Hemp: A Sustainable Plant with High Industrial Value in Food Processing

Abstract

:1. Introduction

2. A Brief History of Hemp Cultivation in the World

3. Reevaluation of Hemp for Its Sustainability

3.1. Cellulose Gap: Applications in the Textile Industry

3.2. Hempcrete

3.3. Biofuels

3.4. Bioplastics

4. Nutrition

4.1. Overview

4.2. Protein

4.2.1. Composition of Hemp Protein (Globulin, Albumin, and Others)

4.2.2. Extractability/Solubility

4.2.3. Digestibility/Allergenicity

4.2.4. Disulfide Structure

5. Applications of Hemp Protein to the Food Processing Industry

5.1. Hemp Milk

5.2. Emulsifier

5.3. Gluten-free Bread

5.4. Hemp Meat

5.4.1. Hemp as a Nutrient Feed Stuff

5.4.2. Vegan Meat Made of Hemp/Soy Proteins

5.4.3. “Meaty” Hemp Meat: Anisotropy and Fibrousness

5.4.4. Membrane Formation

6. Comparative Summary of Hemp, Cotton, and Soybean

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahuti, S. Industrial growth and environmental degradation. Int. Educ. Res. J. 2015, 1, 5–7. [Google Scholar]

- Liu, X.; Liu, W.; Tang, Q.; Liu, B.; Wada, Y.; Yang, H. Global agricultural water scarcity assessment incorporating blue and green water availability under future climate change. Earth’s Future 2022, 10, e2021EF002567. [Google Scholar] [CrossRef]

- Hofmann, B.; Ingold, K.; Stamm, C.; Ammann, P.; Eggen, R.I.L.; Finger, R.; Fuhrimann, S.; Lienert, J.; Mark, J.; McCallum, C.; et al. Barriers to evidence use for sustainability: Insights from pesticide policy and practice. Ambio 2023, 52, 425–439. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.J.; Helmy, M.; Lindley, N.D.; Selvarajoo, K. The transformation of our food system using cellular agriculture: What lies ahead and who will lead it? Trends Food Sci. Technol. 2022, 127, 368–376. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, X.; Zhang, Y.; Liu, H.; Wang, J.; Sun, B. The global concern of food security during the COVID-19 pandemic: Impacts and perspectives on food security. Food Chem. 2022, 370, 130830. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Scherer, L.; Zhang, Q.; Behrens, P. Adoption of plant-based diets across Europe can improve food resilience against the Russia–Ukraine conflict. Nat. Food 2022, 3, 905–910. [Google Scholar] [CrossRef]

- Ben Hassen, T.; El Bilali, H. Impacts of the Russia-Ukraine war on global food security: Towards more sustainable and resilient food systems? Foods 2022, 11, 2301. [Google Scholar] [CrossRef]

- Mirón, I.J.; Linares, C.; Díaz, J. The influence of climate change on food production and food safety. Environ. Res. 2023, 216, 114674. [Google Scholar] [CrossRef] [PubMed]

- Mavroeidis, A.; Roussis, I.; Kakabouki, I. The role of alternative crops in an upcoming global food crisis: A concise review. Foods 2022, 11, 3584. [Google Scholar] [CrossRef]

- Tedeschi, A.; Cerrato, D.; Menenti, M. Is the potential for multi-functional use of industrial hemp greater than maize under saline conditions? Sustainability 2022, 14, 15646. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Lawson, L.; Degenstein, L.M.; Bates, B.; Chute, W.; King, D.; Dolez, P.I. Cellulose textiles from hemp biomass: Opportunities and challenges. Sustainability 2022, 14, 15337. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Traditional and new applications of hemp. Sustain. Agri. Rev. 2020, 42, 37–87. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Wang, Y.; Li, W.; He, D.; Zhang, Y.; Zhang, X.; Xing, X. Emerging natural hemp seed proteins and their functions for nutraceutical applications. Food Sci. Hum. Wellness 2023, 12, 929–941. [Google Scholar] [CrossRef]

- Nadar, R.M.; McDonald, K.; Deruiter, J.; Pathak, S.; Ramesh, S.; Vijayarani, R.; Gopal, K.; Ramapuram, J.B.; Dua, K.; Moore, T.; et al. A re-evaluation of past to present-day use of the blissful neuronal nutraceutical “Cannabis”. J. Food Nutr. Metab. 2022, 5, 1–8. [Google Scholar] [CrossRef]

