Augmenting Functional and Sensorial Quality Attributes of Kefir through Fortification with Encapsulated Blackberry Juice

Abstract

:1. Introduction

2. Material and Methods

2.1. Chemicals

2.2. Plant Material

2.3. Protein Extraction

2.4. Blackberry Juice Encapsulation with Lentil Proteins

2.5. Characterization of Lentil Protein Isolate (LPI) and Encapsulated Blackberry Juice (EBJ)

2.5.1. Physicochemical and Color Properties

2.5.2. Morphological Properties

2.5.3. Phytochemical Content and Antioxidant Properties

2.5.4. Microbiological Profiles

2.6. Preparation of Kefir Fortified with Encapsulated Blackberry Juice (EBJ)

2.7. Monitoring of Kefir Quality Parameters during Storage

2.7.1. Color Analysis and Influence of Encapsulated Blackberry Juice (EBJ) Fortification on Viscosity, pH, and Total Solids

2.7.2. Microbiological Profiling of Encapsulated Blackberry Juice (EBJ)-Fortified Kefir

2.8. Sensory Evaluation

2.9. Statistical Analyses

3. Results and Discussion

3.1. Lentil Protein Isolate (LPI) and Encapsulated Blackberry Juice (EBJ)

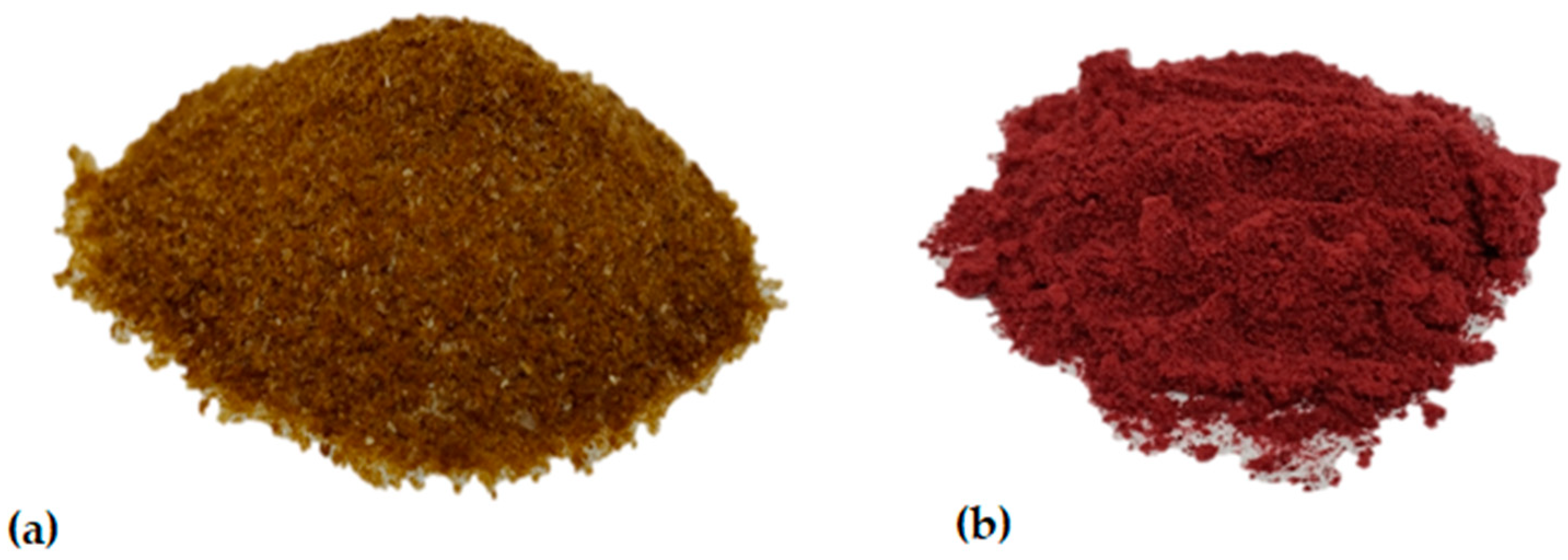

3.1.1. Physicochemical and Color Properties

3.1.2. Morphological Properties

3.1.3. Phytochemical Content and Antioxidant Properties

3.1.4. Microbiological Profiles

3.2. Kefir Fortified with Encapsulated Blackberry Juice (EBJ)

3.2.1. Influence of Encapsulated Blackberry Juice (EBJ) Kefir Fortification on Color, Titratable Acidity, and pH during Storage

3.2.2. Influence of Encapsulated Blackberry Juice (EBJ) Kefir Fortification on Phytochemical Content and Antioxidant Activity during Storage

3.2.3. Influence of Encapsulated Blackberry Juice (EBJ) Kefir Fortification on Microbiological Profile during Storage

3.2.4. Influence of Encapsulated Blackberry Juice (EBJ) Kefir Fortification on Sensory Attributes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roy, B.; Singh, J.; Dewan, T. A comparative study of antioxidant activity and total phenolic content of fresh juices of some common Indian fruits with their commercial counterparts. Curr. Sci. 2020, 118, 300–304. [Google Scholar] [CrossRef]

- Fidelis, M.; Santos, J.S.; Coelho, A.L.K.; Rodionova, O.Y.; Pomerantsev, A.; Granato, D. uthentication of juices from antioxidant and chemical perspectives: A feasibility quality control study using chemometrics. Food Cont. 2017, 73, 796–805. [Google Scholar] [CrossRef]

- Rosales, T.K.O.; Fabi, J.P. Valorization of polyphenolic compounds from food industry by-products for application in polysaccharide-based nanoparticles. Front. Nutr. 2023, 10, 1144677. [Google Scholar] [CrossRef]

