Quality Characteristics of Raspberry Fruits from Dormancy Plants and Their Feasibility as Food Ingredients

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sampling

2.3. Raspberry Fruits Drying

2.4. Raspberry Fruits Characterisation

2.4.1. Physicochemical Parameters Determination

2.4.2. Chromatic Properties

2.4.3. Total Phenolic Content

2.4.4. Phenolic Profile Analysis

2.4.5. Antioxidant Activity

2.5. Muffin Preparation and Characterisation

2.5.1. Preparation of the Muffin Formulations

2.5.2. Characterisation of the Muffins

2.5.3. Sensory Analysis of the Muffins

2.6. Statistical Analysis

3. Results and Discussion

3.1. Fresh Raspberry Fruits Physicochemical Characterisation

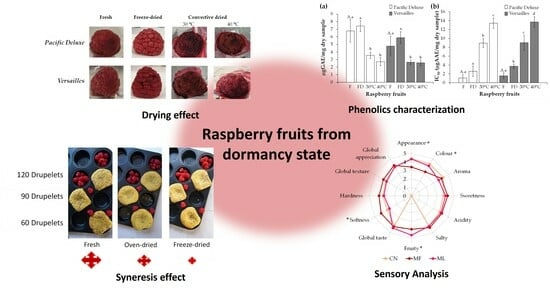

3.2. Raspberry Fruit Drying

3.3. Impact of the Drying Processes

3.3.1. Raspberry Fruit Colour

3.3.2. Raspberry Fruit Phenolics and Antioxidant Activity

3.4. Muffin Development

3.4.1. Influence of Drupelets Incorporation on Physical Properties and Colour of Muffins

3.4.2. Influence of the Raising Agent on the Colour and Physical Properties of the Muffins

3.4.3. Sensory Analysis of Muffins

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hidalgo, G.; Almajano, M. Red Fruits: Extraction of Antioxidants, Phenolic Content, and Radical Scavenging Determination: A Review. Antioxidants 2017, 6, 7. [Google Scholar] [CrossRef] [PubMed]

- Sønsteby, A.; Heide, O.M. Flowering and dormancy relations of raspberry and black currant and effects of management and climate warming on production. Acta Hortic. 2020, 1277, 307–320. [Google Scholar] [CrossRef]

- Pritts, M. Soft Fruits. In Life Sciences, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 268–272. [Google Scholar]

- Dale, A.; Sample, A.; King, E. Breaking dormancy in red raspberries for greenhouse production. Hortscience 2003, 38, 515–519. [Google Scholar] [CrossRef]

- Food and Agriculture Organization Corporate Statistical Database (FAOSTAT). Production of Raspberries in 2020, Pick List by Crops/Regions/Production Quantity; United Nations: New York, NY, USA, 2022. [Google Scholar]

- Ponder, A.; Hallmann, E. The nutritional value and vitamin C content of different raspberry cultivars from organic and conventional production. J. Food Compos. Anal. 2020, 87, 103429. [Google Scholar] [CrossRef]

- Aksic, M.; Nesovic, M.; Ciric, I.; Tesic, Z.; Pezo, L.; Tosti, T.; Gasic, U.; Dojcinovic, B.; Loncar, B.; Meland, M. Chemical Fruit Profiles of Different Raspberry Cultivars Grown in Specific Norwegian Agroclimatic Conditions. Horticulturae 2022, 8, 765. [Google Scholar] [CrossRef]

- Mazur, S.; Nes, A.; Wold, A.; Remberg, S.; Aaby, K. Quality and chemical composition of ten red raspberry (Rubus idaeus L.) genotypes during three harvest seasons. Food Chem. 2014, 160, 233–240. [Google Scholar] [CrossRef]

- Baenas, N.; Nunez-Gomez, V.; Navarro-Gonzalez, I.; Sanchez-Martinez, L.; Garcia-Alonso, J.; Periago, M.; Gonzalez-Barrio, R. Raspberry dietary fibre: Chemical properties, functional evaluation and prebiotic in vitro effect. LWT-Food Sci. Technol. 2020, 134, 110140. [Google Scholar] [CrossRef]