- Donaldson, L. From illegal to ideal: The necessity of hemp production. Nat. Sci. Educ. 2022, 51, e20090. [Google Scholar] [CrossRef]

- Smeu, I.; Dobre, A.A.; Cucu, E.M.; Mustățea, G.; Belc, N.; Ungureanu, E.L. Byproducts from the vegetable oil industry: The challenges of safety and sustainability. Sustainability 2022, 14, 2039. [Google Scholar] [CrossRef]

- Lin, Y.; Pangloli, P.; Dia, V.P. Physicochemical, functional and bioactive properties of hempseed (Cannabis sativa L.) meal, a co-product of hempseed oil and protein production, as affected by drying process. Food Chem. 2021, 350, 129188. [Google Scholar] [CrossRef]

- Xu, Y.; Sismour, E.; Britland, J.W.; Sellers, A.; Abraha-Eyob, Z.; Yousuf, A.; Rao, O.; Kim, J.; Zhao, W. Physicochemical, structural, and functional properties of hemp protein vs. several commercially available plant and animal proteins: A comparative study. ACS Food Sci. Technol. 2022, 2, 1672–1680. [Google Scholar] [CrossRef]

- Ren, G.; Zhang, X.; Li, Y.; Ridout, K.; Serrano-Serrano, M.L.; Yang, Y.; Ravikanth, G.; Nawaz, M.A.; Mumtaz, A.S.; Salamin, N.; et al. Large-scale whole-genome resequencing unravels the domestication history of Cannabis sativa. Sci. Adv. 2021, 7, eabg2286. [Google Scholar]

- Salehi, A.; Puchalski, K.; Shokoohinia, Y.; Zolfaghari, B.; Asgary, S. Differentiating cannabis products: Drugs, food, and supplements. Front Pharmacol. 2022, 13, 906038. [Google Scholar] [CrossRef] [PubMed]

- Reddy, D.S. Therapeutic and clinical foundations of cannabidiol therapy for difficult-to-treat seizures in children and adults with refractory epilepsies. Exp. Neurol. 2023, 359, 114237. [Google Scholar] [CrossRef] [PubMed]

- Rull, V. Origin, early expansion, domestication and anthropogenic diffusion of Cannabis, with emphasis on Europe and the Iberian Peninsula. Perspect. Plant Ecol. Evol. Syst. 2022, 55, 125670. [Google Scholar] [CrossRef]

- Mcgrath, C.; United States Department of Agriculture|Foreign Agricultural Service—China. 2019 Hemp Annual Report. CH20200018; 2020; pp. 1–12. Available online: https://www.fas.usda.gov/data/china-2019-hemp-annual-report (accessed on 18 January 2023).

- Zhou, B.; Marjerison, R.K.; Chang, F.H. Chinese OEM manufacturing roadmap: SMEs–To brand or not to brand. In Handbook of Research on Emerging Business Models and the New World Economic Order; IGI Global: Hershey, PA, USA, 2022; pp. 163–182. [Google Scholar]

- European Commission. Hemp Production in the EU. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 18 January 2023).

- Coxall, G. The next super crop. Land J. 2020, 26–27. Available online: https://www.proquest.com/openview/991a7952c92ae377a489842472aa18de/1?pq-origsite=gscholar&cbl=2028823 (accessed on 18 January 2023).

- Booth, W.; Adam, K. Boris Johnson Used to Mock ‘Eco-Doomsters’. Now He’s a Climate Champion. The Washington Post. 2021. Available online: https://www.washingtonpost.com/world/europe/boris-johnson-climate-cop26/2021/11/02/ffbc2526-3b79-11ec-bd6f-da376f47304e_story.html/ (accessed on 18 January 2023).

- Brown, D.T. Non-medicinal uses of Cannabis sativa. In Cannabis; CRC Press: Boca Raton, FL, USA, 1998; pp. 138–147. [Google Scholar]

- Dickson, K.; Janasie, C.; Willett, K.L. Cannabinoid Conundrum: A Study of Marijuana and Hemp Legality in The united states. Ariz. J. Environ. Law Policy 2019, 10, 132–150. [Google Scholar]

- United States Department of Agriculture. Hemp and Farm Bill Programs. 2019. Available online: https://www.farmers.gov/manage/hemp?utm_medium=email&utm_source=govdelivery (accessed on 18 January 2023).

