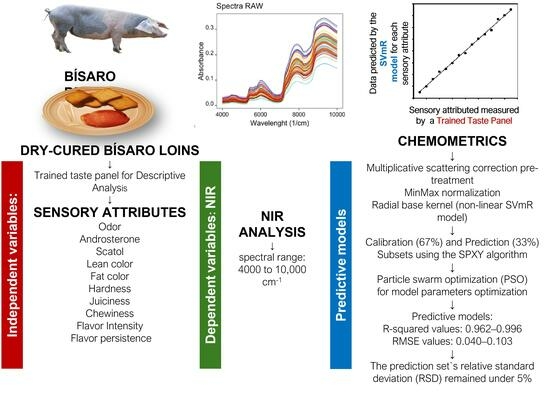

Can Near-Infrared Spectroscopy Replace a Panel of Tasters in Sensory Analysis of Dry-Cured Bísaro Loin?

Abstract

:1. Introduction

2. Materials and Methods

2.1. Animal Management

2.2. Sample Manufacturing

2.3. Sensory Analysis

2.4. Sample Set and NIRS Analysis

2.5. Data Analysis

| Pre-Treatment | Normalization * | SVR Type ** | Kernel ** | PSO Parameters ** |

|---|---|---|---|---|

| MSC | Mean center | ε-SVR | Linear | C |

| SNV | Autoscale | ν-SVR | Polynomial | ε (for ε-SVR) |

| 1st d | Pareto | Radial Base | ν (ν-SVR) | |

| 2nd d | Poison | Sigmoid | γ (except for linear kernel) | |

| MinMax [−1 + 1] | Intercept (for polynomial and sigmoid kernel) | |||

| Degree (2 to 5 for polynomial kernel) |

3. Results and Discussion

3.1. Sensory Analysis

3.1.1. Sensory Attributes

3.1.2. Sensory Data

3.2. NIR Analysis

3.2.1. NIR Spectra

3.2.2. NIR Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- SPREGA. Suínos. Sociedade Portuguesa de Recursos Genéticos Animais. Santarém. 2023. Available online: http://www.sprega.com.pt/conteudo.php?idesp=su%EDnos (accessed on 3 August 2022).

- Araújo, J.; Cerqueira, J.; Pires, P.; Amorim, I.; Durão, J.; Cadavez, V.; Santos Silva, J.; Dominguez, R.; Bermúdez, R.; Lorenzo, J. Growth performance of Bísaro pigs in hoop barn and confinement housing systems. Arch. Zootec. Proc. IX Simp. Int. Sobre El Cerdo Mediterrâneo 2018, 1, 31–35. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=6537176 (accessed on 5 August 2022).

- ANCSUB. Associação Nacional de Criadores de Suínos da Raça Bísara. Raça Bísara. 2023. Available online: http://www.porcobisaro.net/dados/racabisara.php (accessed on 2 July 2022).

- Barbosa, N. Caracterização Físico-Química de Presuntos de Porcos da Raça Bísara com Diferentes Tempos de Cura. Master’s Thesis, Departamento de Tecnologias da Ciência Animal, Escola Superior Agrária do Instituto Politécnico de Bragança, Bragança, Portugal, 2017; pp. 1–87. [Google Scholar]

- Lebret, B.; Candek-Potokar, M. Review: Pork quality attributes from farm to fork. Part II. Processed pork products. Int. J. Anim. Biosci. 2022, 16, 100–383. [Google Scholar] [CrossRef]

- Ramarathnam, N.; Rubin, L.J. The Flavor of Cured Meat; Shahidi, F., Ed.; Flavor of Meat and Meat Products; Blackie Academic Professional: London, UK, 1994; pp. 174–198. [Google Scholar]

- Muriel, E.; Antequera, T.; Petrón, M.J.; Andrés, A.I.; Ruiz, J. Volatile compounds in Iberian dry-cured loin. Meat Sci. 2004, 68, 391–400. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.; Oliveira, M.; Azevedo, J. Efeito do sexo no perfil em ácidos gordos do músculo bíceps femoris de suínos da raça Bísara. In VII Congresso Mundial do Presunto; Instituto Superior de Agronomia, Universidade de Lisboa: Ourique, Portual, 2013. [Google Scholar]