- Rathee, P.; Sehrawat, R.; Rathee, P.; Khatkar, A.; Akkol, E.K.; Khatkar, S.; Redhu, N.; Türkcanoğlu, G.; Sobarzo-Sánchez, E. Polyphenols: Natural Preservatives with Promising Applications in Food, Cosmetics and Pharma Industries; Problems and Toxicity Associated with Synthetic Preservatives; Impact of Misleading Advertisements; Recent Trends in Preservation and Legislation. Materials 2023, 16, 4793. [Google Scholar] [CrossRef]

- Costa, M.; Sezgin-Bayindir, Z.; Losada-Barreiro, S.; Paiva-Martins, F.; Saso, L.; Bravo-Díaz, C. Polyphenols as Antioxidants for Extending Food Shelf-Life and in the Prevention of Health Diseases: Encapsulation and Interfacial Phenomena. Biomedicines 2021, 9, 1909. [Google Scholar] [CrossRef]

- Boye, J.I.; Aksay, S.; Roufik, S.; Ribéreau, S.; Mondor, M.; Farnworth, E.; Rajamohamed, S.H. Comparison of the Functional Properties of Pea, Chickpea and Lentil Protein Concentrates Processed Using Ultrafiltration and Isoelectric Precipitation Techniques. Food Res. Int. 2010, 43, 537–546. [Google Scholar] [CrossRef]

- Chang, C.; Varankovich, N.; Nickerson, M.T. Microencapsulation of Canola Oil by Lentil Protein Isolate-Based Wall Materials. Food Chem. 2016, 212, 264–273. [Google Scholar] [CrossRef] [PubMed]

- Avramenko, N.A.; Chang, C.; Low, N.H.; Nickerson, M.T. Encapsulation of Flaxseed Oil within Native and Modified Lentil Protein-Based Microcapsules. Food Res. Int. 2016, 81, 17–24. [Google Scholar] [CrossRef]

- Quiroz, J.Q.; Velazquez, V.; Corrales-Garcia, L.L.; Torres, J.D.; Delgado, E.; Ciro, G.; Rojas, J. Use of Plant Proteins as Microencapsulating Agents of Bioactive Compounds Extracted from Annatto Seeds (Bixa orellana L.). Antioxidants 2020, 9, 310. [Google Scholar] [CrossRef]

- Dimidi, E.; Cox, S.R.; Rossi, M.; Whelan, K. Fermented Foods: Definitions and Characteristics, Impact on the Gut Microbiota and Effects on Gastrointestinal Health and Disease. Nutrients 2019, 11, 1806. [Google Scholar] [CrossRef]

- Bellilci-Koyu, E.; Sarer-Yurkeli, B.P.; Akyon, Y.; Aydin-Kose, F.; Karagozlu, C.; Ozgen, A.G.; Brinkmann, A.; Nitsche, A.; Ergunay, K.; Yilmaz, E.; et al. Effects of Regular Kefir Consumption on Gut Microbiota in Patients with Metabolic Syndrome: A Parallel-Group, Randomized, Controlled Study. Nutrients 2019, 11, 2089. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira Leite, A.M.; Miguel, M.A.; Peixoto, R.S.; Rosado, A.S.; Silva, J.T.; Paschoalin, V.M. Microbiological, technological and therapeutic properties of kefir: A natural probiotic beverage. Braz. J. Microbiol. 2013, 44, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Ershadi, A.; Parastouei, K.; Khaneghah, A.M.; Hadian, Z.; Lorenzo, J.M. Encapsulation of Curcumin in Persian Gum Nanoparticles: An Assessment of Physicochemical, Sensory, and Nutritional Properties. Coatings 2021, 11, 841. [Google Scholar] [CrossRef]

- Melo, A.; Silva, M.A. Development of fermented and flavoured kefir milk. BMC Proc. 2014, 8, 15. [Google Scholar] [CrossRef]

- Tomas, M.; Toydemir, G.; Boyacıoğlu, D.; Hall, R.; Beekwilder, J.; Çapanoğlu, E. The effects of juice processing on black mulberry antioxidants. Food Chem. 2015, 186, 277–284. [Google Scholar] [CrossRef] [PubMed]

- Türkyılmaz, M.; Tağı, Ş.; Dereli, U.; Özkan, M. Effects of various pressing programs and yields on the antioxidant activity, antimicrobial activity, phenolic content and colour of pomegranate juices. Food Chem. 2013, 138, 1810–1818. [Google Scholar] [CrossRef]

- Oszmiánski, J.; Wojdyło, A. Comparative study of phenolic content and antioxidant activity of strawberry puree, clear, and cloudy juices. Eur. Food Res. Technol. 2009, 228, 623–631. [Google Scholar] [CrossRef]

- Türkyılmaz, M.; Yemiş, O.; Özkan, M. Clarification and pasteurization effects on monomeric anthocyanins and percent polimeric colour of black carrot (Daucus carota L.) juice. Food Chem. 2012, 134, 1052–1058. [Google Scholar] [CrossRef]

- Čakarević, J.; Šeregelj, V.; Tumbas Šaponjac, V.; Ćetković, G.; Čanadanović Brunet, J.; Popović, S.; Kostić, M.H.; Popović, L. Encapsulation of beetroot juice: A study on the application of pumpkin oil cake protein as new carrier agent. J. Microencapsul. 2020, 37, 121–133. [Google Scholar] [CrossRef]

- Perović, M.N.; Pajin, B.S.; Antov, M.G. The Effect of Enzymatic Pretreatment of Chickpea on Functional Properties and Antioxidant Activity of Alkaline Protein Isolate. Food Chem. 2022, 374, 131809. [Google Scholar] [CrossRef]