- Lopez-Corona, A.; Valencia-Espinosa, I.; Gonzalez-Sanchez, F.; Sanchez-Lopez, A.; Garcia-Amezquita, L.; Garcia-Varela, R. Antioxidant, Anti-Inflammatory and Cytotoxic Activity of Phenolic Compound Family Extracted from Raspberries (Rubus idaeus): A General Review. Antioxidants 2022, 11, 1192. [Google Scholar] [CrossRef]

- Padmanabhan, P.; Correa-Betanzo, J.; Paliyath, G. Berries and Related Fruits. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016. [Google Scholar]

- Sette, P.; Franceschinis, L.; Schebor, C.; Salvatori, D. Fruit snacks from raspberries: Influence of drying parameters on colour degradation and bioactive potential. Int. J. Food Sci. Technol. 2017, 52, 313–328. [Google Scholar] [CrossRef]

- Rodriguez, A.; Bruno, E.; Paola, C.; Campanone, L.; Mascheroni, R. Experimental study of dehydration processes of raspberries (Rubus Idaeus) with microwave and solar drying. Food Sci. Technol. 2019, 39, 336–343. [Google Scholar] [CrossRef]

- Borquez, R.; Canales, E.; Redon, J. Osmotic dehydration of raspberries with vacuum pretreatment followed by microwave-vacuum drying. J. Food Eng. 2010, 99, 121–127. [Google Scholar] [CrossRef]

- Rodriguez, A.; Rodriguez, M.; Lemoine, M.; Mascheroni, R. Study and comparison of different drying processes for dehydration of raspberries. Dry. Technol. 2017, 35, 689–698. [Google Scholar] [CrossRef]

- Stamenkovic, Z.; Pavkov, I.; Radojcin, M.; Horecki, A.; Keselj, K.; Kovacevic, D.; Putnik, P. Convective Drying of Fresh and Frozen Raspberries and Change of Their Physical and Nutritive Properties. Foods 2019, 8, 251. [Google Scholar] [CrossRef] [PubMed]

- Tekin-Cakmak, Z.; Cakmakoglu, S.; Avci, E.; Sagdic, O.; Karasu, S. Ultrasound-assisted vacuum drying as alternative drying method to increase drying rate and bioactive compounds retention of raspberry. J. Food Process. Preserv. 2021, 45, e16044. [Google Scholar] [CrossRef]

- Petronilho, S.; Rudnitskaya, A.; Coimbra, M.; Rocha, S. Comprehensive Study of Variety Oenological Potential Using Statistic Tools for the Efficient Use of Non-Renewable Resources. Appl. Sci. 2021, 11, 4003. [Google Scholar] [CrossRef]

- Krzykowski, A.; Dziki, D.; Rudy, S.; Gawlik-Dziki, U.; Janiszewska-Turak, E.; Biernacka, B. Wild Strawberry Fragaria vesca L.: Kinetics of Fruit Drying and Quality Characteristics of the Dried Fruits. Processes 2020, 8, 1265. [Google Scholar] [CrossRef]

- FAO. Dried Fruit. In Fruit Processing Toolkit; Food and Agriculture Organization: Rome, Italy, 2007. [Google Scholar]

- AOAC. Fruits and fruit products. In AOAC Official Method 942.15 Acidity (Titratable) of Fruit Products; AOAC: Rockville, MD, USA, 2000; p. 11. [Google Scholar]

- Radojčin, M.; Babić, M.; Babić, L.; Pavkov, I.; Stojanović, Č. Color parameters change of quince during combined drying. J. Process. Energy Agric. 2010, 14, 81. [Google Scholar]

- Petronilho, S.; Oliveira, A.; Domingues, M.R.; Nunes, F.M.; Coimbra, A.M.; Gonçalves, I. Hydrophobic Starch-Based Films Using Potato Washing Slurries and Spent Frying Oil. Foods 2021, 10, 2897. [Google Scholar] [CrossRef]

- Peixoto, A.M.; Petronilho, S.; Domingues, M.R.; Nunes, F.M.; Lopes, J.; Pettersen, M.K.; Grøvlen, M.S.; Wetterhus, E.M.; Gonçalves, I.; Coimbra, M.A. Potato Chips Byproducts as Feedstocks for Developing Active Starch-Based Films with Potential for Cheese Packaging. Foods 2023, 12, 1167. [Google Scholar] [CrossRef]