- Shen, P.; Gao, Z.; Fang, B.; Rao, J.; Chen, B. Ferreting out the secrets of industrial hemp protein as emerging functional food ingredients. Trends Food Sci. Technol. 2021, 112, 1–15. [Google Scholar] [CrossRef]

- Grand View Research. Industrial Hemp Market Size, Share & Trends Analysis Report By Product (Seeds, Fiber, Shivs), By Application (Animal Care, Textiles, Personal Care), By Region (North America, APAC), And Segment Forecasts, 2022–2030. 2022. Available online: https://www.grandviewresearch.com/industry-analysis/industrial-hemp-market (accessed on 18 January 2023).

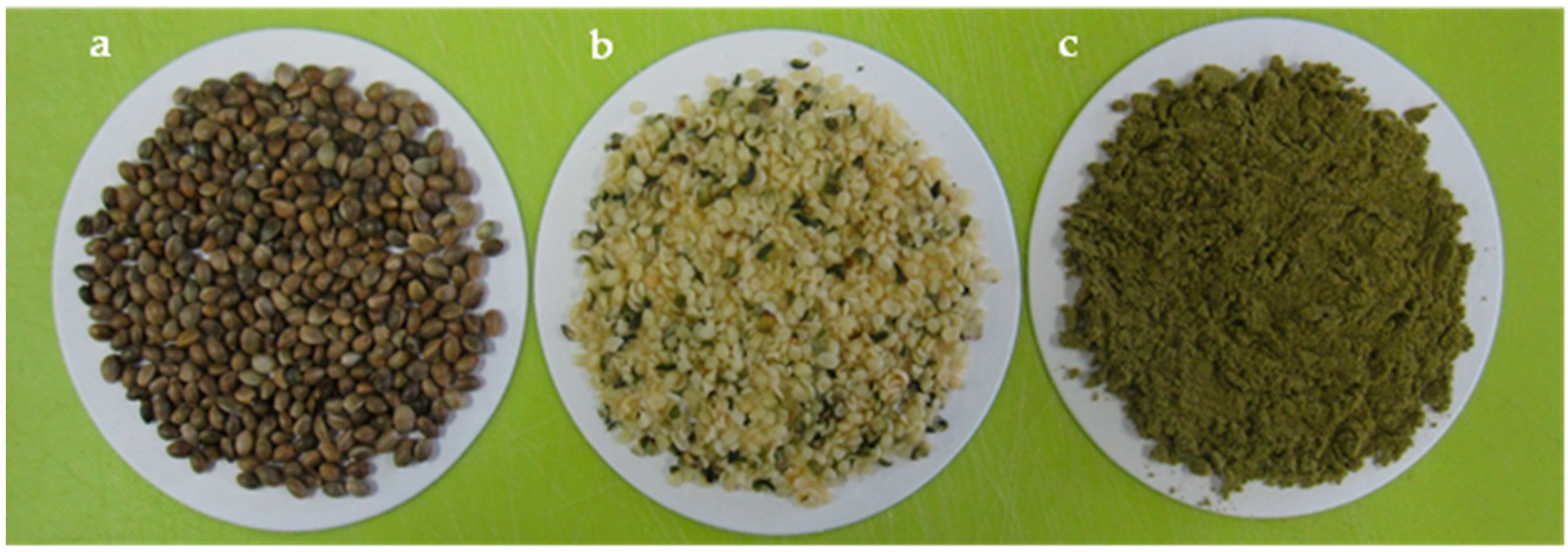

- Burton, R.A.; Andres, M.; Cole, M.; Cowley, J.M.; Augustin, M.A. Industrial hemp seed: From the field to value-added food ingredients. J. Cannabis Res. 2022, 4, 45. [Google Scholar] [CrossRef]

- Ebskamp, M.J.M. Engineering flax and hemp for an alternative to cotton. Trends Biotechnol. 2002, 20, 229–230. [Google Scholar] [CrossRef] [PubMed]

