566 | 856,331 | 408,833 |

| Ethanone, 1-(1H-pyrrol-2-yl)- | 7,890,385 | 5,406,293 | 4801 | 43,41,755.5 | 3,250,949.8 | 13,607.5 |

| Furan 2-methyl | 155,971.5 | 46,441 | 2365 | 140,383 | 63,063 | 3873 |

| Furan 2-pentyl- | 522,208 | 268,804.5 | 152,475.5 | 554,196 | 325,158.7 | 125,227 |

| Furfural | 6,929,990 | 351,426.5 | 4386 | 2143,526.5 | 833,113 | 2407.5 |

| Furfural, 5-methyl- | 6,200,283 | 554,513.5 | 1172.5 | 3,605,694.5 | 1,387,126.8 | 0 |

| Heptanal | 351,220 | 184,604 | 166,322 | 319,639.5 | 223,521.8 | 97,844.5 |

| Hexanal | 1,267,477.5 | 817,366 | 2,308,175.5 | 2,344,020.5 | 1,823,187.3 | 411,623 |

| Methional | 7,324,469 | 2,274,775.5 | 1,803,119 | 7,580,234.5 | 3,886,043 | 2,447,959 |

| Naphthalene | 16,663 | 12,785.5 | 0 | 10,423.5 | 7736.3 | 579 |

| Naphthalene 2-methyl- | 23,123 | 4897.5 | 0 | 12,879.5 | 5925.7 | 0 |

| Nonanal | 94,512.5 | 29,747 | 0 | 31,915 | 20,554 | 0 |

| Octanal | 686,610 | 385,907.5 | 139,016 | 568,157.5 | 364,360.3 | 93,030.5 |

| Oxazole, trimethyl- | 1,360,370.5 | 705,664.5 | 0 | 535,102 | 413,588.8 | 0 |

| Phenol 2-methoxy- | 233,424.5 | 442,647.5 | 145,789.5 | 3,340,033.5 | 1,309,490.2 | 178,036 |

| Propanal 2-methyl- | 2,906,580.5 | 2,133,307.5 | 123,169 | 13,17,808 | 1,191,428.2 | 70,286 |

| Pyrazine, | 929,673.5 | 870,579 | 1047.5 | 875,061.5 | 582,229.3 | 762.5 |

| Pyrazine, 2-ethenyl-6-methyl- | 9,281,106 | 10,237,992.5 | 120,384.5 | 7,146,457 | 5,834,944.7 | 172,323.5 |

| pyrazine, 2-ethyl-3-methyl- | 25,283,235 | 25,027,548 | 198,264 | 9,781,194 | 11,669,002 | 133,329.5 |

| pyrazine, 2-ethyl-5-methyl- | 636,042 | 1,134,905.5 | 7088 | 705,381 | 615,791.5 | 8710 |

| Pyrazine, 2-ethyl-6-methyl- | 33,490,667.5 | 50,884,877.5 | 137,283.5 | 32,411,201 | 27,811,120.7 | 128,274.5 |

| Pyrazine, 2,3-diethyl-5-methyl- | 1,719,778 | 1,309,362 | 40,042.5 | 891,565 | 746,989.8 | 30,240 |

| Pyrazine, 2,3-dimethyl | 6,364,209 | 4,528,647.5 | 102,383.5 | 5,922,310.5 | 3,517,780.5 | 1548.5 |

| Pyrazine, 2,3-dimethyl-5-(2-methylpropyl | 1,950,925.5 | 1,423,921 | 16,650 | 1,650,089 | 1,030,220 | 23,849.5 |

| Pyrazine, 2,5-diethyl- | 2,750,524 | 2,302,242.5 | 107,681 | 2,528,630 | 1,646,184.5 | 107,905.5 |

| Pyrazine, 2,5-dimethyl- | 233,282 | 179,421 | 4824 | 238,776.5 | 141,007.2 | 3889 |

| Pyrazine, 2,5-dimethyl-3-(2-methylpropyl | 5,715,465 | 5,773,194.5 | 96,171.5 | 7,771,879.5 | 4,547,081.8 | 121,422 |

| Pyrazine, 2,5-dimethyl-3-(3-methylbutyl) | 2,970,391 | 2,225,034.5 | 31,534 | 3,722,482.5 | 1,993,017 | 38,555 |

| Pyrazine, 2,6-dimethyl | 57,821,792.5 | 31,092,731.5 | 27,078.5 | 59,054,175 | 30,057,995 | 23,567.5 |