- Petronilho, S.; Navega, J.; Pereira, C.; Almeida, A.; Siopa, J.; Nunes, F.M.; Coimbra, M.A.; Passos, C.P. Bioactive Properties of Instant Chicory Melanoidins and Their Relevance as Health Promoting Food Ingredients. Foods 2023, 12, 134. [Google Scholar] [CrossRef]

- Bustos, M.C.; Rocha-Parra, D.; Sampedro, I.; de Pascual-Teresa, S.; León, A.E. The Influence of Different Air-Drying Conditions on Bioactive Compounds and Antioxidant Activity of Berries. J. Agric. Food Chem. 2018, 66, 2714–2723. [Google Scholar] [CrossRef] [PubMed]

- Martín-Gómez, J.; Varo, M.Á.; Mérida, J.; Serratosa, M.P. Influence of drying processes on anthocyanin profiles, total phenolic compounds and antioxidant activities of blueberry (Vaccinium corymbosum). LWT-Food Sci. Technol. 2020, 120, 108931. [Google Scholar] [CrossRef]

- Raspberry Chocolate Chip Cookies. Available online: https://www.dessertnowdinnerlater.com/RASPBERRY-CHOCOLATE-CHIP-COOKIES/ (accessed on 10 May 2021).

- Žilić, S.; Kocadağlı, T.; Vančetović, J.; Gökmen, V. Effects of baking conditions and dough formulations on phenolic compound stability, antioxidant capacity and color of cookies made from anthocyanin-rich corn flour. LWT-Food Sci. Technol. 2016, 65, 597. [Google Scholar] [CrossRef]

- Morodi, V.; Kaseke, T.; Fawole, O. Impact of Gum Arabic Coating Pretreatment on Quality Attributes of Oven-Dried Red Raspberry (Rubus idaeus L.) Fruit. Processes 2022, 10, 1629. [Google Scholar] [CrossRef]

- Stevanovic, S.; Petrovic, T.; Markovic, D.; Milovancevic, U.; Stevanovic, S.; Urosevic, T.; Kozarski, M. Changes of quality and free radical scavenging activity of strawberry and raspberry frozen under different conditions. J. Food Process. Preserv. 2022, 46, e15981. [Google Scholar] [CrossRef]

- Purgar, D.; Duralija, B.; Voca, S.; Vokurka, A.; Ercisli, S. A Comparison of Fruit Chemical Characteristics of Two Wild Grown Rubus Species from Different Locations of Croatia. Molecules 2012, 17, 10390–10398. [Google Scholar] [CrossRef] [PubMed]

- Convert L*a*b* Values to the Nearest Standard Colour. Available online: https://www.e-paint.co.uk/convert-lab.asp (accessed on 7 May 2021).

- Alibabic, V.; Skender, A.; Bajramovic, M.; Sertovic, E.; Bajric, E. Evaluation of morphological, chemical, and sensory characteristics of raspberry cultivars grown in Bosnia and Herzegovina. Turk. J. Agric. For. 2018, 42, 67–74. [Google Scholar] [CrossRef]

- Hossain, M.; Barry-Ryan, C.; Martin-Diana, A.; Brunton, N. Effect of drying method on the antioxidant capacity of six Lamiaceae herbs. Food Chem. 2010, 123, 85–91. [Google Scholar] [CrossRef]

- Mizrahi, S. Syneresis in food gels and its implications for food quality. In Chemical Deterioration and Physical Instability of Food and Beverages; Elsevier: Amsterdam, The Netherlands, 2010; pp. 324–348. [Google Scholar] [CrossRef]

- Rodriguez-Amaya, D.B. Natural food pigments and colorants. In Bioactive Molecules in Food; Mérillon, J.M., Ramawat, K.G., Eds.; Springer: Cham, Switzerland, 2019; pp. 867–901. [Google Scholar] [CrossRef]

- Quintanilla, A.; Zhang, H.; Powers, J.; Sablani, S.S. Developing Baking-Stable Red Raspberries with Improved Mechanical Properties and Reduced Syneresis. Food Bioprocess Technol. 2021, 14, 804. [Google Scholar] [CrossRef]