- Tan, E.S.; Ying-Yuan, N.; Gan, C.Y. A Comparative Study of Physicochemical Characteristics and Functionalities of Pinto Bean Protein Isolate (PBPI) against the Soybean Protein Isolate (SPI) after the Extraction Optimisation. Food Chem. 2014, 152, 447–455. [Google Scholar] [CrossRef] [PubMed]

- Šeregelj, V.; Cetković, G.; Čanadanović-Brunet, J.; Šaponjac, V.T.; Vulić, J.; Lević, S.; Nedović, V.; Brandolini, A.; Hidalgo, A. Encapsulation of Carrot Waste Extract by Freeze and Spray Drying Techniques: An Optimization Study. LWT 2021, 138, 110696. [Google Scholar] [CrossRef]

- Jinapong, N.; Suphantharika, M.; Jamnong, P. Production of Instant Soymilk Powders by Ultrafiltration, Spray Drying and Fluidized Bed Agglomeration. J. Food Eng. 2008, 84, 194–205. [Google Scholar] [CrossRef]

- Šeregelj, V.; Ćetković, G.; Čanadanović-Brunet, J.; Tumbas Šaponjac, V.; Vulić, J.; Stajčić, S. Encapsulation and Degradation Kinetics of Bioactive Compounds from Sweet Potato Peel During Storage. Food Technol. Biotechnol. 2020, 58, 314–324. [Google Scholar] [CrossRef]

- Lee, J.; Durst, R.W.; Wrosltad, R.E. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method: Collaborative study. J AOAC Int. 2005, 88, 1269–1278. [Google Scholar] [CrossRef] [PubMed]

- Šaponjac, V.T.; Ćetković, G.; Čanadanović-Brunet, J.; Pajin, B.; Đilas, S.; Petrović, J.; Lončarević, I.; Stajčić, S.; Vulić, J. Sour cherry pomace extract encapsulated in whey and soy proteins: Incorporation in cookies. Food Chem. 2016, 207, 27–33. [Google Scholar] [CrossRef]

- Šaponjac, V.T.; Gironés-Vilaplana, A.; Djilas, S.; Mena, P.; Cetkovi’c, G.; Moreno, D.A.; Kruni´c, M. Anthocyanin profiles and biological properties of caneberry (Rubuss pp.) press residues. JSFA 2014, 94, 2393–2400. [Google Scholar] [CrossRef]

- Oyaizu, M. Studies on products of browning reaction–antioxidant activities of products of browning reaction prepared from glucosamine. Jpn. J. Nutr. 1986, 44, 307–315. [Google Scholar] [CrossRef]

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. ISO: Geneva, Switzerland, 2013.

- ISO 21527-1:2008; Microbiology of Food and Animal Feeding Stuffs Horizontal Method for the Enumeration of Yeasts and Moulds—Part 1: Colony Count Technique in Products with Water Activity Greater than 0. ISO: Geneva, Switzerland, 2008.

- ISO 21528-2:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 2: Colony-Count Technique. ISO: Geneva, Switzerland, 2017.

- ISO 7937:2004; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Clostridium Perfringens—Colony-Count Technique. ISO: Geneva, Switzerland, 2004.

- Gürsoy, O.; Kocatürk, K.; Güler Dal, H.O.; Yakalı, H.N.; Yılmaz, Y. Physicochemical and rheological properties of commercial kefir drinks. Akad. Gıda 2020, 18, 375–381. [Google Scholar] [CrossRef]

- Kabakcı, S.A.; Türkyılmaz, M.; Özkan, M. Changes in the Quality of Kefir Fortified with Anthocyanin-Rich Juices during Storage. Food Chem. 2020, 326, 126977. [Google Scholar] [CrossRef]

- ISO 7889:2003; Yogurt—Enumeration of Characteristic Microorganisms—Colony-Count Technique at 37 °C. ISO: Geneva, Switzerland, 2003.

- ISO 7251:2005; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Detection and Enumeration of Presumptive Escherichia coli—Most Probable Number Technique. ISO: Geneva, Switzerland, 2005.

- ISO 11290-2:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 2. Switzerland: ISO. Enumeration Method. ISO: Geneva, Switzerland, 2017.

- ISO 6888-1:1999/AMD 2:2018; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and Other Species)—Part 1: Technique Using Baird-Parker Agar Medium—Amendment 2: Inclusion of an Alternative Confirmation Test Using RPFA Stab Method. ISO: Geneva, Switzerland, 2018.

- ISO 6579-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp. ISO: Geneva, Switzerland, 2017.

- Carpenter, R.; Lyon, D.; Hasdell, T. Guidelines for Sensory Analysis in Food Product Development and Quality Control; Aspen Publishers, Inc.: Gaithersburg, MD, USA, 2000; pp. 71–91. [Google Scholar] [CrossRef]

- Nthimole, T.; Kaseke, T.; Fawole, O.A. Micro-Encapsulation and Characterization of Anthocyanin-Rich Raspberry Juice Powder for Potential Applications in the Food Industry. Processes 2022, 10, 1038. [Google Scholar] [CrossRef]

- GEA Niro. Hygroscopicity—Method A14a. GEA Niro Analytical Methods of Dry Milk Products, GEA Niro, Soeborg, Denmark. 2005, pp. 1–3. Available online: https://efps.gr/products/dryers-particle-processing-plants/spray-dryers/food-dairy-products/analytical-methods-dry-milk-products/ (accessed on 22 September 2023).