- Schouteten, J.J.; De Steur, H.; De Pelsmaeker, S.; Lagast, S.; Juvinal, J.G.; De Bourdeaudhhuij, I.; Gellynck, X. Emotional and sensory profiling of insect-, plant- and meat-based burgers under blind, expected and informed conditions. Food Qual. Prefer. 2016, 52, 27–31. [Google Scholar] [CrossRef]

- Teixeira, A.; Rodrigues, S. Consumer perceptions towards healthier meat products. Curr. Opin. Food Sci. 2021, 38, 147–154. [Google Scholar] [CrossRef]

- Prieto, N.; Pawluczyk, O.; Dugan, M.E.R.; Aalhus, J.L. A review of the principles and applications of near-infrared spectroscopy to characterize meat, fat, and meat products. Appl. Spectrosc. 2017, 71, 1403–1426. [Google Scholar] [CrossRef]

- Caballero, D.; Rodríguez, P.G.; Caro, A.; del Mar’Avila, M.; Torres, J.P.; Antequera, T.; Perez-Palacios, T. An experimental protocol to determine quality parameters of dry-cured loins using low-field magnetic resonance imaging. J. Food Eng. 2022, 313, 110–750. [Google Scholar] [CrossRef]

- Cafferky, J.; Sweeney, T.; Allena, P.; Sahara, A.; Downeya, G.; Cromiec, A.R.; Hamilla, R.M. Investigating the use of visible and near infrared spectroscopy to predict sensory and texture attributes of beef M. longissimus thoracis et lumborum. Meat Sci. 2020, 159, 107915. [Google Scholar] [CrossRef]

- Saldaña, E.; Merlo, T.C.; Patinho, I.; Rios-Mera, J.D.; Contreras-Castillo, C.J.; Selani, M.M. Use of sensory science for the development of healthier processed meat products: A critical opinion. Curr. Opin. Food Sci. 2021, 40, 13–19. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Delgado-Pando, G. Sensory analysis and consumer research in new meat products development. Foods 2021, 10, 429. [Google Scholar] [CrossRef]

- Hernández-Jiménez, M.; Hernández-Ramos, P.; Martínez-Martína, I.; Vivar-Quintana, A.M.; González-Martín, I.; Revilla, I. Comparison of artificial neural networks and multiple regression tools applied to near infrared spectroscopy for predicting sensory properties of products from quality labels. Microchem. J. 2020, 159, 105459. [Google Scholar] [CrossRef]

- Vestergaard, C.; Erbou, S.G.; Thauland, T.; Adler-Nissen, J.; Berg, P. Salt distribution in dry-cured ham measured by computed tomography and image analysis. Meat Sci. 2005, 69, 9–15. [Google Scholar] [CrossRef] [PubMed]

- González-Mohino, A.; Antequera, T.; Ventanas, S.; Caballero, D.; Mir-Bel, J.; Pérez-Palacios, T. Near-infrared spectroscopy-based analysis to study sensory parameters on pork loins as affected by cooking methods and conditions. Sci. Food Agric. 2018, 98, 4227–4236. [Google Scholar] [CrossRef] [PubMed]

- Perez-Palacios, T.; Caballero, D.; González-Mohíno, A.; Mir-Bel, J.; Antequera, T. Near infrared reflectance spectroscopy to analyse texture related characteristics of sous vide pork loin. J. Food Eng. 2019, 263, 417–423. [Google Scholar] [CrossRef]

- Fan, Y.; Liao, Y.; Cheng, F. Predicting of intramuscular fat content in pork using near infrared spectroscopy and multivariate analysis. Int. J. Food Prop. 2018, 21, 1180–1189. [Google Scholar] [CrossRef]

- Ortiz, A.; Parrini, S.; Tejerina, D.; Pinto de Araújo, J.P.; Čandek-Potokar, M.; Crovetti, A.; Bozzi, R. Potential use of near-infrared spectroscopy to predict fatty acid profile of meat from different european autochthonous pig breeds. Appl. Sci. 2020, 10, 5801. [Google Scholar] [CrossRef]

- Vasconcelos, L.; Dias, L.G.; Leite, A.; Ferreira, I.; Pereira, E.; Silva, S.; Rodrigues, S.; Teixeira, A. SVM Regression to Assess Meat Characteristics of Bísaro Pig Loins Using NIRS Methodology. Foods 2023, 12, 470. [Google Scholar] [CrossRef]

- Savoia, S.; Albera, A.; Brugiapaglia, A.; Di Stasio, L.; Ferragina, A.; Cecchinato, A.; Bittante, G. Prediction of meat quality traits in the abattoir using portable and hand-held near-infrared spectrometers. Meat Sci. 2020, 161, 108017. [Google Scholar] [CrossRef]