- Zhao, S.; Park, C.H.; Yang, J.; Yeo, H.J.; Kim, T.J.; Kim, J.K.; Park, S.U. Molecular characterization of anthocyanin and betulinic acid biosynthesis in red and white mulberry fruits using high-throughput sequencing. Food Chem. 2019, 279, 364. [Google Scholar] [CrossRef]

- Teixeira, M.; Tao, W.; Fernandes, A.; Faria, A.; Ferreira, I.M.P.L.V.O.; He, J.; Freitas, V.; Mateus, N.; Oliveira, H. Anthocyanin-rich edible flowers, current understanding of a potential new trend in dietary patterns. Trends Foods Sci. Technol. 2023, 138, 708. [Google Scholar] [CrossRef]

- Choi, I.; Lee, J.Y.; Lacroix, M.; Han, J. Intelligent pH indicator film composed of agar/potato starch and anthocyanin extracts from purple sweet potato. Food Chem. 2017, 218, 122. [Google Scholar] [CrossRef]

- Yoshida, C.M.; Maciel, V.B.V.; Mendonça, M.E.D.; Franco, T.T. Chitosan biobased and intelligent films: Monitoring pH variations. LWT-Food Sci. Technol. 2014, 55, 83. [Google Scholar] [CrossRef]

| Variety | Weight (g) 1 | pH | °Brix | Titratable Acidity (% CAE/100mL) 2 | Moisture (%) 3 |

|---|---|---|---|---|---|

| Pacific Deluxe | 5.73 ± 0.04 a | 3.25 ± 0.14 a | 5.10 ± 0.17 a | 0.90 ± 0.02 a | 90.21 ± 1.13 a |

| Versailles | 6.96 ± 0.26 b | 2.86 ± 0.06 b | 9.07 ± 0.12 b | 1.25 ± 0.03 b | 86.98 ± 1.58 b |

| L* | a* | b* | ΔE | Colour 1 | |

|---|---|---|---|---|---|

| Pacific Deluxe | |||||

| Fresh | 33.35 ± 0.83 A,a | 29.16 ± 4.26 A,a | 12.78 ± 1.71 A,a | - | |

| Freeze-dried | 32.68 ± 2.53 a | 35.74 ± 2.64 b | 10.85 ± 0.94 b | 6.89 | |

| Dried at 30 °C | 20.17 ± 1.81 b | 22.02 ± 4.77 c | 7.57 ± 2.12 c | 15.87 | |

| Dried at 40 °C | 25.01 ± 3.38 c | 29.05 ± 1.66 a | 11.50 ± 0.97 b | 8.44 | |

| Versailles | |||||

| Fresh | 32.86 ± 1.39 A,a | 31.98 ± 2.32 A,a | 13.42 ± 1.93 A,a | - | |

| Freeze-dried | 25.55 ± 2.08 b | 34.68 ± 3.05 a | 11.73 ± 1.20 a | 7.98 | |

| Dried at 30 °C | 25.03 ± 4.45 b | 29.82 ± 6.33 a | 11.85 ± 3.39 a | 8.28 | |

| Dried at 40 °C | 28.15 ± 3.72 b | 30.52 ± 3.50 a | 11.90 ± 1.73 a | 5.16 |

| Cy 3-s | Cy 3-gr | Cy 3-(6”-dg) | Cy 3-(6”-s-gl) | Total | |

|---|---|---|---|---|---|

| Pacific Deluxe | |||||

| Fresh | 7.54 ± 0.36 A,a | 2.52 ± 0.08 A,a | 1.00 ± 0.08 A,a | 0.46 ± 0.02 A,a | 11.52 ± 0.38 A,a |

| Freeze-dried | 8.01 ± 0.79 a | 2.87 ± 0.34 a | 1.10 ± 0.10 a | 0.53 ± 0.04 a | 12.52 ± 1.29 a |

| Dried at 30 °C | 6.29 ± 0.11 b | 2.18 ± 0.09 b | 0.92 ± 0.03 b | 0.47 ± 0.01 a | 9.86 ± 0.16 b |