- Zayas, J. Functionality of Proteins in Food; Springer: Berlin/Heidelberg, Germany, 1997; ISBN 9783642624759. [Google Scholar]

- Vulić, J.; Šeregelj, V.; Tumbas Šaponjac, V.; Karadžić Banjac, M.; Kovačević, S.; Šovljanski, O.; Ćetković, G.; Čanadanović-Brunet, J.; Jevrić, L.; Podunavac-Kuzmanović, S. From Sweet Corn By-Products to Carotenoid-Rich Encapsulates for Food Applications. Processes 2022, 10, 1616. [Google Scholar] [CrossRef]

- Jiménez-Aguilar, D.M.; Ortega-Regules, A.E.; Lozada-Ramírez, J.D.; PérezPérez, M.C.I.; Vernon-Carter, E.J.; Welti-Chanes, J. Color and chemical stability of spray-dried blueberry extract using mesquite gum as wall material. J. Food Comp. Anal. 2011, 24, 889–894. [Google Scholar] [CrossRef]

- Ahmed, M.; Akter, M.S.; Lee, J.-C.; Eun, J.-B. Encapsulation by spray drying of bioactive components, physicochemical and morphological properties from purple sweet potato. LWT-Food Sci. Technol. 2010, 43, 1307–1312. [Google Scholar] [CrossRef]

- Weiss, V.; Okun, Z.; Shpigelman, A. Utilization of hydrocolloids for the stabilization of pigments from natural sources. COCIS 2023, 68, 101756. [Google Scholar] [CrossRef]

- Chen, C.; Chi, Y.-J.; Xu, W. Comparisons on the Functional Properties and Antioxidant Activity of Spray-Dried and Freeze-Dried Egg White Protein Hydrolysate. Food Bioprocess Technol. 2011, 5, 2342–2352. [Google Scholar] [CrossRef]

- Fernandes, L.P.; Candido, R.C.; Oliveira, W.P. Spray drying microencapsulation of Lippia sidoides extracts in carbohydrate blends. Food Bioprod. Process. 2012, 90, 425–432. [Google Scholar] [CrossRef]

- Dumitrașcu, L.; Stănciuc, N.; Aprodu, I. Encapsulation of Anthocyanins from Cornelian Cherry Fruits Using Heated or Non-Heated Soy Proteins. Foods 2021, 10, 1342. [Google Scholar] [CrossRef]

- Díaz, D.I.; Beristain, C.I.; Azuara, E.; Luna, G.; Jimenez, M. Effect of wall material on the antioxidant activity and physicochemical properties of Rubus fruticosus juice microcapsules. J. Microencapsul. 2015, 32, 247–254. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, P.; Wang, J.; Wu, Y.; Han, Y.; Zhou, J. Combining various wall materials for encapsulation of blueberry anthocyanin extracts: Optimization by artificial neural network and genetic algorithm and a comprehensive analysis of anthocyanin powder properties. Powder Technol. 2017, 311, 77–87. [Google Scholar] [CrossRef]

- Kaur, C.; Kapoor, H.C. Antioxidants in Fruits and Vegetables—The Millennium’s Health. Int. J. Food Sci. Technol. 2001, 36, 703–725. [Google Scholar] [CrossRef]

- Du, X.; Myracle, A.D. Development and evaluation of kefir products made with aronia or elderberry juice: Sensory and phytochemical characteristics. Int. Food Res. J. 2018, 25, 4. Available online: http://www.ifrj.upm.edu.my/25%20(04)%202018/(7).pdf (accessed on 22 September 2023).

- Barrett, A.J. The classes of proteolytic enzymes. In Plant Proteolytic Enzymes; Dalling, M.J., Ed.; CRC Press: Boca Raton, FL, USA, 1986; Volume 1, pp. 1–16. [Google Scholar]

- Kopjar, M.; Ćorković, I.; Buljeta, I.; Šimunović, J.; Pichler, A. Fortification of Pectin/Blackberry Hydrogels with Apple Fibers: Effect on Phenolics, Antioxidant Activity and Inhibition of α-Glucosidase. Antioxidants 2022, 11, 1459. [Google Scholar] [CrossRef] [PubMed]

- Barretto, F.J.d.F.P.; Clemente, H.A.; Santana, A.L.B.D.; Vasconcelo, M.A.d.S. Stability of Encapsulated and Non-Encapsulated Anthocyanin in Yogurt Produced with Natural Dye Obtained from Solanum melongena L. Bark. Rev. Bras. Frutic. 2020, 42, e137. [Google Scholar] [CrossRef]

- Esatbeyoglu, T.; Fischer, A.; Legler, A.D.S.; Oner, M.E.; Wolken, H.F.; Kopsel, M.; Ozogul, Y.; Ozyurt, G.; Biase, D.; Ozogul, F. Physical, chemical, and sensory properties of water kefir produced from Aronia melanocarpa juice and pomace. Food Chem. X 2023, 18, 100683. [Google Scholar] [CrossRef]

- Wu, X.; Beecher, G.R.; Holden, J.M.; Haytowitz, D.B.; Gebhardt, S.E.; Prior, R.L. Concentrations of Anthocyanins in Common Foods in the United States and Estimation of Normal Consumption. J. Agric. Food Chem. 2006, 54, 4069–4075. [Google Scholar] [CrossRef]

- Codex Alimentarius Commision, International Food Standards (2003). Standards For Fermented Milks CXS 243-2003, Food and Agriculture Organization of the United Nations, WHO. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B243-2003%252FCXS_243e.pdf (accessed on 22 September 2023).