- Zimniewska, M. Hemp fibre properties and processing target textile: A review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. Environmental analysis of a cotton yarn supply chain. J. Clean. Prod. 2014, 82, 154–165. [Google Scholar] [CrossRef]

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial hemp fiber: A sustainable and economical alternative to cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Teleszko, M.; Zając, A.; Rusak, T. Hemp Seeds of the Polish ‘Bialobrzeskie’ and ‘Henola’ Varieties (Cannabis sativa L. var. sativa) as Prospective Plant Sources for Food Production. Molecules 2022, 27, 1448. [Google Scholar] [CrossRef] [PubMed]

- Ahirwar, M.; Behera, B.K. Development of hemp-blended cotton fabrics and analysis on handle behavior, low-stress mechanical and aesthetic properties. J. Text. Inst. 2022, 113, 934–942. [Google Scholar] [CrossRef]

- Okur, N. Thermo-physiological and handle-related comfort properties of hemp and flax blended denim fabrics. J. Nat. Fibers 2021, 19, 10179–10192. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Zvirgzds, K.; Kirilovs, E.; Kukle, S.; Gross, U. Production of particleboard using various particle size hemp shives as filler. Materials 2022, 15, 886. [Google Scholar] [CrossRef]

- Sinka, M.; Spurina, E.; Korjakins, A.; Bajare, D. Hempcrete—CO2 neutral wall solutions for 3D printing. Environ. Clim. Technol. 2022, 26, 742–753. [Google Scholar] [CrossRef]

- Khan, S.; Naushad, M.; Iqbal, J.; Bathula, C.; Al-Muhtaseb, A.H. Challenges and perspectives on innovative technologies for biofuel production and sustainable environmental management. Fuel 2022, 325, 124845. [Google Scholar] [CrossRef]

- Marrot, L.; Candelier, K.; Valette, J.; Lanvin, C.; Horvat, B.; Legan, L.; DeVallance, D.B. Valorization of hemp stalk waste through thermochemical conversion for energy and electrical applications. Waste Biomass Valor. 2022, 13, 2267–2285. [Google Scholar] [CrossRef]

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef]

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading recycled polypropylene from textile wastes in wood plastic composites with short hemp fiber. Polymers 2021, 13, 1248. [Google Scholar] [CrossRef]

- Nabels-Sneiders, M.; Platnieks, O.; Grase, L.; Gaidukovs, S. Lamination of cast hemp paper with bio-based plastics for sustainable packaging: Structure-thermomechanical properties relationship and biodegradation studies. J. Compos. Sci. 2022, 6, 246. [Google Scholar] [CrossRef]

- Tyagi, P.; Gutierrez, J.N.; Nathani, V.; Lucia, L.A.; Rojas, O.J.; Hubbe, M.A.; Pal, L. Hydrothermal and mechanically generated hemp hurd nanofibers for sustainable barrier coatings/films. Ind. Crops Prod. 2021, 168, 113582. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef] [PubMed]

- Mohd Fairulnizal, M.N.; Norhayati, M.K.; Zaiton, A.; Norliza, A.H.; Rusidah, S.; Aswir, A.R.; Suraiami, M.; Mohd Naeem, M.N.; Jo-Lyn, A.; Mohd Azerulazree, J.; et al. Nutrient content in selected commercial rice in Malaysia: An update of Malaysian food composition database. Int. Food Res. J. 2015, 22, 768–776. [Google Scholar]

- Wieser, H.; Koehler, P.; Scherf, K.A. The two faces of wheat. Front Nutr. 2020, 7, 517313. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Androsova, N.V.; Toshev, A.D.; El Enshasy, H.A. Nutritional quality, chemical, and functional characteristics of hemp (Cannabis sativa ssp. sativa) protein Isolate. Plants 2022, 11, 2825. [Google Scholar] [CrossRef]

- Kan, L.; Nie, S.; Hu, J.; Wang, S.; Bai, Z.; Wang, J.; Zhou, Y.; Jiang, J.; Zeng, Q.; Song, K. Comparative study on the chemical composition, anthocyanins, tocopherols and carotenoids of selected legumes. Food Chem. 2018, 260, 317–326. [Google Scholar] [CrossRef]