- Wang, W.; Peng, Y.; Sun, H.; Zheng, X.; Wei, W. Real-time inspection of pork quality attributes using dual-band spectroscopy. J. Food Eng. 2018, 237, 103–109. [Google Scholar] [CrossRef]

- Weng, S.; Guo, B.; Tang, P.; Yin, X.; Pan, F.; Zhao, J.; Zhang, D. Rapid detection of adulteration of minced beef using Vis/NIR reflectance spectroscopy with multivariate methods. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 230, 118005. [Google Scholar] [CrossRef]

- Leite, A.; Vasconcelos, L.; Ferreira, I.; Domínguez, R.; Pereira, E.; Rodrigues, S.; Lorenzo, J.M.; Teixeira, A. Effect of the inclusion of olive cake in the diet on the physicochemical characteristics of dry-cured loin and dry-cured “cachaço” of Bísaro pig. Appl. Sci. 2023, 13, 1439. [Google Scholar] [CrossRef]

- Fernandez-Barroso, M.A.; Parrini, S.; Munoz, M.; Palma-Granados, P.; Matos, G.; Ramírez, L.; Crovetti, A.; García-Casco, J.M.; Bozzi, R. Use of NIRS for the assessment of meat quality traits in open-air free-range Iberian pigs. J. Food Compost. Anal. 2021, 102, 104018. [Google Scholar] [CrossRef]

- Cáceres-Nevado, J.M.; Garrido-Varo, A.; De Pedro-Sanz, E.; Pérez-Marín, D.C. Fourier transform near-infrared spectroscopy coupled to a long fibre optic head for the quality control of IBERIAN pork loins: Intact versus minced. Meat Sci. 2019, 153, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.N.; Hossain, M.N.; Shoshe, N.Z.; Toma, S.A.; Belal, S.A.; Akanda, M.R.; Zaman, M.A.; Hossain, F.M.A.; Maburutse, B.E. Impact of near infrared (NIR) spectroscopy and hyperspectral (HS) imaging system to predict physicochemical composition and quality attributes of meat: A review. J. Food Agric. Environ. 2021, 2, 55–65. [Google Scholar] [CrossRef]

- Aouadi, B.; Zaukuu, J.L.Z.; Vitalis, F.; Bodor, Z.; Feher, O.; Gillay, Z.; Bazar, G.; Kovacs, Z. Historical evolution and food control achievements of near infrared spectroscopy, electronic nose, and electronic tongue—Critical overview. Sensors 2020, 20, 5479. [Google Scholar] [CrossRef]

- Àlvarez-Rodríguez, J.; Teixeira, A. Slaughter weight rather than sex affects carcass cuts and tissue composition of Bísaro pigs. Meat Sci. 2019, 154, 54–60. [Google Scholar] [CrossRef]

- Council Regulation (EC) No. 1099/2009 on the Protection of Animals at the Time of Killing. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02009R1099-20180518 (accessed on 10 April 2022).

- UNE-EN ISO 8586:2014; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2014.

- UNE-EN ISO 8589:2010/A1:2014; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2014.

- UNE-EN ISO 6658:2005; Sensory Analysis—Methodology—General Guidance. International Organization for Standardization: Geneva, Switzerland, 2005.

- Fearn, T.; Riccioli, C.; Garrido-Varo, A.; Guerrero-Ginel, J.E. On the geometry of SNV and MSC. Chemom. Intell. Lab. Syst. 2009, 96, 22–26. [Google Scholar] [CrossRef]

- Galvao, R.; Araujo, M.; Jose, G.; Pontes, M.; Silva, E.; Saldanha, T. A method for calibration and validation subset partitioning. Talanta 2005, 67, 736–740. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Prentice Hall: Hoboken, NJ, USA, 2008; ISBN 978-0-13147-139-9. [Google Scholar]

- Marini, F.; Walczak, B. Particle swarm optimization (PSO). A tutorial. Chemom. Intell. Lab. Syst. 2015, 149, 153–165. [Google Scholar] [CrossRef]

- Bona, E.; Março, P.H.; Valderrama, P. Chemometrics applied to food control. In Food Control and Biosecurity, 1st ed.; Holban, A.M., Grumezescu, A.M., Eds.; Academic Press: Cambridge, MA, USA, 2018; Volume 16, pp. 105–133. [Google Scholar] [CrossRef]