| Pyrazine, 3-ethyl-2,5-dimethyl | 102,969,897 | 85,418,501 | 1,780,924.5 | 59,578,984 | 48,926,136.5 | 1,266,235.5 |

| Pyrazine, 3,5-diethyl-2-methyl- | 20,807,908 | 18,040,734.5 | 318,802.5 | 12,248,286.5 | 10,202,607.8 | 258,228 |

| Pyrazine, ethenyl- | 1,797,855.5 | 2,030,248 | 6541.5 | 1,829,591.5 | 1,288,793.7 | 4904.5 |

| Pyrazine, ethyl- | 698,437 | 650,239 | 8910 | 695,049.5 | 451,399.5 | 9952 |

| Pyrazine, methyl- | 54,750,739 | 45,196,613.5 | 5066.5 | 47,333,874.5 | 30,845,184.8 | 0 |

| pyrazine, trimethyl- | 15,060,797.5 | 3,151,401 | 32,095 | 20,960,252 | 8,047,916 | 15,097 |

| Pyrrole | 1,957,153.5 | 558,749.5 | 2571 | 1,343,357.5 | 634,892.7 | 9786 |

| Undecanal | 132,075 | 20,445.5 | 11,672 | 81,748 | 37,955.2 | 14,976 |

| Name | Threshold (μg·kg−1) | Aroma Characteristic | ROAV | |||||

|---|---|---|---|---|---|---|---|---|

| D1418 | D23 | |||||||

| 0.6_AA | 0.3_AA | CK | 0.6_AA | 0.3_AA | CK | |||

| Ethanone, 1-(1H-pyrrol-2-yl)- | 114.39 | Bread aroma | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Pyrazine, 3-ethyl-2,5-dimethyl | 7.257 | Baking odor | 0.1 | 0.1 | <0.01 | <0.01 | <0.01 | <0.01 |

| 1H-Pyrrole, 1-(2-furanylmethyl)- | 0.1 | Roasted, hazelnut, coffee like aroma | 0.1 | 0.1 | <0.01 | <0.01 | <0.01 | <0.01 |

| Phenol 2-methoxy- | 0.02 | Special fragrance | <0.01 | 0.1 | 0.6 | 0.4 | 0.8 | 0.6 |

| Pyrazine, 2,3-diethyl-5-methyl- | 0.001 | Coffee, nuts | 6.3 | 6 | 3.1 | 4.9 | 4 | 2.2 |

| pyrazine, 2-ethyl-3-methyl- | 0.315 | Roasted flavor | 0.3 | 0.4 | <0.01 | 0.2 | 0.1 | <0.01 |

| Pyrazine, 3,5-diethyl-2-methyl- | - | Roasted flavor | - | - | - | - | - | - |

| 2,6-Nonadienal (E,E)- | 0.001 | Melon, Fatty | 0.2 | 0.2 | 5.3 | 0.3 | 0.1 | 4 |

| 2-Isobutyl-3-methylpyrazine | 0.002 | Roasted flavor | 20.2 | 16.7 | 3.2 | 18 | 20 | 3.1 |

| 2,4-Heptadienal, (E,E)- | 0.1 | Fat, fruits, spices | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Benzaldehyde | 350 | Almond flavor | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Benzeneacetaldehyde | 4 | Almond, cherry | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Furfural | 6.474 | Almond flavor | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Pyrazine, 2-ethenyl-6-methyl- | - | Roasted flavor | - | - | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Li, K.; Zhang, X.; Yang, C.; Zhang, R.; Guo, H. The Impact of the Foliar Application of Amino Acid Aqueous Fertilizer on the Flavor of Potato Tubers. Foods 2023, 12, 3951. https://doi.org/10.3390/foods12213951

Hu S, Li K, Zhang X, Yang C, Zhang R, Guo H. The Impact of the Foliar Application of Amino Acid Aqueous Fertilizer on the Flavor of Potato Tubers. Foods. 2023; 12(21):3951. https://doi.org/10.3390/foods12213951

Chicago/Turabian StyleHu, Songhe, Kaifeng Li, Xing Zhang, Changwei Yang, Rui Zhang, and Huachun Guo. 2023. "The Impact of the Foliar Application of Amino Acid Aqueous Fertilizer on the Flavor of Potato Tubers" Foods 12, no. 21: 3951. https://doi.org/10.3390/foods12213951

APA StyleHu, S., Li, K., Zhang, X., Yang, C., Zhang, R., & Guo, H. (2023). The Impact of the Foliar Application of Amino Acid Aqueous Fertilizer on the Flavor of Potato Tubers. Foods, 12(21), 3951. https://doi.org/10.3390/foods12213951