- Docimo, T.; Caruso, I.; Ponzoni, E.; Mattana, M.; Galasso, I. Molecular characterization of edestin gene family in Cannabis sativa L. Plant Physiol. Biochem. 2014, 84, 142–148. [Google Scholar] [CrossRef]

- Patel, S.; Cudney, R.; McPherson, A. Crystallographic characterization and molecular symmetry of edestin, a legumin from hemp. J. Mol. Biol. 1994, 235, 361–363. [Google Scholar] [CrossRef] [PubMed]

- Malomo, S.A.; Aluko, R.E. A comparative study of the structural and functional properties of isolated hemp seed (Cannabis sativa L.) albumin and globulin fractions. Food Hydrocoll. 2015, 43, 743–752. [Google Scholar] [CrossRef]

- Kahraman, O.; Petersen, G.E.; Fields, C. Physicochemical and functional modifications of hemp protein concentrate by the application of ultrasonication and pH shifting treatments. Foods 2022, 11, 587. [Google Scholar] [CrossRef]

- Mamone, G.; Picariello, G.; Ramondo, A.; Nicolai, M.A. Production, digestibility and allergenicity of hemp (Cannabis sativa L.) protein isolates. Food Res. Int. 2019, 115, 562–571. [Google Scholar] [CrossRef] [PubMed]

- Banskota, A.H.; Tibbetts, S.M.; Jones, A.; Stefanova, R.; Behnke, J. Biochemical characterization and in vitro digestibility of protein isolates from hemp (Cannabis sativa L.) by-products for salmonid feed applications. Molecules 2022, 27, 4794. [Google Scholar] [CrossRef] [PubMed]

- Odani, S.; Odani, S. Isolation and primary structure of a methionine- and cystine-rich seed protein of Cannabis sativa. Biosci. Biotechnol. Biochem. 1998, 62, 650–654. [Google Scholar] [CrossRef]

- Hewage, A.; Olatunde, O.O.; Nimalaratne, C.; Malalgoda, M.; Aluko, R.E.; Bandara, N. Novel extraction technologies for developing plant protein ingredients with improved functionality. Trends Food Sci. Technol. 2022, 129, 492–511. [Google Scholar] [CrossRef]

- Fang, B.; Gu, Z.; Ohm, J.B.; Chen, B.; Rao, J. Reverse micelles extraction of hemp protein isolate: Impact of defatting process on protein structure, functionality, and aromatic profile. Food Hydrocoll. 2023, 135, 108158. [Google Scholar] [CrossRef]

- Tang, C.-H.; Ten, Z.; Wang, X.-S.; Yang, X.-Q. Physicochemical and functional properties of hemp (Cannabis sativa L.) protein isolate. J. Agric. Food Chem. 2006, 54, 8945–8950. [Google Scholar] [CrossRef]

- Nasrollahzadeh, F.; Roman, L.; Swaraj, V.J.S.; Ragavan, K.V.; Vidal, N.P.; Dutcher, J.R.; Martinez, M.M. Hemp (Cannabis sativa L.) protein concentrates from wet and dry industrial fractionation: Molecular properties, nutritional composition, and anisotropic structuring. Food Hydrocoll. 2022, 131, 107755. [Google Scholar] [CrossRef]

- Avraham, T.; Badani, H.; Galili, S.; Amir, R. Enhanced levels of methionine and cysteine in transgenic alfalfa ( Medicago sativa L.) plants over-expressing the Arabidopsis cystathionine γ-synthase gene. Plant Biotechnol. J. 2005, 3, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Yano, H.; Wong, J.H.; Lee, Y.M.; Cho, M.J.; Buchanan, B.B. A strategy for the identification of proteins targeted by thioredoxin. Proc. Nat. Acad. Sci. USA 2001, 98, 4794–4799. [Google Scholar] [CrossRef] [PubMed]

- Yano, H. Improvements in the bread-making quality of gluten-free rice batter by glutathione. J. Agric. Food Chem. 2010, 58, 7949–7954. [Google Scholar] [CrossRef] [PubMed]

- Yano, H. Comparison of oxidized and reduced glutathione in the breadmaking qualities of rice batter. J. Food Sci. 2012, 77, 182–188. [Google Scholar] [CrossRef]