- Goncu, B.; Celikel, A.; Guler-Akin, M.B.; Serdar Akin, M. Some properties of kefir enriched with apple and lemon fiber. Mljekarstvo 2017, 67, 208–216. [Google Scholar] [CrossRef]

- Aiello, F.; Restuccia, D.; Spizzirri, U.G.; Carullo, G.; Leporini, M.; Loizzo, M.R. Improving Kefir Bioactive Properties by Functional Enrichment with Plant and Agro-Food Waste Extracts. Fermentation 2020, 6, 83. [Google Scholar] [CrossRef]

- Bourrie, B.C.T.; Willing, B.P.; Cotter, P.D. The microbiota and health promoting characteristics of the fermented beverage kefir. Front. Microbiol. 2016, 7, 647. [Google Scholar] [CrossRef]

- Vieira, C.P.; Rosario, A.; Lelis, C.A.; Rekowsky, B.S.S.; Carvalho, A.P.A.; Rosario, D.K.A.; Elias, T.A.; Costa, M.P.; Foguel, D.; Conte-Junior, C.A. Bioactive Compounds from Kefir and Their Potential Benefits on Health: A Systematic Review and Meta-Analysis. Oxidative Med. Cell. Longev. 2021, 2021, 9081738. [Google Scholar] [CrossRef]

- Šeregelj, V.; Tumbas Šaponjac, V.; Lević, S.; Kalušević, A.; Ćetković, G.; Čanadanović-Brunet, J.; Vidaković, A. Application of encapsulated natural bioactive compounds from red pepper waste in yogurt. J. Microencapsul. 2019, 36, 704–714. [Google Scholar] [CrossRef] [PubMed]

- Rubio, F.T.V.; Haminiuk, C.W.I.; Santos, M.M.; Thomazini, M.; Moraes, I.C.F.; Martelli-Tosi, M.; Fávaro-Trindade, C.S. Development of Natural Pigments Microencapsulated in Waste Yeast Saccharomyces cerevisiae Using Spray Drying Technology and Their Application in Yogurt. Food Funct. 2021, 12, 8946–8959. [Google Scholar] [CrossRef] [PubMed]

- Pinto, K.R.D.; Tulini, F.L.; Guimarães, J.d.G.L.; Moraes, I.C.F.; Ditchfield, C.; Lima, C.G.d.; Silva, V.L.d.S.; Favaro-Trindade, C.S. Production and Evaluation of Yogurt Colored with Anthocyanin-Rich Pigment Prepared from Jabuticaba (Myrciaria cauliflora Mart.) Skin. Processes 2023, 11, 526. [Google Scholar] [CrossRef]

| Properties | Lentil Protein Isolate (LPI) | Encapsulated Blackberry Juice (EBJ) |

|---|---|---|

| Water activity (aw) | 0.09 ± 0.00 | 0.24 ± 0.00 |

| Moisture content (g/100 g) | 1.64 ± 0.00 | 2.17 ± 0.01 |

| Hygroscopic moisture (g/100 g) | 2.71 ± 0.01 | 2.98 ± 0.02 |

| Solubility (%) | 56.50 ± 0.26 | 29.30 ± 0.26 |

| Water-holding capacity (WHC) (g/g) | 1.72 ± 0.06 | 1.55 ± 0.03 |

| Oil-holding capacity (OHC) (g/g) | 1.48 ± 0.02 | 3.66 ± 0.36 |

| Bulk density (Db) (g/mL) | 0.91 ± 0.00 | 0.87 ± 0.00 |

| Tapped density (Dt) (g/mL) | 1.79 ± 0.00 | 1.10 ± 0.00 |

| Compressibility ratio (CR) | 49.16 ± 0.00 | 20.91 ± 0.00 |

| Hausner ratio (HR) | 1.97 ± 0.00 | 1.26 |

| Flowability | Very bad | Fair |

| Cohesiveness | High | Intermediate |

| L* | 17.90 ± 0.02 | 16.30 ± 0.04 |

| a* | 17.75 ± 0.02 | 35.80 ± 0.04 |

| b* | 54.05 ± 0.03 | 13.90 ± 0.03 |

| C* | 56.89 ± 0.02 | 38.40 ± 0.04 |

| Properties | Lentil Protein Isolate (LPI) | Encapsulated Blackberry Juice (EBJ) |

|---|---|---|

| Total polyphenol content (TPC) (mg GAE/100 g) | 124.08 ± 7.76 | 411.06 ± 9.87 |

| Total anthocyanin content (TAC) (mg CyGE/100 g) | nd | 323.81 ± 14.65 |

| EE TPC (%) | - | 89.68 ± 2.14 |

| EE TAC (%) | - | 91.12 ± 4.55 |

| DPPH (µmol TE/100 g) | 116.41 ± 3.68 | 1024.09 ± 14.11 |

| RP (µmol TE/100 g) | 75.99 ± 4.56 | 547.12 ± 17.22 |

| ABTS (µmol TE/100 g) | 214.03 ± 13.57 | 1452.71 ± 28.30 |

| Microbiological Parameter Log CFU/g | Lentil Protein Isolate (LPI) | Encapsulated Blackberry Juice (EBJ) |

|---|---|---|

| Aerobic mesophilic bacteria | 1.20 ± 0.54 | <1 |

| Yeast and mold | 1.40 ± 0.00 | <1 |

| Enterobacteriaceae | <1 | <1 |

| Clostridium perfringens | <1 | <1 |

| Kefir Sample | Parameter | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Control | L* | 97.20 ± 1.54 a | 98.20 ± 1.11 a | 95.14 ± 1.20 a | 96.20 ± 0.24 a | 97.10 ± 1.65 b |

| a* | −1.60 ± 0.20 a | −1.91 ± 0.01 b | −2.00 ± 0.01 b | −2.31 ± 0.00 c | −2.40 ± 0.01 c | |

| b* | 3.31 ± 0.04 a | 3.45 ± 0.01 a | 3.41 ± 0.0 a | 3.36 ± 0.00 a | 3.29 ± 0.04 a | |

| Cr* | 3.68 ± 0.25 a | 3.94 ± 0.02 b | 3.95 ± 0.01 b | 4.08 ± 0.00 b | 4.07 ± 0.05 b | |

| 1% | L* | 74.80 ± 1.31 a | 74.51 ± 1.49 a | 76.50 ± 1.27 a | 75.11 ± 1.14 a | 74.20 ± 1.61 a |