- Chang, C.C.; Lin, C.J. LIBSVM: A library for support vector machines. ACM Trans. Intell. Syst. Technol. 2011, 2, 1–27. [Google Scholar] [CrossRef]

- Van den Berg, R.A.; Hoefsloot, H.C.; Westerhuis, J.A.; Smilde, A.K.; Van der Werf, M.J. Centering, scaling, and transformations: Improving the biological information content of metabolomics data. BMC Genom. 2006, 7, 142. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Purriños, L.; Pérez-Santaescolástica, C.; Pateiro, M.; Barba, F.J.; Tomasevic, I.; Campagnol, P.C.B.; Lorenzo, J.M. Characterization of volatile compounds of dry-cured meat products using HS-SPME-GC/MS technique. Food Anal. Methods 2019, 12, 1263–1284. [Google Scholar] [CrossRef]

- Nilsen, A.; Rødbotten, M.; Prusa, K.; Fedler, C. Sensory analyses-general considerations. In Handbook of Fermented Meat and Poultry, 2nd ed.; Toldrá, F., Hui, Y.H., Astiasrán, I., Sebranek, J.G., Talon, R., Eds.; Wiley Blackwell: Hoboken, NJ, USA, 2005; pp. 189–194. [Google Scholar] [CrossRef]

- Leite, A.; Vasconcelos, L.; Ferreira, I.; Domínguez, R.; Pateiro, M.; Rodrigues, S.; Pereira, E.; Campagnol, P.B.C.; Pérez-Alvarez, J.A.; Lorenzo, J.M.; et al. Did the Addition of Olive Cakes Obtained by Different Methods of Oil Extraction in the Finishing Diet of Bísaro Pigs Affect the Volatile Compounds and Sensory Characteristics of Dry-Cured Loin and “Cachaço”? Foods 2023, 12, 249. [Google Scholar] [CrossRef] [PubMed]

- Válková, V.; Saláková, A.; Buchtová, H.; Tremlová, B. Chemical, instrumental and sensory characteristics of cooked pork ham. Meat Sci. 2007, 77, 608–615. [Google Scholar] [CrossRef]

- Martins, J.; Neves, J.; Freitas, A.; Tirapicos, J. Effect of long-term betaine supplementation on chemical and physical characteristics of three muscles from the Alentejano pig. J. Sci. Food Agric. 2012, 92, 2122–2127. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Lonergan, S.M.; Yu, C. Rapid determination of pork sensory quality using Raman spectroscopy. Meat Sci. 2012, 91, 232–239. [Google Scholar] [CrossRef]

- Revilla, I.; Vivar-Quintana, A.M.; González-Martín, M.I.; Hernández-Jiménez, M.; Martínez-Martín, I.; Hernández-Ramos, P. NIR spectroscopy for discriminating and predicting the sensory profile of dry-cured beef “Cecina”. Sensors 2020, 20, 6892. [Google Scholar] [CrossRef]

- Ruivo, L. Produção de Suínos em Regime Intensivo e Gestão Dos seus Efluentes. Master’s Dissertation, Faculdade de Medicina Veterinária da Universidade de Lisboa, Lisboa, Portugal, 2017; pp. 39–97. [Google Scholar]

- Domínguez, R.; Pateiro, M.; Sosa-Morales, M.E.; Reyes, J.F.; Pazos, A.; Nieto, G.; Munekata, P.E.S.; Lorenzo, J.M. Dry-cured loin. In Production of Traditional Mediterranean Meat Products; Lorenzo, J.M., Domínguez, R., Pateiro, M., Munekata, P.E.S., Eds.; Methods and Protocols in Food Science; Humana: New York, NY, USA, 2022; pp. 79–85. ISBN 978-1-0716-2102-8. [Google Scholar]

- Feiner, G. Cured air-dried meat products. In Meat Products Handbook; Feiner, G., Ed.; Woodhead Publishing: Cambridge, UK, 2006; pp. 417–441. ISBN 978-1-84569-050-2. [Google Scholar]

- Seong, P.N.; Park, K.M.; Kang, G.H.; Cho, S.H.; Park, B.Y.; Ba, H.V. The Impact of Ripening Time on Technological Quality Traits, Chemical Change and Sensory Characteristics of Dry-cured Loin. Asian Australas. J. Anim. Sci. 2015, 28, 677–685. [Google Scholar] [CrossRef]