- Zhang, T.; Guo, J.; Chen, J.-F.; Wang, J.-M.; Wan, Z.-L.; Yang, X.-Q. Heat stability and rheological properties of concentrated soy protein/egg white protein composite microparticle dispersions. Food Hydrocoll. 2020, 100, 105449. [Google Scholar] [CrossRef]

- Yano, H.; Fu, W. Effective Use of Plant Proteins for the Development of “New” Foods. Foods 2022, 11, 1185. [Google Scholar] [CrossRef]

- Yano, H. Development of protein-rich, low carbohydrate food material composed mainly of plant protein. Bull. NARO Res. 2022, 12, 25–59. [Google Scholar]

- Reyes-Jurado, F.; Soto-Reyes, N.; Dávila-Rodríguez, M.; Lorenzo-Leal, A.C.; Jiménez-Munguía, M.T.; Mani-López, E.; López-Malo, A. Plant-based milk alternatives: Types, processes, benefits, and characteristics. Food Rev. Int. 2021, 1–32. [Google Scholar] [CrossRef]

- Collier, E.S.; Harris, K.L.; Bendtsen, M.; Norman, C.; Niimi, J. Just a matter of taste? Understanding rationalizations for dairy consumption and their associations with sensory expectations of plant-based milk alternatives. Food Qual. Prefer. 2023, 104, 104745. [Google Scholar] [CrossRef]

- Vahanvaty, U.S. Hemp seed and hemp milk. ICAN Infant Child Adolesc. Nutr. 2009, 1, 232–234. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, J.; Xiong, L. High pressure homogenization combined with pH shift treatment: A process to produce physically and oxidatively stable hemp milk. Food Res. Int. 2018, 106, 487–494. [Google Scholar] [CrossRef] [PubMed]

- Klojdová, I.; Stathopoulos, C. The potential application of Pickering multiple emulsions in food. Foods 2022, 11, 1558. [Google Scholar] [CrossRef]

- Ramsdem, W. Separation of solids in the surface-layers of solutions and ‘suspensions’ (observations on surface-membranes, bubbles, emulsions, and mechanical coagulation)—Preliminary account. Proc. R. Soc. Lond. 1904, 72, 156–164. [Google Scholar]

- Pickering, S.U. Emulsions. J. Chem. Soc. 1907, 91, 2001–2021. [Google Scholar] [CrossRef]

- Wang, C.; Wu, J.; Wang, C.; Mu, C.; Ngai, T.; Lin, W. Advances in Pickering emulsions stabilized by protein particles: Toward particle fabrication, interaction and arrangement. Food Res. Int. 2022, 157, 111380. [Google Scholar] [CrossRef]

- Jing, X.; Cai, Y.; Liu, T.; Chen, B.; Zhao, Q.; Deng, X.; Zhao, M. Formation, texture, and stability of yolk-free mayonnaise: Effect of soy peptide aggregates concentration. Food Chem. 2023, 403, 134337. [Google Scholar] [CrossRef]

- Strieder, M.M.; Silva, E.K.; Mekala, S.; Meireles, M.A.A.; Saldaña, M.D.A. Pulsed high-pressure processing of barley-based non-dairy alternative milk: β-carotene retention, protein solubility and antioxidant activity. Innov. Food Sci. Emerg. Technol. 2022, 82, 103212. [Google Scholar] [CrossRef]

- Haji, F.; Cheon, J.; Baek, J.; Wang, Q.; Tam, K.C. Application of Pickering emulsions in probiotic encapsulation-A review. Curr. Res. Food Sci. 2022, 5, 1603–1615. [Google Scholar] [CrossRef]

- Yano, H.; Fukui, A.; Kajiwara, K.; Kobayashi, I.; Yoza, K.-I.; Satake, A.; Villeneuve, M. Development of gluten-free rice bread: Pickering stabilization as a possible batter-swelling mechanism. LWT 2017, 79, 632–639. [Google Scholar] [CrossRef]

- Dapčević-Hadnađev, T.; Dizdar, M.; Poji’c, M.; Krstonosi´c, V. Emulsifying properties of hemp proteins: Effect of isolation technique. Food Hydrocoll. 2019, 89, 912–920. [Google Scholar] [CrossRef]