| a* | 10.72 ± 0.33 b | 9.85 ± 0.24 a | 11.31 ± 0.21 c | 10.62 ± 0.17 b | 11.11 ± 0.08 c | |

| b* | −4.51 ± 0.02 a | −4.42 ± 0.00 a | −4.91 ± 0.17 b | −4.42 ± 0.02 a | −4.64 ± 0.13 a | |

| Cr* | 11.61 ± 0.55 b | 10.80 ± 0.25 a | 12.33 ± 0.40 c | 11.50 ± 0.20 b | 12.04 ± 0.34 c | |

| 2.5% | L* | 62.53 ± 1.32 b | 59.11 ± 1.07 a | 62.50 ± 0.99 b | 62.52 ± 1.00 b | 60.31 ± 0.56 a,b |

| a* | 21.90 ± 1.60 a | 22.32 ± 2.04 a | 22.31 ± 0.74 a | 22.40 ± 1.08 a | 22.32 ± 0.27 a | |

| b* | −11.20 ± 0.63 a,b | −12.11 ± 1.65 c | −12.10 ± 0.00 c | −10.79 ± 0.19 a | −11.62 ± 0.68 b,c | |

| Cr* | 24.60 ± 2.25 a | 25.39 ± 3.70 a | 25.38 ± 0.75 a | 24.86 ± 1.30 a | 25.16 ± 1.00 a | |

| 5% | L* | 43.72 ± 1.84 b | 40.50 ± 0.53 a | 43.75 ± 0.00 b | 41.71 ± 1.51 a,b | 41.00 ± 0.02 a |

| a* | 33.86 ± 0.64 a | 34.11 ± 0.35 a | 33.89 ± 0.65 a | 33.25 ± 0.21 a | 33.41 ± 0.18 a | |

| b* | −11.52 ± 0.00 a | −11.51 ± 0.07 a | −11.42 ± 0.18 a | −11.44 ± 0.06 a | −10.99 ± 0.02 a | |

| Cr* | 35.77 ± 0.65 a | 34.55 ± 0.42 a | 35.77 ± 0.85 a | 35.16 ± 0.27 a | 35.17 ± 0.20 a | |

| 7.5% | L* | 34.30 ± 1.84 a | 36.21 ± 0.00 b | 37.92 ± 0.91 b | 33.45 ± 0.21 a | 33.72 ± 1.17 a |

| a* | 45.00 ± 0.01 b,c | 43.54 ± 1.11 a,b | 41.78 ± 0.97 a | 47.31 ± 1.61 c | 44.12 ± 0.40 b | |

| b* | −10.42 ± 0.65 a | −11.11 ± 0.07 a | −10.82 ± 1.96 a | −10.36 ± 0.75 a | −10.47 ± 0.07 a | |

| Cr* | 46.19 ± 0.66 b,c | 44.94 ± 1.19 a | 43.16 ± 2.02 a | 48.43 ± 2.40 b,c | 45.35 ± 0.05 a,b | |

| Kefir Sample | Parameters | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Control | Viscosity | 1.89 ± 0.01 a | 1.91 ± 0.04 a | 1.87 ± 0.00 a | 1.91 ± 0.52 a | 1.93 ± 0.11 a |

| Titrable acidity | 71.00 ± 1.5 c | 69.00 ± 0.56 c | 69.00 ± 0.00 c | 64.50 ± 0.56 b | 61.00 ± 0.00 a | |

| pH | 4.21 ± 0.02 a | 4.27 ± 0.00 a | 4.31 ± 0.56 a,b | 4.47 ± 0.07 b,c | 4.67 ± 0.05 c | |

| 1% | Viscosity | 1.91 ± 0.06 a | 2.04 ± 0.04 b | 2.03 ± 0.10 b | 2.07 ± 0.16 b,c | 2.17 ± 0.56 c |

| Titrable acidity | 71.00 ± 1.00 b | 70.00 ± 0.00 b | 69.00 ± 0.00 b | 69.00 ± 1.0 b | 64.00 ± 0.56 a | |

| pH | 4.12 ± 0.05 a | 4.17 ± 0.00 a | 4.23 ± 0.56 a | 4.27 ± 0.14 a | 4.21 ± 0.04 a | |

| 2.5% | Viscosity | 1.94 ± 0.00 a | 2.10 ± 0.24 b | 2.12 ± 0.17 b | 2.12 ± 0.56 b | 2.14 ± 0.41 b |

| Titrable acidity | 74.00 ± 2.00 a | 74.00 ± 1.00 a | 73.00 ± 0.00 a | 72.00 ± 1.00 a | 72.00 ± 0.00 a | |

| pH | 4.01 ± 0.03 a | 4.08 ± 0.07 a | 4.17 ± 0.01 a | 4.20 ± 0.00 a | 4.19 ± 0.34 a | |

| 5% | Viscosity | 1.95 ± 0.02 a | 2.15 ± 0.01 b | 2.21 ± 0.17 b | 2.23 ± 0.23 b | 2.23 ± 0.00 b |

| Titrable acidity | 81.00 ± 1.00 a | 82.00 ± 0.00 a | 82.00 ± 0.00 a | 83.00 ± 0.00 a | 82.00 ± 0.00 a | |

| pH | 3.88 ± 0.10 a | 3.79 ± 0.09 a | 3.81 ± 0.03 a | 3.84 ± 0.51 a | 3.82 ± 0.07 a | |

| 7.5% | Viscosity | 2.03 ± 0.19 a | 2.21 ± 0.11 b | 2.19 ± 0.25 b | 2.25 ± 0.41 b | 2.26 ± 0.09 b |