- Goulart, J. Avaliação Nutricional e Organolética de Carne Proveniente de Suínos Sujeitos a Diferentes Dietas: Resultados Preliminares. Master’s Dissertation, Departamento de Tecnologia e Segurança Alimentar, Faculdade de Ciências e Tecnologias da Universidade Nova de LISBOA, Lisboa, Portugal, 2013; pp. 20–81. [Google Scholar]

- Lebret, B.; Faure, J. La viande et les produits du porc: Comment satisfaire des attentes qualitatives variées. INRA Prod. Anim. 2015, 28, 111–114. [Google Scholar] [CrossRef]

- Squires, E.; Bonneau, M. Boar taint: Biological causes and practical means to alleviate it. In Encyclopedia of Meat Sciences, 2nd ed.; Dikeman, M., Devine, C., Eds.; Academic Press: Cambridge, MA, USA, 2014; pp. 97–103. [Google Scholar]

- Ruiz, J.; Ventanas, J.; Cava, R.; Timon, M.L.; Garcia, C. Sensory characteristics of Iberian ham: Influence of processing time and slice location. Food Res. Int. 1998, 31, 53–58. [Google Scholar] [CrossRef]

- Flores, M. Understanding the implications of current health trends on the aroma of wet and dry cured meat products. Review. Meat Sci. 2018, 144, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Raimundo, A. Análise das categorias da qualidade da carne suína num matadouro. Rev. Das Ciências Agrárias 2017, 40, 365–377. [Google Scholar] [CrossRef]

- Totaro, M.P.; Squeo, G.; De Angelis, D.; Pasqualone, A.; Caponio, F.; Summo, C. Application of NIR spectroscopy coupled with DD-SIMCA class modelling for the authentication of pork meat. J. Food Compost. Anal. 2023, 118, 105–211. [Google Scholar] [CrossRef]

- Varrà, M.O.; Fasolato, L.; Serva, L.; Ghidini, S.; Novelli, E.; Zanardi, E. Use of near infrared spectroscopy coupled with chemometrics for fast detection of irradiated dry fermented sausages. Food Control 2020, 110, 107009. [Google Scholar] [CrossRef]

- Bona, E.; Marquetti, I.; Link, J.V.; Makimori, G.Y.F.; da Costa Arca, V.; Guimarães Lemes, A.L.; Ferreira, J.M.G.; dos Santos Scholz, M.B.; Valderrama, P.; Poppi, R.J. Support vector machines in tandem with infrared spectroscopy for geographical classification of green arabica coffee. LWT 2017, 76, 330–336. [Google Scholar] [CrossRef]

- Sanchez, J.L.; Pereira, S.B.G.; de Lima, P.C.; Possebon, G.; Tanamati, A.; Poppi, R.J.; Tanamati, A.A.C.; Bona, E. Mid-infrared spectroscopy and support vector machines applied to control the hydrogenation process of soybean oil. Eur. Food Res. Technol. 2017, 243, 1447–1457. [Google Scholar] [CrossRef]

- Olivieri, A.C. Introduction to Multivariate Calibration; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 1–239. ISBN 978-3-319-97096-7. [Google Scholar] [CrossRef]

- Hernández-Ramos, P.; Vivar-Quintana, A.M.; Revilla, I.; González-Martín, M.I.; Hernández-Jiménez, M.; Martínez-Martín, I. Prediction of Sensory Parameters of Cured Ham: A Study of the Viability of the Use of NIR Spectroscopy and Artificial Neural Networks. Sensors 2020, 20, 5624. [Google Scholar] [CrossRef]

- Ripoll, G.; Albertí, P.; Panea, B.; Olleta, J.L.; Sañudo, C. Near-infrared reflectance spectroscopy for predicting chemical, instrumental and sensory quality of beef. Meat Sci. 2008, 80, 697–702. [Google Scholar] [CrossRef]

- Prieto, N.; Ross, D.W.; Navajas, E.A.; Nute, G.R.; Richardson, R.I.; Hyslop, J.J.; Roehe, R. On-line application of visible and near infrared reflectance spectroscopy to predict chemical-physical and sensory characteristics of beef quality. Meat Sci. 2009, 83, 96–103. [Google Scholar] [CrossRef]