| Dried at 40 °C | 4.90 ± 0.58 c | 1.99 ± 0.27 b | 0.76 ± 0.05 c | 0.41 ± 0.04 a | 8.06 ± 0.49 c |

| Versailles | |||||

| Fresh | 5.41 ± 0.10 B,a | 2.82 ± 0.12 B,a | 1.18 ± 0.05 B,a | 1.22 ± 0.07 B,a | 10.63 ± 0.05 B,a |

| Freeze-dried | 5.84 ± 0.24 a | 3.07 ± 0.11 a | 1.23 ± 0.03 a | 1.37 ± 0.09 a | 11.51 ± 0.57 a |

| Dried at 30 °C | 3.25 ± 0.11 b | 1.73 ± 0.24 b | 0.93 ± 0.21 b | 0.84 ± 0.11 b | 6.75 ± 0.23 b |

| Dried at 40 °C | 2.95 ± 0.07 c | 1.46 ± 0.18 b | 0.81 ± 0.18 b | 0.70 ± 0.09 b | 5.92 ± 0.13 c |

| Parameters (cm) | |||||||

|---|---|---|---|---|---|---|---|

| Drupelets | Weight (g) | 1 | 2 | 3 | 4 | 5 | |

| Fresh | 0 | 38.3 ± 2.0 a | 6.8 ± 0. 1a | 8.3 ± 0.4 a | 1.5 ± 0.2 a | 2.6 ± 0.5 a | 2.7 ± 0.0 a |

| 60 | 41.3 ± 2.1 a | 7.4 ± 0.5 a | 8.2 ± 0.2 a | 1.5 ± 0.2 a | 2.7 ± 0.3 a | 2.7 ± 0.0 a | |

| 90 | 46.3 ± 2.1 b | 7.4 ± 0.5 a | 8.8 ± 0.2 b | 1.5 ± 0.2 a | 2.6 ± 0.1 a | 2.7 ± 0.0 a | |

| 120 | 51.7 ± 1.5 c | 7.3 ± 0.3 a | 9.1 ± 0.2 b | 1.5 ± 0.1 a | 2.5 ± 0.2 a | 2.8 ± 0.1 a | |

| Freeze-dried | 0 | 38.3 ± 2.1 a | 6.8 ± 0.1 a | 8.3 ± 0.4 a | 1.5 ± 0.2 a | 2.6 ± 0.5 a | 2.7 ± 0.0 a |

| 60 | 38.0 ± 1.0 a | 7.7 ± 0.2 b | 7.8 ± 0.2 a | 1.5 ± 0.1 a | 2.4 ± 0.1 a | 2.2 ± 0.2 b | |

| 90 | 36.0 ± 1.5 b | 7.8 ± 0.5 b | 8.3 ± 0.3 a | 1.5 ± 0.2 a | 2.6 ± 0.3 a | 1.9 ± 0.2 b | |

| 120 | 34.7 ± 1.0 b | 7.3 ± 0.2 b | 7.9 ± 0.2 a | 1.5 ± 0.1 a | 2.6 ± 0.1 a | 1.9 ± 0.2 b | |

| Dried at 40 °C | 0 | 38.3 ± 3.1 a | 7.7 ± 0.3 a | 8.6 ± 0.2 a | 1.5 ± 0.0 a | 2.8 ± 0.3 a | 2.0 ± 0.1 a |

| 60 | 42.3 ± 2.1 a | 8.9 ± 1.0 a | 9.0 ± 0.4 a | 1.6 ± 0.2 a | 2.9 ± 0.2 a | 1.9 ± 0.0 a | |

| 90 | 41.7 ± 2.5 a | 7.8 ± 0.7 a | 9.1 ± 0.2 a | 1.4 ± 0.1 a | 2.7 ± 0.2 a | 1.8 ± 0.0 a | |

| 120 | 46.0 ± 1.0 b | 8.1 ± 0.2 a | 8.8 ± 0.2 a | 1.5 ± 0.2 a | 2.7 ± 0.1 a | 2.1 ± 0.1 a | |