| Titrable acidity | 83.00 ± 0.50 b,c | 84.00 ± 2.00 c | 81.00 ± 0.00 b,c | 79.00 ± 0.00 b | 67.00 ± 1.00 a | |

| pH | 3.81 ± 0.00 a | 3.64 ± 0.52 a | 3.74 ± 0.14 a | 4.18 ± 0.21 b | 4.34 ± 0.05 b | |

| Kefir Sample | Parameter | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Control | TPC | nd | nd | nd | nd | nd |

| TAC | nd | nd | nd | nd | nd | |

| DPPH | 20.01 ± 0.06 b | 20.65 ± 1.02 b | 18.14 ± 0.26 a | 18.11 ± 1.35 a | 17.41 ± 0.23 a | |

| RP | nd | nd | nd | nd | nd | |

| ABTS | 44.11 ± 2.15 b | 45.18 ± 2.13 b | 41.56 ± 1.101 a | 40.35 ± 0.89 a | 40.15 ± 1.65 a | |

| 1% | TPC | 98.64 ± 0.78 a | 99.11 ± 2.14 a | 98.96 ± 3.58 a | 98.05 ± 2.14 a | 98.71 ± 3.44 a |

| TAC | 18.25 ± 0.63 a | 18.12 ± 2.26 a | 19.21 ± 1.14 b | 19.06 ± 2.17 a,b | 18.11 ± 1.09 a | |

| DPPH | 181.16 ± 9.81 a | 180.99 ± 10.12 a | 176.58 ± 13.69 a | 179.36 ± 9.11 a | 180.47 ± 21.07 a | |

| RP | 10.13 ± 0.51 a | 11.79 ± 0.65 a | 10.34 ± 0.74 a | 11.55 ± 0.98 a | 11.10 ± 0.36 a | |

| ABTS | 265.04 ± 13.44 c | 249.11 ± 7.29 b | 233.15 ± 10.41 a | 251.29 ± 17.21 b | 248.15 ± 16.54 b | |

| 2.5% | TPC | 126.42 ± 9.15 a,b | 129.87 ± 5.13 b | 125.30 ± 8.91 a,b | 125.52 ± 11.60 a,b | 123.10 ± 9.56 a |

| TAC | 21.62 ± 1.51 b | 21.98 ± 3.22 b | 20.87 ± 2.09 a | 20.91 ± 2.86 a,b | 20.44 ± 1.13 a | |

| DPPH | 205.23 ± 14.63 a | 211.58 ± 10.55 a | 209.78 ± 13.17 a | 206.34 ± 9.15 a | 204.19 ± 5.68 a | |

| RP | 12.78 ± 0.98 b | 13.71 ± 1.63 c | 11.25 ± 0.44 a | 13.41 ± 0.97 b,c | 13.55 ± 1.11 c | |

| ABTS | 287.10 ± 22.65 a,b | 292.51 ± 13.74 b | 276.77 ± 13.81 a | 296.86 ± 15.19 b | 289.16 ± 5.00 a,b | |

| 5% | TPC | 163.71 ± 9.08 a | 160.12 ± 2.50 a | 161.41 ± 3.82 a | 160.99 ± 7.85 a | 159.84 ± 5.06 a |

| TAC | 38.40 ± 1.25 b | 34.13 ± 2.81 a | 34.54 ± 3.96 a | 33.41 ± 2.21 a | 34.07 ± 4.20 a | |

| DPPH | 256.08 ± 5.01 a | 249.66 ± 11.40 a | 247.35 ± 6.39 a | 243.17 ± 16.58 a | 244.96 ± 7.89 a | |

| RP | 17.99 ± 3.47 d | 15.81 ± 2.07 b,c | 16.33 ± 2.50 c | 15.36 ± 1.18 b | 14.18 ± 2.00 a | |

| ABTS | 328.10 ± 15.06 a | 324.45 ± 11.43 a | 313.06 ± 12.98 a | 310.55 ± 17.62 a | 312.69 ± 5.14 a | |

| 7.5% | TPC | 181.12 ± 9.10 a | 179.57 ± 8.97 a | 175.13 ± 12.01 a | 174.41 ± 6.33 a | 172.08 ± 6.25 a |

| TAC | 44.56 ± 2.96 b | 43.91 ± 0.81 a,b | 44.63 ± 1.17 b | 42.09 ± 2.74 a | 43.36 ± 1.25 a,b | |

| DPPH | 221.41 ± 11.52 b | 215.31 ± 14.52 a,b | 208.12 ± 17.65 a | 208.41 ± 13.58 a | 205.10 ± 6.28 a | |

| RP | 17.97 ± 1.36 d | 16.95 ± 2.83 c | 14.25 ± 1.08 a | 15.35 ± 2.97 b | 14.51 ± 1.88 a | |

| ABTS | 301.20 ± 28.15 b | 295.42 ± 15.14 b | 276.77 ± 13.81 a | 280.77 ± 19.09 a | 280.10 ± 14.53 a | |

| Kefir Sample | Parameter | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Control | LAB 1 | 8.02 ± 0.33 c | 8.10 ± 0.74 c | 7.80 ± 0.33 b | 7.40 ± 0.64 b | 6.90 ± 0.00 a |

| LAB 2 | 7.10 ± 0.00 d | 6.90 ± 0.56 c | 6.80 ± 0.00 c | 6.50 ± 0.56 a | 6.10 ± 0.33 a | |

| AMB | 7.20 ± 0.64 d | 7.00 ± 0.00 c | 7.00 ± 0.33 c | 6.70 ± 0.37 b | 6.50 ± 0.00 a | |

| Yeast and mold | 4.80 ± 0.37 a | 4.90 ± 0.33 a | 4.90 ± 0.56 a | 5.30 ± 0.00 b | 5.70 ± 0.74 c | |