- Feng, Y.; Yu, D.; Lin, T.; Jin, Q.; Wu, J.; Chen, C.; Huang, H. Complexing hemp seed protein with pectin for improved emulsion stability. J. Food Sci. 2021, 86, 3137–3147. [Google Scholar] [CrossRef]

- Li, N.; Wang, T.; Yang, X.; Qu, J.; Wang, N.; Wang, L.; Yu, D.; Han, C. Effect of high-intensity ultrasonic treatment on the emulsion of hemp seed oil stabilized with hemp seed protein. Ultrason. Sonochem. 2022, 86, 106021. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xu, J.; Lin, W.; Wang, J.; Yan, H.; Sun, P. Citral and cinnamaldehyde–Pickering emulsion stabilized by zein coupled with chitosan against Aspergillus. spp and their application in food storage. Food Chem. 2023, 403, 134272. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Yano, H. Development of “new” bread and cheese. Processes 2020, 8, 1541. [Google Scholar] [CrossRef]

- Banskota, A.H.; Jones, A.; Hui, J.P.M.; Stefanova, R. Triacylglycerols and other lipids profiling of hemp by-products. Molecules 2022, 27, 2339. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

- Nissen, L.; Bordoni, A.; Gianotti, A. Shift of volatile organic compounds (VOCs) in gluten-free hemp-enriched sourdough bread: A metabolomic approach. Nutrients 2020, 12, 1050. [Google Scholar] [CrossRef] [Green Version]

- Petel, C.; Prost, C.; Onno, B. Sourdough volatile compounds and their contribution to bread: A review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

- Neuser, F.; Zorn, H.; Berger, R.G. Generation of odorous acyloins by yeast pyruvate decarboxylases and their occurrence in sherry and soy sauce. J. Agric. Food Chem. 2000, 48, 6191–6195. [Google Scholar] [CrossRef]

- Shaghaghian, S.; McClements, D.J.; Khalesi, M.; Garcia-Vaquero, M.; Mirzapour-Kouhdasht, A. Digestibility and bioavailability of plant-based proteins intended for use in meat analogues: A review. Trends Food Sci. Technol. 2022, 129, 646–656. [Google Scholar] [CrossRef]

- Ishaq, A.; Irfan, S.; Sameen, A.; Khalid, N. Plant-based meat analogs: A review with reference to formulation and gastrointestinal fate. Curr. Res. Food Sci. 2022, 5, 973–983. [Google Scholar] [CrossRef]

- Younis, K.; Ashfaq, A.; Ahmad, A.; Anjum, Z.; Yousuf, O. A critical review focusing the effect of ingredients on the textural properties of plant-based meat products. J. Texture Stud. 2022, 1–18. [Google Scholar] [CrossRef]

- Kim, J.W.; Nyachoti, C.M. Net energy of hemp hulls and processed hemp hull products fed to growing pigs and the comparison of net energy determined via indirect calorimetry and calculated from prediction equations. J. Animal Sci. 2017, 95, 2649–2657. [Google Scholar] [CrossRef]

- Semwogerere, F.; Chenaimoyo, L.F.; Chikwanha, O.; Marufu, M.; Mapiye, C. Bioavailability and bioefficacy of hemp by-products in ruminant meat production and preservation: A review. Frontiers 2020, 7, 572906. [Google Scholar] [CrossRef]

- Ncogo Nchama, C.N.; Fabro, C.; Baldini, M.; Saccà, E.; Foletto, V.; Piasentier, E.; Sepulcri, A.; Corazzin, M. Hempseed by-product in diets of Italian simmental cull dairy cows and its effects on animal performance and meat quality. Animals 2022, 12, 1014. [Google Scholar] [CrossRef]

- Yalcin, H.; Konca, Y.; Durmuscelebi, F. Effect of dietary supplementation of hemp seed (Cannabis sativa L.) on meat quality and egg fatty acid composition of Japanese quail (Coturnix coturnix japonica). J. Anim. Physiol. Anim. Nuttr. 2018, 102, 131–141. [Google Scholar] [CrossRef] [PubMed]

- Skřivan, M.; Englmaierová, M.; Taubner, T.; Skřivanová, E. Effects of dietary hemp seed and flaxseed on growth performance, meat fatty acid compositions, liver tocopherol concentration and bone strength of cockerels. Animals 2020, 10, 458. [Google Scholar] [CrossRef] [Green Version]