| Drupelets | L* | a* | b* | ΔE | Colour 1 | |

|---|---|---|---|---|---|---|

| Fresh | 0 | 66.06 ± 5.79 a | 6.07 ± 1.35 a | 38.34 ± 5.68 a | - | |

| 60 | 52.53 ± 2.74 b | 2.35 ± 1.02 b | 28.61 ± 4.13 b | 17.08 | ||

| 90 | 53.57 ± 6.19 b | 2.46 ± 0.61 b | 26.81 ± 3.89 b | 17.37 | ||

| 120 | 52.46 ± 4.01 b | 3.19 ± 1.35 b | 26.81 ± 2.94 b | 18.06 | ||

| Freeze-dried | 0 | 66.06 ± 5.79 a | 6.07 ± 1.35 a | 38.34 ± 5.68 a | - | |

| 60 | 68.02 ± 2.44 a | 6.06 ± 1.48 a | 38.43 ± 5.17 a | 0.09 | ||

| 90 | 68.31 ± 1.99 a | 4.64 ± 1.54 a | 39.62 ± 3.13 a | 2.96 | ||

| 120 | 69.24 ± 2.40 a | 5.43 ± 1.35 a | 41.93 ± 3.07 a | 4.84 | ||

| Dried at 40 °C | 0 | 66.03 ± 5.79 a | 6.22 ± 1.22 a | 27.20 ± 5.68 a | - | |

| 60 | 52.59 ± 5.51 a | 4.27 ± 0.68 b | 31.59 ± 2.64 a | 14.69 | ||

| 90 | 55.98 ± 6.25 a | 4.78 ± 0.89 b | 25.03 ± 4.20 a | 10.38 | ||

| 120 | 46.18 ± 5.25 a | 4.39 ± 1.07 b | 35.02 ± 2.85 a | 24.01 |

| Raising | Drupelets | L* | a* | b* | ΔE | Colour 1 |

|---|---|---|---|---|---|---|

| Upper side | ||||||

| Bicarbonate | 0 | 67.01 ± 4.84 a,A | 6.63 ± 0.70 a,A | 37.11 ± 2.49 a,A | - | |

| 120 | 55.98 ± 2.49 b,B | 4.78 ± 0.96 b,A | 35.03 ± 2.67 a,A | 11.37 | ||

| Yeast | 0 | 68.56 ± 4.23 a,A | 7.92 ± 0.33 a,A | 36.70 ± 1.95 a,A | - | |

| 120 | 63.91 ± 4.82 a,A | 6.32 ± 1.64 a,A | 36.66 ± 2.18 a,A | 4.91 | ||

| Lower side | ||||||

| Bicarbonate | 0 | 46.17 ± 3.22 a,A | 15.94 ± 2.04 a,A | 36.36 ± 1.94 a,A | - | |

| 120 | 38.38 ± 2.04 b,B | 14.58 ± 2.38 a,A | 26.32 ± 1.95 b,B | 10.95 | ||

| Yeast | 0 | 47.77 ± 3.40 a,A | 18.40 ± 1.10 a,A | 37.45 ± 2.20 a,A | - | |

| 120 | 48.79 ± 3.34 a,A | 17.26 ± 1.17 a,A | 36.32 ± 1.95 a,A | 2.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petronilho, S.; Coimbra, M.A.; Passos, C.P. Quality Characteristics of Raspberry Fruits from Dormancy Plants and Their Feasibility as Food Ingredients. Foods 2023, 12, 4443. https://doi.org/10.3390/foods12244443

Petronilho S, Coimbra MA, Passos CP. Quality Characteristics of Raspberry Fruits from Dormancy Plants and Their Feasibility as Food Ingredients. Foods. 2023; 12(24):4443. https://doi.org/10.3390/foods12244443

Chicago/Turabian StylePetronilho, Sílvia, Manuel A. Coimbra, and Cláudia P. Passos. 2023. "Quality Characteristics of Raspberry Fruits from Dormancy Plants and Their Feasibility as Food Ingredients" Foods 12, no. 24: 4443. https://doi.org/10.3390/foods12244443

APA StylePetronilho, S., Coimbra, M. A., & Passos, C. P. (2023). Quality Characteristics of Raspberry Fruits from Dormancy Plants and Their Feasibility as Food Ingredients. Foods, 12(24), 4443. https://doi.org/10.3390/foods12244443