| L. monocytogenes | nd | |||||

| Salmonella spp. | ||||||

| S. aureus | <1 | |||||

| E. coli | ||||||

| Enterobacteriaceae | ||||||

| Cl. perfringens | ||||||

| 1% | LAB 1 | 8.20 ± 0.00 d | 8.00 ± 0.00 c,d | 7.70 ± 0.74 c | 7.10 ± 0.33 b | 6.80 ± 0.27 a |

| LAB 2 | 7.10 ± 0.33 c | 6.80 ± 0.33 b | 6.60 ± 0.27 b | 6.20 ± 0.74 a | 5.90 ± 0.00 a | |

| AMB | 7.50 ± 0.56 c | 7.50 ± 0.74 c | 7.20 ± 0.00 b,c | 6.90 ± 0.64 a,b | 6.60 ± 0.33 a | |

| Yeast and mold | 5.10 ± 0.00 a | 5.20 ± 0.64 a | 5.50 ± 0.33 b | 5.70 ± 0.37 b | 6.10 ± 0.56 c | |

| L. monocytogenes | nd | |||||

| Salmonella spp. | ||||||

| S. aureus | <1 | |||||

| E. coli | ||||||

| Enterobacteriaceae | ||||||

| Cl. perfringens | ||||||

| 2.5% | LAB 1 | 8.20 ± 0.00 c | 8.10 ± 0.74 c | 7.80 ± 0.33 b,c | 7.40 ± 0.00 a,b | 7.00 ± 0.64 a |

| LAB 2 | 7.00 ± 0.00 c | 6.80 ± 0.33 b,c | 6.50 ± 1.32 b | 6.00 ± 0.00 a | 5.70 ± 0.33 a | |

| AMB | 7.70 ± 0.64 c | 7.60 ± 0.00 c | 7.10 ± 0.37 b | 6.80 ± 0.32 a,b | 6.50 ± 0.33 a | |

| Yeast and mold | 5.20 ± 0.56 a | 5.30 ± 0.74 a | 5.70 ± 0.64 c | 6.00 ± 0.74 c,d | 6.30 ± 0.00 d | |

| L. monocytogenes | nd | |||||

| Salmonella spp. | ||||||

| S. aureus | <1 | |||||

| E. coli | ||||||

| Enterobacteriaceae | ||||||

| Cl. perfringens | ||||||

| 5% | LAB 1 | 8.10 ± 0.33 d | 7.60 ± 0.27 c | 7.10 ± 0.00 b | 6.70 ± 0.00 a | 6.50 ± 0.33 a |

| LAB 2 | 7.00 ± 0.33 c | 6.80 ± 0.00 c | 6.40 ± 0.37 b | 6.00 ± 0.74 a | 5.80 ± 0.37 a | |

| AMB | 7.90 ± 0.0 d | 7.40 ± 0.64 c | 6.90 ± 0.33 b | 6.70 ± 0.64 a,b | 6.50 ± 0.74 a | |

| Yeast and mold | 5.50 ± 0.00 a | 5.80 ± 0.74 a,b | 6.10 ± 0.00 b | 6.10 ± 0.33 b | 6.50 ± 1.32 c | |

| L. monocytogenes | nd | |||||

| Salmonella spp. | ||||||

| S. aureus | <1 | |||||

| E. coli | ||||||

| Enterobacteriaceae | ||||||

| Cl. perfringens | ||||||

| 7.5% | LAB 1 | 8.10 ± 0.33 d | 7.40 ± 0.00 c | 7.10 ± 0.64 c | 6.60 ± 0.00 b | 6.20 ± 0.33 a |

| LAB 2 | 7.00 ± 0.00 d | 6.50 ± 0.56 c | 6.20 ± 0.00 b,c | 6.00 ± 0.74 a,b | 5.80 ± 1.32 a | |

| AMB | 8.10 ± 0.37 e | 7.60 ± 0.37 d | 7.10 ± 0.00 c | 6.50 ± 0.74 b | 6.10 ± 0.00 a | |

| Yeast and mold | 5.90 ± 0.00 a | 6.30 ± 0.74 b | 6.60 ± 0.33 b,c | 6.80 ± 0.33 c | 6.90 ± 0.64 c | |

| L. monocytogenes | nd | |||||

| Salmonella spp. | ||||||

| S. aureus | <1 | |||||

| E. coli | ||||||

| Enterobacteriaceae | ||||||

| Cl. perfringens | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Travičić, V.; Šovljanski, O.; Tomić, A.; Perović, M.; Milošević, M.; Ćetković, N.; Antov, M. Augmenting Functional and Sensorial Quality Attributes of Kefir through Fortification with Encapsulated Blackberry Juice. Foods 2023, 12, 4163. https://doi.org/10.3390/foods12224163

Travičić V, Šovljanski O, Tomić A, Perović M, Milošević M, Ćetković N, Antov M. Augmenting Functional and Sensorial Quality Attributes of Kefir through Fortification with Encapsulated Blackberry Juice. Foods. 2023; 12(22):4163. https://doi.org/10.3390/foods12224163

Chicago/Turabian StyleTravičić, Vanja, Olja Šovljanski, Ana Tomić, Milica Perović, Maja Milošević, Nenad Ćetković, and Mirjana Antov. 2023. "Augmenting Functional and Sensorial Quality Attributes of Kefir through Fortification with Encapsulated Blackberry Juice" Foods 12, no. 22: 4163. https://doi.org/10.3390/foods12224163

APA StyleTravičić, V., Šovljanski, O., Tomić, A., Perović, M., Milošević, M., Ćetković, N., & Antov, M. (2023). Augmenting Functional and Sensorial Quality Attributes of Kefir through Fortification with Encapsulated Blackberry Juice. Foods, 12(22), 4163. https://doi.org/10.3390/foods12224163