- Mourot, J.; Guillevic, M. Effect of introducing hemp oil into feed on the nutritional quality of pig meat. OCL Oilseeds Fats Crops Lipids 2015, 22, D612. [Google Scholar] [CrossRef]

- Vispute, M.M.; Sharma, D.; Biswas, A.K.; Rokade, J.J.; Chaple, A.R.; Biswas, A.; Gopi, M.; Kapgate, M.G. Dietary hemp (Cannabis sativa L.) and dill seed (Anethum graveolens) improve physicochemical properties, oxidative stability, and sensory attributes of broiler meat. ACS Food Sci. Technol. 2021, 1, 453–461. [Google Scholar] [CrossRef]

- Wittek, P.; Ellwanger, F.; Karbstein, H.P.; Emin, M.A. Morphology development and flow characteristics during high moisture extrusion of a plant-based meat analogue. Foods 2021, 10, 1753. [Google Scholar] [CrossRef]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of high-moisture meat analogues with hemp and soy protein using extrusion cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef] [PubMed]

- Dekkers, B.L.; Boom, R.M.; Goot, A.J.V.D. Structuring processes for meat analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Boukid, F. Plant-based meat analogues: From niche to mainstream. Eur. Food Res. Technol. 2021, 247, 297–308. [Google Scholar] [CrossRef]

- Lin, M. Identifying traction in cattle bones. In Origins of Cattle Traction and the Making of Early Civilisations in North China; Interdisciplinary Contributions to Archaeology; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Oppen, D.; Berger, L.M.; Gibis, M.; Weiss, J. Sensory texture and mastication physics of multi-phase meat products. Appl. Sci. 2022, 12, 11076. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Kaplan, D.L.; Wang, Q. High-moisture extruded protein fiber formation toward plant-based meat substitutes applications: Science, technology, and prospect. Trends Food Sci. Technol. 2022, 128, 202–216. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of soy protein: Investigations on the formation of anisotropic product structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Zhang, Y.; Liu, H.; Li, T.; Wang, Q.; Kaplan, D.L. Microscopic insight into the interactions between pea protein and fatty acids during high-moisture extrusion processing. Food Chem. 2023, 404, 134176. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Liu, H.; Li, T.; Wang, Q. Mechanism of high-moisture extruded protein fibrous structure formation based on the interactions among pea protein, amylopectin, and stearic acid. Food Hydrocoll. 2023, 136, 108254. [Google Scholar] [CrossRef]

- Dai, H.; An, H. Effects of cysteine on physicochemical properties of high-moisture extrudates prepared from plant protein. Foods 2022, 11, 3109. [Google Scholar] [CrossRef]

- Dinani, S.T.; van der Harst, J.P.; Boom, R.; van der Goot, A.J. Effect of l-cysteine and l-ascorbic acid addition on properties of meat analogues. Food Hydrocoll. 2023, 134, 108059. [Google Scholar] [CrossRef]

| Whole Hemp Seed | Soybean | |

|---|---|---|

| Protein | 23.54 | 34.96 |

| Carbohydrate | 30.89 | 31.6 |

| Sugar | 2.01 | 3.99 |

| Dietary fiber | 28.88 | 27.61 |

| Fat | 32.28 | 22.19 |

| Saturated fat/Total fat (%) | 11.32% | 13.77% |

| Unsaturated fat/Total fat (%) | 89.06% | 86.23% |

| Hemp | Cotton | Soybean | |

|---|---|---|---|

| Sustainability | ++ | + | + |

| Fiber/Textile use | + | + | - |

| Nutritional use | + | - | + |

| Distinctive Food processing feature of the protein | SH donor | - | SH recipient |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yano, H.; Fu, W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods 2023, 12, 651. https://doi.org/10.3390/foods12030651

Yano H, Fu W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods. 2023; 12(3):651. https://doi.org/10.3390/foods12030651

Chicago/Turabian StyleYano, Hiroyuki, and Wei Fu. 2023. "Hemp: A Sustainable Plant with High Industrial Value in Food Processing" Foods 12, no. 3: 651. https://doi.org/10.3390/foods12030651