- Rødbotten, R.; Nilsen, B.N.; Hildrum, K.I. Prediction of beef quality attributes from early post mortem near infrared reflectance spectra. Food Chem. 2000, 69, 427–436. [Google Scholar] [CrossRef]

| Attributes | Definition | Min | Max | Mean (±Sd) |

|---|---|---|---|---|

| Odor | The presence of a typical odor of a dry-cured product [16] | 5.13 | 6.78 | 5.92 (±0.38) |

| Andros | The presence of the metabolites of testosterone [45] | 1.11 | 2.38 | 1.50 (±0.28) |

| Scatol | The presence of organic compounds that contribute to a fecal odor [45] | 1.00 | 1.78 | 1.24 (±0.19) |

| Lean color | The color of the part of the muscle sample [45] | 2.88 | 6.11 | 4.05 (±0.73) |

| Fat color | The color intensity and brightness of the fat [45] | 1.56 | 4.89 | 3.11 (±0.85) |

| Hardness | The force necessary to penetrate the meat with incisors [16] | 2.44 | 6.56 | 3.90 (±1.23) |

| Juiciness | The amount of juice given off by the sample when chewed [16] | 3.44 | 6.11 | 5.10 (±0.64) |

| Chewiness | The number of times the sample must be chewed before it can be swallowed [16] | 2.13 | 5.44 | 3.62 (±0.85) |

| Flavor intensity | The intensity of the overall flavor of the samples [16] | 5.11 | 6.44 | 5.89 (±0.33) |

| Flavor persistence | The persistence of the overall flavor of the mouthfeel [16] | 4.56 | 6.33 | 5.67 (±0.42) |

| Calibration * | Prediction * | |||||||

|---|---|---|---|---|---|---|---|---|

| Attribute | C | ε | γ | RMSE | R2 | RMSE | R2 | RSD (%) |

| Odor | 23.43 | 0.0161 | 0.0227 | 0.0155 | 0.9995 | 0.0549 | 0.9888 | 0.98 |

| Andros | 18.11 | 0.0010 | 0.0258 | 0.0011 | 1.0000 | 0.0400 | 0.9892 | 2.87 |

| Scatol | 87.79 | 0.0051 | 0.0221 | 0.0051 | 0.9998 | 0.0548 | 0.9616 | 4.47 |

| Lean color | 39.03 | 0.0074 | 0.0151 | 0.0072 | 0.9998 | 0.0507 | 0.9853 | 1.85 |

| Fat color | 100.0 | 0.0010 | 0.0446 | 0.0010 | 1.0000 | 0.0685 | 0.9878 | 2.26 |

| Hardness | 100.0 | 0.0010 | 0.0257 | 0.0011 | 1.0000 | 0.0403 | 0.9955 | 1.03 |

| Juiciness | 34.28 | 0.0522 | 0.0155 | 0.0499 | 0.9966 | 0.1031 | 0.9705 | 2.65 |

| Chewiness | 40.46 | 0.0395 | 0.0090 | 0.0374 | 0.9966 | 0.0674 | 0.9800 | 1.81 |

| Flavor intensity | 53.00 | 0.0252 | 0.0135 | 0.0240 | 0.9974 | 0.0554 | 0.9876 | 0.98 |

| Flavor persistence | 51.00 | 0.0010 | 0.0124 | 0.0011 | 1.0000 | 0.0417 | 0.9907 | 0.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasconcelos, L.; Dias, L.G.; Leite, A.; Ferreira, I.; Pereira, E.; Bona, E.; Mateo, J.; Rodrigues, S.; Teixeira, A. Can Near-Infrared Spectroscopy Replace a Panel of Tasters in Sensory Analysis of Dry-Cured Bísaro Loin? Foods 2023, 12, 4335. https://doi.org/10.3390/foods12234335

Vasconcelos L, Dias LG, Leite A, Ferreira I, Pereira E, Bona E, Mateo J, Rodrigues S, Teixeira A. Can Near-Infrared Spectroscopy Replace a Panel of Tasters in Sensory Analysis of Dry-Cured Bísaro Loin? Foods. 2023; 12(23):4335. https://doi.org/10.3390/foods12234335

Chicago/Turabian StyleVasconcelos, Lia, Luís G. Dias, Ana Leite, Iasmin Ferreira, Etelvina Pereira, Evandro Bona, Javier Mateo, Sandra Rodrigues, and Alfredo Teixeira. 2023. "Can Near-Infrared Spectroscopy Replace a Panel of Tasters in Sensory Analysis of Dry-Cured Bísaro Loin?" Foods 12, no. 23: 4335. https://doi.org/10.3390/foods12234335